Mechanical control spray additive

A technology of spraying adjuvant and surfactant, applied in preparation and application, ratio of mechanized spraying adjuvant, agricultural mechanized spraying prevention and control, can solve problems such as unsatisfactory effect, poor effect, etc. The effect of the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

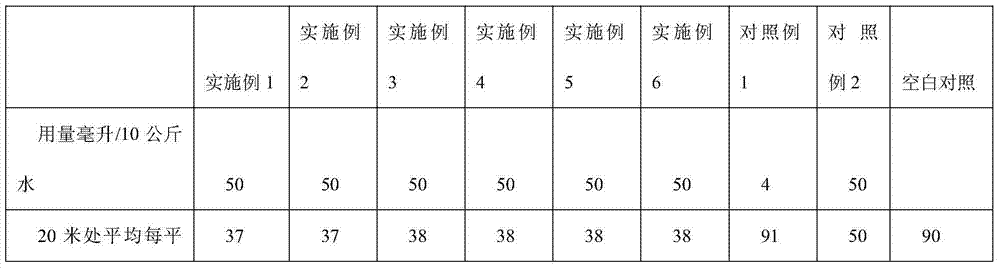

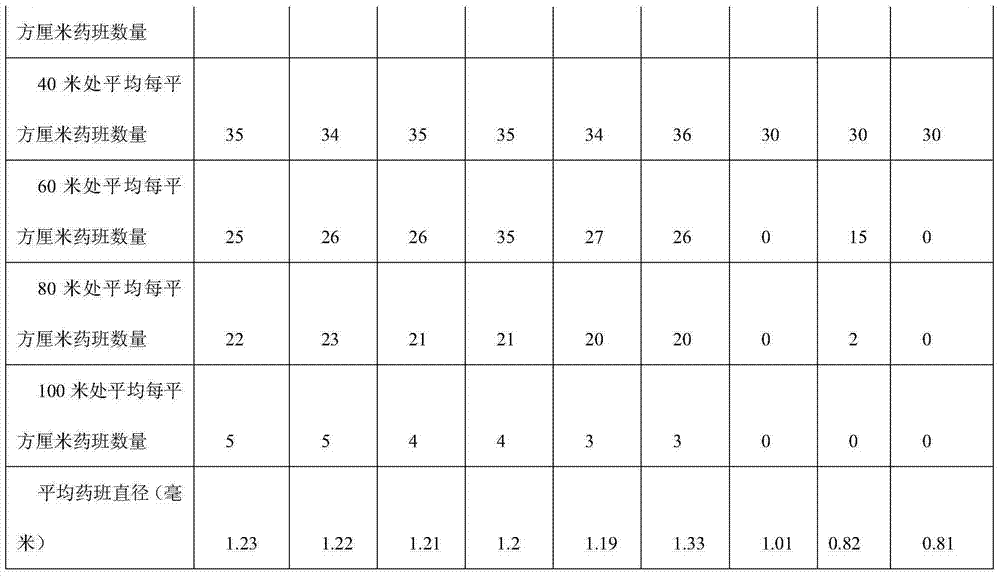

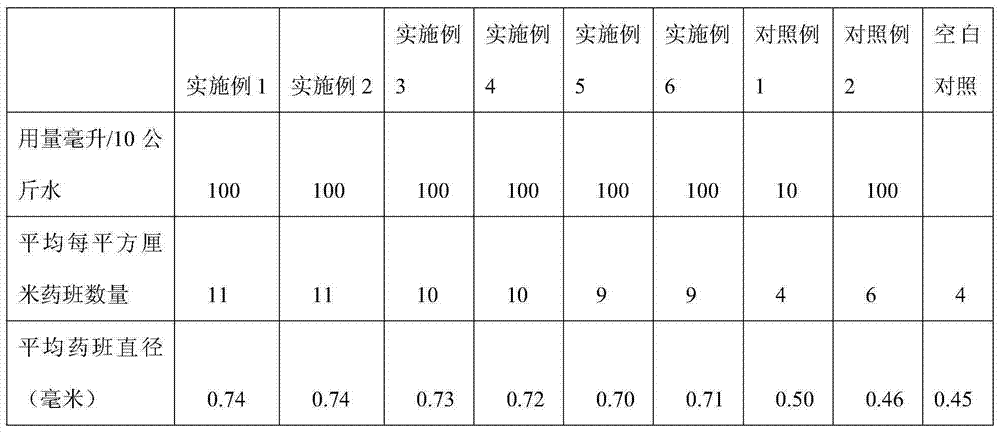

Examples

Embodiment 1

[0027] Take the preparation of 1 kg of machine anti-spray additives as an example: 200 grams of silicone 408 (ethoxy-modified trisiloxane), 100 grams of glycerin, commercially available soybean oil emulsifiers (such as Rhodia VO01, Grimm EF89, etc. ) 160 grams (can be made by yourself: 40 grams of fatty alcohol polyoxyethylene ether, 45 grams of Span 80 emulsifier, 35 grams of polyethylene glycol dioleate, 30 grams of linoleic acid polyethylene glycol glyceride, dodecane Calcium phenyl sulfonate 10 grams), soybean oil 540 grams. Mixing is carried out in a conventional manner.

Embodiment 2

[0029] Take the preparation of 1 kg of machine anti-spray additives as an example: 150 grams of silicone 408 (ethoxy-modified trisiloxane), 100 grams of glycerin, commercially available soybean oil emulsifiers (such as Rhodia VO01, Grimm EF89, etc. ) 160 grams (can be made by yourself: 40 grams of fatty alcohol polyoxyethylene ether, 45 grams of Span 80 emulsifier, 35 grams of polyethylene glycol dioleate, 30 grams of linoleic acid polyethylene glycol glyceride, dodecane Calcium phenyl sulfonate 10 grams), corn oil 590 grams. Mixing is carried out in a conventional manner.

Embodiment 3

[0031] Take the preparation of 1 kg of machine anti-spray additives as an example: 100 grams of silicone S240 (ethoxylated trisiloxane), 80 grams of glycerin, 160 grams of self-prepared cottonseed oil emulsifier (40 grams of fatty alcohol polyoxyethylene ether , Sorbitol palmitate 5 grams, Span 80 emulsifier 40 grams, polyethylene glycol dioleate 35 grams, linoleic acid macrogol glycerides 35 grams, calcium dodecylbenzenesulfonate 5 grams ), 660 grams of cottonseed oil. Mixing is carried out in a conventional manner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com