Preparation method of low-temperature proton exchange membrane fuel cell membrane electrode

A proton exchange membrane and fuel cell membrane technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of reducing production efficiency, affecting membrane electrode performance, and catalyst sedimentation, so as to reduce the amount of Pt and avoid catalyst sedimentation , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Immerse a 10cm X 10cm carbon paper in 2% PTFE emulsion for 5-10 minutes, take it out and dry it, repeat several times until the percentage of PTFE in the carbon paper reaches 5%, and get the hydrophobic treated carbon paper ;

[0039] 2. Weigh 80mg of XC-72 and 1000mg of 2% PTFE emulsion, add an appropriate amount of ethanol, stir it evenly with ultrasonic waves, and evenly apply it on the surface of the hydrophobic treated carbon paper. After drying, protect it in an argon atmosphere At 350°C for 60 minutes, cooled to room temperature to obtain carbon paper with MPL layer;

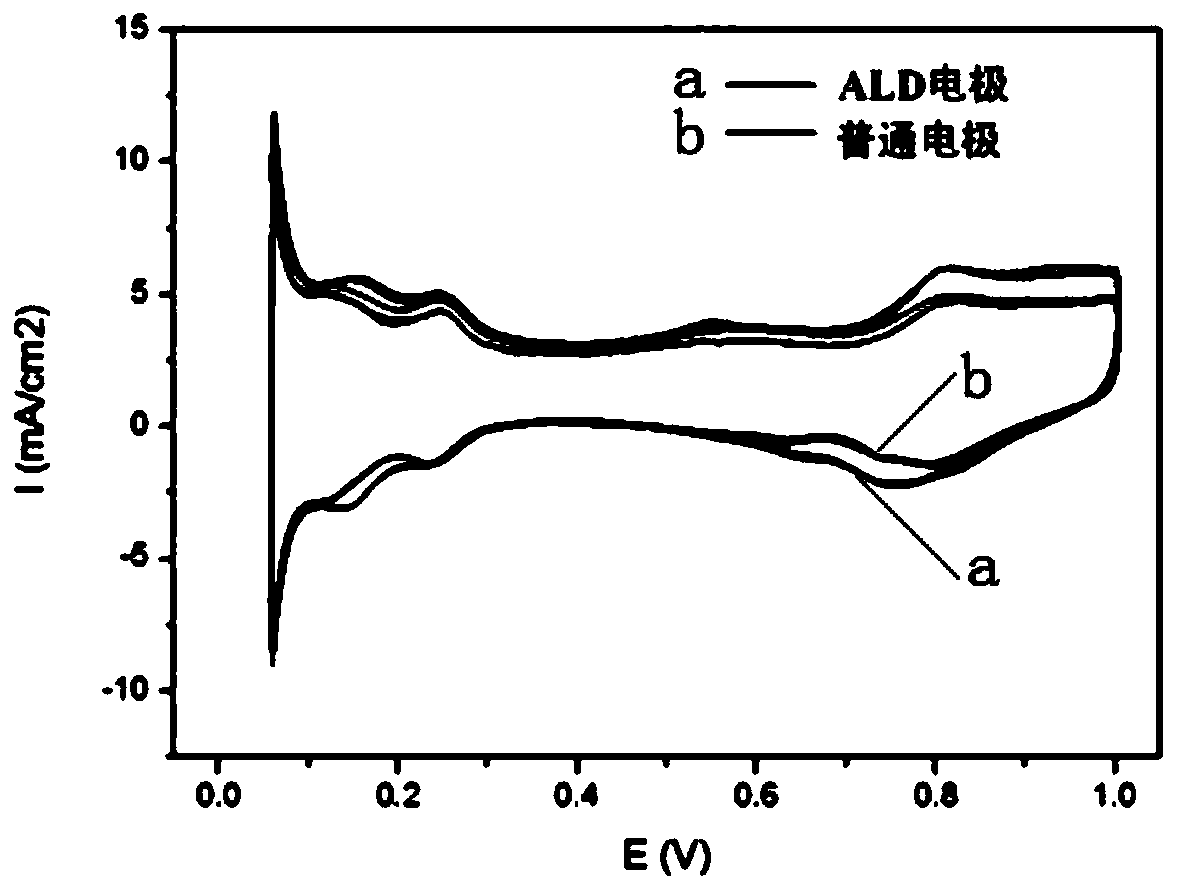

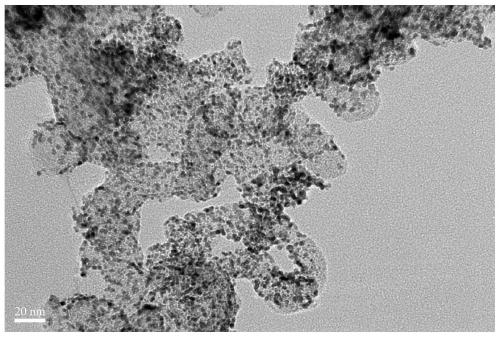

[0040] 3. Place the side of the carbon paper with the MPL layer up, place it in the ALD reactor, vacuumize and heat at the same time, until the temperature in the reactor reaches 240°C and the pressure is lower than 0.01atm, start heating the source bottle of the platinum source To 200°C, open the control valve of the platinum source for 0.05s, then close it, open the oxygen valve again, pass o...

Embodiment 2

[0044] 1. Immerse a 10cm X 10cm carbon paper in 5% PTFE emulsion for 5-10 minutes, take it out and dry it, and repeat it several times until the percentage of PTFE in the carbon paper reaches 10%, and the hydrophobic treated carbon paper is obtained ;

[0045] 2. Weigh 70mg of BP-2000 and 1500mg of 2% PTFE emulsion, add an appropriate amount of ethanol, stir it evenly with ultrasonic waves, and evenly coat it on the surface of the hydrophobic treated carbon paper. After drying, protect it in an argon atmosphere At 350°C for 60 minutes, a carbon paper with an MPL layer was obtained;

[0046] 3. Place the side of the carbon paper with the MPL layer up, place it in the ALD reactor, vacuumize and heat at the same time, until the temperature in the reactor reaches 240°C and the pressure is lower than 0.01atm, start heating the source bottle of the platinum source to 200°C, open the control valve of the platinum source for 0.1s, then close it, open the oxygen valve again, pass oxygen...

Embodiment 3

[0050] 1. Immerse a 10cm X 10cm carbon paper in 2% PTFE emulsion for 5-10 minutes, take it out and dry it, repeat several times until the percentage of PTFE in the carbon paper reaches 5%, and get the hydrophobic treated carbon paper ;

[0051] 2. Weigh 80mg of XC-72 and 1000mg of 2% PTFE emulsion, add an appropriate amount of ethanol, stir it evenly with ultrasonic waves, and evenly apply it on the surface of the hydrophobic treated carbon paper. After drying, protect it in an argon atmosphere At 400°C for 30 minutes, a carbon paper with an MPL layer was obtained;

[0052] 3. Place the side of the carbon paper with the MPL layer up, place it in the ALD reactor, vacuumize and heat at the same time, until the temperature in the reactor reaches 240°C and the pressure is lower than 0.01atm, start heating the source bottle of the platinum source to 200°C, open the control valve of the platinum source for 0.05s, then close it, open the oxygen valve again, pass oxygen for 30 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com