Structures and methods of manufacture for gas diffusion electrodes and electrode components

a technology of diffusion electrodes and electrode components, which is applied in the direction of cell components, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of inability to communicate information as to how to produce this structure with economical means, and the effect of reducing the number of fabrication steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

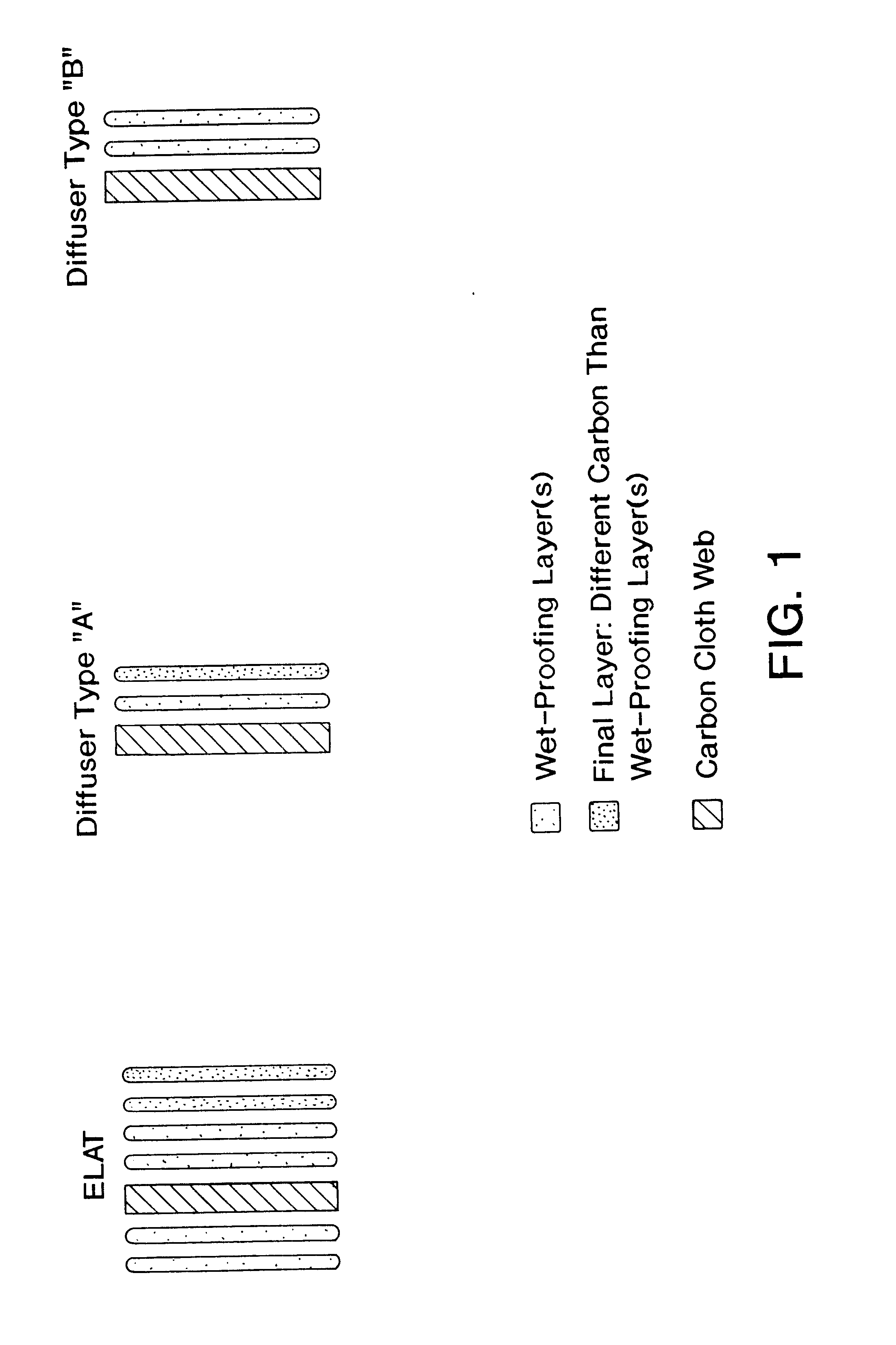

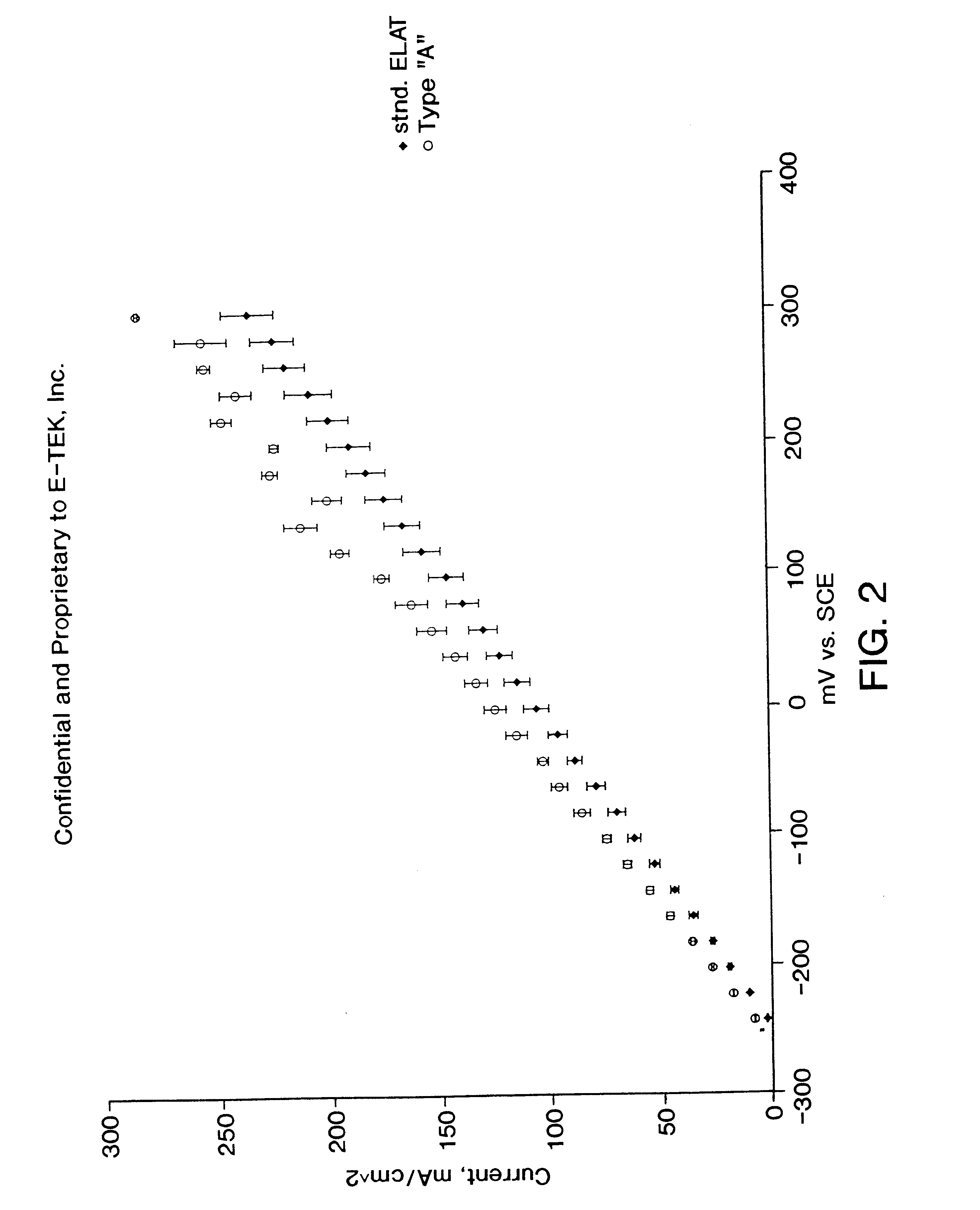

To construct a gas diffusion electrode or diffuser of type "A" structure of the invention, an identical procedure as outlined for Example 1 was followed, except the SAB / Teflon wetproofing layer was applied to one side of the web at approximately half the total carbon black loading, i.e. 1.5-3 mg / cm.sup.2. The catalyst coat and final treatment followed that as detailed above. To make a diffuser, similar steps were performed except uncatalyzed Vulcan XC 72 with a loading range of 0.5-1.5 mg / cm.sup.2 carbon black was employed.

example 3

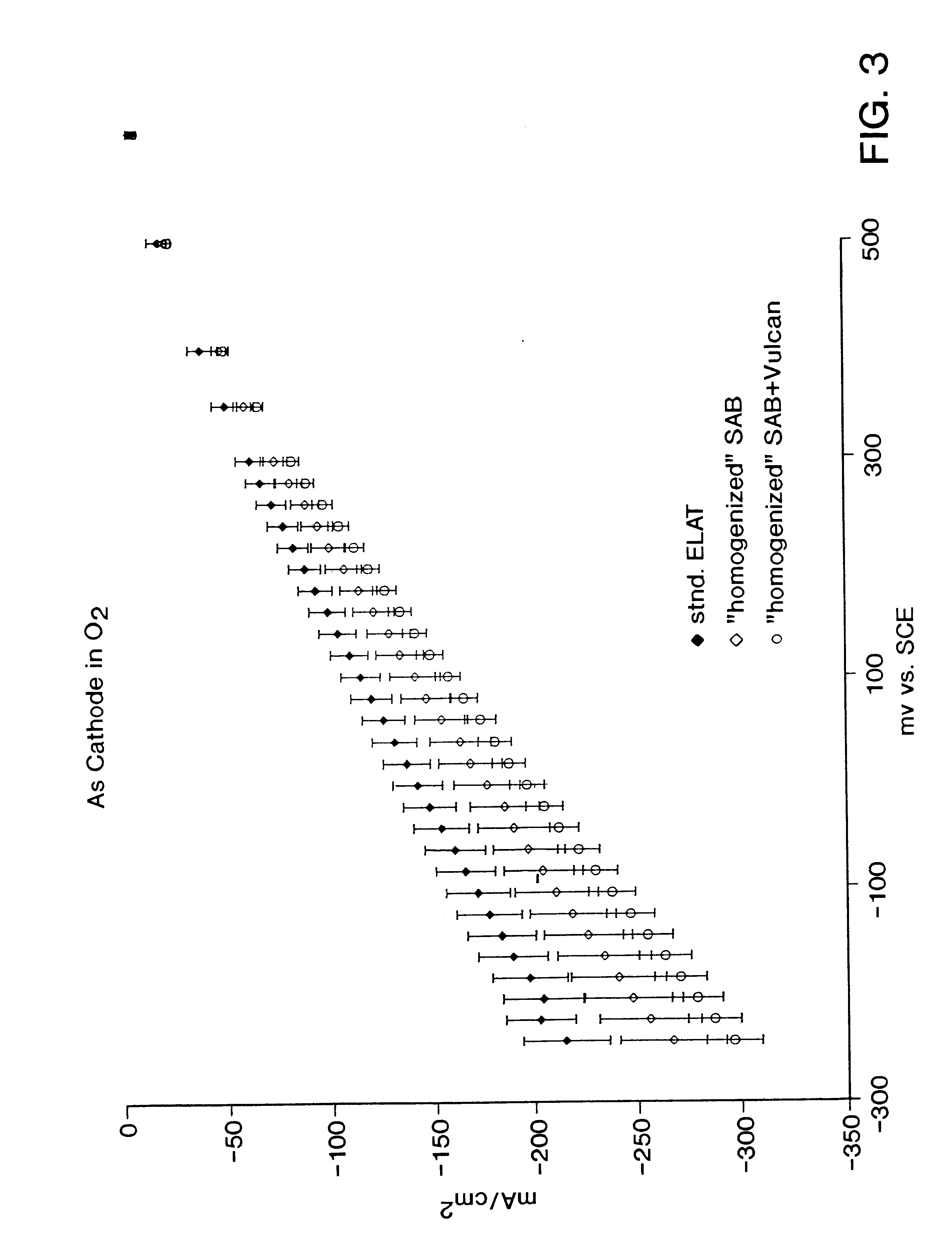

To construct a gas diffusion electrode or diffuser of type "B" structure of the invention, an identical procedure as outlined for Example 2 was followed. However, only the SAB / Teflon wetproofing layer or platinum catalyzed Vulcan XC-72 was applied to one side of the web at at total loading of approximately 0.5-5 mg / cm.sup.2. Similar drying and heating steps as Example 1 followed. A diffuser was constructed in an identical manner except either SAB or Vulcan XC-72 without catalyst was employed.

example 4

A type "B" gas diffusion electrode similar to that of Example 3 was constructed through an automated coater. For this example, a knife-over-plate coater was used and the coater employed a 255 mm perpendicular stainless steel blade with a 45.degree. C. beveled edge. The blade was positioned over the cloth with a fixed gap of approximately 10 mils. The line speed was 2 meters / min., and mix, prepared as in Example 3, was fed at continuous rate to a reservoir in front of the blade. Samples thus prepared were subjected to the same heating and drying steps of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| widths | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com