Colorful electrophoretic display with electric field response photonic crystal characteristics and preparation method and display method thereof

A color electrophoresis, photonic crystal technology, applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problems of difficulty in expressing various colors, low color performance effects, etc., and achieve the effect of preventing agglomeration and sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Step 1: Electrophoresis display particle Fe with a particle size of 150±10nm 3 o 4 SiO 2 Preparation of : First, prepare Fe 3 o 4 Particles, specifically:

[0078] (1) Dissolve 6.36g of trisodium citrate dihydrate in 400mL of ethylene glycol at normal temperature and pressure, stir to obtain a clear solution, which is designated as solution A;

[0079] (2) 16.38g of ferric chloride was dissolved in 200mL of ethylene glycol to obtain a clear solution, which was designated as solution B;

[0080] (3) Add anhydrous sodium acetate (30g) and deionized water (15g) with a mass ratio of 1:0.5 into solution A, stir until completely dissolved to obtain solution C;

[0081] (4) Then add solution B to solution C, stir to make it fully mixed to obtain brown-black clear solution D;

[0082] (5) Place the brownish-black clear solution D in a high-temperature and high-pressure reactor with a volume of 1 L, set the temperature at 200° C., and react at this temperature for 10 h.

[...

Embodiment 2

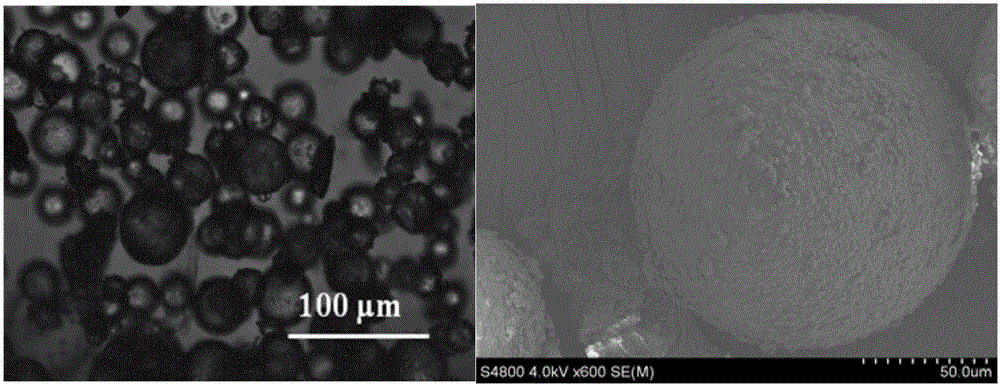

[0099] Step 1: Electrophoretic display particle SiO with different particle sizes 2 TiO 2 specific preparation process.

[0100] SiO 2 Particle preparation:

[0101] (1) At a temperature of 50°C and a mechanical stirring speed of 400rpm, put 8mL of ammonia water, 5mL of water, and 147mL of absolute ethanol in a 500mL three-necked flask and mix evenly to obtain solution A;

[0102] (2) Pump 7.2mL tetraethyl orthosilicate into solution A with a peristaltic pump, and continue to react for 4 hours to obtain solution B;

[0103] (3) Add 38 mL of absolute ethanol into solution B, and continue stirring for 10 min to obtain solution C.

[0104] Core-shell SiO 2 TiO 2 Particle preparation:

[0105] (1) Take 100mL of the above solution C and place it in a 250mL three-necked flask;

[0106] (2) At a stirring speed of 400rpm, use a peristaltic pump to drop the mixed solution of isopropyl titanate and absolute ethanol into the above-mentioned 100mL solution C (pH=11, T=50°C) at a c...

Embodiment 3

[0114] Step 1: Electrophoresis display particle Fe with a particle size of 170±25nm 3 o 4 The specific preparation process of CFe 3 o 4 The preparation of particle: (same as embodiment 1)

[0115] Fe 3 o 4Preparation of C particles:

[0116] (1) Dissolve 0.3g ferrocene in 30mL acetone at normal temperature and pressure, stir for 1h, and then perform ultrasonic treatment;

[0117] (2) Pump 1 mL of hydrogen peroxide (30%) into the solution with a peristaltic pump, and stir for 2 hours after ultrasonic treatment;

[0118] (3) Place the solution in a high-temperature and high-pressure reactor, set the temperature to 210° C., and react at this temperature for 30 hours;

[0119] (4) After the reaction is completed, the obtained mixed solution is subjected to magnetic separation, and the obtained solid is washed several times with deionized water and absolute ethanol to obtain the prepared sample.

[0120] Fe with different particle sizes can be obtained by adjusting the amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com