Method for implementing hot rolling swirl pool constructional engineering by top-down method

A technology for structural engineering and swirling pools, applied in building types, buildings, large-capacity bulk material storage, etc., can solve the problems of low engineering cost and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

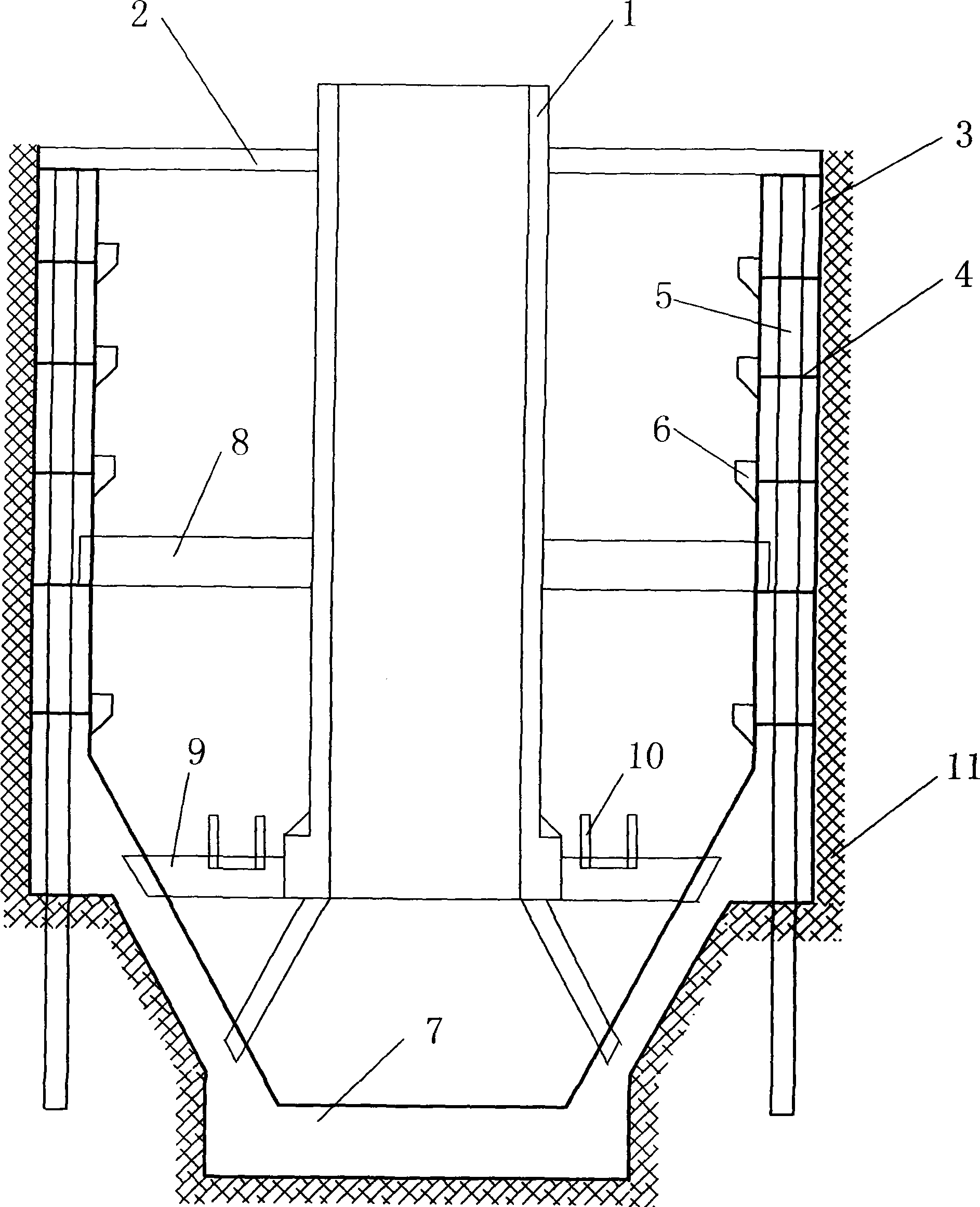

[0016] The invention considers that the stability of the outer soil wall and the frictional force are affected by groundwater and surface water, and the concrete sinks due to its own weight. The outer cylinder of the pool is constructed from top to bottom in sections and sections. With reference to accompanying drawing, concrete steps of the present invention are:

[0017] 1) Construction of the reinforced concrete waterproof structure of the outer cylinder of the swirl pool:

[0018] ①Pile foundation holes according to the number and position of the designed measure piles, make brick retaining walls, pour measure piles, and measure piles until the position about 5.5 meters below the outer cylinder of the pool.

[0019] ②Construction of the outer cylinder of the pool by the reverse method, starting from the design elevation of the top surface of the hot-rolled swirl pool, and construction down to the bottom of the outer cylinder in sections. The specific method is to divide th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com