Multi-Stage Process and Device for Distributive Production of a Low Sulfur Heavy Marine Fuel Oil

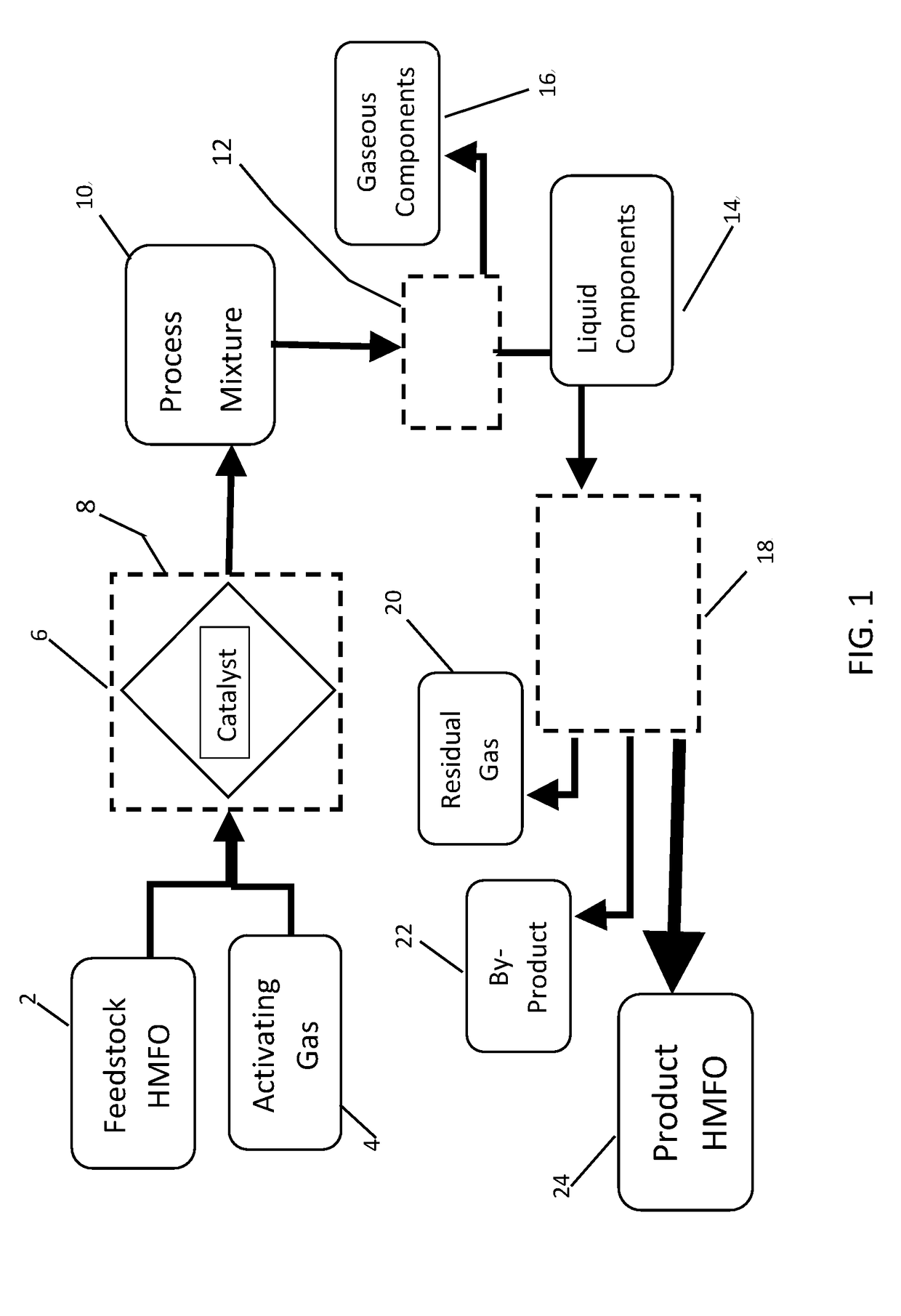

a technology of marine fuel oil and multi-stage process, which is applied in the direction of hydrocarbon oil treatment products, combustion using catalytic materials, physical/chemical process catalysts, etc., can solve the problems of not being able to realize or bring to market the solution for transforming high sulfur hmfo into low sulfur hmfo, and the constraint in the global supply of middle distillate materials, so as to reduce environmental contaminates and minimize the changes in the desirable properties of hm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Overview:

[0107]The purpose of a pilot test run is to demonstrate that feedstock HMFO can be processed through a reactor loaded with commercially available catalysts at specified conditions to remove environmental contaminates, specifically sulfur and other contaminants from the HMFO to produce a product HMFO that is MARPOL compliant, that is production of a Low Sulfur Heavy Marine Fuel Oil (LS—HMFO) or Ultra-Low Sulfur Heavy Marine Fuel Oil (USL-HMFO).

Pilot Unit Set Up:

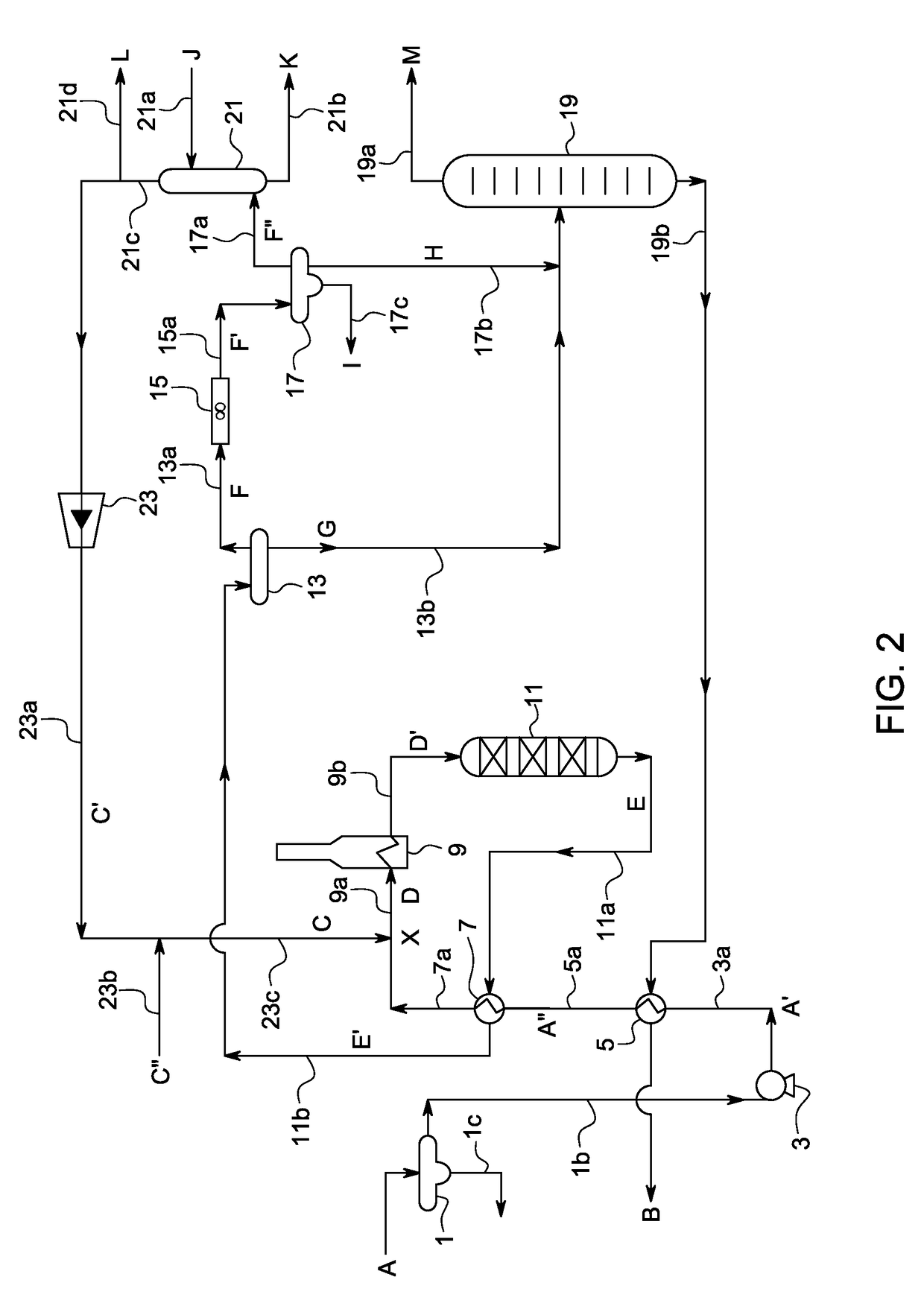

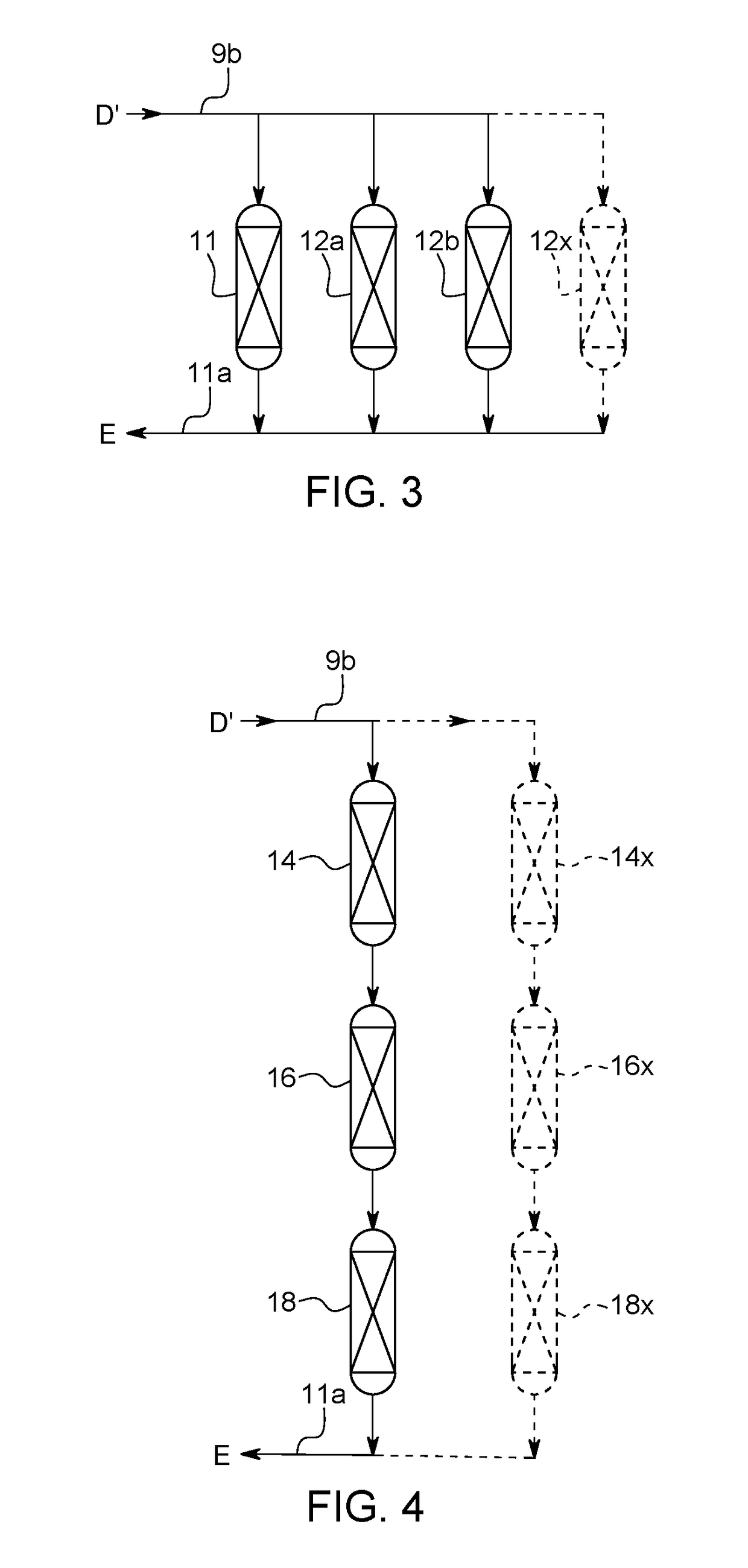

[0108]The pilot unit will be set up with two 434 cm3 reactors arranged in series to process the feedstock HMFO. The lead reactor will be loaded with a blend of a commercially available hydrodemetallization (HDM) catalyst and a commercially available hydro-transition (HDT) catalyst. One of skill in the art will appreciate that the HDT catalyst layer may be formed and optimized using a mixture of HDM and HDS catalysts combined with an inert material to achieve the desired intermediate / transition activity levels. The sec...

example 2

MFO

Pilot Unit Set Up:

[0118]A pilot unit was set up as noted above in Example 1 with these changes: the first reactor was loaded with: as the first (upper) layer encountered by the feedstock 70% vol Albemarle KFR 20 series hydrodemetallization catalyst and 30% vol Albemarle KFR 30 series hydro-transition catalyst as the second (lower) layer. The second reactor was loaded with 20% Albemarle KFR 30 series hydrotransition catalyst as the first (upper) layer and 80% vol hydrodesulfurization catalyst as the second (lower) layer. The catalyst was activated by sulfiding the catalyst with dimethyldisulfide (DMDS) in a manner well known to one of skill in the art.

[0119]Upon completion of the activating step, the pilot unit was ready to receive the feedstock HMFO and Activating Gas feed. The Activating Gas was technical grade or better hydrogen gas. The Feedstock HMFO was a commercially available and merchantable ISO 8217 (2017) compliant HMFO, except for a high sulfur con...

example 3

MFO

[0123]The feedstock to the pilot reactor utilized in example 2 above was changed to a commercially available and merchantable ISO 8217 (2017) RMK-500 compliant HMFO, except that it has high environmental contaminates (i.e. sulfur (3.3 wt %)). Other bulk characteristic of the RMK-500 feedstock high sulfur HMFO are provide below:

TABLE 8Analytical Results—Feedstock HMFO (RMK-500)Sulfur Content, mass %3.3Density @ 15° C., kg / m31006Kinematic Viscosity @ 50° C., mm2 / s500

[0124]The mixed Feedstock (RMK-500) HMFO and Activating Gas was provided to the pilot plant at rates and conditions and the resulting sulfur levels achieved in the table below

TABLE 9Process ConditionsHC Feed Nm3 ProductRateH2 / m3(RMK-500)(ml / h),oil / scf TempPressuresulfur Case[LHSV( / h)]H2 / bbl oil(° C. / ° F.)(MPa(g) / psig)% wt.A108.5 [0.25] 640 / 3600377 / 71013.8 / 20000.57B95.5 [0.22]640 / 3600390 / 73513.8 / 20000.41C95.5 [0.22]640 / 3600390 / 73511.7 / 17000.44D95.5 [0.22]640 / 3600393 / 74010.3 / 15000.61E95.5 [0.22]640 / 3600393 / 74017.2 / 25000.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| total pressure | aaaaa | aaaaa |

| total pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com