Marine fuel oil and production process and device thereof

A technology for production equipment and fuel oil, which is applied in the fields of fuel, petroleum industry, liquid carbon-containing fuel, etc., and can solve the problems of long separation time, high cost of raw materials, and only suitable for small static tests.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Take the raw material oil according to the following mass ratio:

[0040] FCC oil slurry: 70 parts;

[0042] Methanol or ethanol: 8 parts;

[0043] Shale oil: 5 parts;

[0044] Vacuum residue: 5 parts;

[0045] Accelerator: 1 part;

[0046] Co-solvent: 1 part.

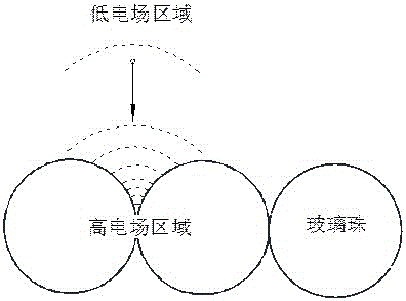

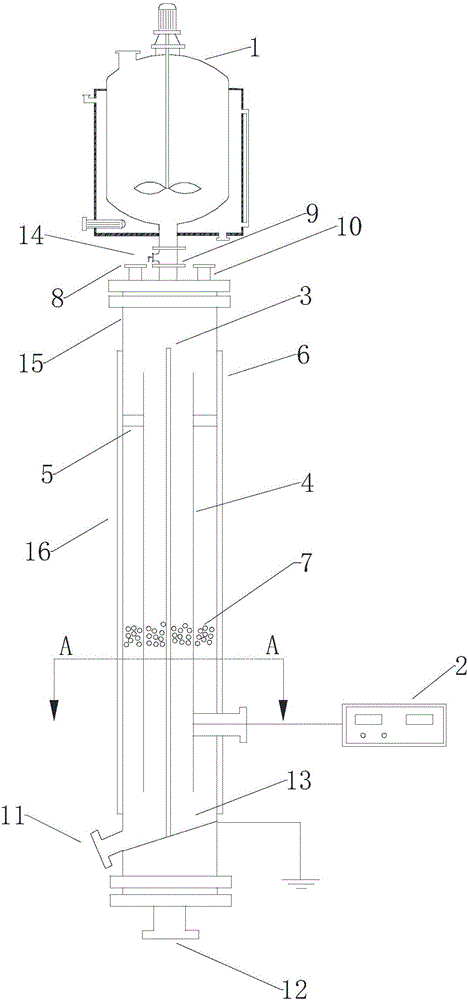

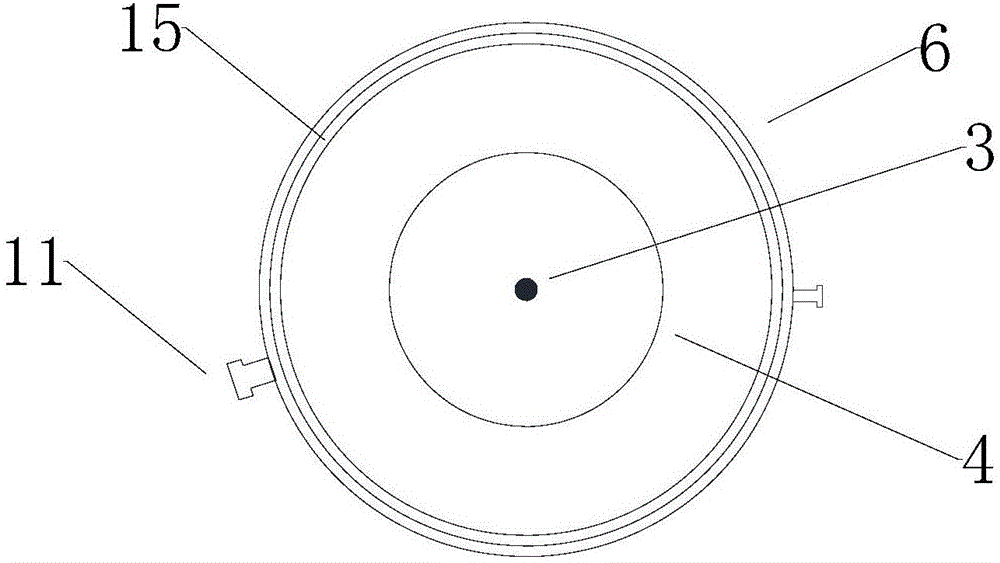

[0047] First, add the FCC oil slurry to the heating and stirring tank, adjust the heating temperature to 65°C, and the rotation speed of the stirring paddle to 2000r / min. After the viscosity of the oil slurry is reduced, add light oil and additives in turn, heat and mix for 30 minutes, and take the pre-separation 20g of oil sample is used to evaluate the separation effect. At the same time, turn on the high-voltage electrostatic power supply, open the bottom valve 14, and put the fully mixed raw material oil into the separator. At this time, the raw material oil flows through the separator along the gap between the glass beads , the glass beads provide adsorption points and inc...

Embodiment 2

[0049] Weigh the raw material oil according to the following ratio:

[0050] FCC oil slurry: 80 parts;

[0051] Coal tar: 2 parts;

[0052] Methanol or ethanol: 8 parts;

[0053] Shale oil: 3 parts;

[0054] Vacuum residue: 5 parts;

[0055] Accelerator: 1 part;

[0056] Co-solvent: 1 part.

[0057] First, add the FCC oil slurry to the heating and stirring tank, adjust the heating temperature to 80°C, and the rotation speed of the stirring paddle to 2000r / min. After the viscosity of the oil slurry decreases, add light oil and additives in sequence, heat and mix for 10 minutes, and take the 20g of oil sample is used to evaluate the separation effect. At the same time, turn on the high-voltage electrostatic power supply, open the bottom valve 14, and put the fully mixed raw material oil into the separator. At this time, the raw material oil flows through the separator along the gap between the glass beads , the glass beads provide adsorption points and increase the blendin...

Embodiment 3

[0059] The raw material oil is weighed according to the following mass percentage ratio:

[0060] FCC oil slurry: 60 parts;

[0061] Coal tar: 5 parts;

[0062] Catalytic diesel oil: 5 parts;

[0063] Methanol or ethanol: 7 parts;

[0064] Shale oil: 10 parts;

[0065] Coker wax oil: 5 parts;

[0066] Vacuum residue: 5 parts;

[0067] Combustion aid: 2 parts;

[0068] Co-solvent: 1 part.

[0069] First, add the FCC oil slurry to the heating and stirring tank, adjust the heating temperature to 70°C, and the rotation speed of the stirring paddle to 2000r / min. After the viscosity of the oil slurry decreases, add light oil and additives in turn, heat and mix for 60 minutes, and take the 20g of oil sample is used to evaluate the separation effect. At the same time, turn on the high-voltage electrostatic power supply, open the bottom valve 14, and put the fully mixed raw material oil into the separator. At this time, the raw material oil flows through the separator along the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com