Combined desulphurization and denitration device and method of marine diesel engine

A technology for marine diesel engine, desulfurization and denitrification, which is applied in the field of marine exhaust emission control, can solve the problems of higher cooling effect requirements of coolers, reduced engine thermal efficiency, large exhaust gas mass flow, etc., to reduce design difficulty, ensure effective power, The effect of reducing the generation and emission of NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples describe the present invention in more detail.

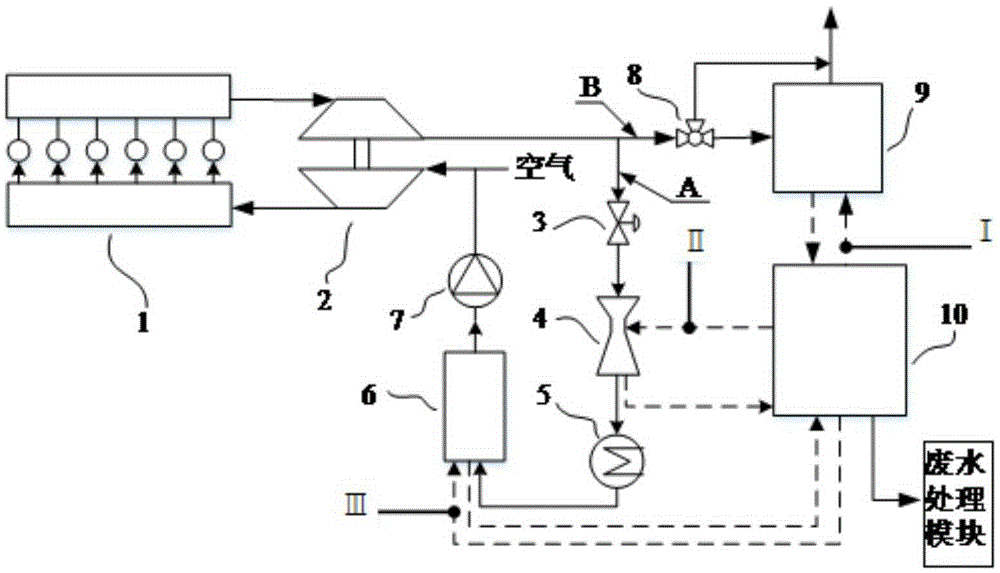

[0033] In conjunction with Fig. 1, the device of the marine diesel engine united desulfurization and denitrification of the present invention comprises a turbocharger 2, a one-way stop valve 3, a Venturi scrubber 4, a cooler 5, a cleaner 6, a blower 7, a three-way valve 8, a scrubber The tower 9 and the washing liquid buffer tank 10; the exhaust pipe of the diesel engine 1 is connected with the turbine in the turbocharger, the outlet of the turbine is connected with the one-way shut-off valve and the three-way valve, the Venturi scrubber is connected with the one-way shut-off valve and the cooler, and the cooler The outlet and the inlet of the washer are connected by pipelines, the outlet of the washer is connected to the blower, and the outlet of the blower is directly connected to the inlet of the compressor in the turbocharger. The one-way stop valve, Venturi scrubber, cooler, washer and blower co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com