Main chain degradation type zinc polyacrylate resin prepared by post-grafting method, and method and application of main chain degradation type zinc polyacrylate resin

A technology of zinc polyacrylate, chain degradation, applied in biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve problems such as marine microplastic pollution, achieve thorough polishing, meet antifouling requirements, and solve The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

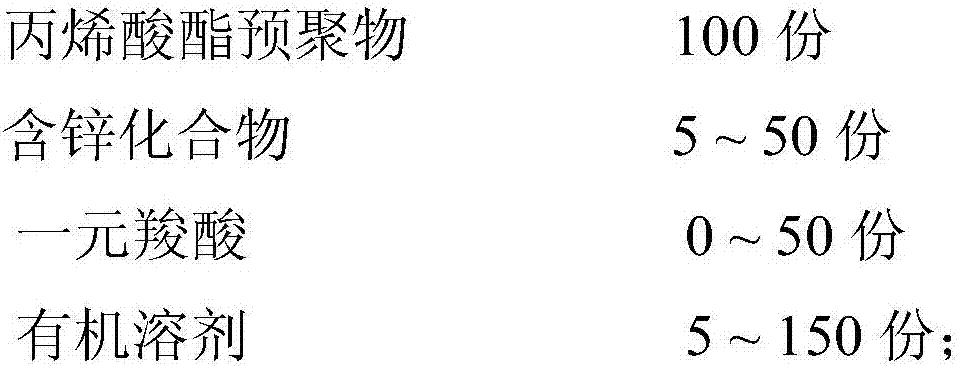

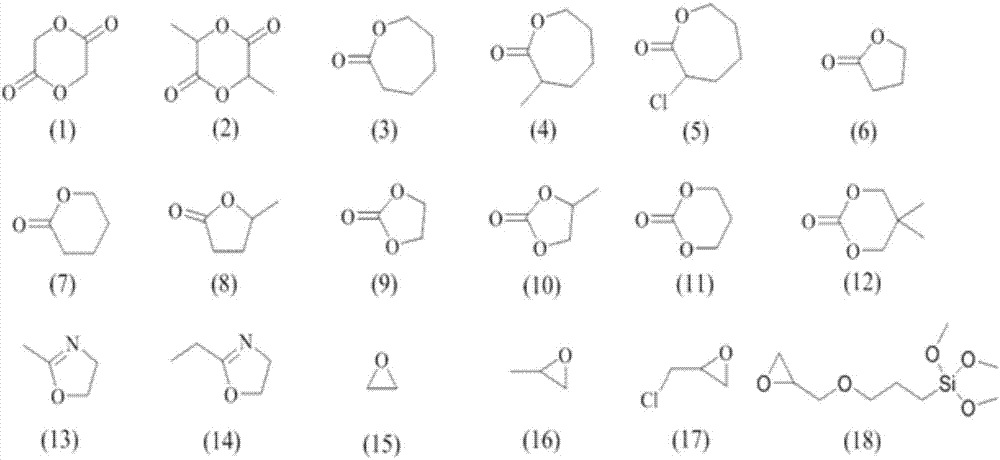

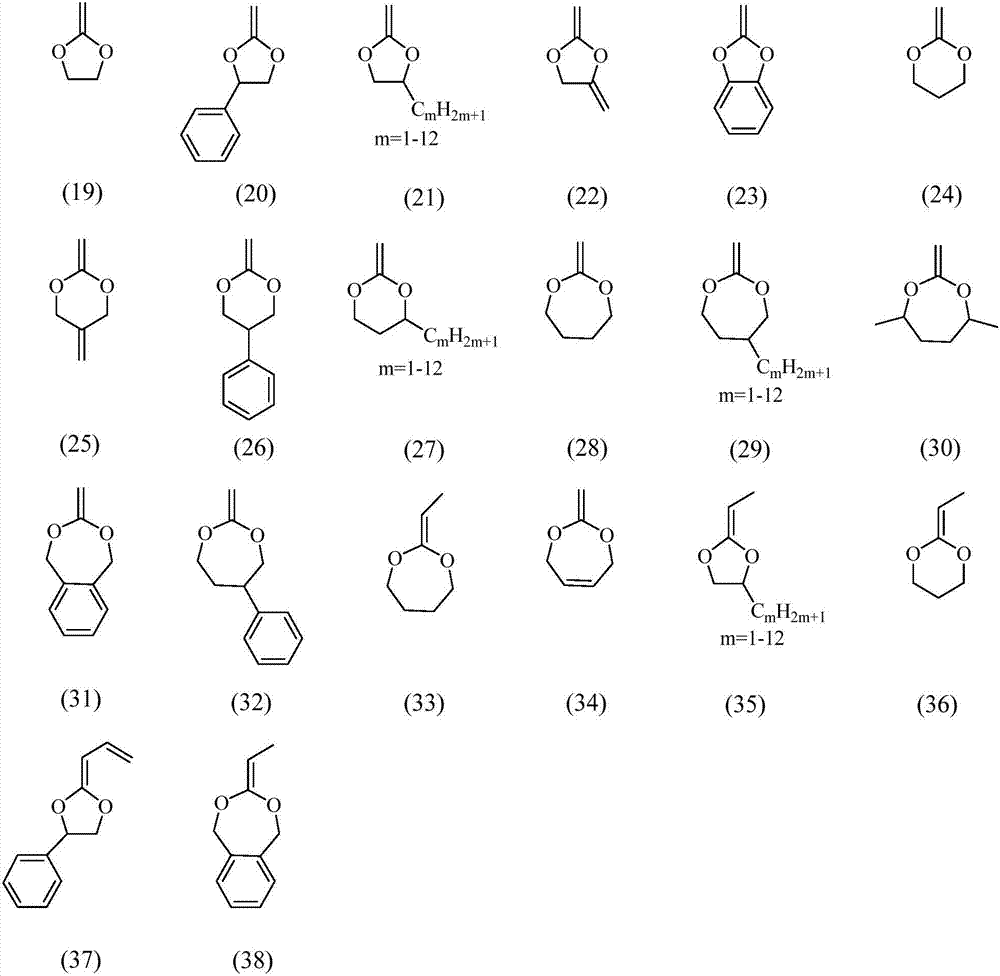

Method used

Image

Examples

Embodiment 1

[0058] A preparation method of main chain degradable polyacrylic acid zinc resin, specifically comprising the following steps:

[0059] (1) Synthesis of acrylate prepolymer:

[0060] Add 64g of xylene and 16g of n-butanol to the reaction vessel, heat to 90°C under a nitrogen atmosphere, and dropwise add 40g of 4-methylcyclohexyl acrylate, 40g of methyl methacrylate, 10g of 2-chloro – ε-caprolactone, 10 g parts of acrylic acid, 0.1 g ethanol, and 70 μL of t-BuP 4 n-hexane solution (containing 0.04g of t-BuP 4 ) formed mixture, after the dropwise addition was completed, it was incubated for 2 hours to obtain an acrylate prepolymer;

[0061] (2) Synthesis of zinc polyacrylate resin:

[0062] Add 25.2g zinc acetate, 47.2g naphthenic acid (acid value 165) and 100g dimethylbenzene in the acrylate prepolymer of step (1), react in 130 ℃ for 8 hours, obtain polyacrylic acid zinc resin (brown transparent resin solution .)

[0063] Resin number average molecular weight M in the pres...

Embodiment 2

[0065] A preparation method of main chain degradable polyacrylic acid zinc resin, specifically comprising the following steps:

[0066] (1) Synthesis of acrylate prepolymer:

[0067] Add 64g of xylene and 16g of propylene glycol methyl ether to the reaction vessel, heat to 95°C under nitrogen atmosphere, and dropwise add 20g of 4-tert-butylcyclohexyl methacrylate, 40g of ethyl acrylate, 25g of 2-methylene Base-1,3-dioxane, 15g of methacrylic acid, 2g of azobisisobutyronitrile and 0.5g of tert-dodecylmercaptan, after the dropwise addition, keep warm for 2 hours to obtain acrylate prepolymer;

[0068] (2) Synthesis of polyacrylic acid zinc resin: add 14.2g zinc oxide, 5g deionized water and 30g xylene in the acrylate prepolymer of step (1), in 140 ℃ of reactions 8 hours, obtain polyacrylic acid zinc resin ( colorless transparent resin solution).

[0069] Resin number average molecular weight M in the present embodiment n 2.0×10 4 g / mol, the zinc content is 5.1%, and the aci...

Embodiment 3

[0071] A preparation method of main chain degradable polyacrylic acid zinc resin, specifically comprising the following steps:

[0072] (1) Synthesis of acrylate prepolymer:

[0073] Add 80g of xylene to the reaction vessel, heat to 100°C under nitrogen atmosphere, dropwise add 10g of polyethylene glycol methacrylate (polymerization degree: 9), 10g of hydroxypropyl methacrylate, 60g of isoacrylate A mixture of octyl esters, 10g 2-methylene-1,3-dioxo-5-cycloheptene, 10g methacrylic acid, 2.5g azobisisovaleronitrile and 0.5g α-methylstyrene dimer , after the dropwise addition was completed, the insulation was kept for 2 hours to obtain an acrylate prepolymer;

[0074] (2) Synthesis of zinc polyacrylate resin: add 11.5g zinc hydroxide, 35.2g abietic acid and 80g xylene to the acrylate prepolymer of step (1), and react at 140°C for 8 hours to obtain zinc polyacrylate resin (yellow transparent resin solution).

[0075] Resin number average molecular weight M in the present embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com