Timing rotation accurate supplying device

A precise and rotating baffle technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problem of no efficient supply, and achieve the effect of convenient and fast installation, easy promotion and application, and high interchangeability of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to better understand the present invention, specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

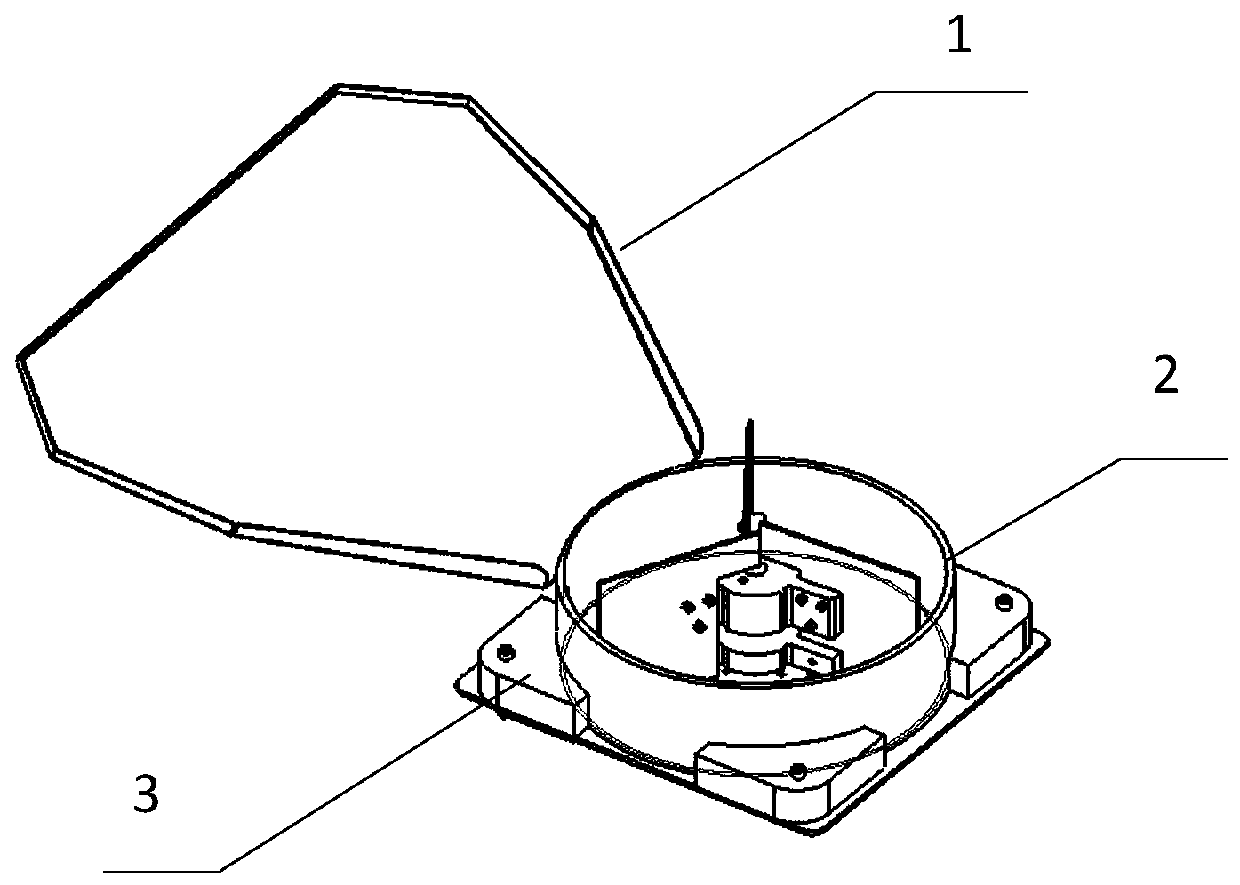

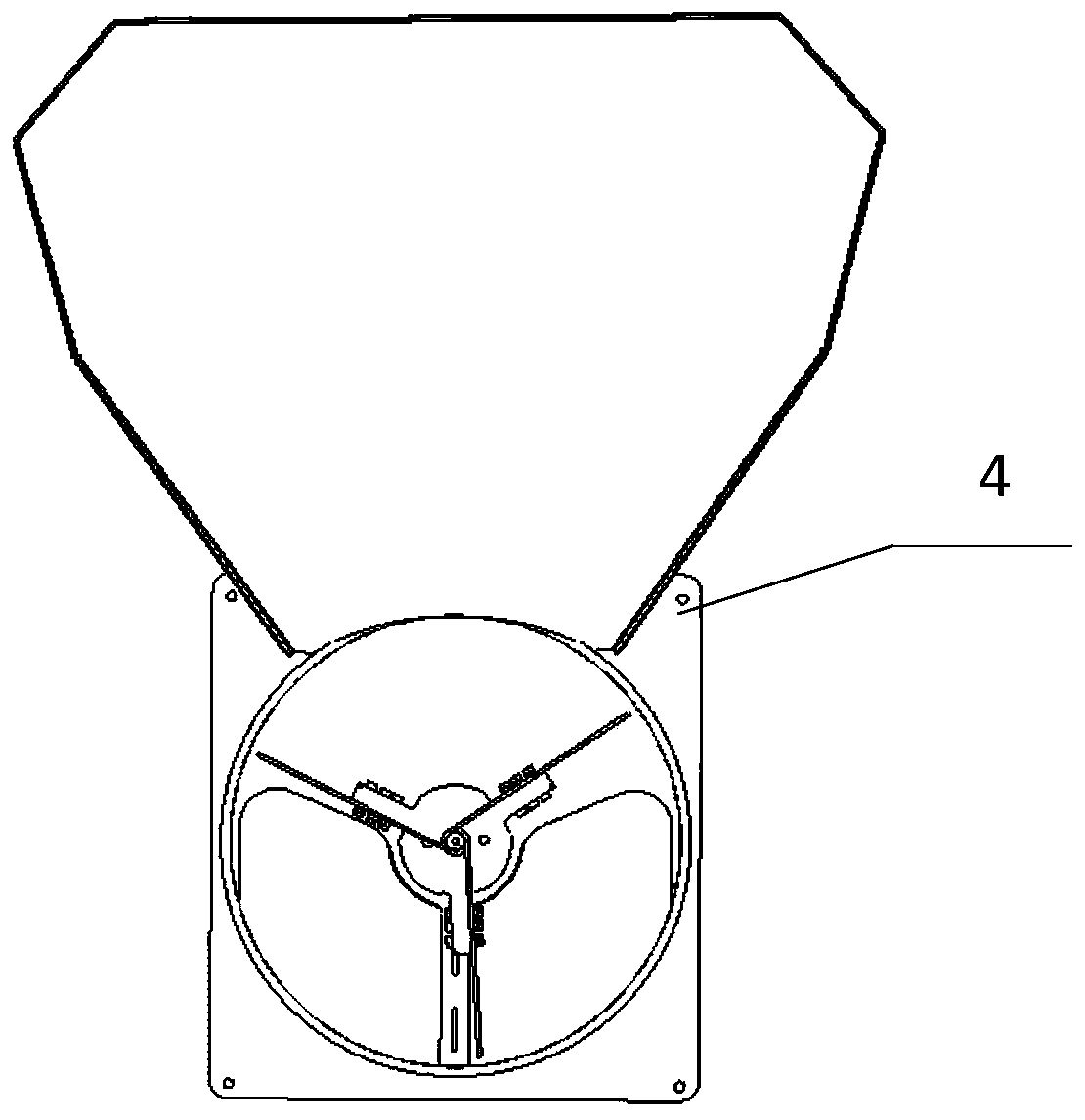

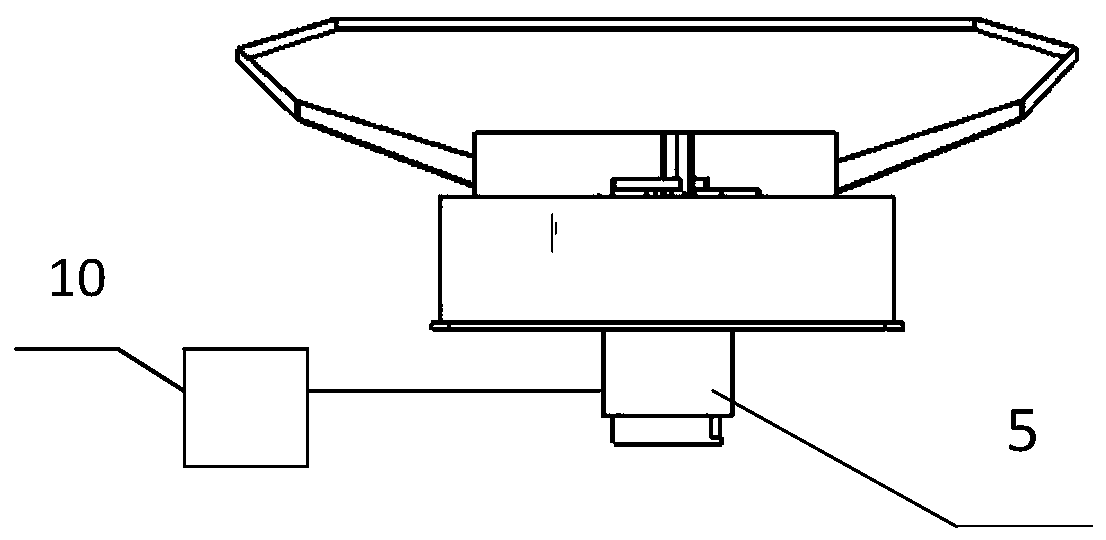

[0042] like Figure 1 to Figure 4 As shown, a timed rotation precise replenishment device, including:

[0043] support plate 4;

[0044] The cylindrical shell 2 is fixedly arranged on the upper surface of the support plate 4, and the support plate 4 is provided with a material storage area 42 and two discharge ports 41 along the circumference in the area surrounded by the cylindrical shell 2;

[0045] The motor 5 adopts a servo motor or a stepping motor, and is fixed on the lower surface of the support plate 4 by bolts, and its output shaft extends through the support plate 4 into the cylindrical shell 2;

[0046] The rotary pushing device is installed in the cavity enclosed by the cylindrical shell 2 and the support plate 4, including:

[0047] a fixing member, which is driven and connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com