Method of creating production plan of demand variation input type and method of creating production plan minimizing risk of demand variations

a production plan and input type technology, applied in the field of creating production plans of demand variation input types and methods of creating production plans minimizing demand variation risk, can solve the problems of shortening the time required for materials procurement, affecting the amount of sales, and affecting the quality of materials, so as to minimize the risk of demand variation and maximize the achievement ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention hereinafter will be described with reference to the accompanying drawings.

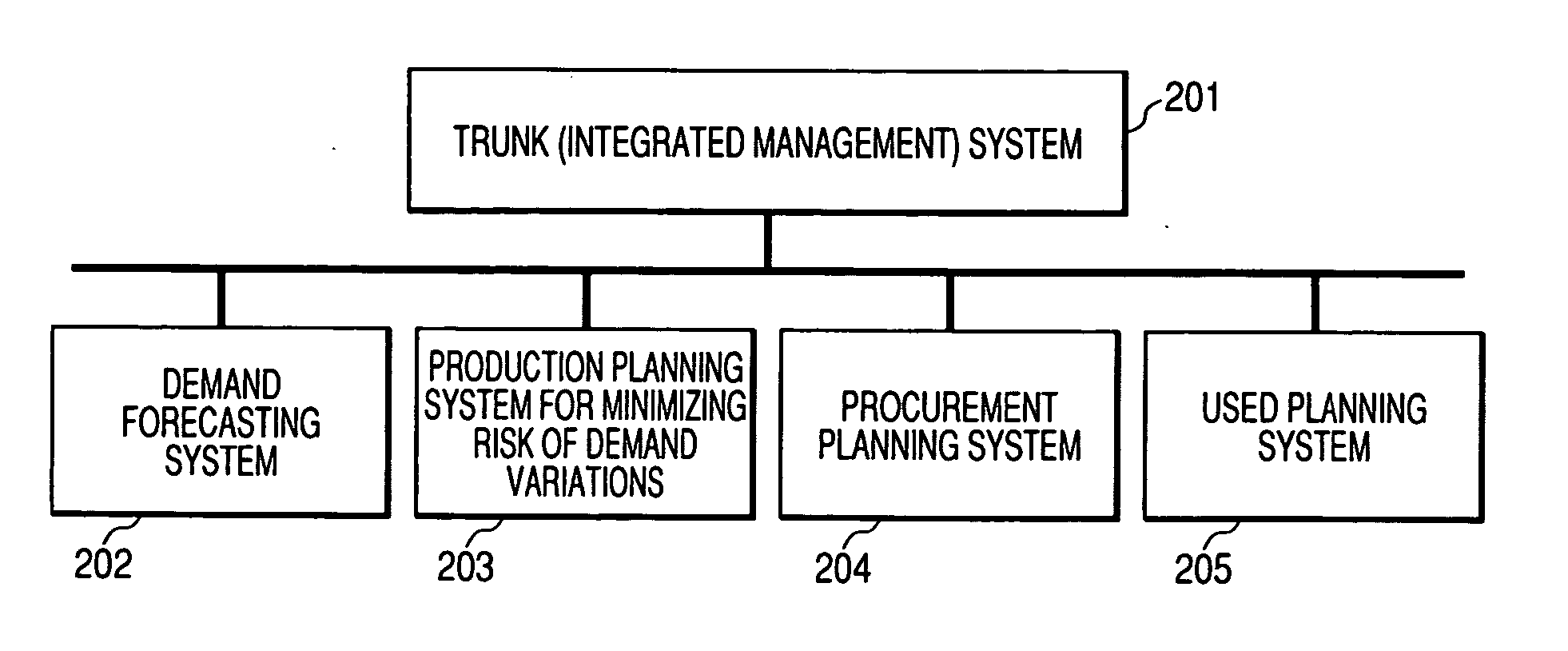

[0028] The hardware configuration of a production planning system for minimizing the risk of demand variations is shown in FIG. 1. Of the processing performed by a method of creating a production plan, so as to minimize the risk of demand variations in accordance with the present invention, given processing functions (characteristic processing functions) are imparted to the planning system. The present system shown in FIG. 1 comprises a computer 105 (or 106), an external output device 104, and input devices including a keyboard and a mouse (not shown). The computer 105 has a CPU 101, a memory 102, and a recording medium 103, such as a HDD. Programs having given functions of the method of creating the production plan in such a way as to minimize the risk of demand variations in accordance with the present invention are stored in the recording medium 103. The programs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com