Replenishment method and device

A replenishment method and replenishment technology, applied in the field of replenishment methods and devices, can solve the problem that the lower limit of the replenishment model fails to comprehensively consider inventory costs and out-of-stock costs, cannot adapt to the changing trend of sales, and the order fulfillment rate is low. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A replenishment device of this embodiment includes:

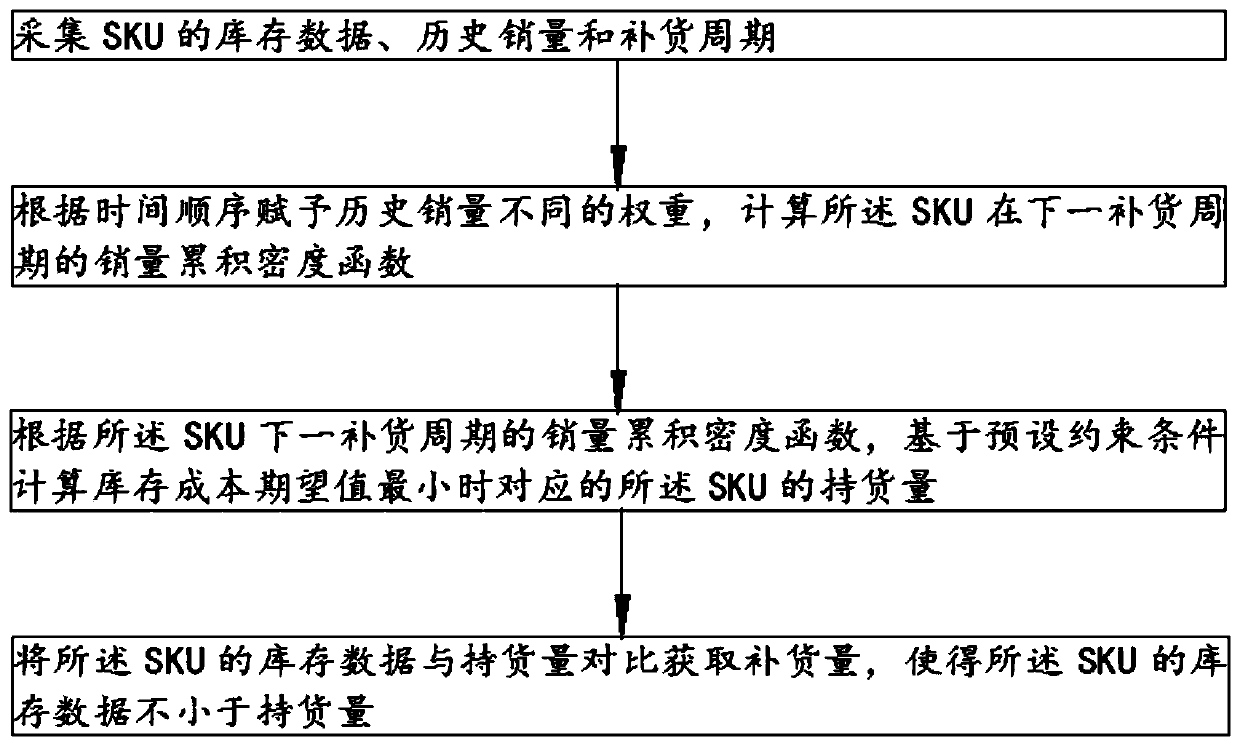

[0070] The data collection module is configured to collect SKU inventory data, historical sales, replenishment cycle, and unit inventory cost; the inventory data includes at least one of the following: inventory, volume, weight, location volume, temporary Replenishment data.

[0071] The sales forecast module is configured to assign different weights to historical sales according to the time sequence, and calculate the cumulative sales density function of the SKU in the next replenishment period; the replenishment period includes at least one of the following: days, n days, weeks, Month, year. Specifically, the sales forecast module includes:

[0072] Frequency allocation unit, configured to assign different weights to historical sales data of SKU based on time sequence;

[0073] The weight allocation unit is configured to assign weights from small to large to historical sales data of SKUs based on chronological order;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com