Patents

Literature

277 results about "Fault tree analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fault tree analysis (FTA) is a top-down, deductive failure analysis in which an undesired state of a system is analyzed using Boolean logic to combine a series of lower-level events. This analysis method is mainly used in the fields of safety engineering and reliability engineering to understand how systems can fail, to identify the best ways to reduce risk or to determine (or get a feeling for) event rates of a safety accident or a particular system level (functional) failure. FTA is used in the aerospace, nuclear power, chemical and process, pharmaceutical, petrochemical and other high-hazard industries; but is also used in fields as diverse as risk factor identification relating to social service system failure. FTA is also used in software engineering for debugging purposes and is closely related to cause-elimination technique used to detect bugs.

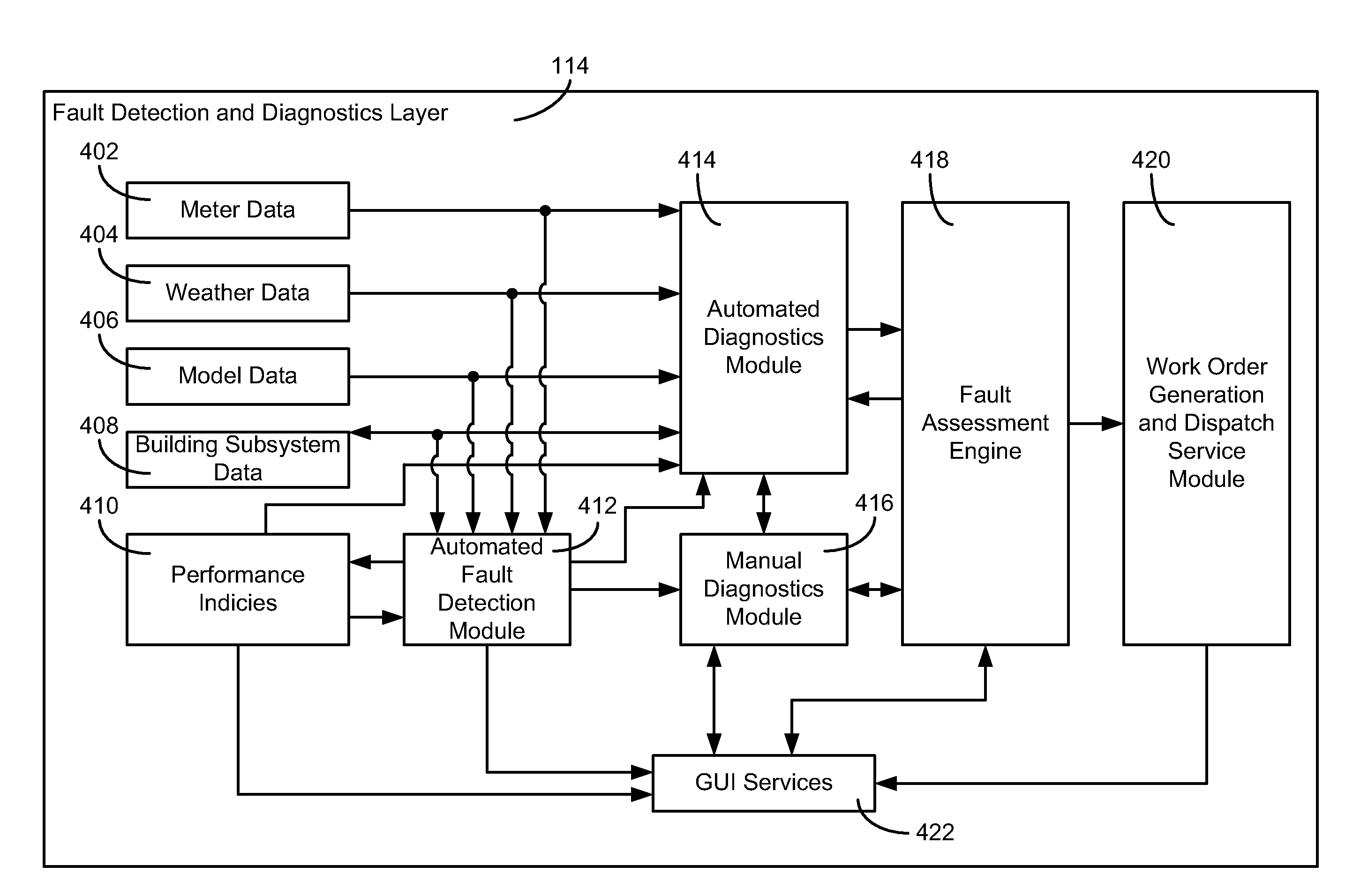

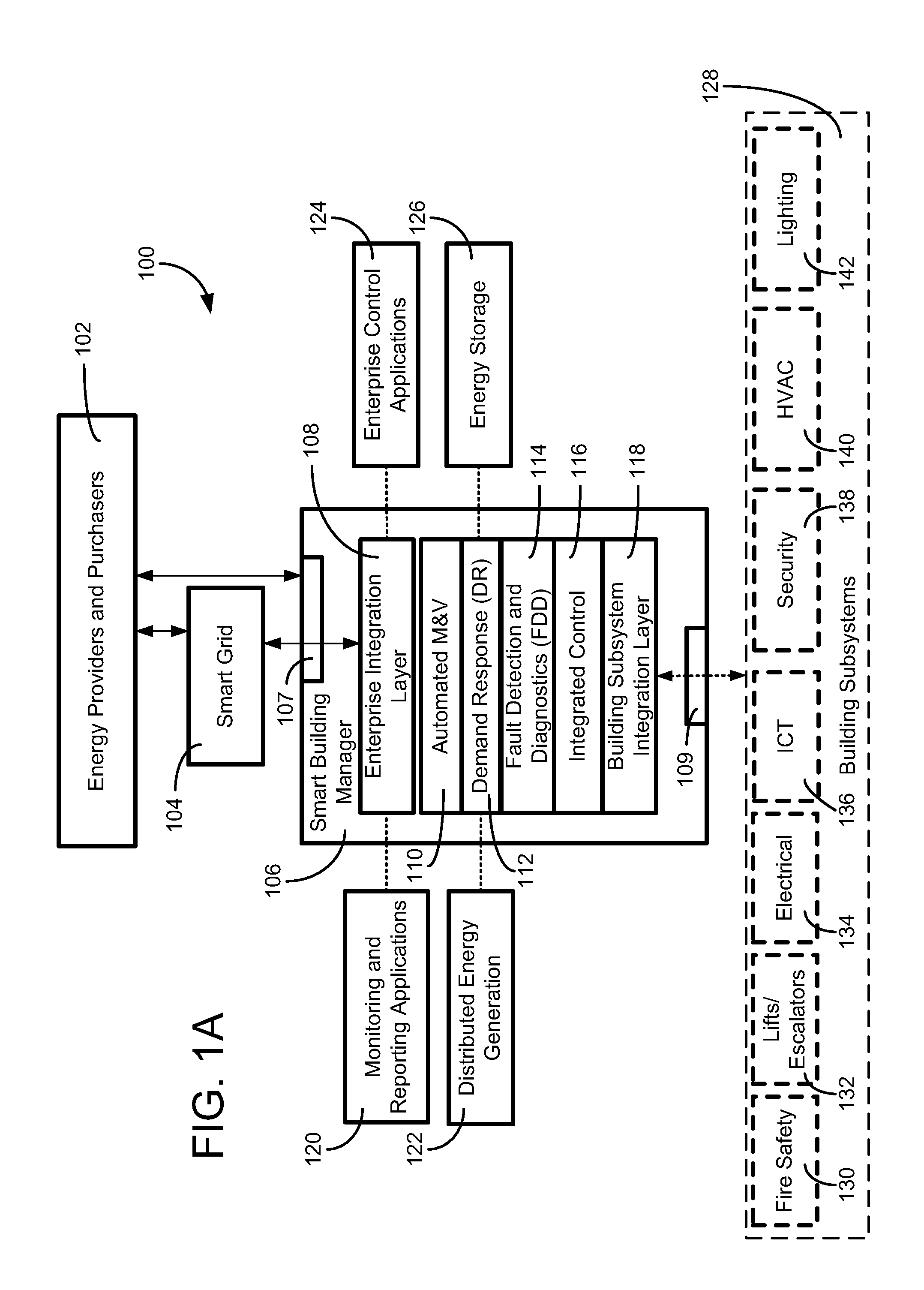

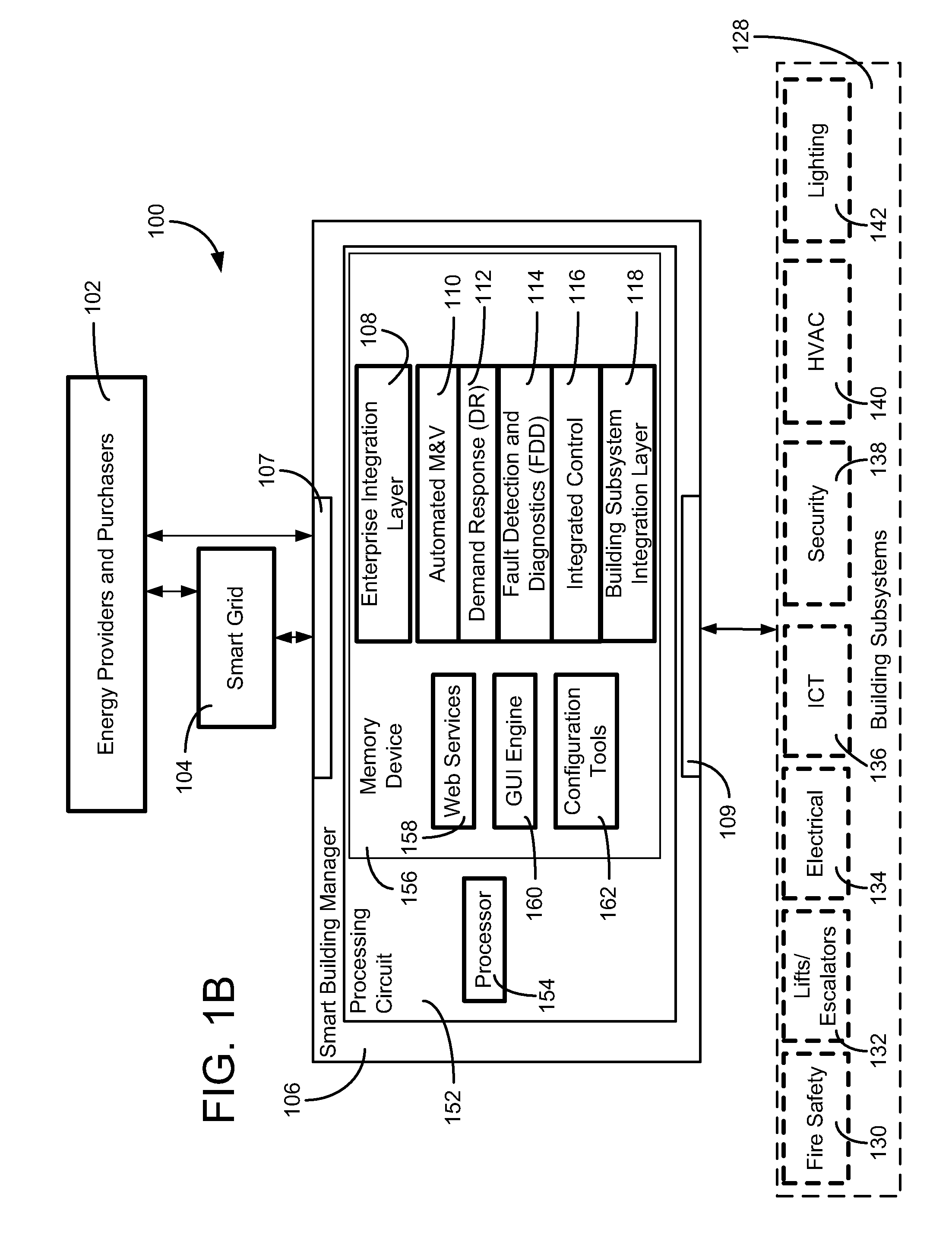

Building management system with fault analysis

ActiveUS20110178977A1Enhance data loggingTechnology managementFuzzy logic based systemsEngineeringFault analysis

Owner:JOHNSON CONTROLS TECH CO

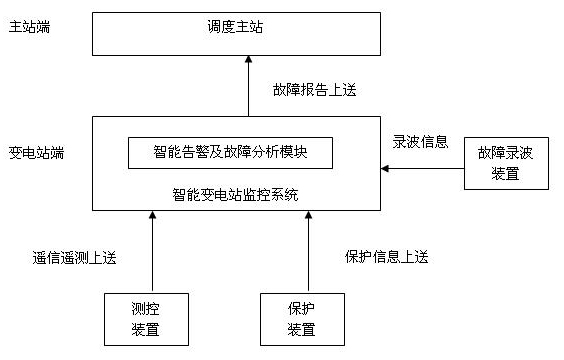

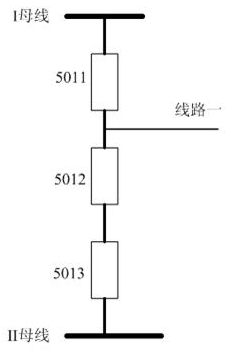

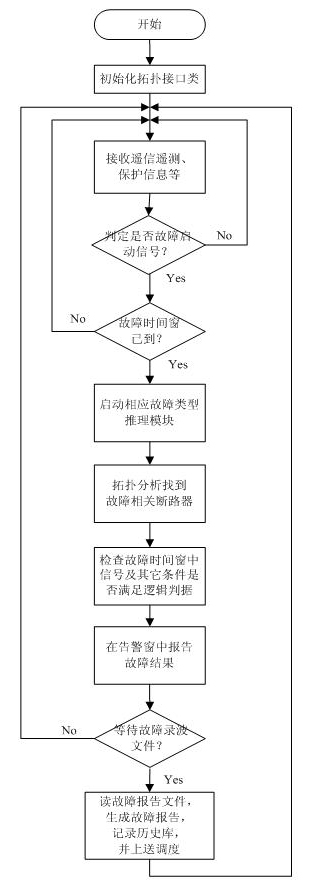

Intelligent warning and fault analysis realizing method for intelligent transformer substation monitoring system

ActiveCN102035260AReduce workloadImprove troubleshooting efficiencyCircuit arrangementsInformation technology support systemSmart substationMaster station

The invention relates to an intelligent warning and fault analysis realizing method applied to an intelligent transformer substation monitoring system, which belongs to the technical field of transformer substation automation. An intelligent warning and fault analyzing module is used for analyzing various pieces of information reported by a measurement and control device, a protective device and a fault recorder, generating a fault analysis report by combining topology with every fault in an automatic identification fault reasoning model, and submitting the generated fault analysis report to a scheduling master station at a master station end. The workload of personnel on duty is greatly reduced, and the fault processing efficiency is improved. The requirement of an intelligent transformer substation on an intelligent warning and fault analysis system can be met, faults can be quickly judged and analyzed, and processing schemes can be provided so as to assist the personnel on duty in quickly processing the faults, and reduce the loss caused by the faults.

Owner:NARI TECH CO LTD +1

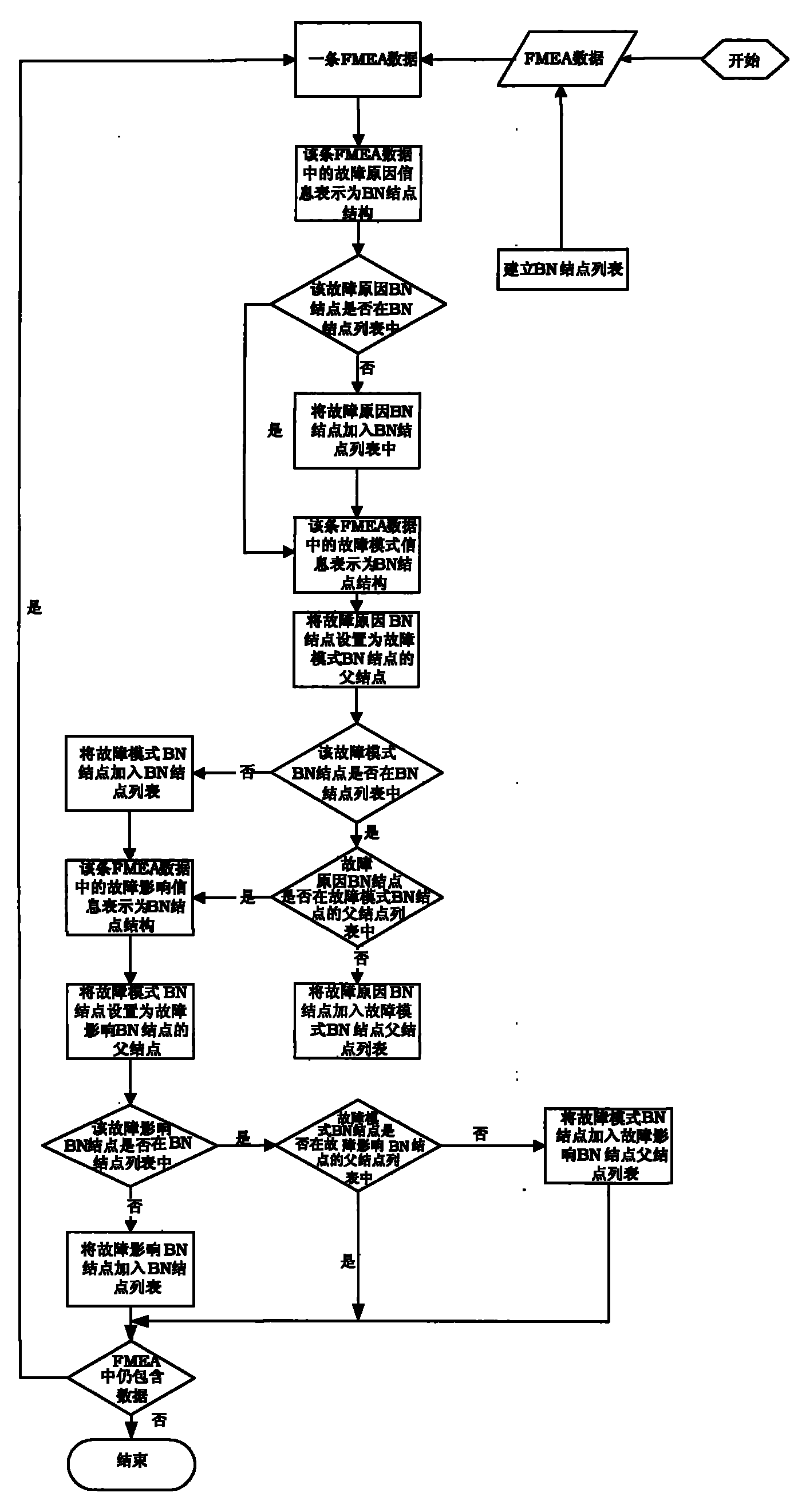

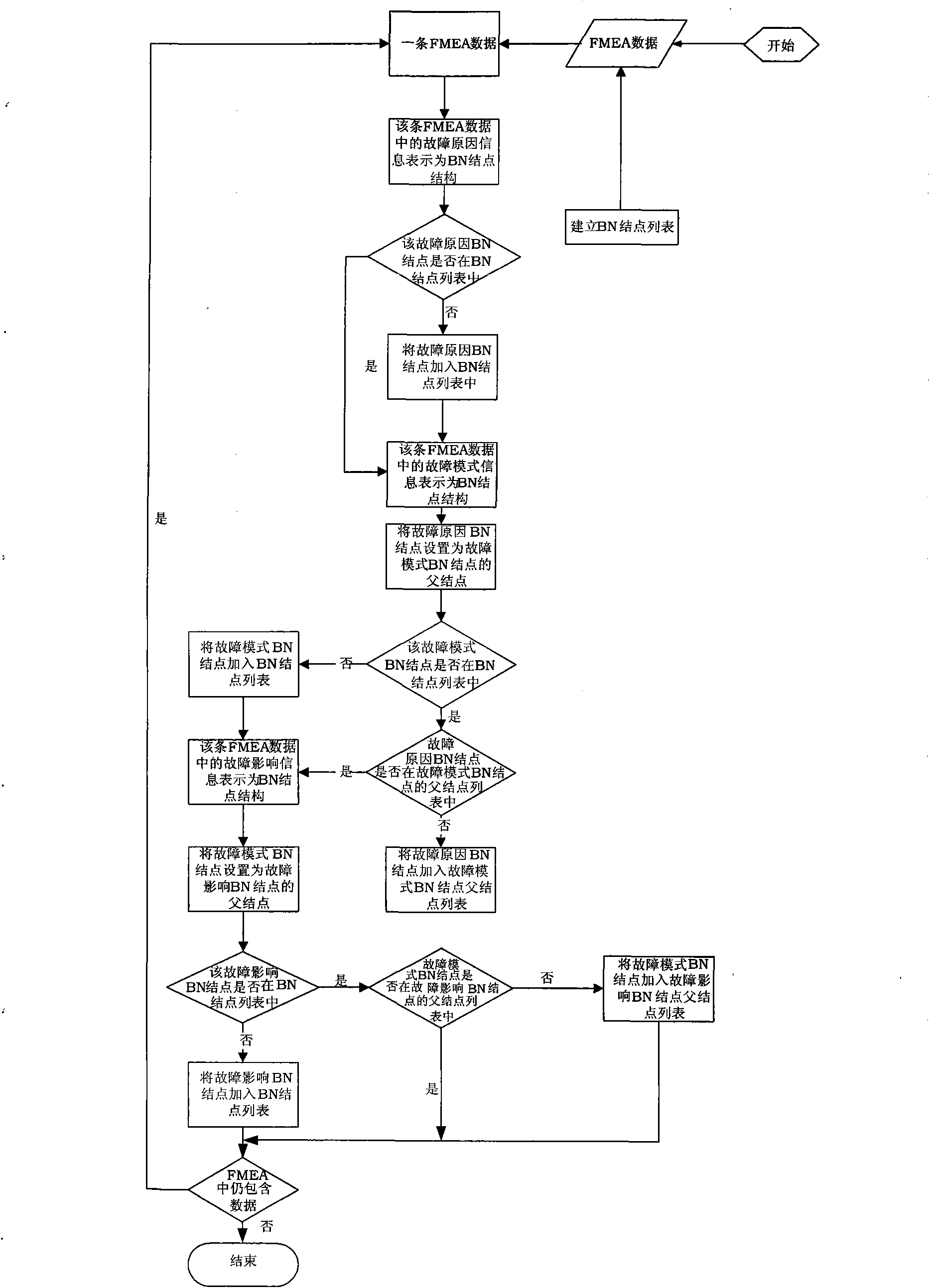

Method for performing fault diagnosis by using model conversion

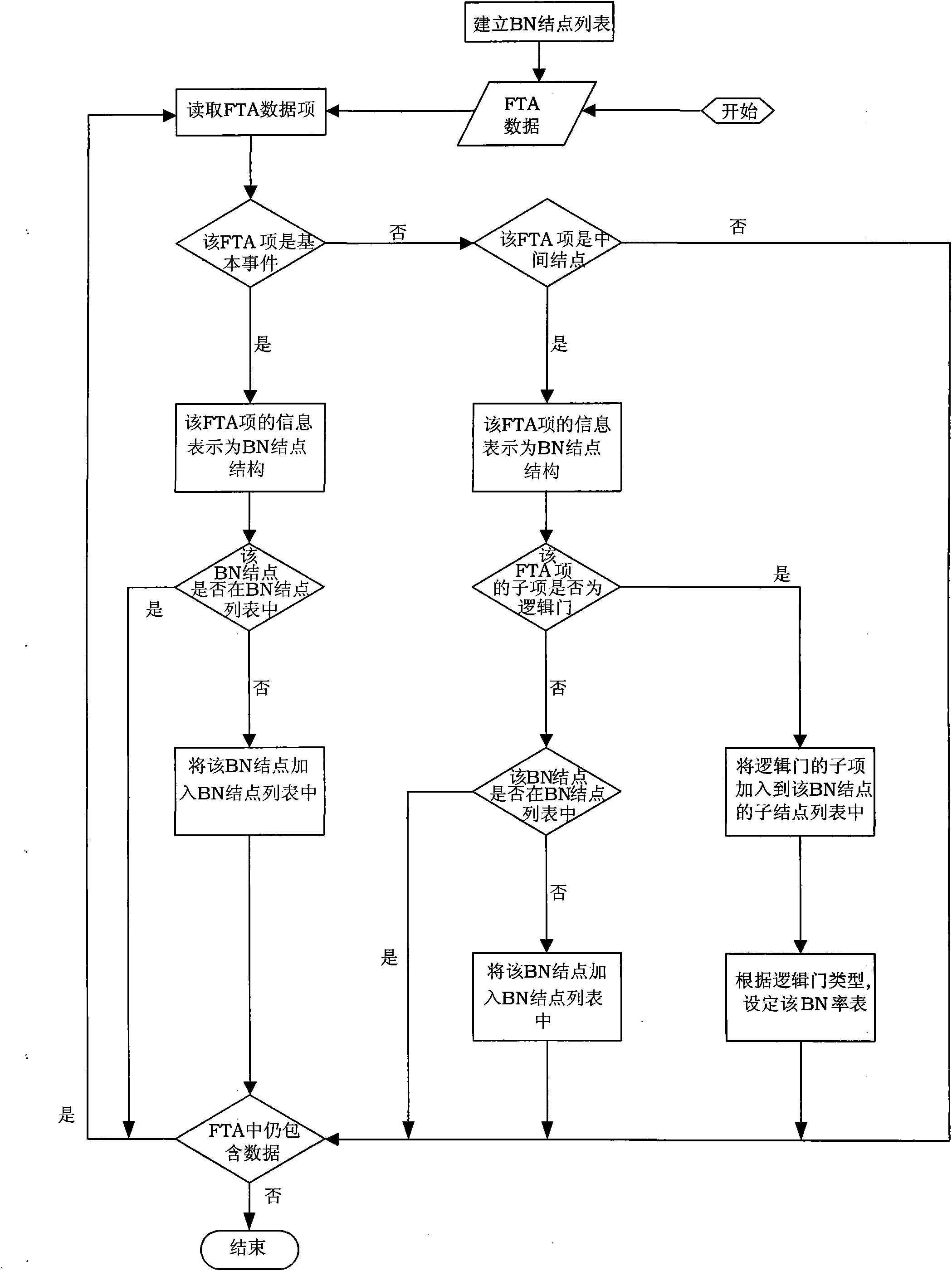

ActiveCN101814114AEasy to useImprove diagnostic accuracyMathematical modelsSpecial data processing applicationsCorresponding conditionalLogic gate

The invention discloses a method for performing fault diagnosis by using model conversion. According to the method, processed related information of a fault mode effect analysis model is converted into a corresponding Bayesian network model by using a self-defined data structure while ensuring complete data, an elementary event, a logic gate and an intermediate event of a fault tree in a fault tree analysis model are converted into nodes in a Bayesian network respectively, and a corresponding conditional probability table in the Bayesian network is set. The fault diagnosis is performed through the converted Bayesian network model. The method of the invention expands the use of the Bayesian network model in the fault diagnosis, improves the diagnosis accuracy of a fault diagnosis model in practical application, ensures the universality of model conversion, and can realize cross-tool conversion among different fault mode effect analysis, fault tree analysis result and the generated Bayesian network.

Owner:BEIHANG UNIV

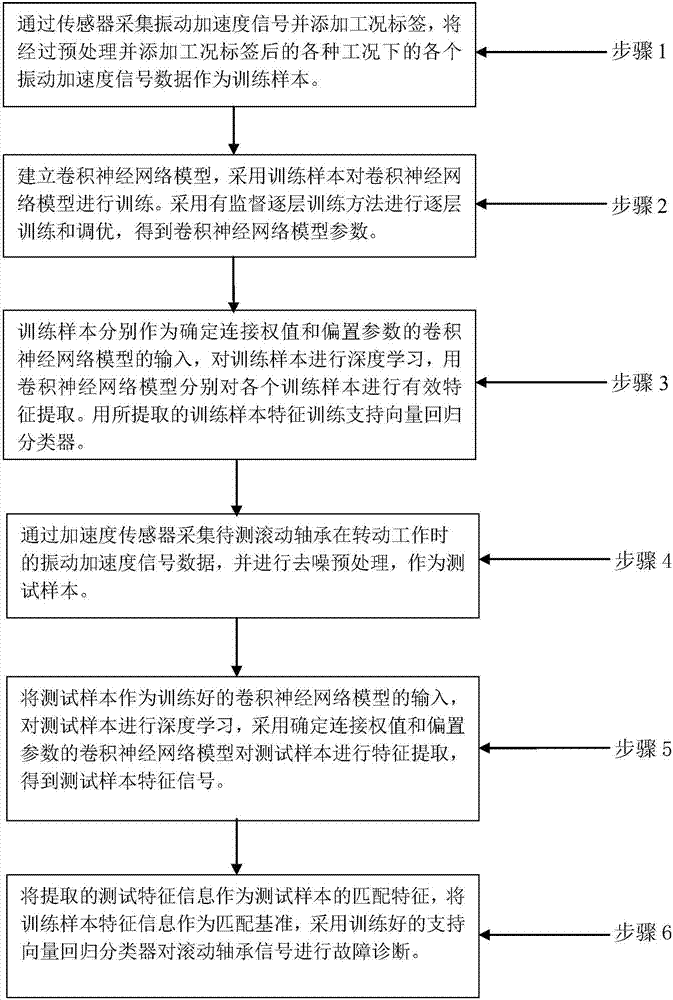

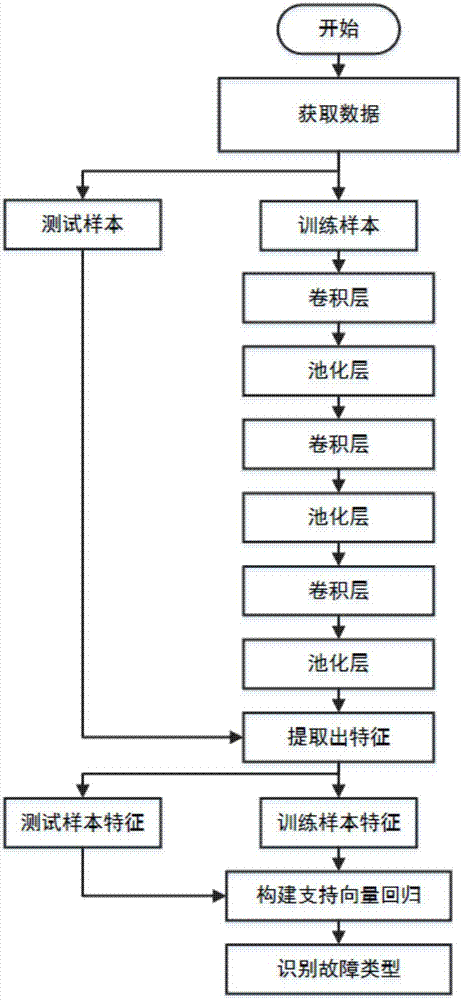

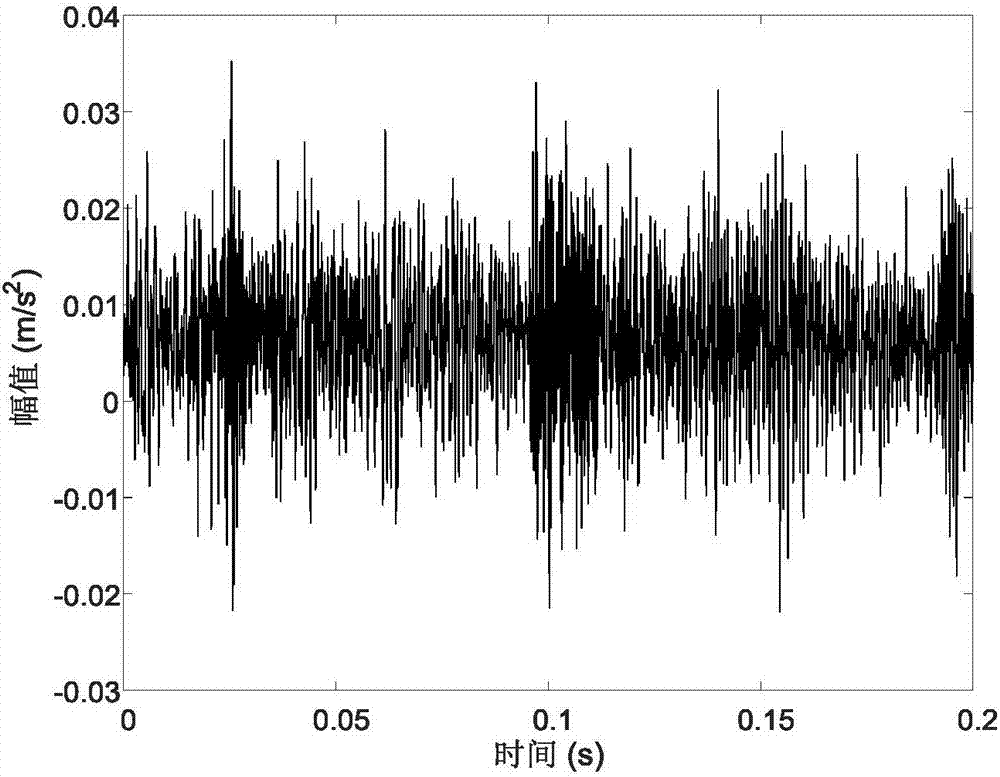

Rolling bearing fault diagnosis method

InactiveCN106874957AGet rid of dependenceSave labor timeMachine bearings testingCharacter and pattern recognitionAviationChemical industry

The invention relates to a rolling bearing fault diagnosis method. The method uses a learning algorithm of a CNN (Convolutional Neural Network) theory to complete a feature extraction task needed by fault diagnosis, and does not rely one manual selection, intrinsic features of input data are extracted automatically from simple to complex and from low-level to high-level, and abundant information hidden in known data can be dug out automatically; and a support vector regression method is used to identity a test sample in a classifying manner, support vector regression with a high generalization capability can be used to identity an unknown new sample in higher precision, and the disadvantage that a default classifier of deep learning tends to be low in the generalization capability can be overcome when support vector regression serves as a classifier to identify samples in the classified manner. The rolling bearing fault diagnosis accuracy and validity can be improved, a new effective approach is provided for solving problems in rolling bearing fault diagnosis, and the method of the invention can be widely applied to fault analysis of complex mechanical systems in the fields of chemical industry, metallurgy, electric power, aviation and the like.

Owner:SUZHOU UNIV

Collaborative troubleshooting computer systems using fault tree analysis

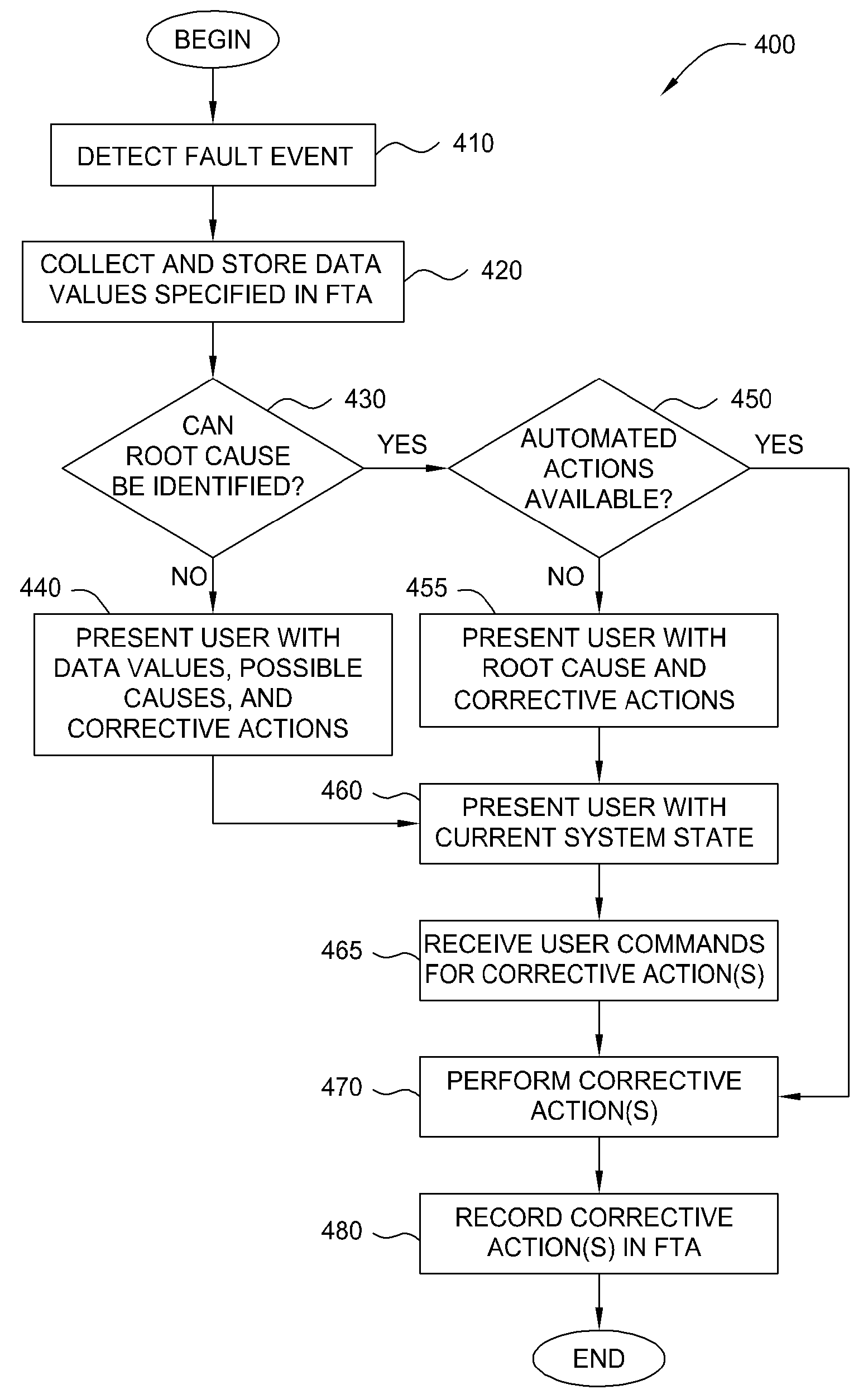

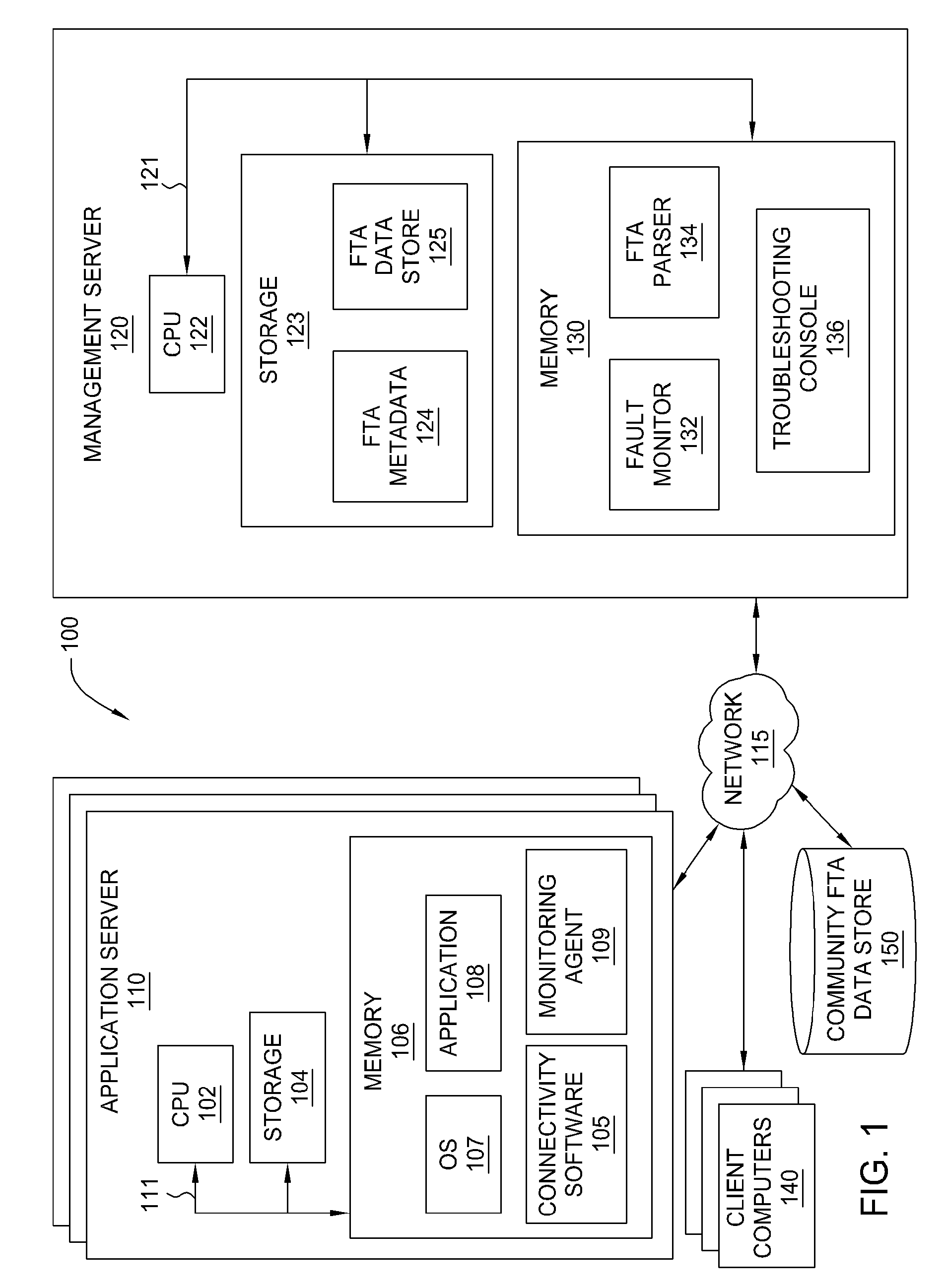

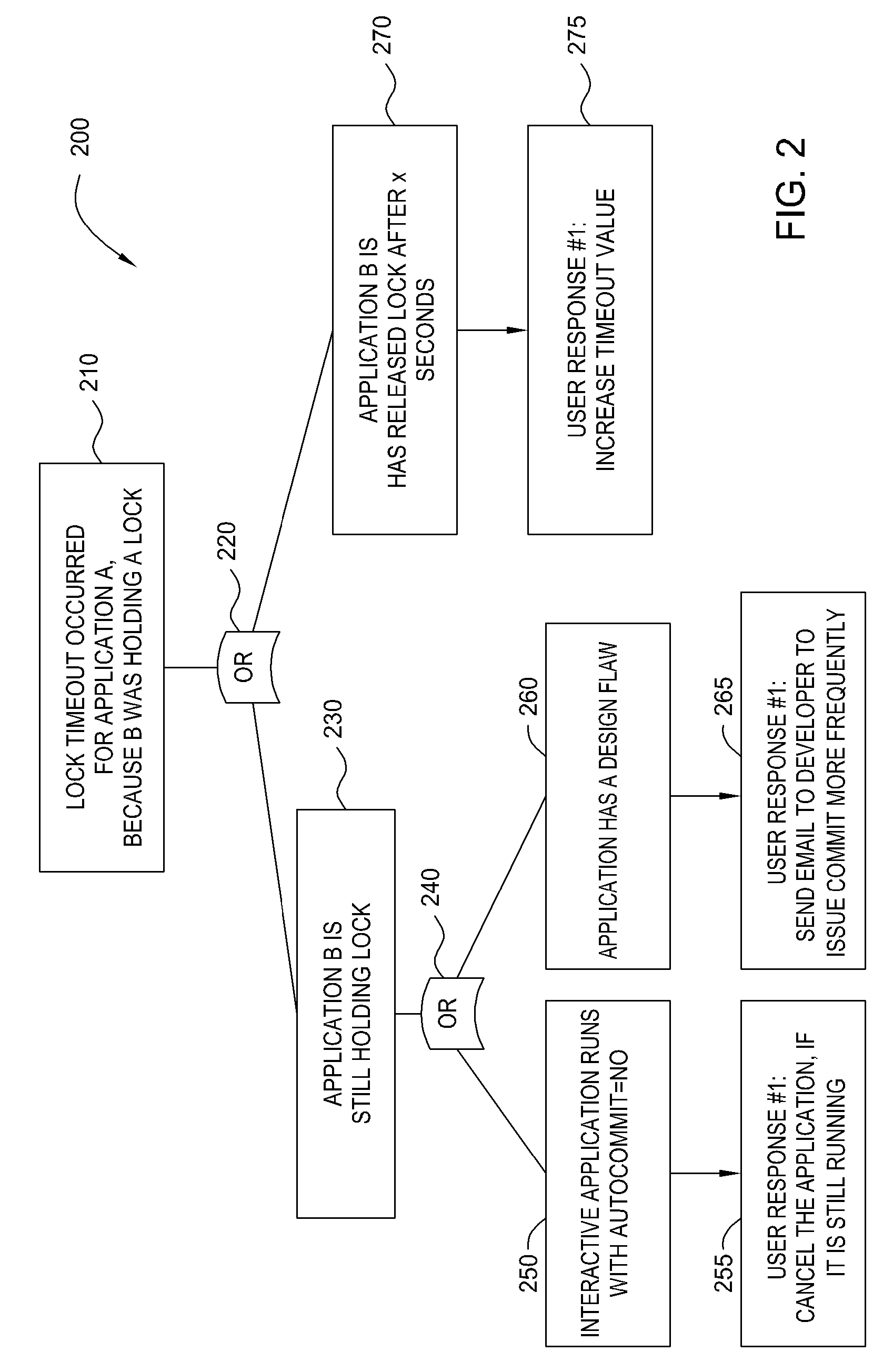

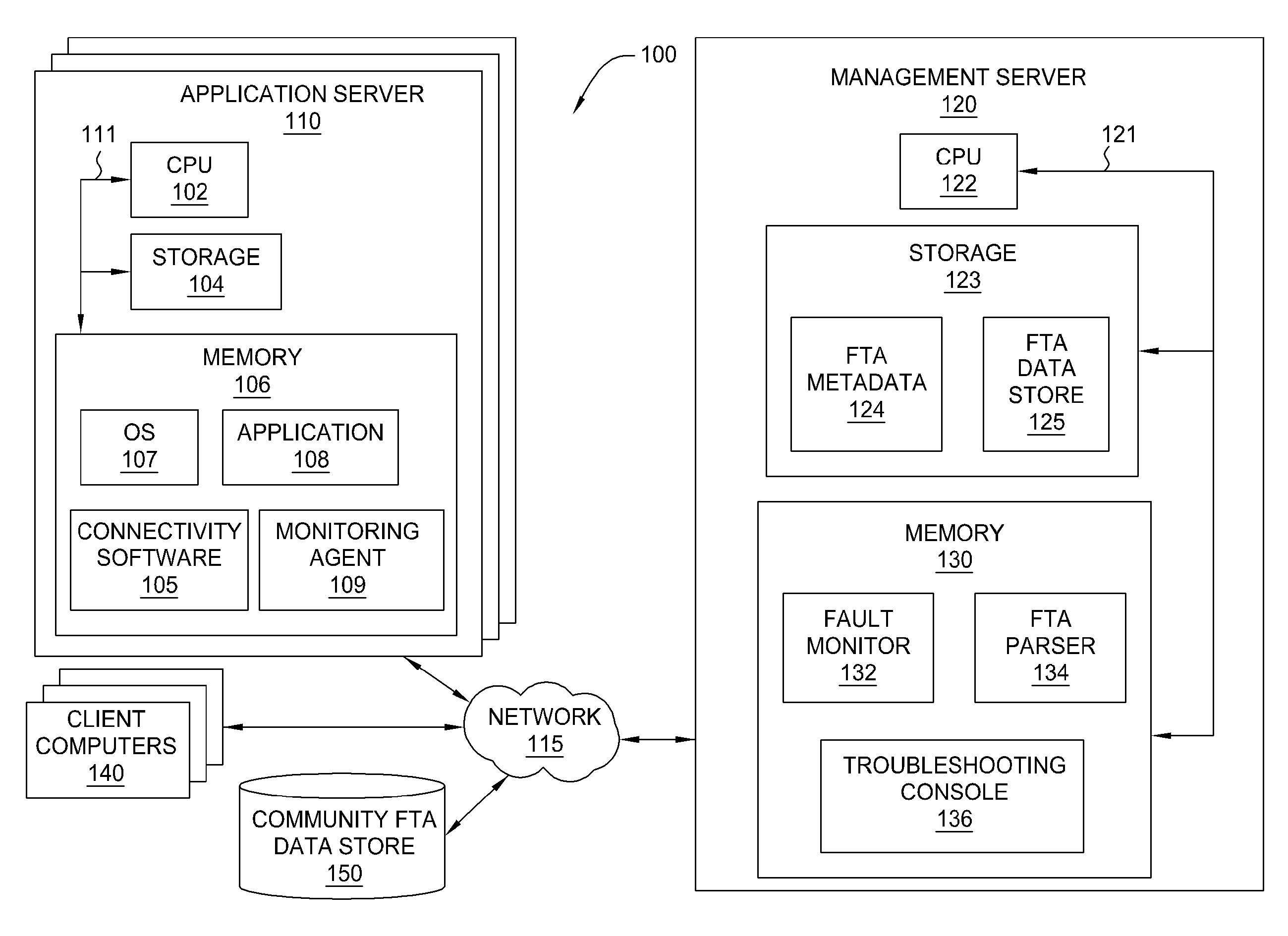

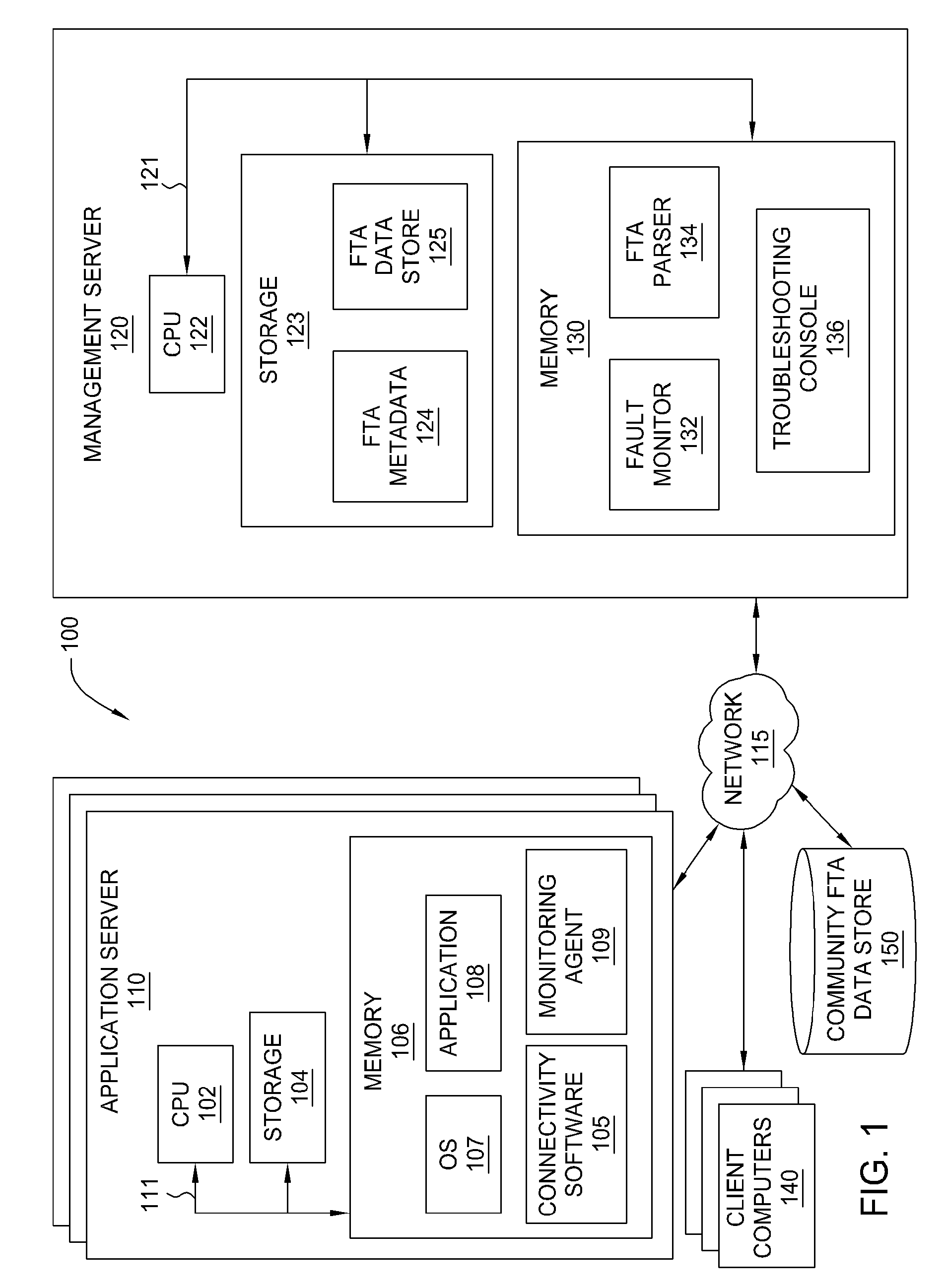

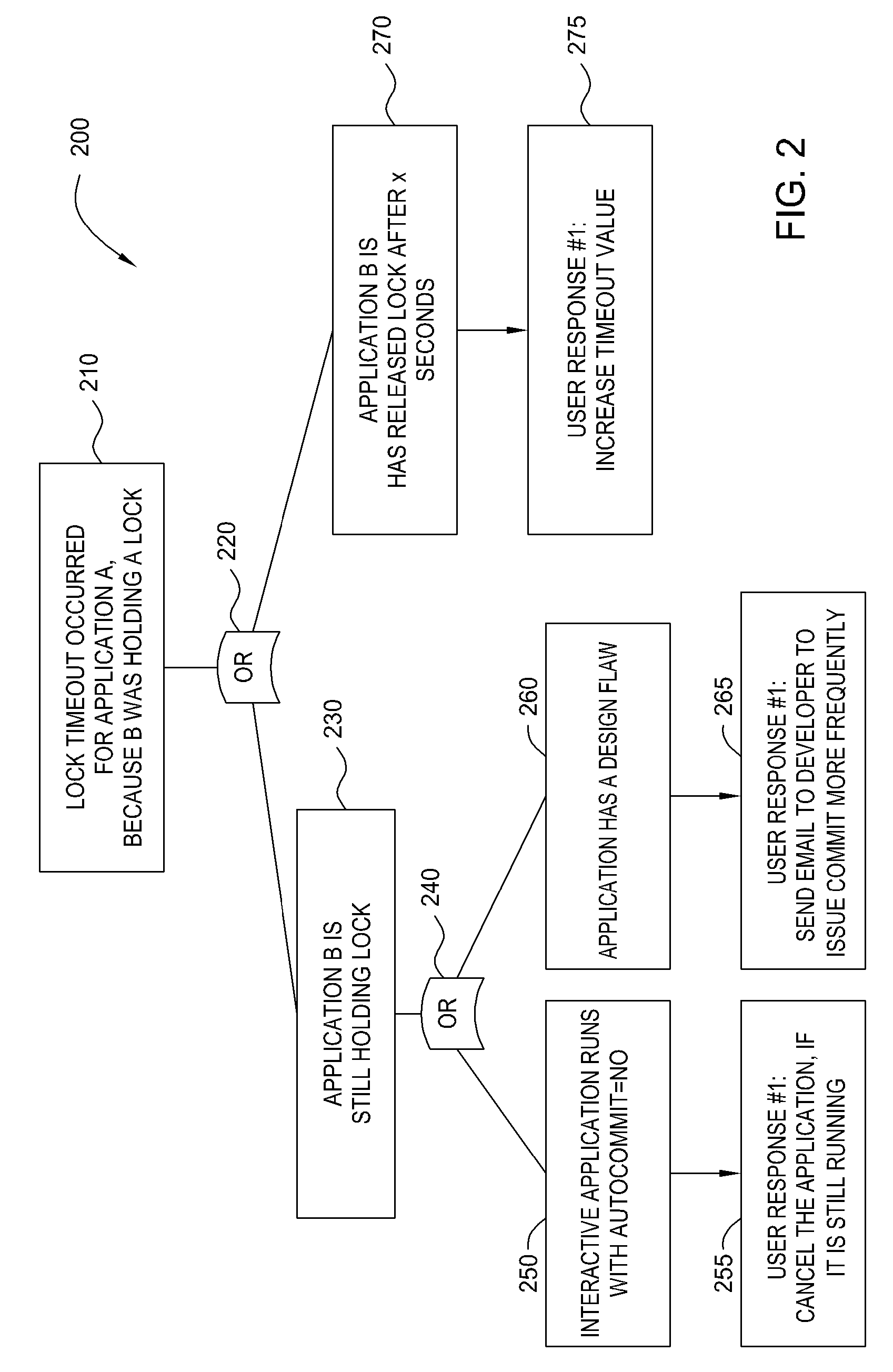

Embodiments of the invention provide techniques for troubleshooting of computer systems using a fault tree analysis. In one embodiment, data parameters describing a status of a system may be monitored to determine the existence of a fault. In the event of a fault, fault tree analysis metadata may be evaluated to attempt to determine a root cause of the fault. If a root cause can be automatically determined, it may be presented to a user in a troubleshooting console, or may be used to trigger an automated corrective action. Alternatively, if a root cause cannot be automatically determined, the user may be presented with additional fault tree analysis metadata and any relevant data parameters in the troubleshooting console, so that the user may determine the root cause of the fault event.

Owner:GLOBALFOUNDRIES US INC

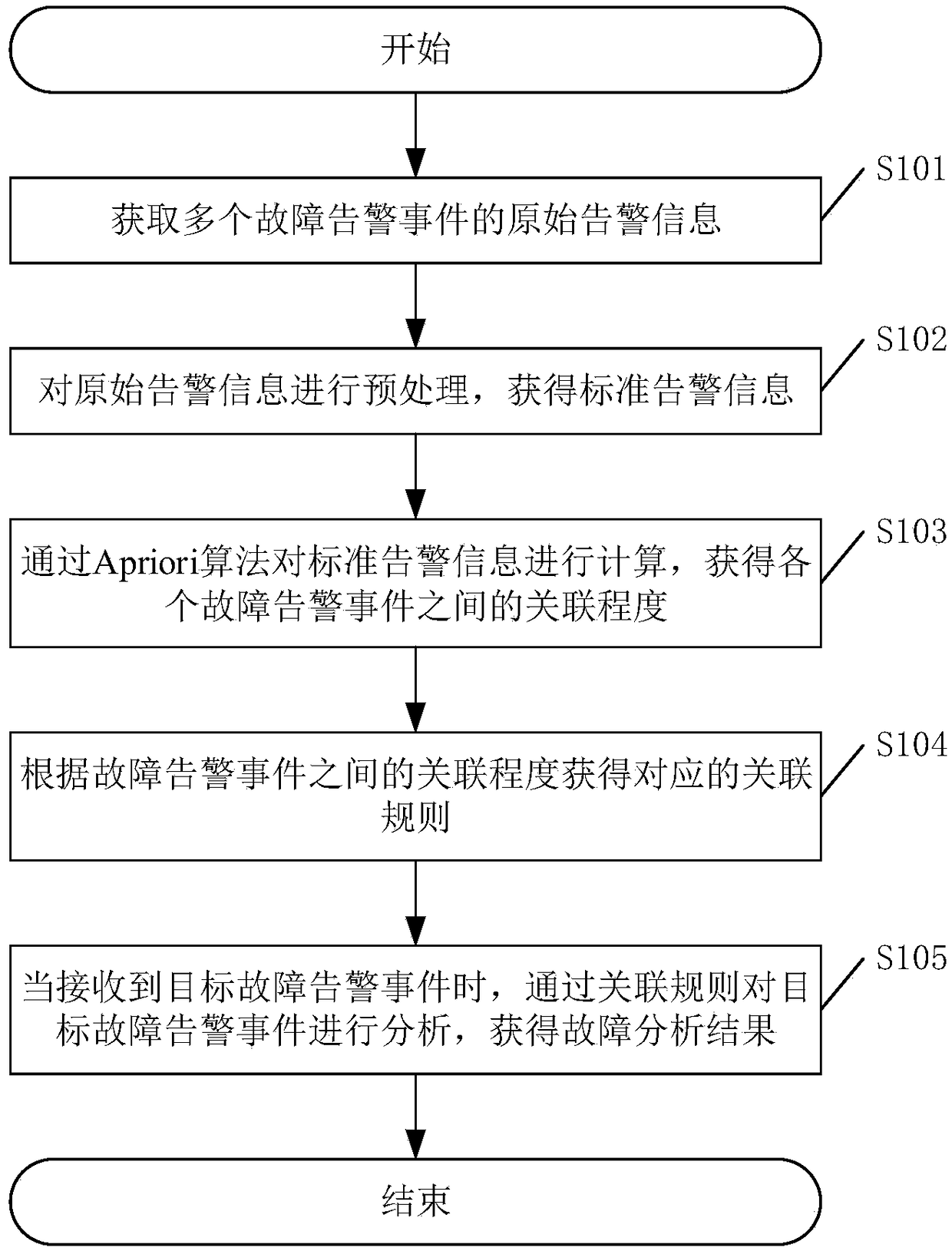

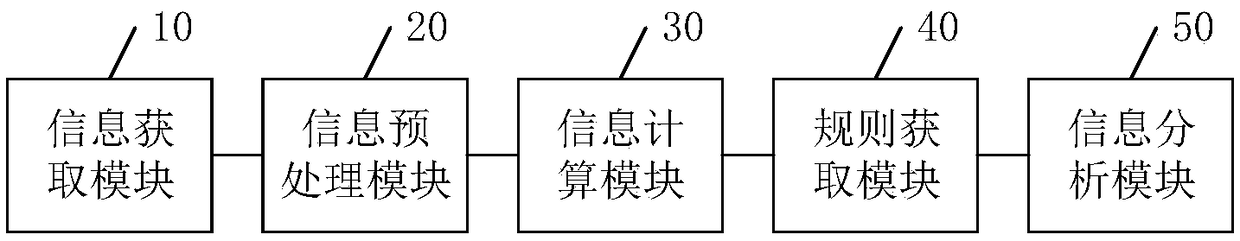

Method and device for fault analysis and related equipment

InactiveCN109358602AImprove processing efficiencyMeet the needs of intelligent operation and maintenance trendsElectric testing/monitoringFault analysisApriori algorithm

The application discloses a method for fault analysis, comprising the following steps of: obtaining original alarm information of multiple fault alarm events; preprocessing the original alarm information to obtain standard alarm information; calculating the standard alarm information by using an Apriori algorithm, and obtaining a correlation degree between each fault alarm event; obtaining a corresponding correlation rule according to the correlation degree between the fault alarm events; and analyzing the target fault alarm events by using the correlation rule, and obtaining a fault analysisresult when the target fault alarm events are received. According to the method for the fault analysis, the fault alarm event can be effectively analyzed, so that the processing efficiency of the fault of the operation and maintenance is improved, and the reliability of the system is further enhanced. The application further discloses a device for fault analysis, equipment, and a computer readablestorage medium, which have the above beneficial effects.

Owner:山东中创软件商用中间件股份有限公司

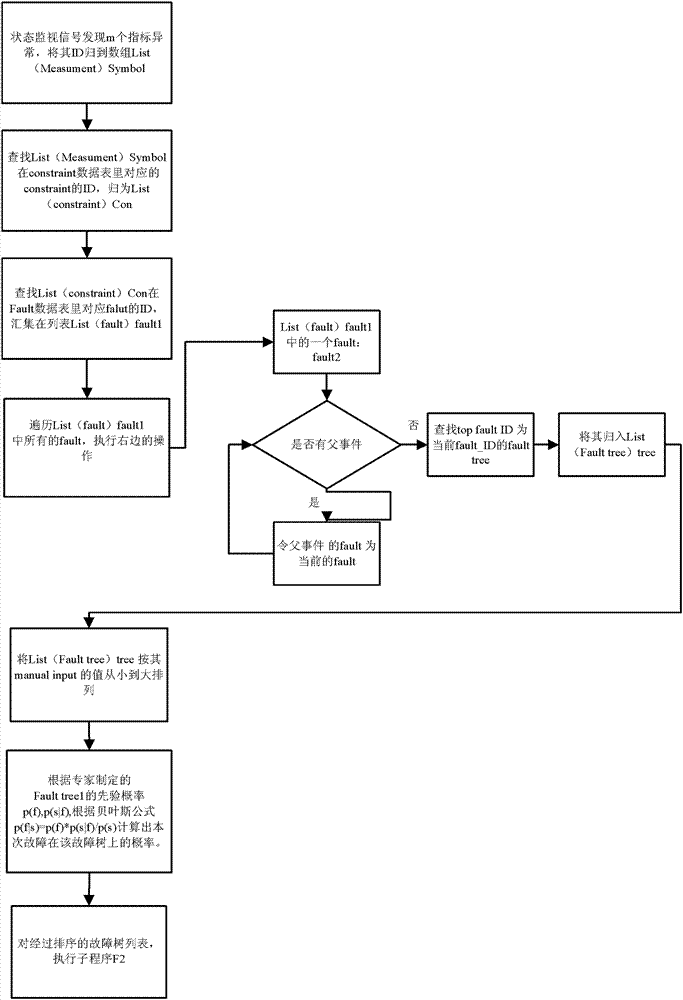

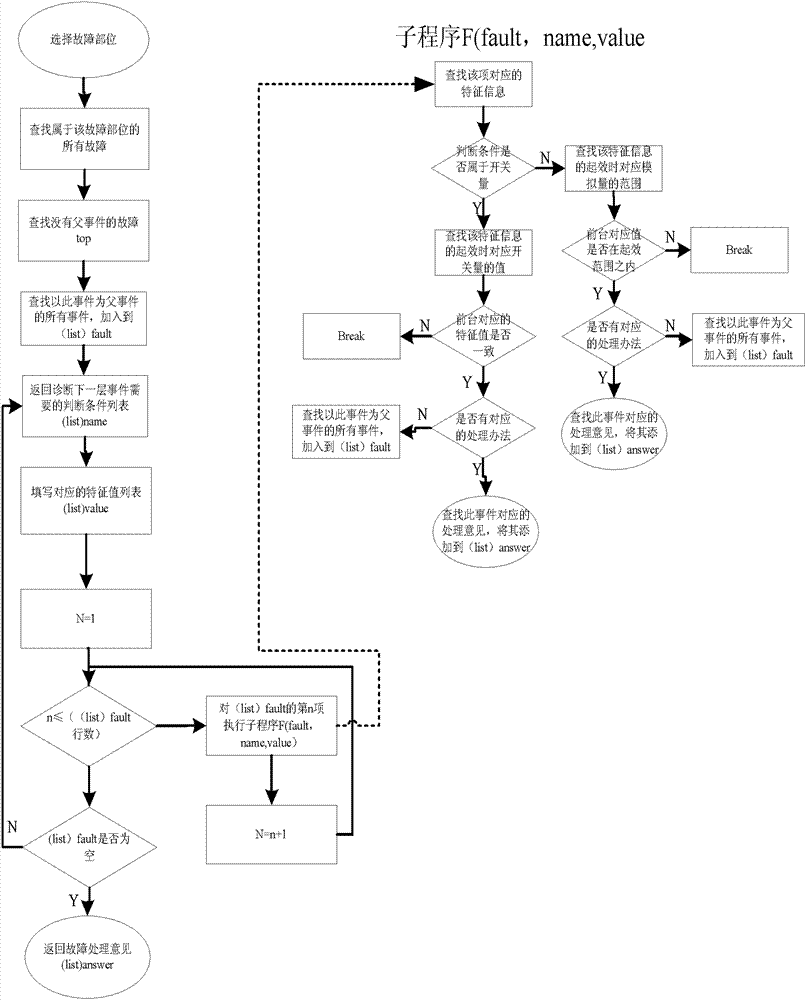

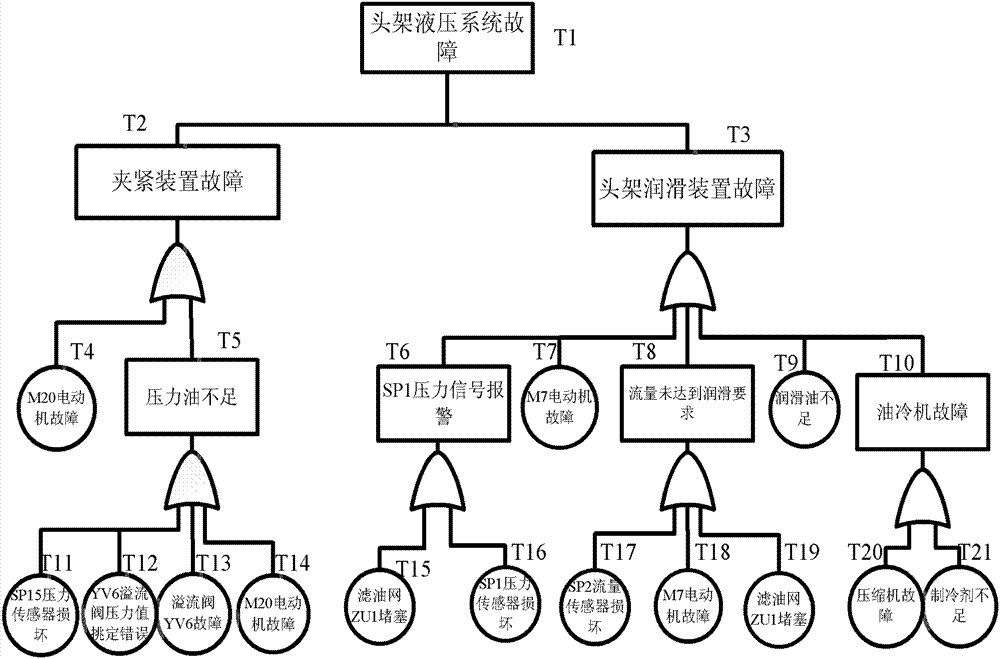

Intelligent fault diagnosis method of numerical control machine tool

InactiveCN102819239AExact searchQuick searchProgramme controlComputer controlNumerical controlDiagnosis methods

The invention provides an intelligent fault diagnosis method of a numerical control machine tool. The intelligent fault diagnosis method uses fault tree diagnosis as a base, faults are diagnosed by combining a Bayes probability and rule reasoning method, fault cause is found, and maintenance advices are proposed. The intelligent fault diagnosis method includes: firstly extracting fault information from historical maintenance records and machine tool operation instructions, and establishing a numerical control machine tool fault information knowledge base; searching fault trees belonging to a fault position in the fault information knowledge base according to fault characteristic information, calculating probability of occurrence of each fault tree under the current condition if a plurality of fault trees fit conditions, and determining sequence for diagnosing the fault trees according to size of the probability; and finally judging whether all sub-events of top events of the fault trees occur, returning to a fault treatment method corresponding to the events and serving as a solution if the sub-evens are bottom events of the fault trees, otherwise searching sub-events of the events continuously until finding all bottom events fit the fault characteristic information. The intelligent fault diagnosis method of the numerical control machine tool is rapid in diagnosis speed and accurate and reasonable in diagnosis result.

Owner:TONGJI UNIV

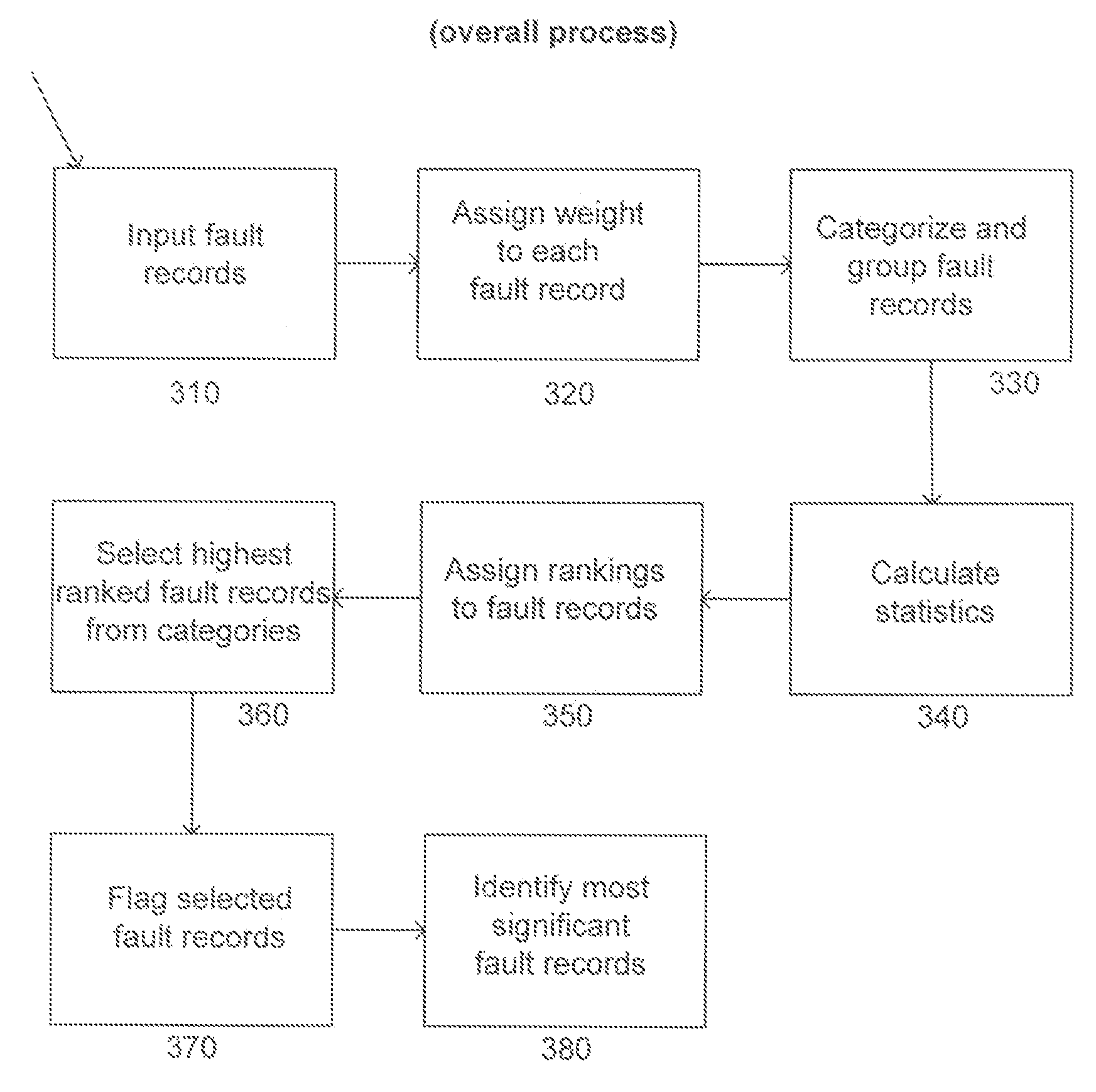

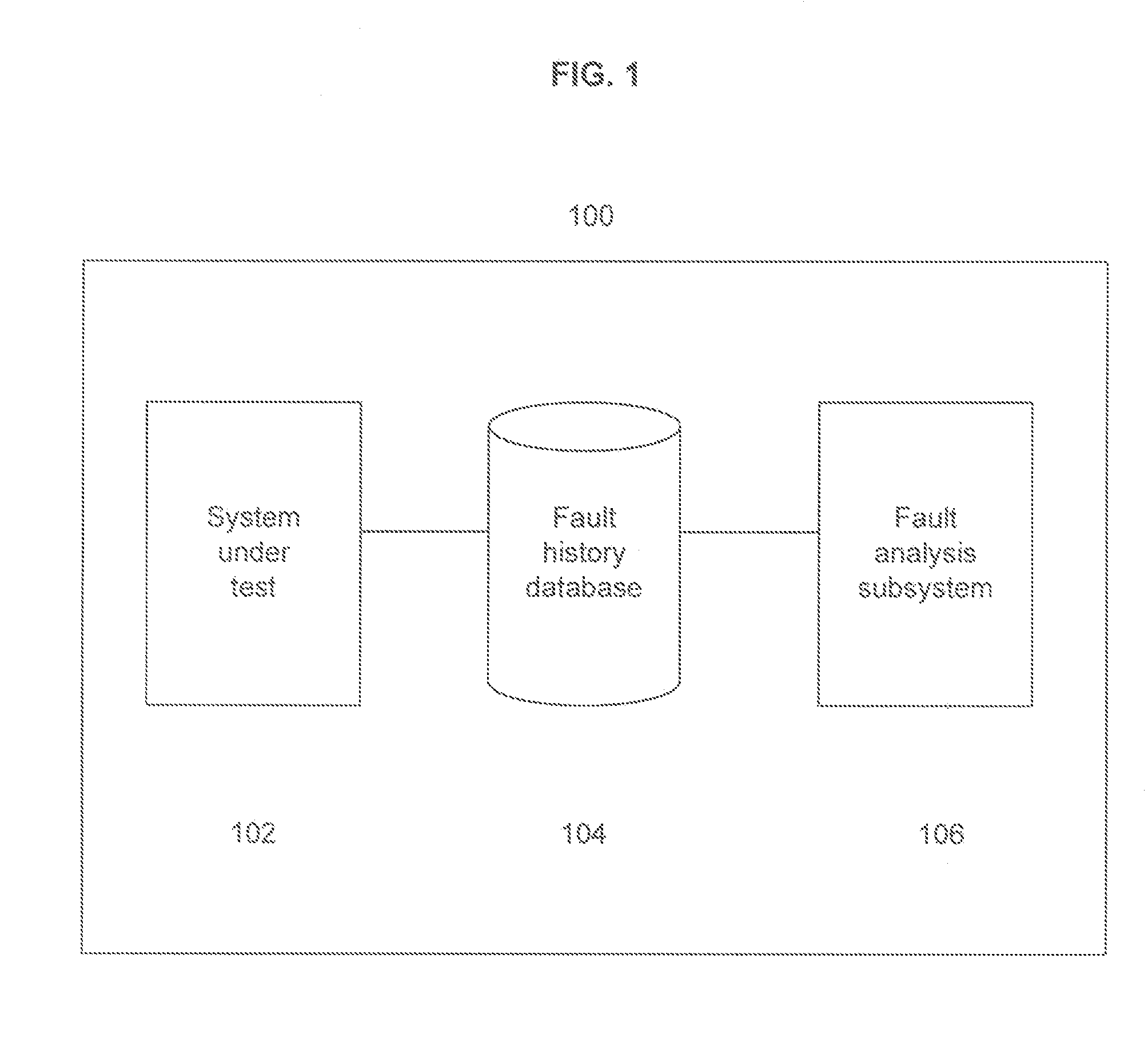

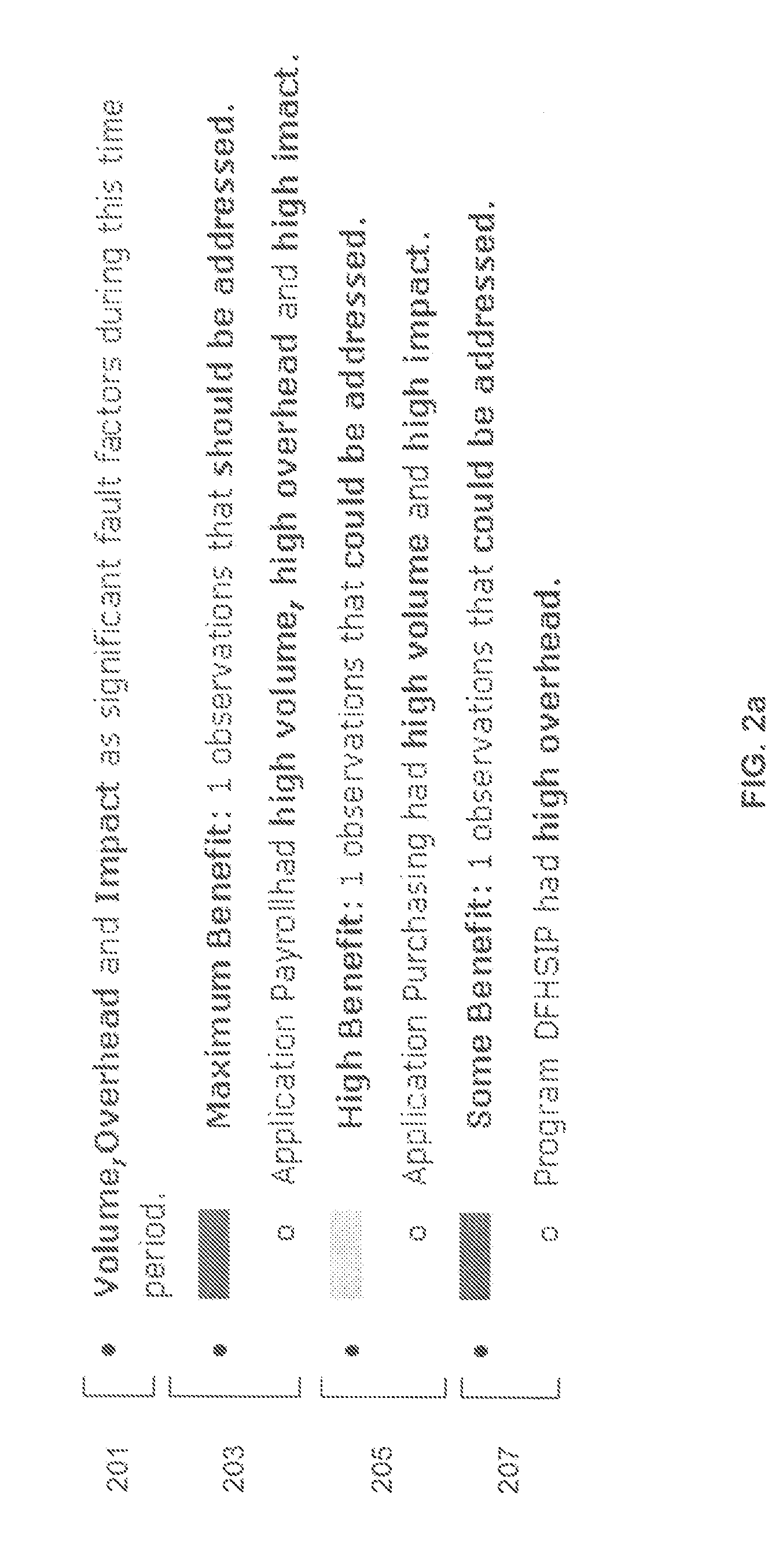

Resolution of Computer Operations Problems Using Fault Trend Analysis

ActiveUS20080307269A1Shorten the timeHardware monitoringNon-redundant fault processingComputer scienceTrend analysis

A set of fault records representing faults previously detected in an enterprise computer system is received and analyzed. The analysis comprises a variety of analytical operations and results in a report provided to a user, the report particularly including a set of fault sources identified as highly important to address, with respect both to the system as a whole and to particular categories of faults.

Owner:BMC SOFTWARE

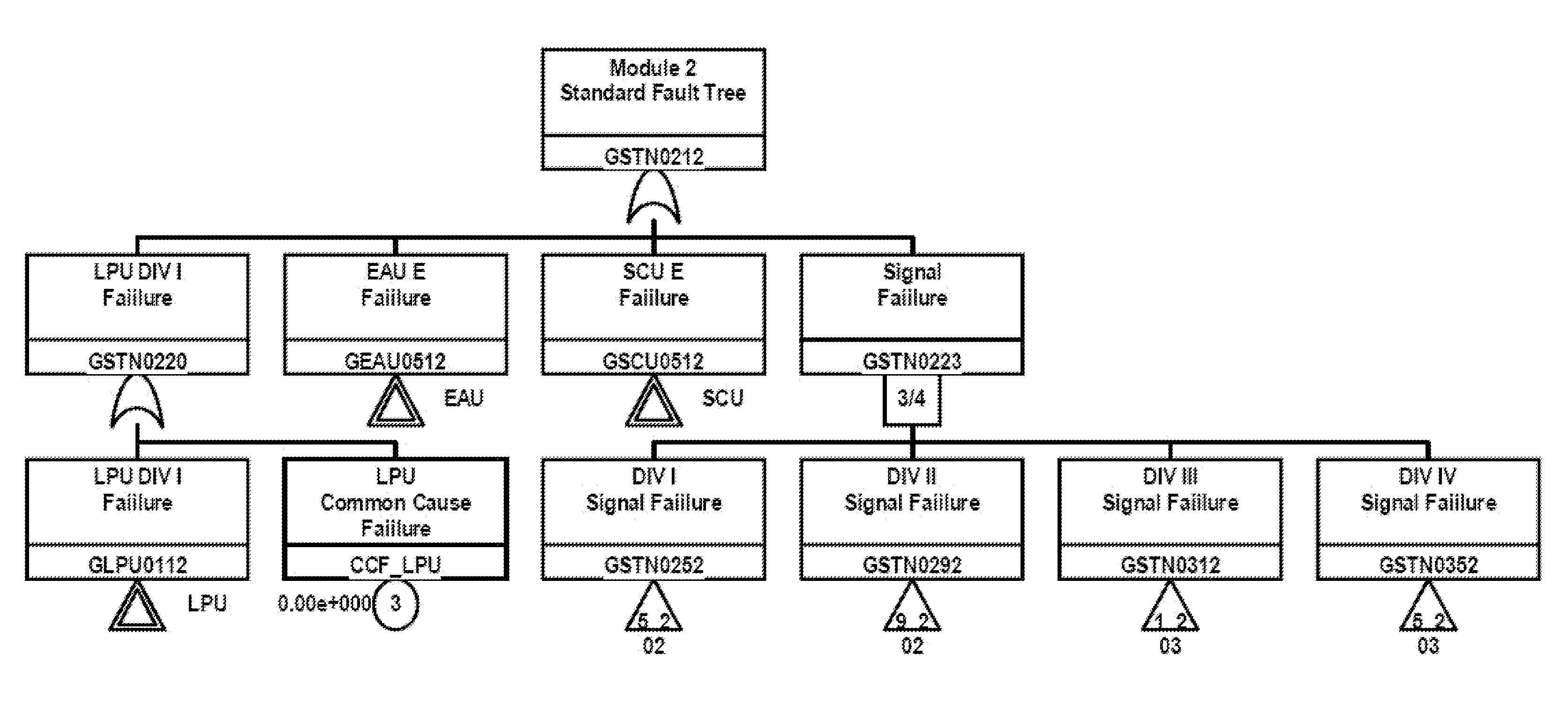

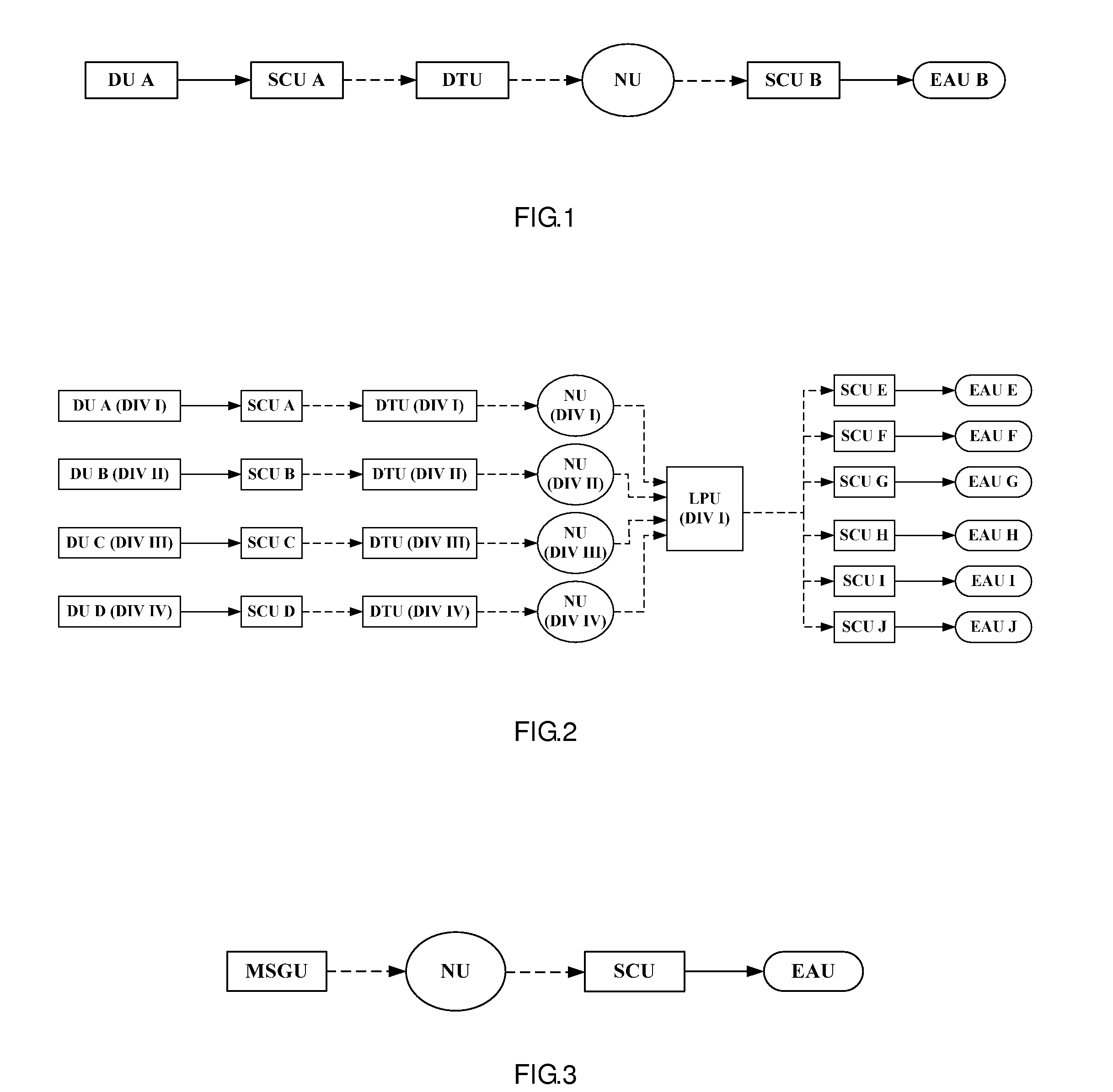

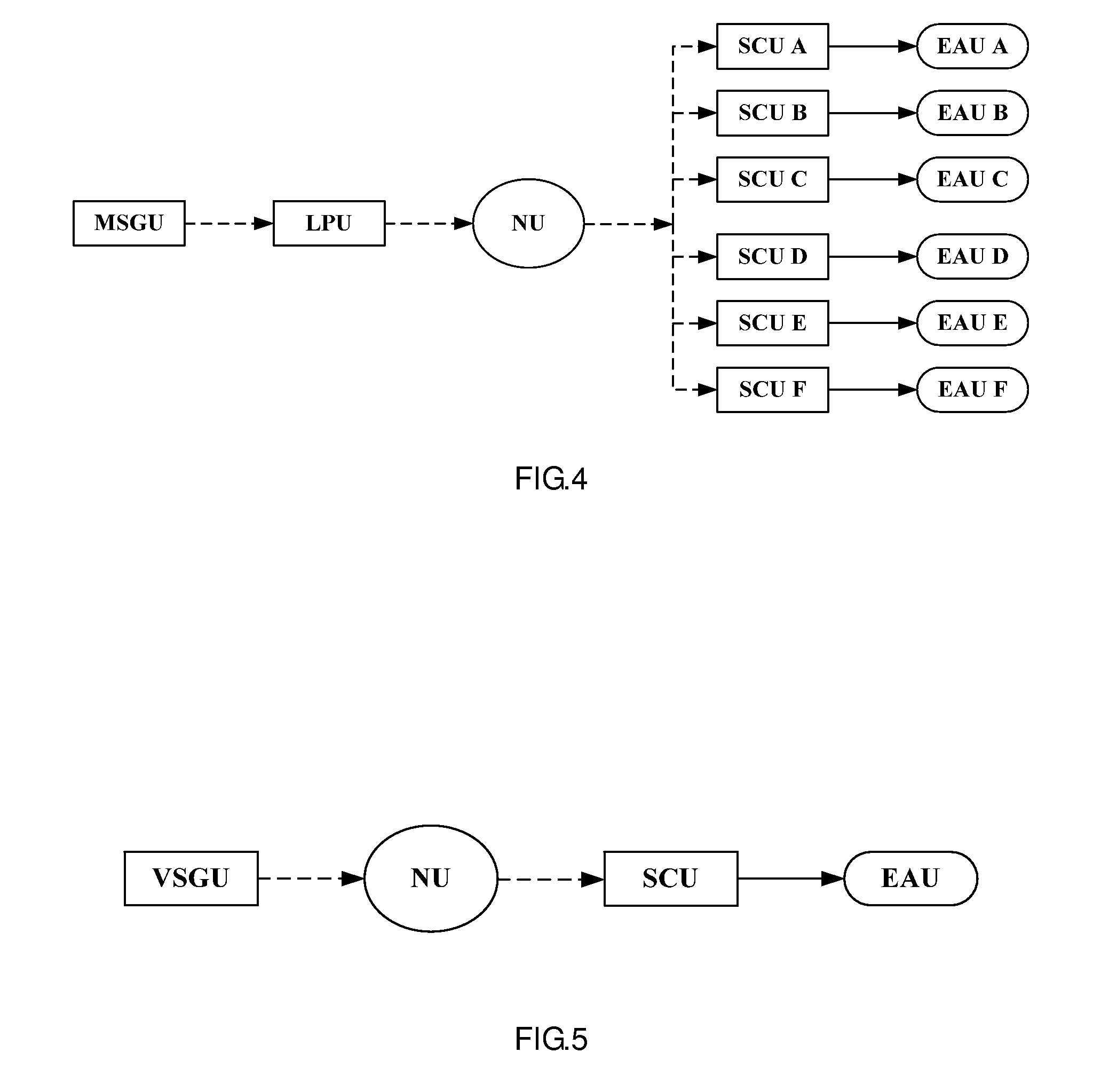

Fault Tree Analysis System for the Instrument Control Process for Nuclear Power Plant with Advanced Boiling Water Reactor Background

InactiveUS20100100251A1Fast and accurate to establishLevel controlAnalogue computers for nuclear physicsProbabilistic risk assessmentBiology

The invention relates to the fault tree analysis system for a nuclear power plant with advanced boiling water reactor. The full digital instrument control system uses six different modes to simulate the transmission of the digital signals and the analog signals from the detection units. It is to develop the fault tree for various signal transmission modes to support the nuclear power plant in probabilistic risk assessment (PRA) and meet requirements for simulated signal detection, transmission, logic operation and equipment actuation. Thus, the digital instrument control flow process can fit into PRA model and properly reflect its importance in risk assessment.

Owner:INST NUCLEAR ENERGY RES ROCAEC

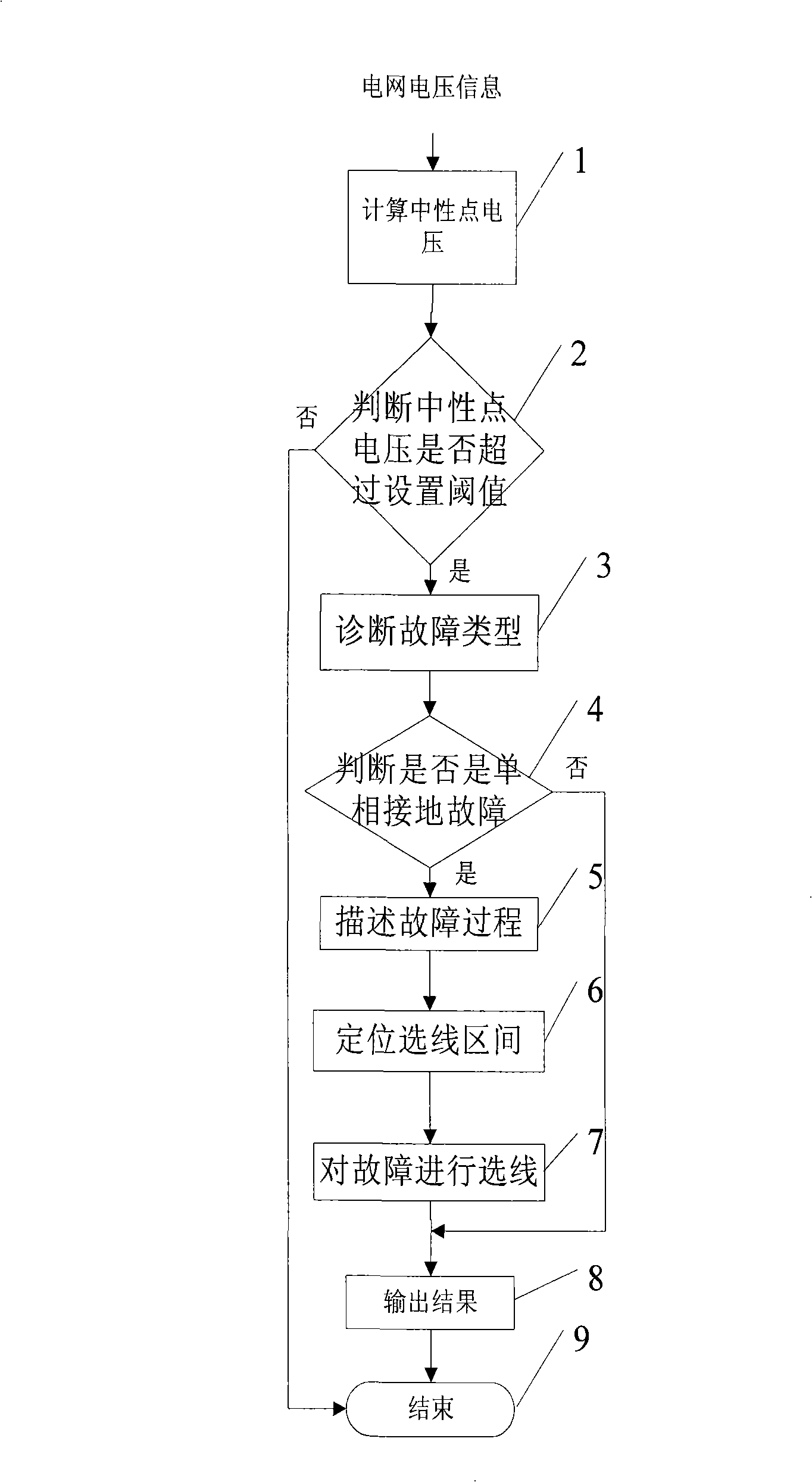

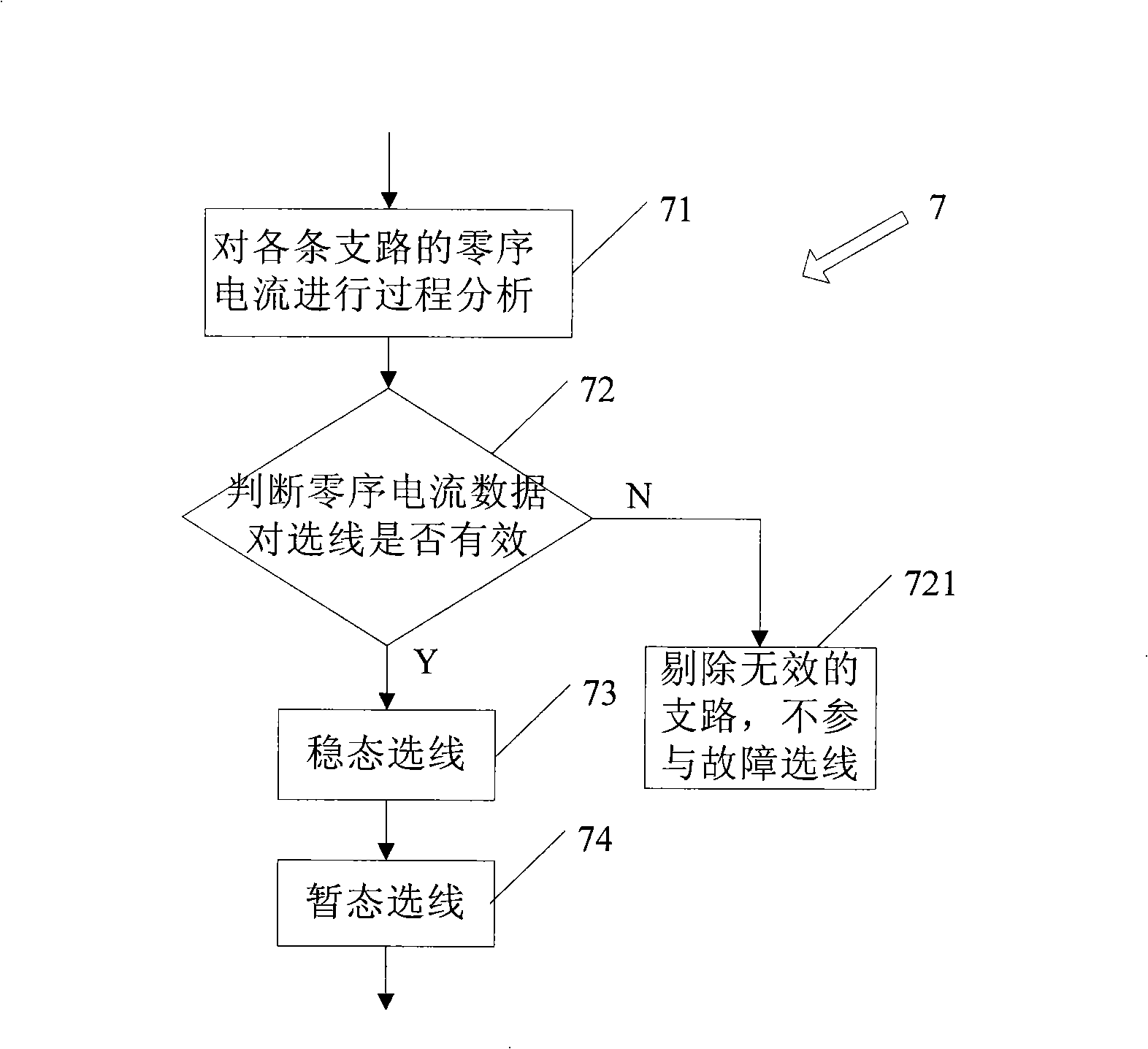

Medium-voltage power distribution network single-phase ground fault route selection method based on fault procedure analysis

ActiveCN101295873AFault development complies withEmergency protective circuit arrangementsFault locationDistribution networksVoltage

The invention provides a single phase grounding fault line selection method for medium voltage distribution networks based on fault process analysis, which comprises the steps of calculating neutral point voltage, determining whether the neutral point voltage exceeds a preset threshold value, diagnosing fault type, determining whether the fault is a single phase grounding fault, describing fault process, positioning line selection area, selecting line for the fault, outputting result and finishing. The method can reflect the process of fault development and evolution intuitively and constitutionally, effectively selects the line for stable grounding with single phase grounding fault time more than 500 milliseconds, and can totally capture and describe transient fault during the fault process.

Owner:SHANGHAI ELECTRIC POWER COMM +3

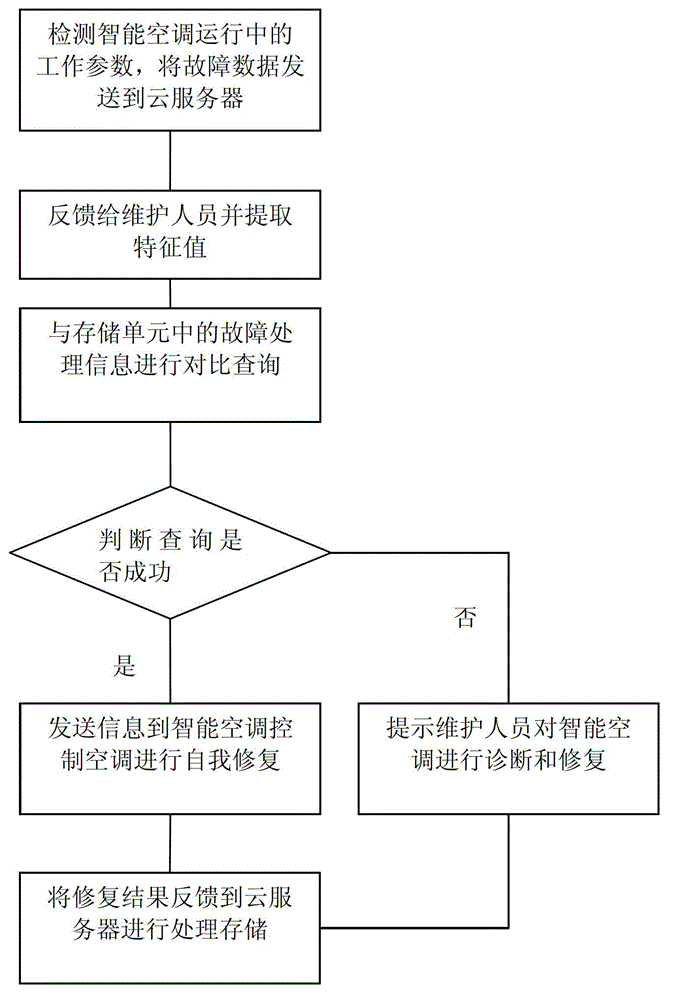

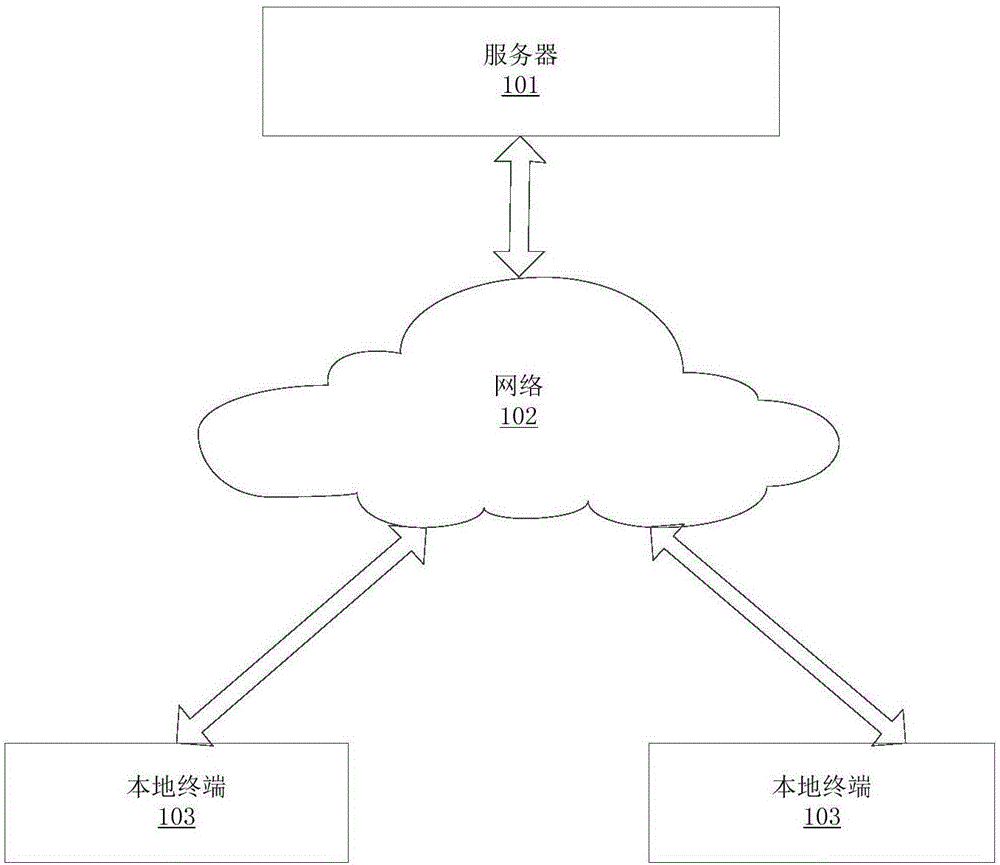

Remote fault processing method for intelligent air conditioner

ActiveCN103062862AImprove the quality of after-sales serviceLower service costsSpace heating and ventilation safety systemsLighting and heating apparatusComputer moduleFault analysis

The invention relates to the intelligent control technology, in particular to a remote fault processing method for an intelligent air conditioner. The remote fault processing method includes main steps that: fault data are analyzed through a detection module by detecting working parameters of the intelligent air conditioner and are transmitted to a cloud server; the cloud server performs comparison query according to characteristic values of the fault data and fault processing information in a storage unit, the intelligent air conditioner performs self repair according to contents of the fault processing information and feeds the repair result back to the cloud server if matched fault processing information is obtained, and maintainers perform fault analysis and repair for the intelligent air conditioner and input fault analysis and repair contents into the cloud server to be stored in the storage unit if the matched fault processing information is not obtained. The remote fault processing method for the intelligent air conditioner has the advantages of being an efficient and intelligent remote fault processing mode, being capable of effectively improving after-sale service quality of the intelligent air conditioner devices and saving service cost, and further is especially applicable to the intelligent air conditioner.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

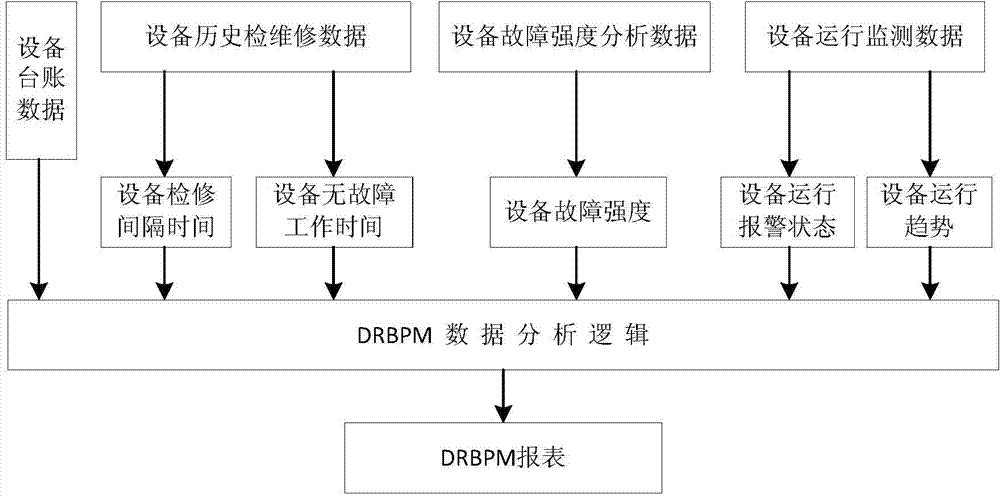

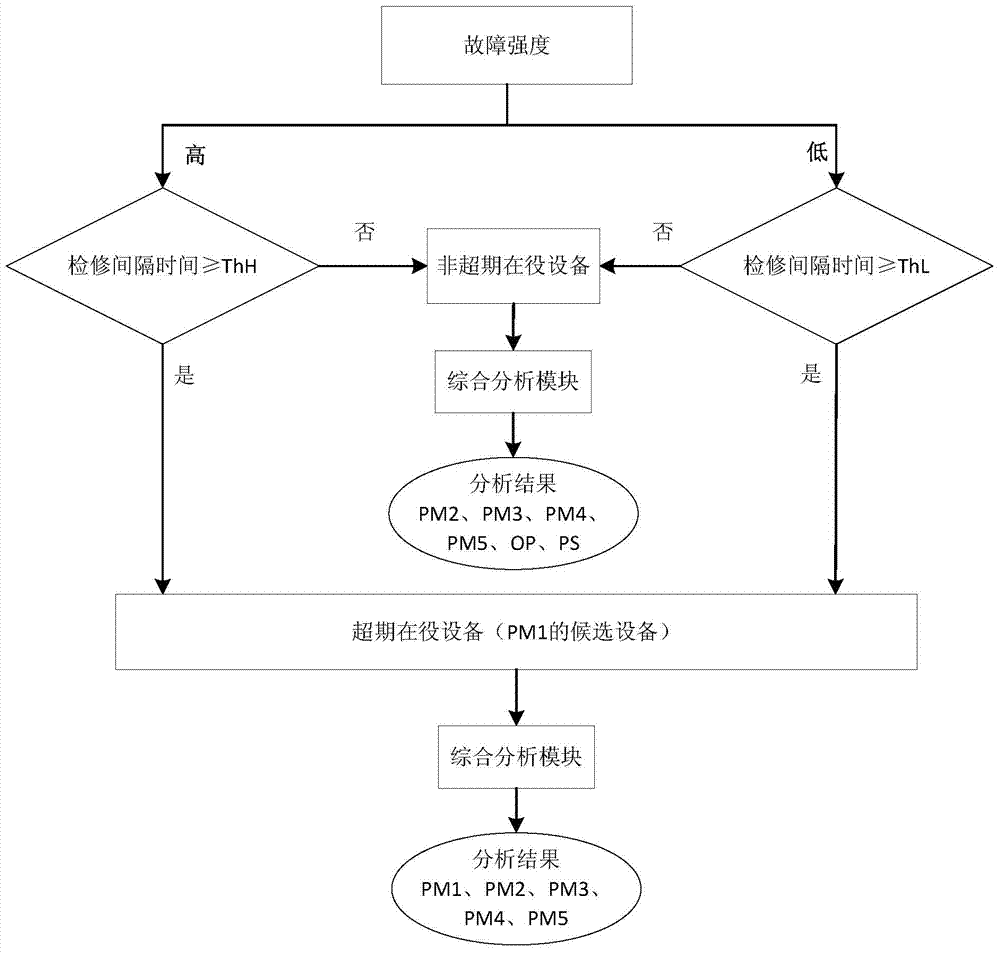

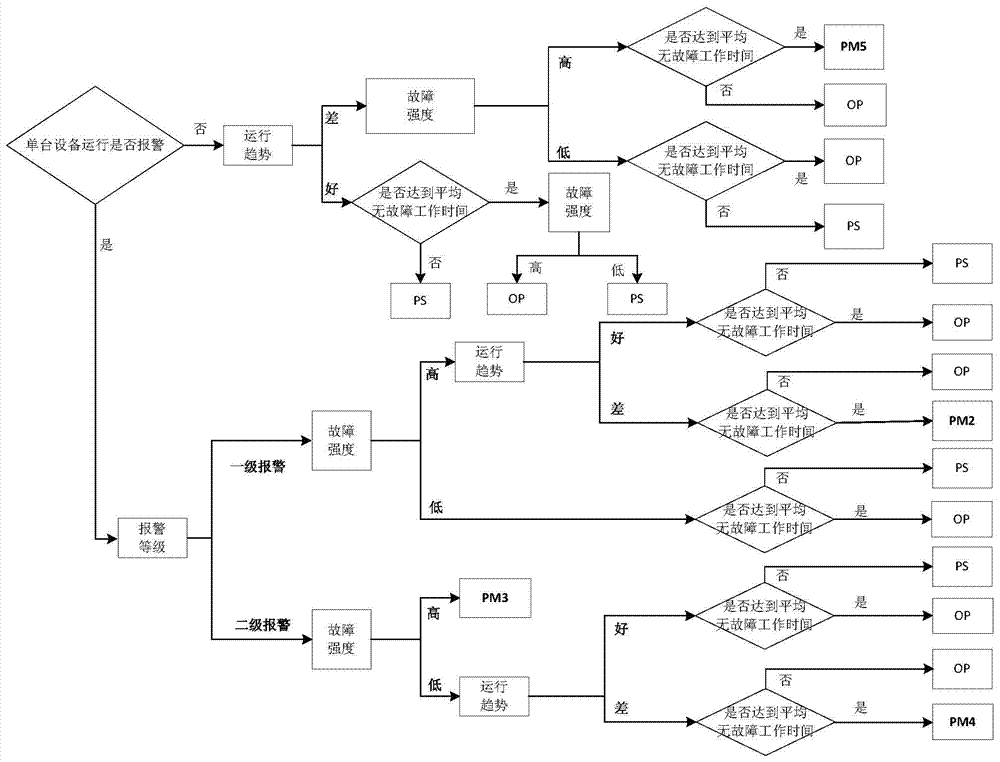

Preventative device maintenance method based on dynamic reliability

ActiveCN104268678ADecision scienceScientific and effective maintenance measuresResourcesAnalysis dataMaintenance planning

The invention discloses a preventative device maintenance method based on dynamic reliability and belongs to the technical field of petrochemical equipment management. The preventative device maintenance method based on the dynamic reliability comprises the following steps of 1 establishing a device basic database including equipment accounts, historical maintenance and repair data, a fault strength analysis data, operation monitoring data and the like; 2 utilizing basic data to conduct operation time analysis, fault strength analysis and alarm state and operation trend analysis on devices; 3 utilizing results to establish a device reliability level and fault strength incidence matrix, formulate DRBPM data analysis logic, automatically screen preventative maintenance devices and generate preventative maintenance planning reports of the devices; 4 examining, verifying and executing the preventative maintenance planning reports of the devices. The preventative device maintenance method based on the dynamic reliability can be used for dynamic analysis and management of states of petrochemical equipment, facilitate formulation of scientific and effective device maintenance measures and provide guarantee for timely device fault elimination and production continuity reliability and can be widely applied to the technical field of petrochemical equipment management.

Owner:中国石油化工股份有限公司武汉分公司 +1

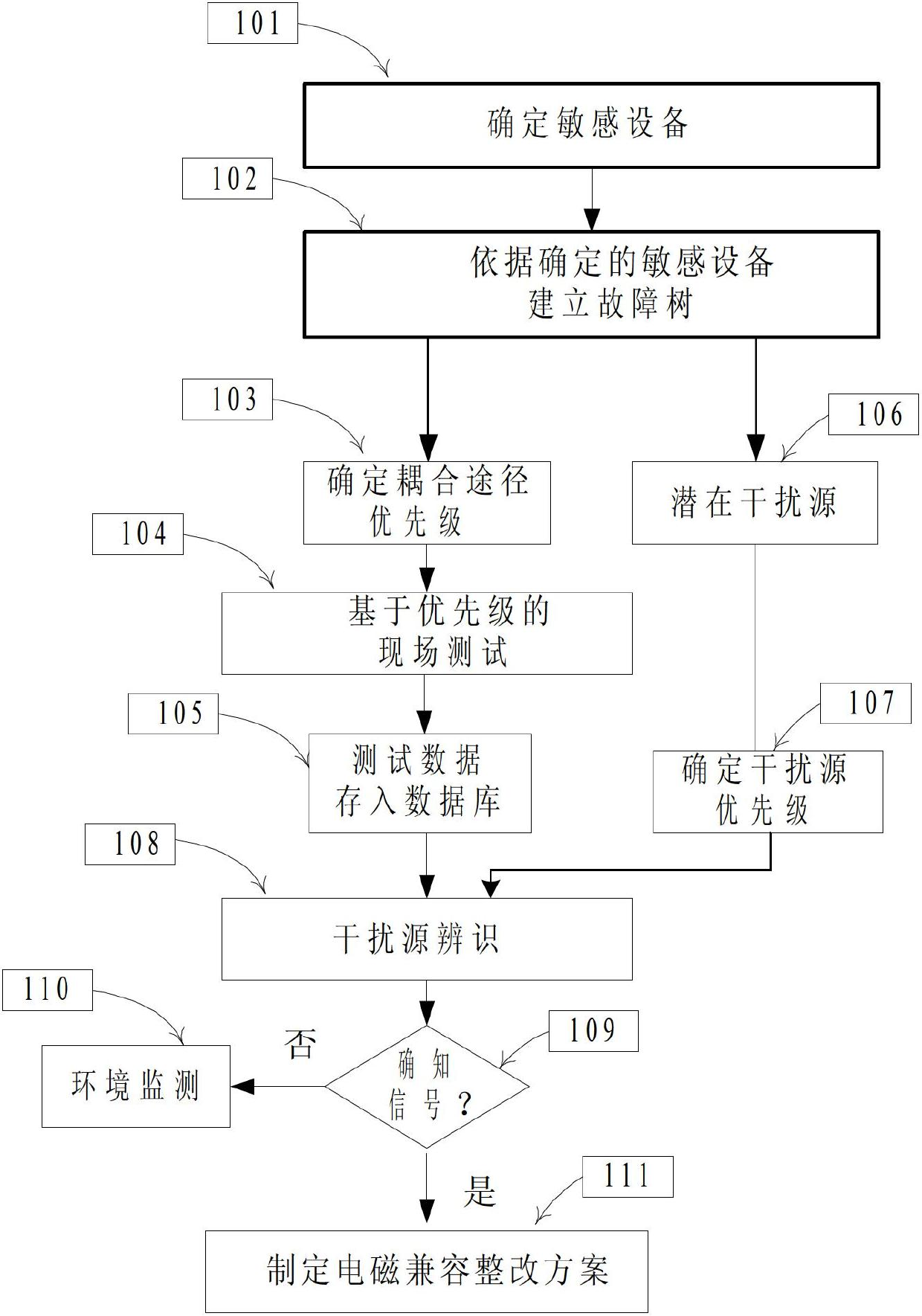

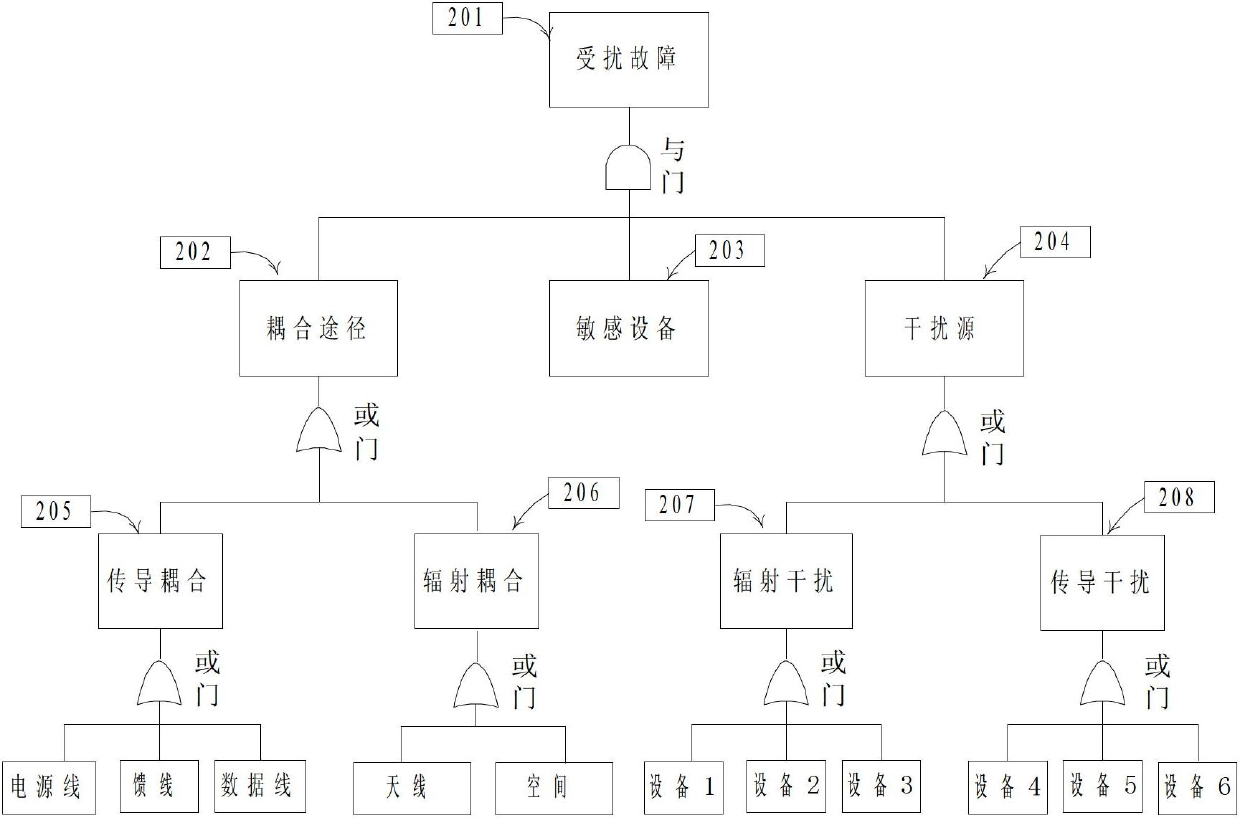

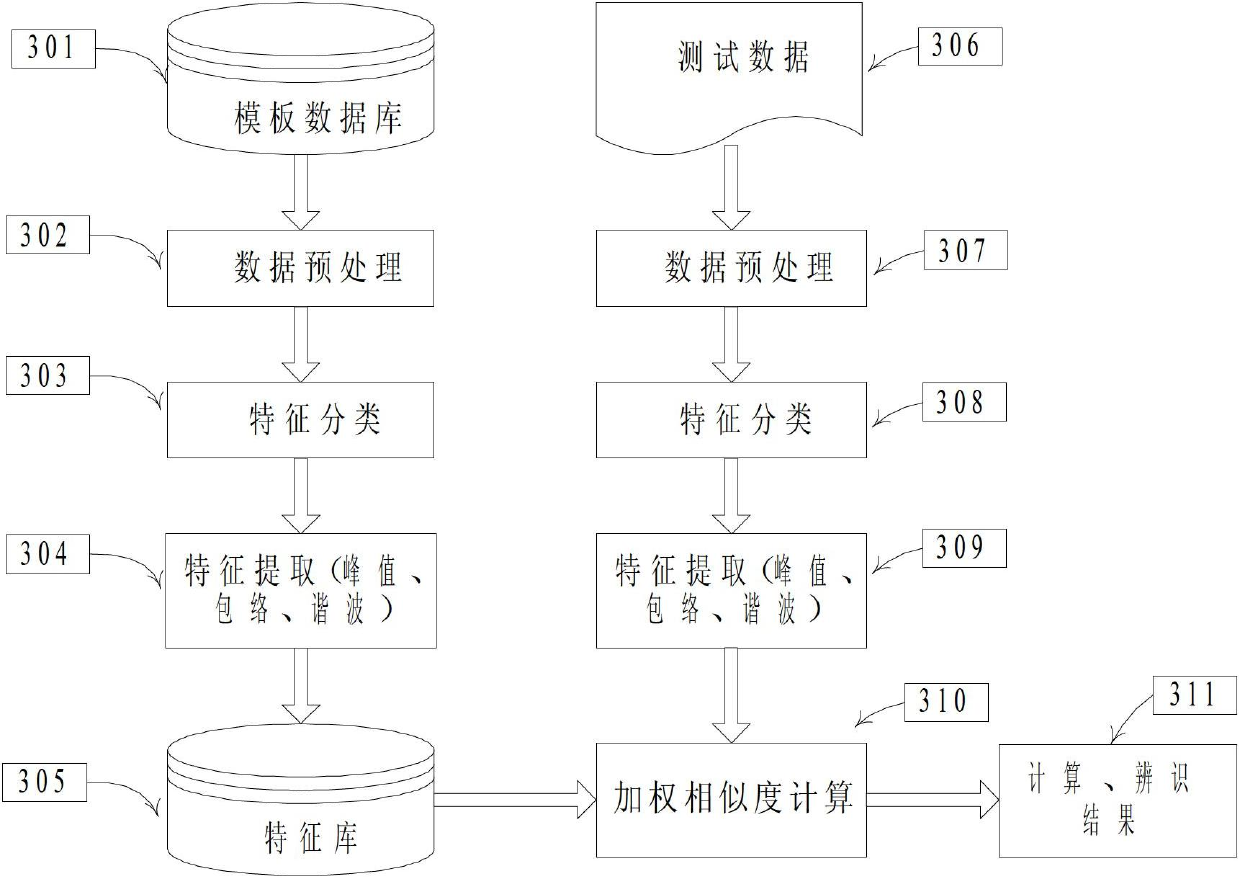

Interference source identification method in system-grade electromagnetic compatibility fault diagnosis

InactiveCN102680825ARealize automatic identificationCurrent/voltage measurementElectrical testingDiagnosis methodsDiagnostic system

The invention belongs to an electromagnetic compatibility fault diagnosis method and particularly relates to an interference source identification method in a system-grade electromagnetic compatibility fault diagnosis. The interference source identification method is characterized by comprising the following steps of: step 101, utilizing positioning sensitive equipment; step 102, carrying out fault tree analysis on the positioning sensitive equipment; step 103, performing the fault tree analysis so as to obtain a priority level of a coupling path; step 104, testing to obtain interference testing data; step 105, storing the testing data into a database; step 106, obtaining a potential interference source through the fault tree analysis of the step 102; step 107, searching and determining the priority level of the interference source; step 108, combining the step 105 and the step 107 to identify the interference source; step 109, judging whether the interference source is a determined interference signal or not; if not, carrying out step 110; otherwise, carrying out step 111; step 110, carrying out environment monitoring; and step 111, obtaining the determined interference signal and finally, finishing the compatibility fault diagnosis. The interference source identification method in an electromagnetic compatibility fault diagnosis system has the advantages of convenience for use, short period, low cost and controllable faults.

Owner:XIDIAN UNIV

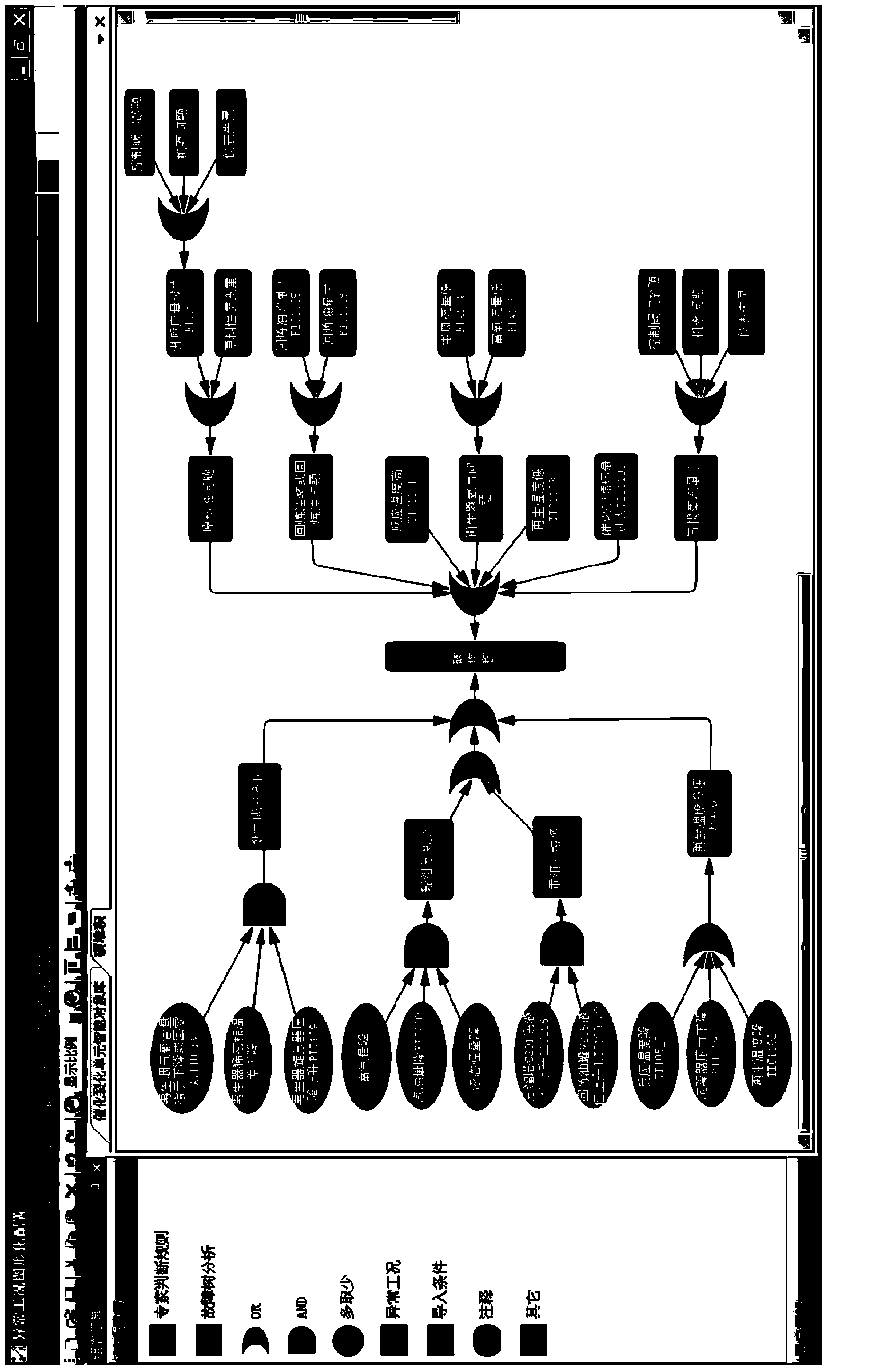

Modeling and graphical displaying method for causal relationship reasoning model of unusual working conditions of chemical process

ActiveCN104298225AEasy to collectPromote accumulationElectric testing/monitoringMachine learningChemical process

The invention relates to a modeling and graphical displaying method for a causal relationship reasoning model of unusual working conditions of a chemical process. The method mainly solves the problems that in the prior art, the root causes of the unusual working conditions are not judged accurately and a graphical displaying effect is poor. According to the modeling and graphical displaying method for the causal relationship reasoning model of the unusual working conditions of the chemical process, real-time data of a control system are collected, an expert rule model which is closely related to the judging process of the unusual working conditions is established, a fault tree logical reasoning model for root cause analysis of the unusual working conditions is established according to a root cause analysis mode of the unusual working conditions, an intelligent computing method is adopted, through the fact that threshold value judgment and feature extraction are carried out on key safety technical parameters, feature matching is carried out on the established expert rule model and the established fault tree analysis model, intelligent monitoring and early warning on the unusual working conditions of a production process and root cause analysis are achieved, the problems are solved better through the technical solutions, and the method can be applied to treatment of the unusual working conditions of the chemical process.

Owner:CHINA PETROLEUM & CHEM CORP +1

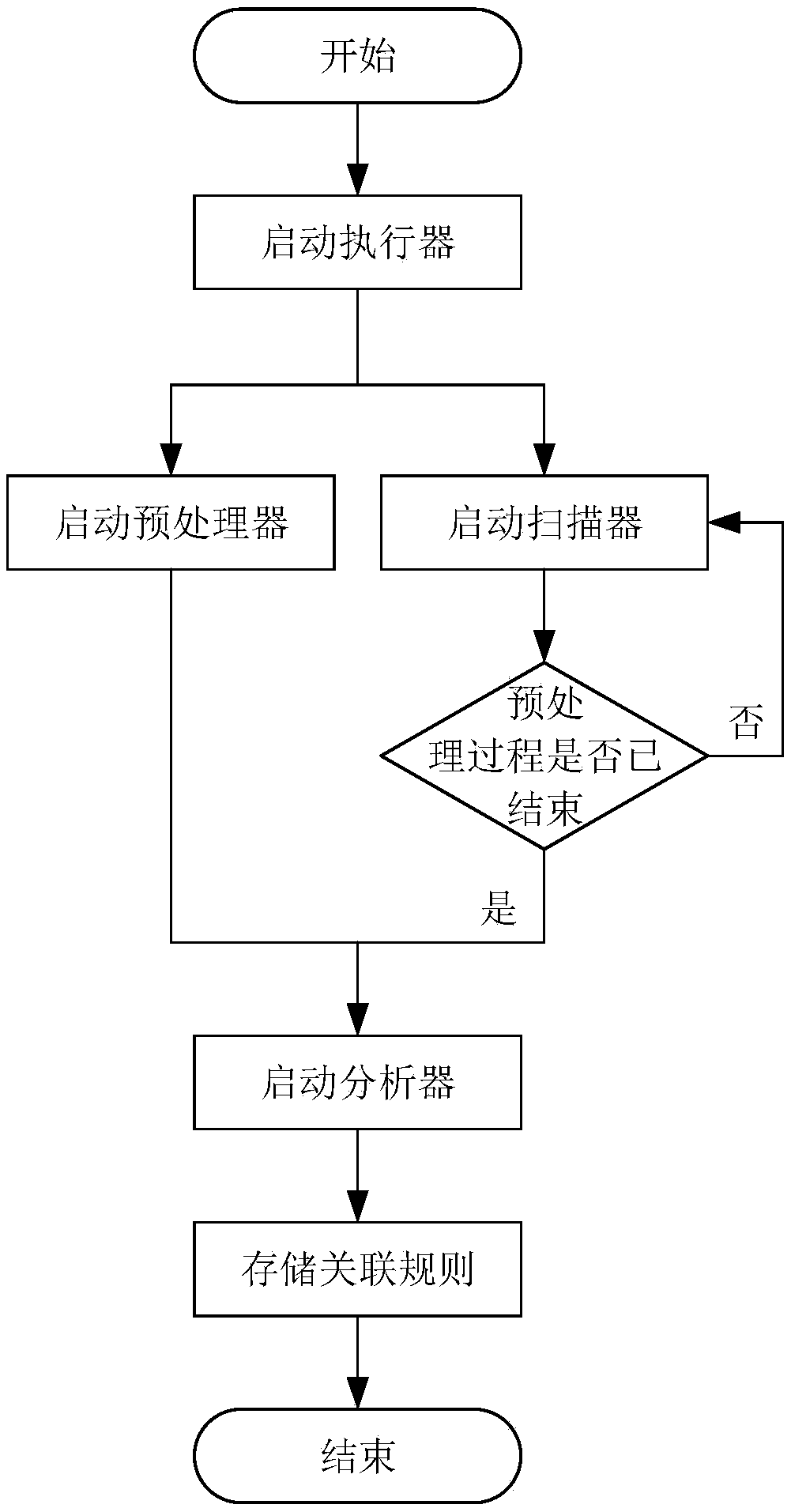

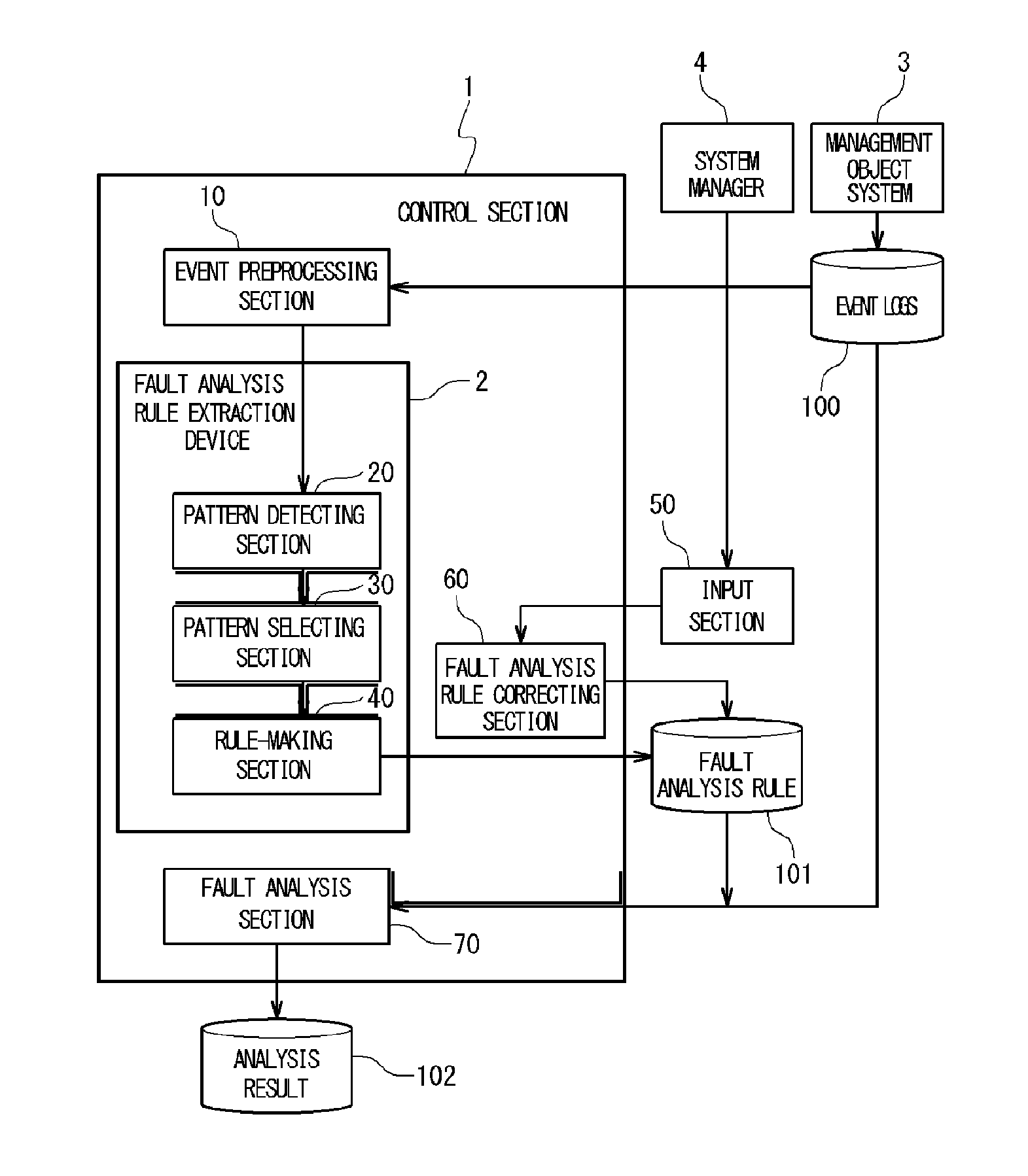

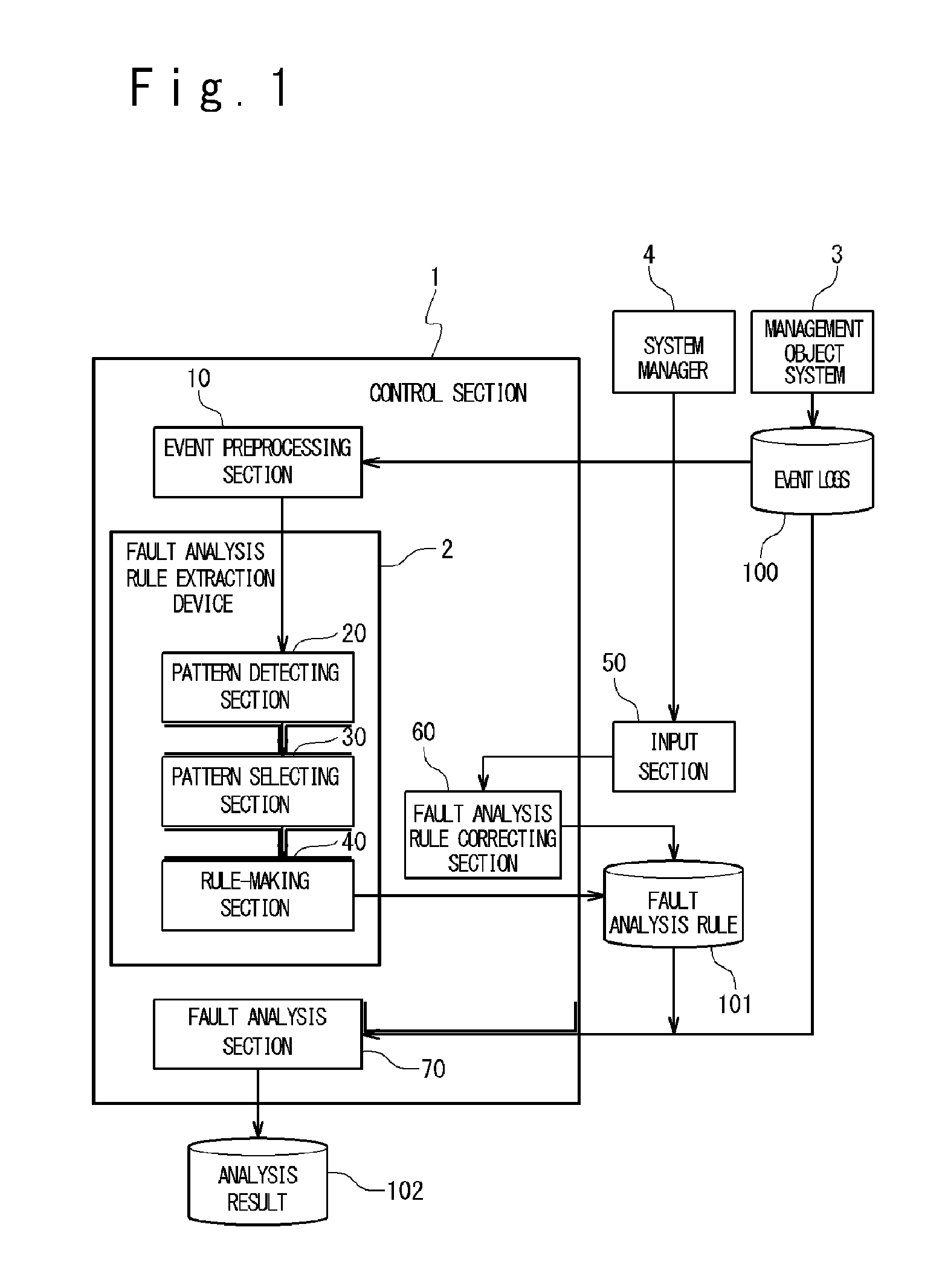

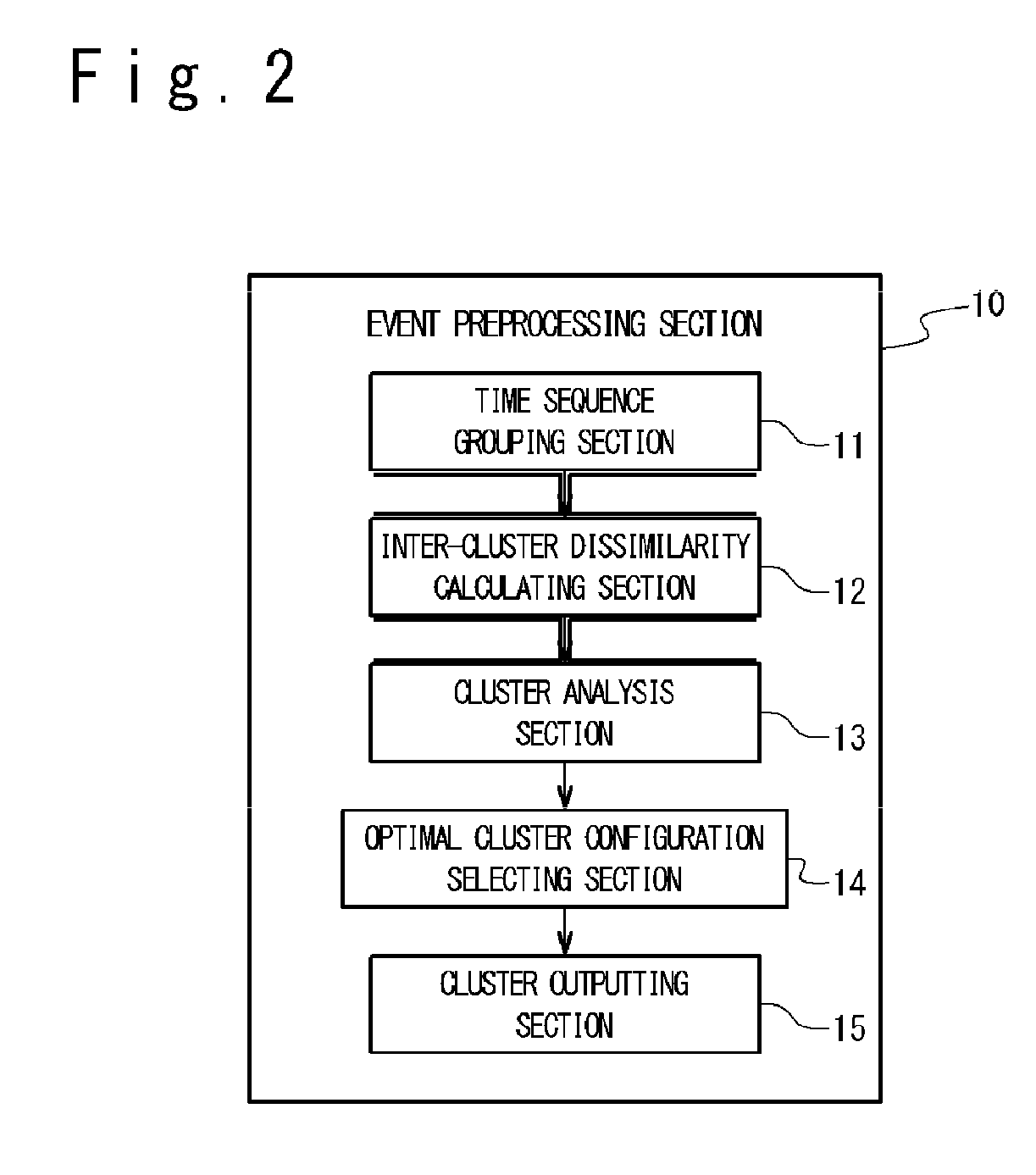

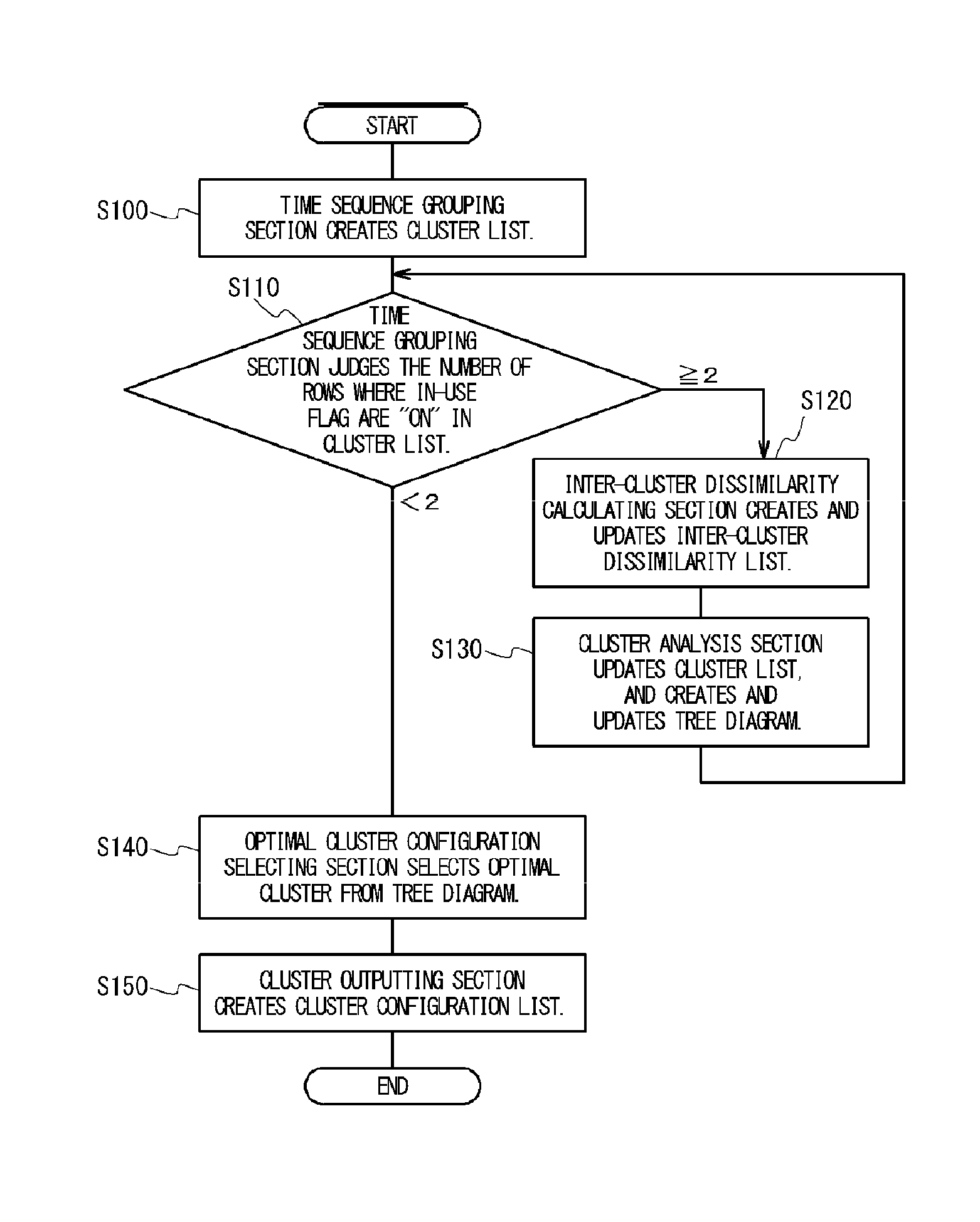

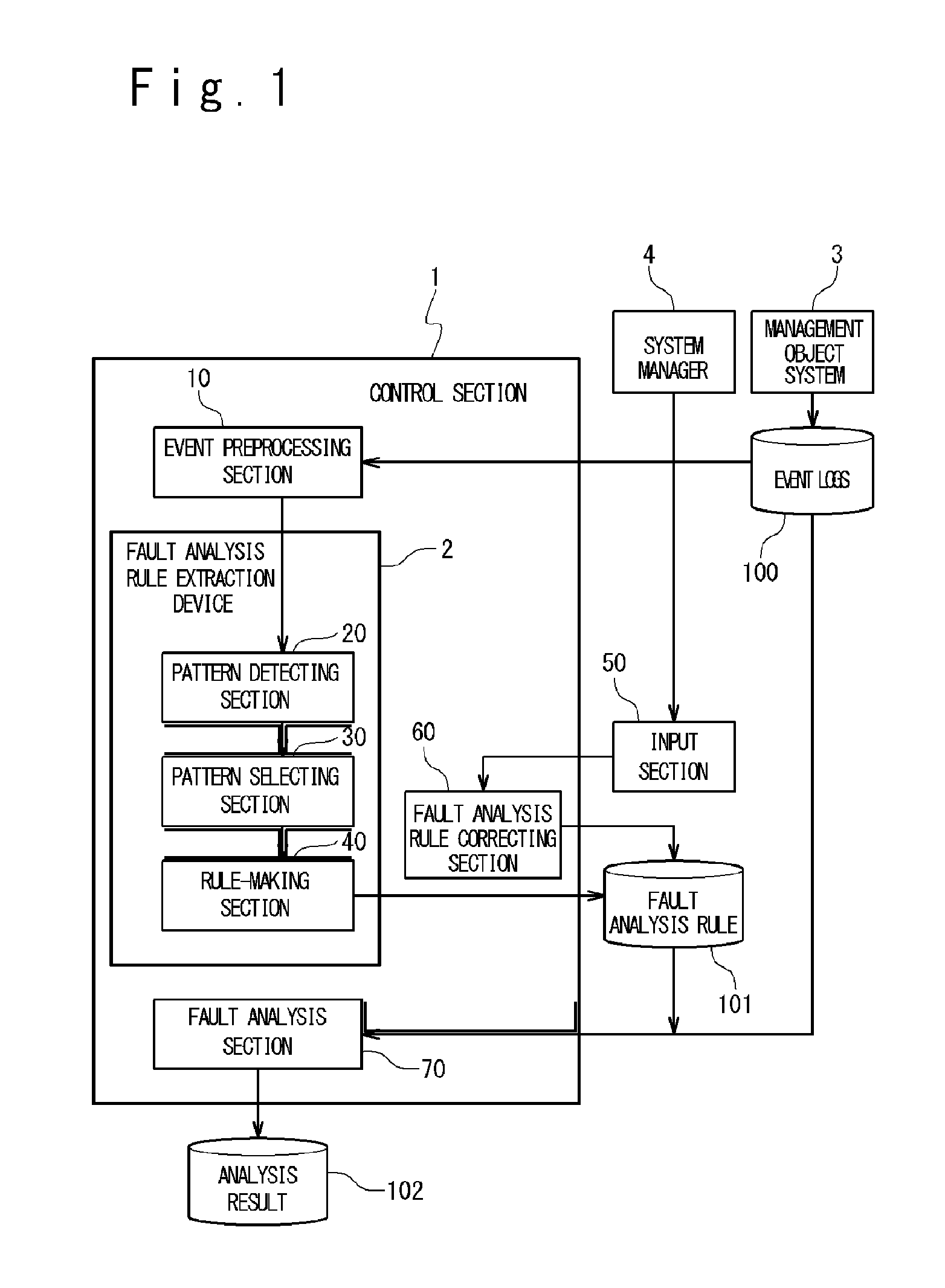

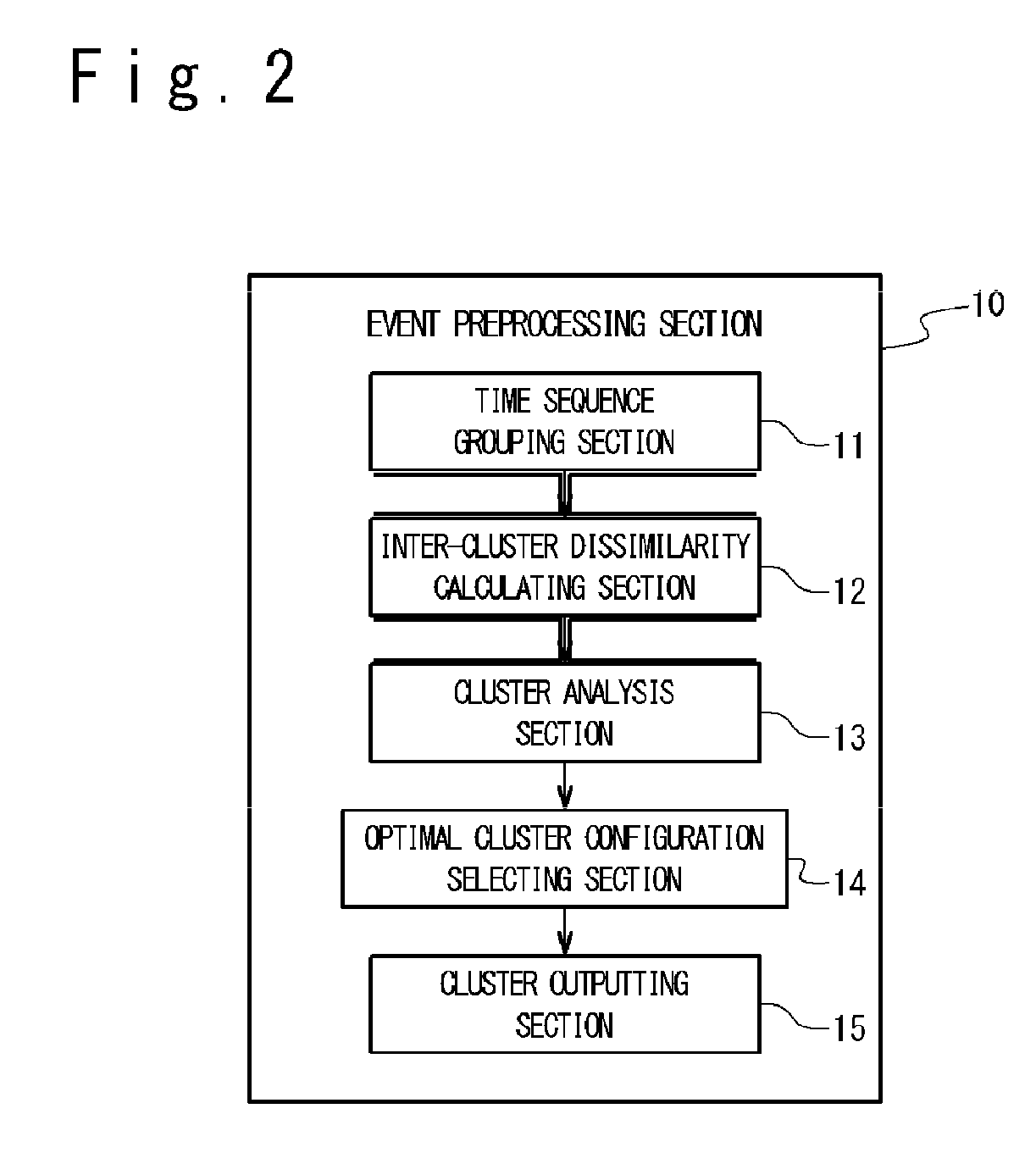

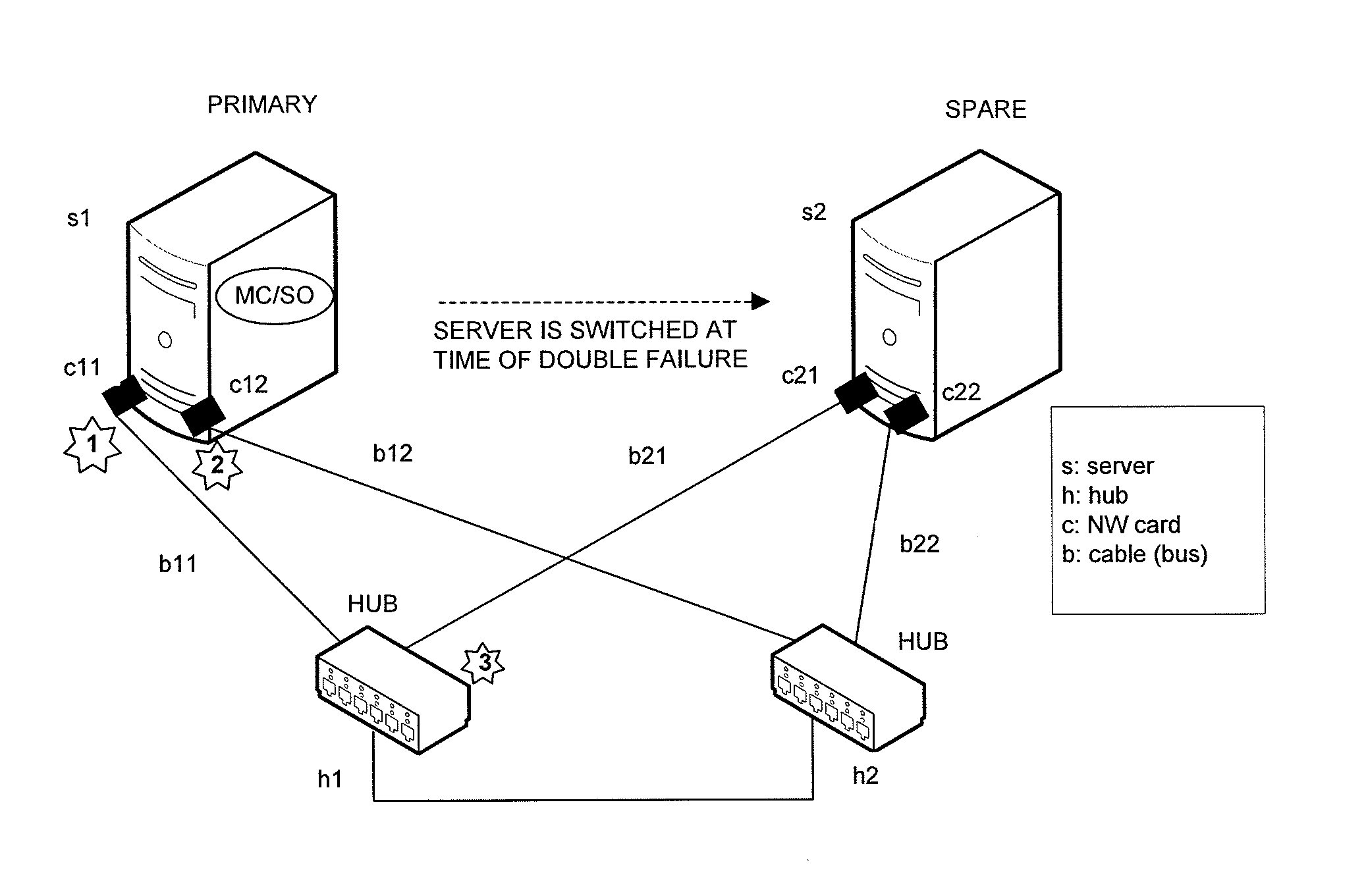

Fault analysis rule extraction device, fault analysis rule extraction method and storage medium

InactiveUS20130042147A1Improve accuracyLess omissionRedundant data error correctionFault analysisData mining

The disclosed fault analysis rule extraction device includes: an event preprocessing section and a fault analysis rule extraction section. The event preprocessing section merges, with respect to event groups each of which is grouped every certain time period, event groups that can be presumed to occur from the same fault by a cluster analysis. The fault analysis rule extraction section extracts a fault analysis rule useful for a fault analysis by relating event logs to clusters. By the fault analysis rule extraction device of the above configuration, highly accurate fault analysis rule are automatically provided from the event logs of a system.

Owner:NEC CORP

Collaborative troubleshooting computer systems using fault tree analysis

Embodiments of the invention provide techniques for troubleshooting of computer systems using a fault tree analysis. In one embodiment, data parameters describing a status of a system may be monitored to determine the existence of a fault. In the event of a fault, fault tree analysis metadata may be evaluated to attempt to determine a root cause of the fault. If a root cause can be automatically determined, it may be presented to a user in a troubleshooting console, or may be used to trigger an automated corrective action. Alternatively, if a root cause cannot be automatically determined, the user may be presented with additional fault tree analysis metadata and any relevant data parameters in the troubleshooting console, so that the user may determine the root cause of the fault event.

Owner:GLOBALFOUNDRIES U S INC

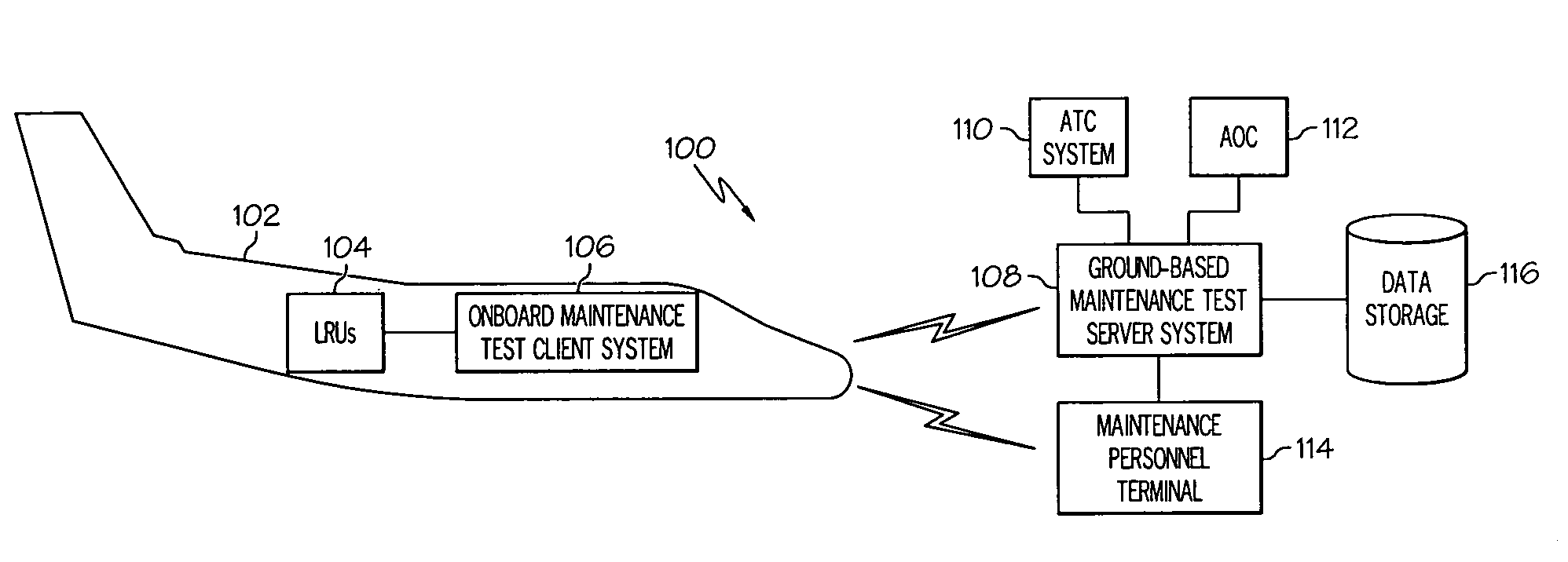

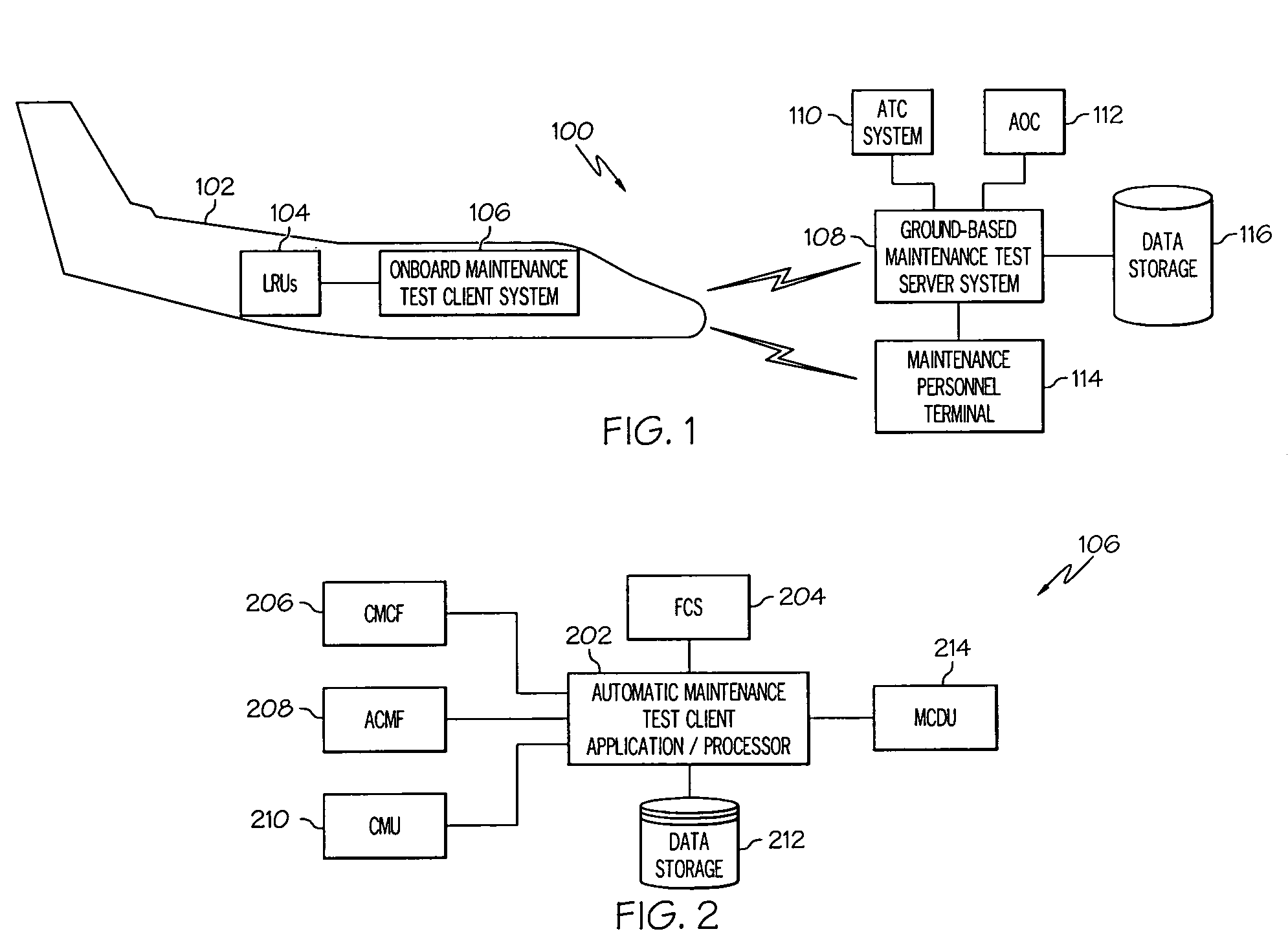

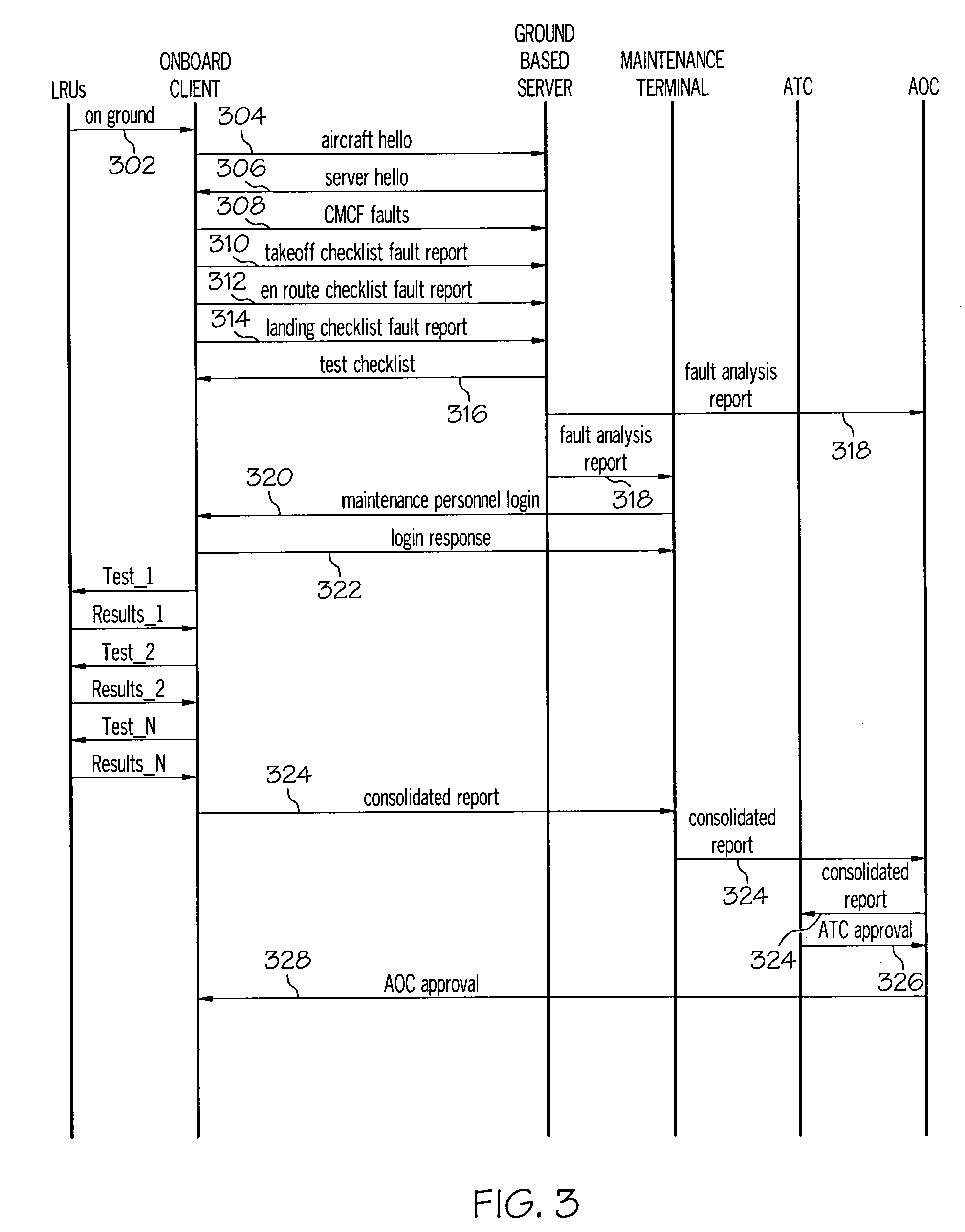

System and method of automated fault analysis and diagnostic testing of an aircraft

Owner:HONEYWELL INT INC

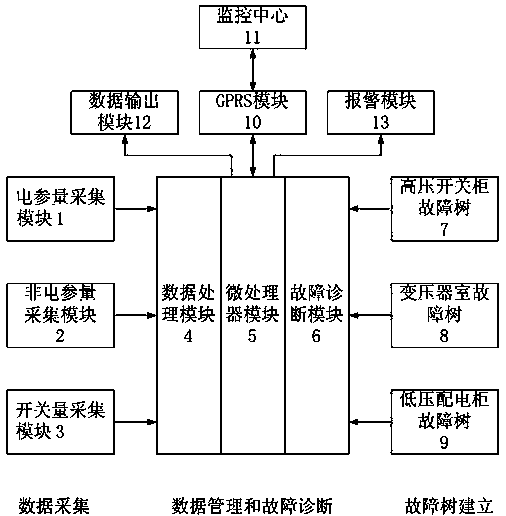

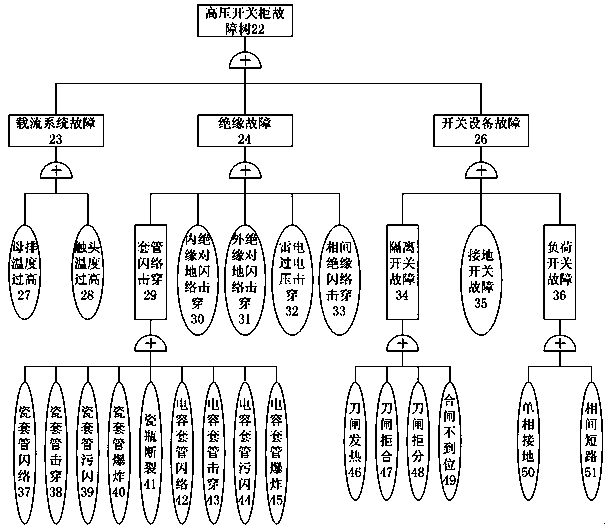

Box-type substation intelligent online failure diagnosis system

InactiveCN103412217AAccurate collectionTimely and accurate exclusionTransmission systemsElectrical testingLow voltageTransformer

A box-type substation intelligent online failure diagnosis system comprises an electric parameter collection module, a non-electric-parameter collection module, a switch value collection module, a data processing module, a micro-processor module, a failure diagnosis module, a high-voltage switch cabinet failure tree, a transformer room failure tree, a low-voltage switch box failure tree, a GPRS module, a monitoring center, a data output module and a warning module. The substation intelligent online failure diagnosis system has the advantages that operation state data of a box-type substation in real time can be collected and warnings are given out if abnormal-condition data occur so that workers can predict probable failures; failure symptom data can be timely and precisely collected so that online failure diagnosis can be carried out, the failures can be timely eliminated, and failure diagnosis efficiency is improved; a failure diagnosis method based on a failure tree analysis method is adopted, searching efficiency of failure diagnosis knowledge is improved, meanwhile readability of the failure diagnosis knowledge is also improved, and maintenance of failure diagnosis procedures is facilitated.

Owner:CHINA SCI TIANGONG ELECTRICAL HLDG

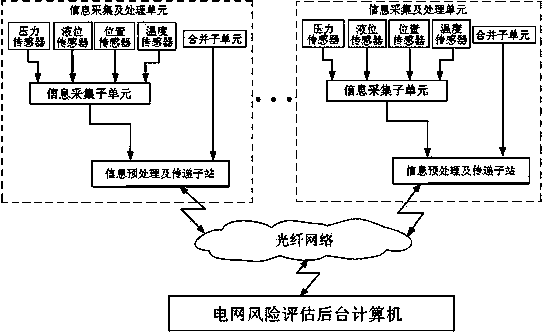

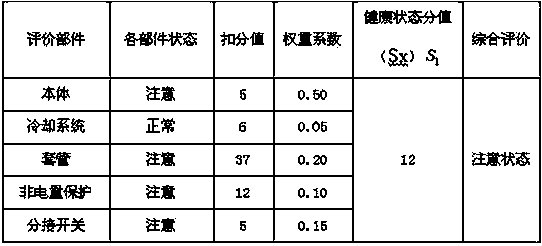

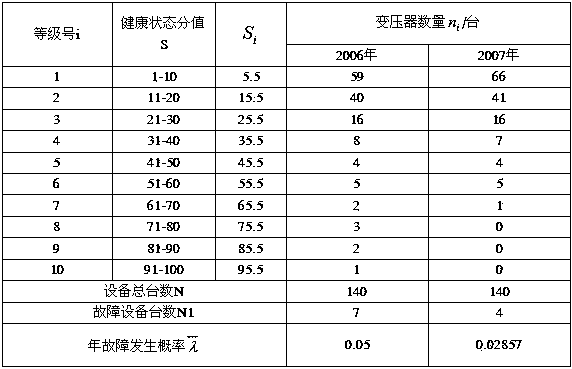

Distributed power grid risk assessment system and distributed power grid risk assessment method based on fault feature of electric circuit

ActiveCN103439593AIdentify operational vulnerabilitiesSafe and stable operationElectrical testingElectrical devicesEngineering

The invention discloses a distributed power grid risk assessment system and a distributed power grid risk assessment method based on a fault feature of an electric circuit. The distributed power grid risk assessment system comprises at least three information collecting and processing units and a power grid risk assessment backstage computer. The information collecting and processing units comprise pressure sensors, position sensors, liquid level sensors, temperature sensors, information collecting sub-units, merging sub-units and information pre-processing and transmitting sub-stations. The output ends of the all the sensors are connected with the corresponding input ends of the information collecting sub-units through optical cables respectively. The output ends of the information collecting sub-units and the merging sub-units are connected with the input ends of the information pre-processing and transmitting sub-stations through optical cables respectively. The information pre-processing and transmitting sub-stations are connected with the power grid risk assessment backstage computer in a double-direction mode through an optical fiber network. The distributed power grid risk assessment system and the distributed power grid risk assessment method based on the fault feature of the electric circuit have the advantage of being capable of carrying out fault feature analysis on electric devices of the distributed power grid and ensuring safe and stable operation of power grid devices.

Owner:STATE GRID CORP OF CHINA +2

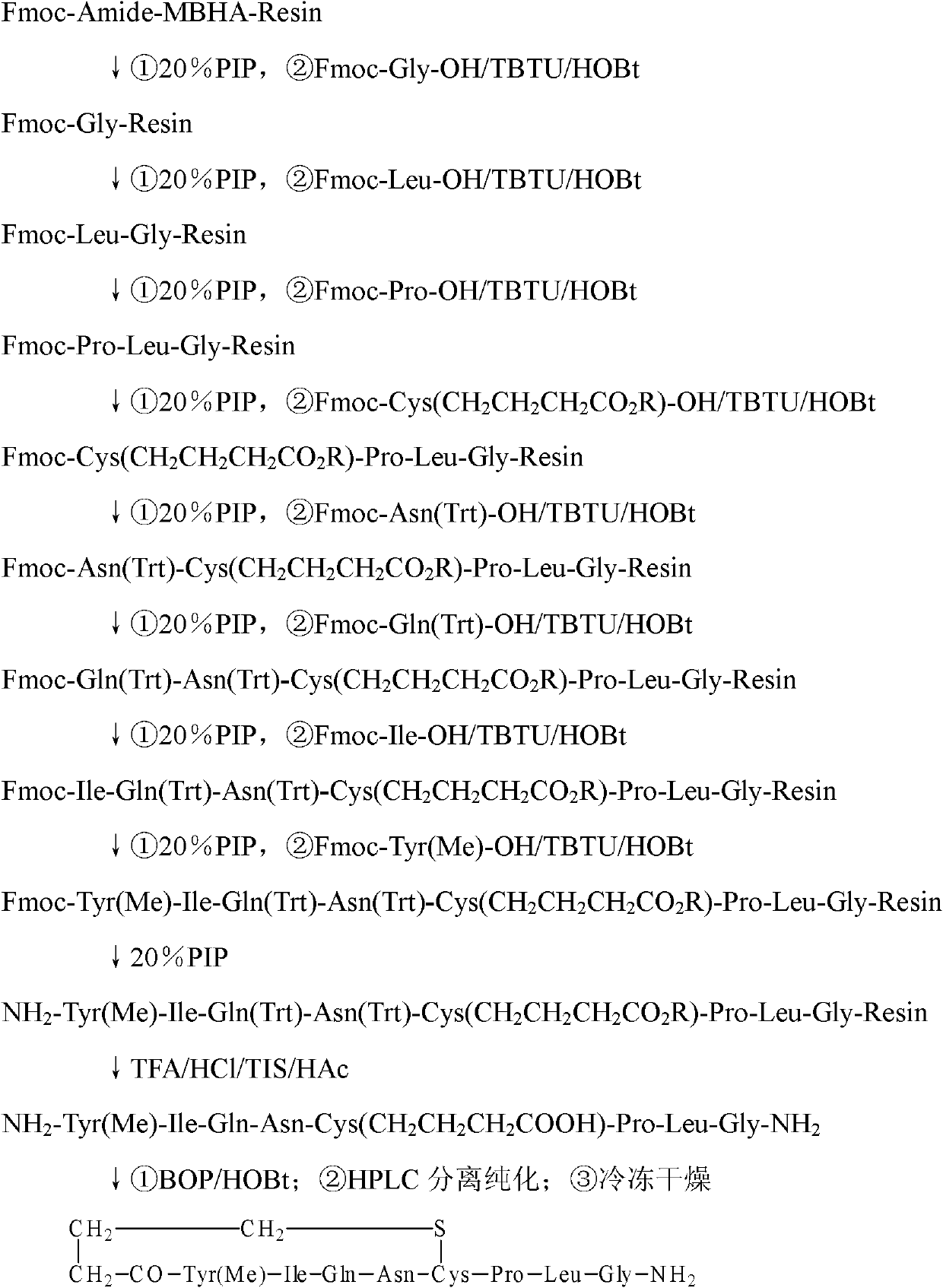

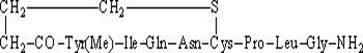

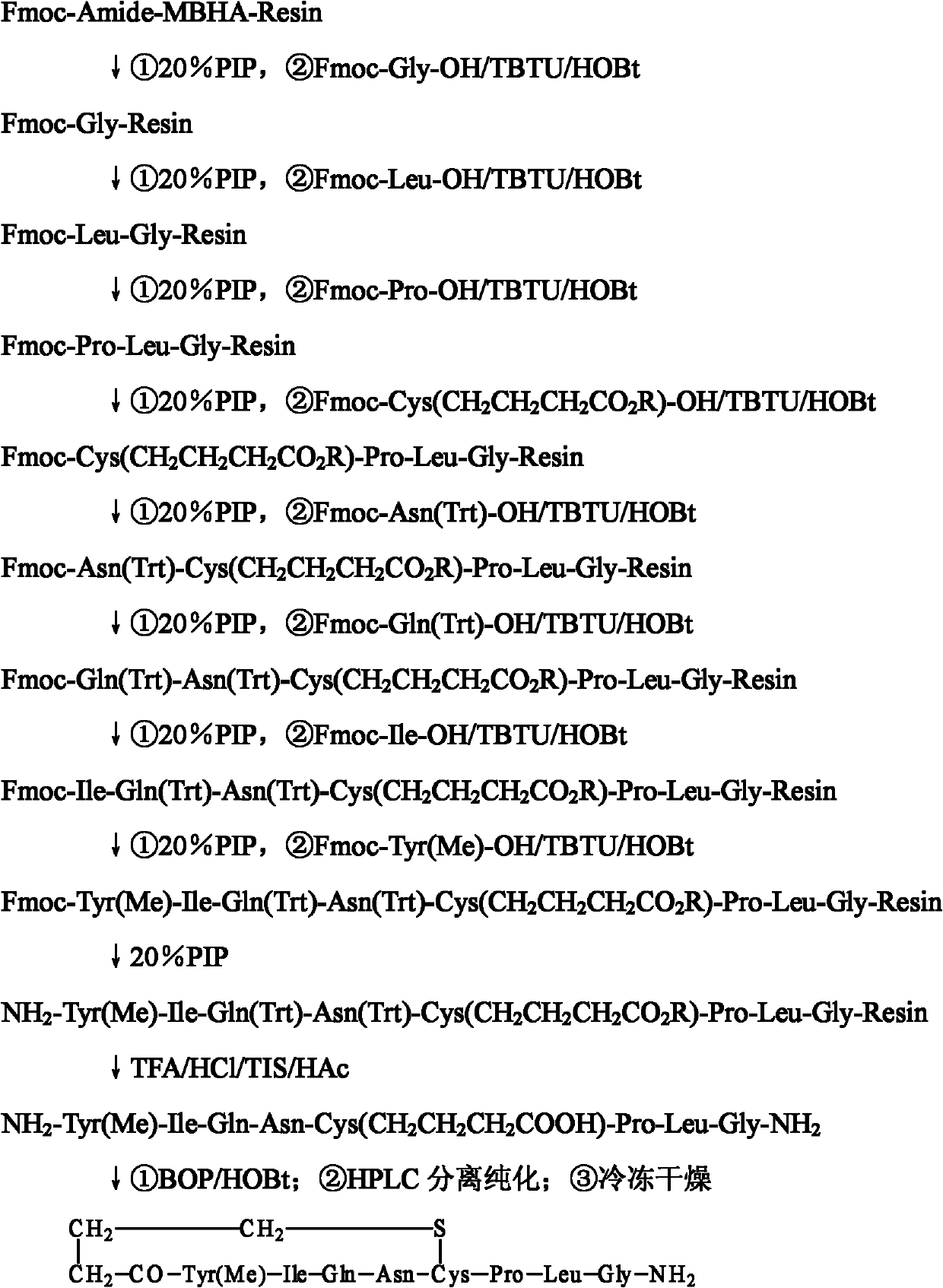

Preparation method of polypeptide synthesis carbetocin

ActiveCN102167723AConvenient sourceHigh peptide yieldPeptide preparation methodsCarbetocinDiethyl ether

The invention discloses a preparation method of polypeptide synthesis carbetocin. The technical scheme of the method comprises the steps of taking Rink Amide MBHA (methylbenzene hydrogen amine) resin as an initial raw material; taking Fmoc-protected amino acid as a monomer; sequentially connecting amino acid, wherein Cys adopts Fmoc-Cys (CH2CH2CH2COOR)-OH, and the last amino acid uses Fmoc-Tyr (Me)-OH, and obtaining protected nonapeptide resin; removing the Fmoc azyl protected group of Tyr; cutting straight chain peptide from the resin by peptide cutting reagents such as FTA (fault tree analysis) and the like; precipitating a straight chain peptide rough product by adding diethyl ether; performing ring formation reaction by adding BOP (butyl octyl phthalate) / HOBt (oxhydryl benzotriazole) / DMF (dimethyl formamide); and purifying the preparation type HPLC (high performance liquid chromatography) in a separating way to obtain a target product. After the method is used, the each-step peptide connecting yield is more than 99%, the peptide cutting yield is 96.2%, and the gross yield is as high as more than 35%. The preparation method is convenient to industrial implementation, and has a higher industrial prospect.

Owner:SHANGHAI SOHO YIMING PHARMA

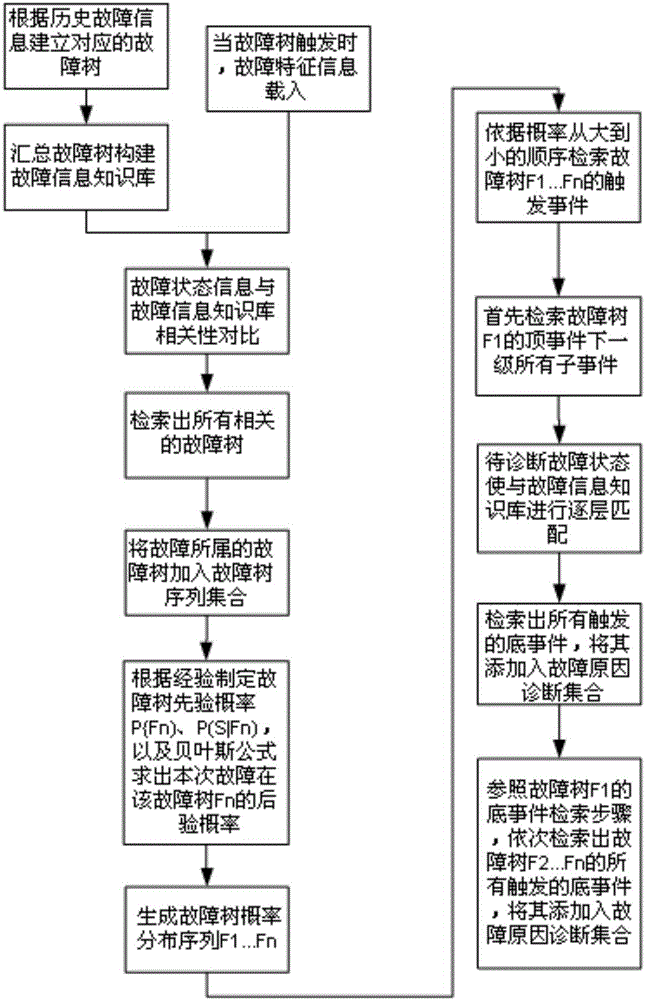

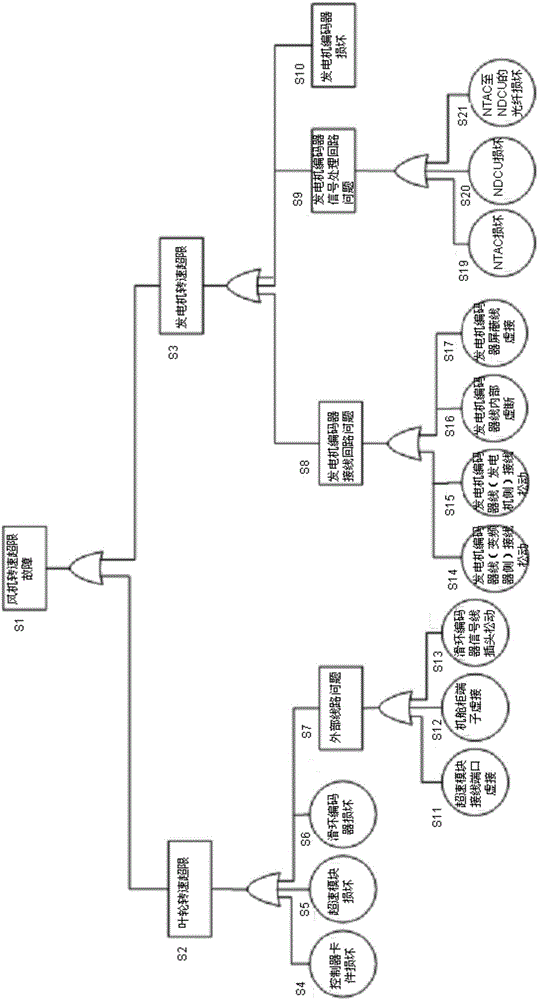

Method and system for diagnosing transmission chain fault of wind generating set

ActiveCN106050580AIntelligent diagnosis of fault causesFault cause diagnosis Intelligent diagnosisEngine fuctionsMachines/enginesElectricityEconomic benefits

The invention discloses a method for diagnosing the transmission chain fault of a wind generating set. The method comprises the steps that a wind generating set transmission chain fault information knowledge base of a fault tree structure is established; the knowledge base is searched according to fault feature information detected in real time, and a corresponding fault tree is located; reasoning is carried out according to preset data in the knowledge base and the bayesian network, the posterior probability P(Fn|S) of the fault trees Fn is obtained, and the probability distribution sequence of the fault trees is obtained; and retrieval is sequentially carried out according to the probability distribution sequence of the fault trees, all triggered bottom events under all the fault trees are obtained through judgment, and a fault reason diagnosis set is formed. The invention further provides a transmission chain fault diagnosing method applying the method for diagnosing the fault. The bayesian network technology is introduced on the basis of a fault tree analysis method, a powerful basis is provided for fast and effective diagnosis of the fan transmission chain fault reason, the shutdown time of the wind generating set is shortened, the manual maintenance cost is reduced, and the power generating rate and economic benefits are increased.

Owner:GUODIAN UNITED POWER TECH

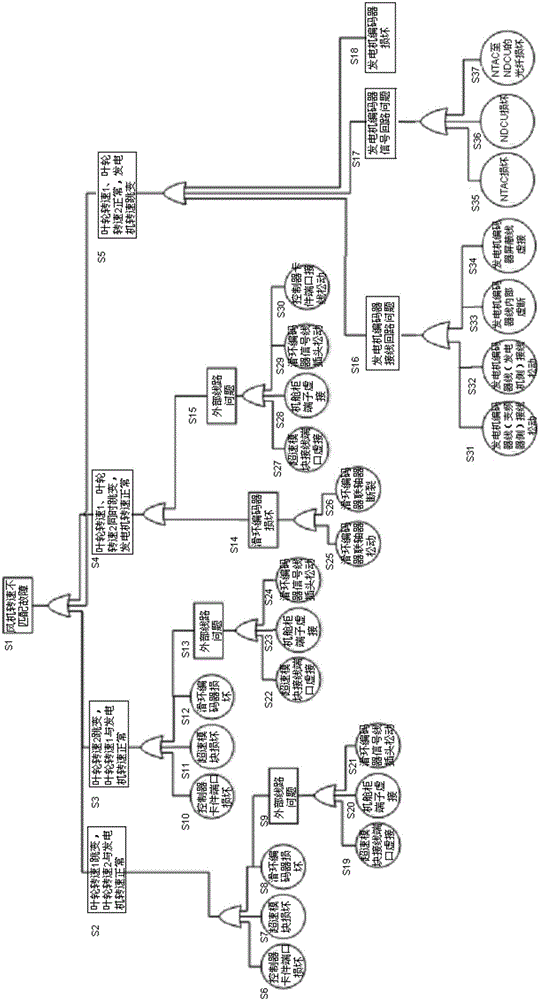

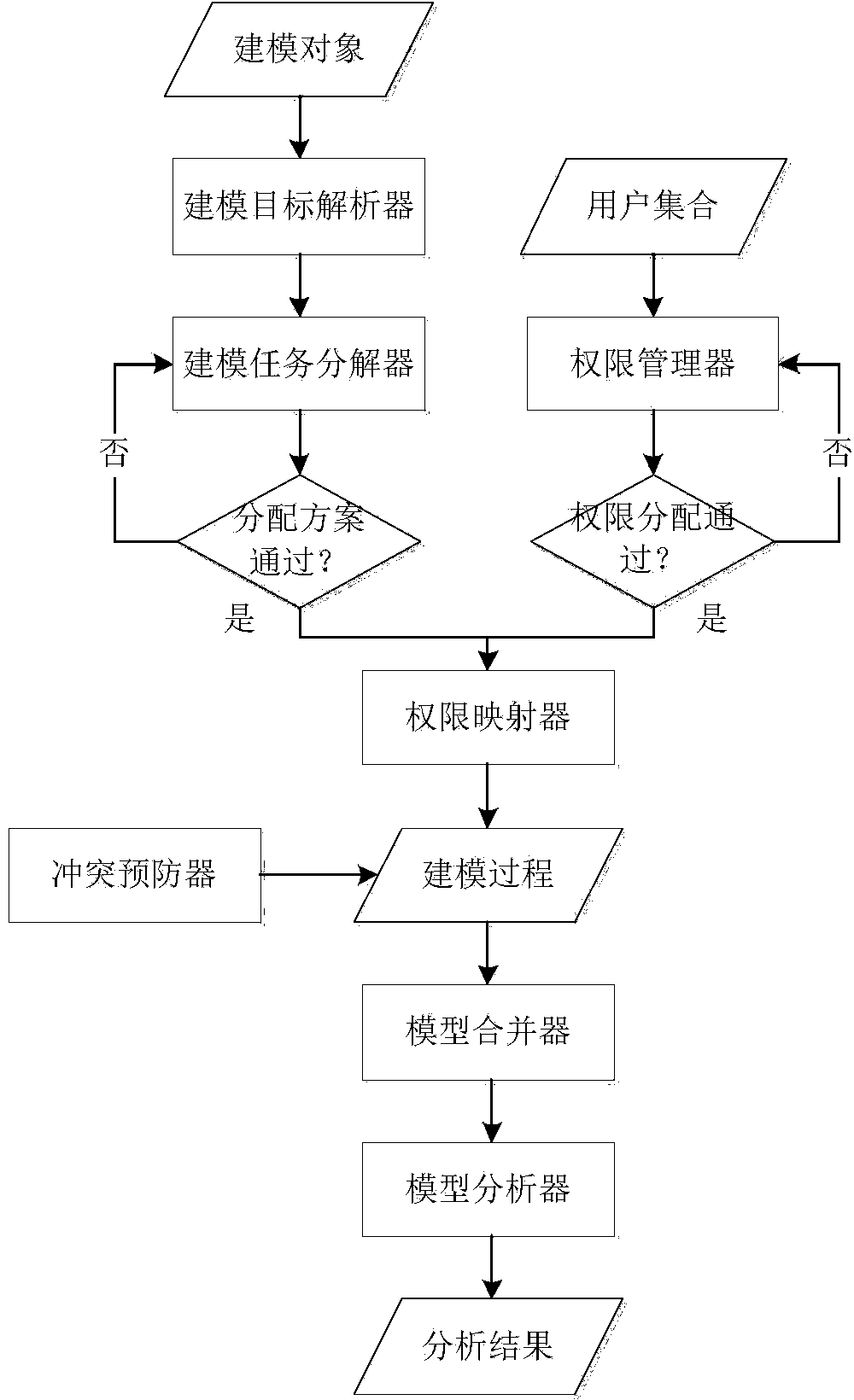

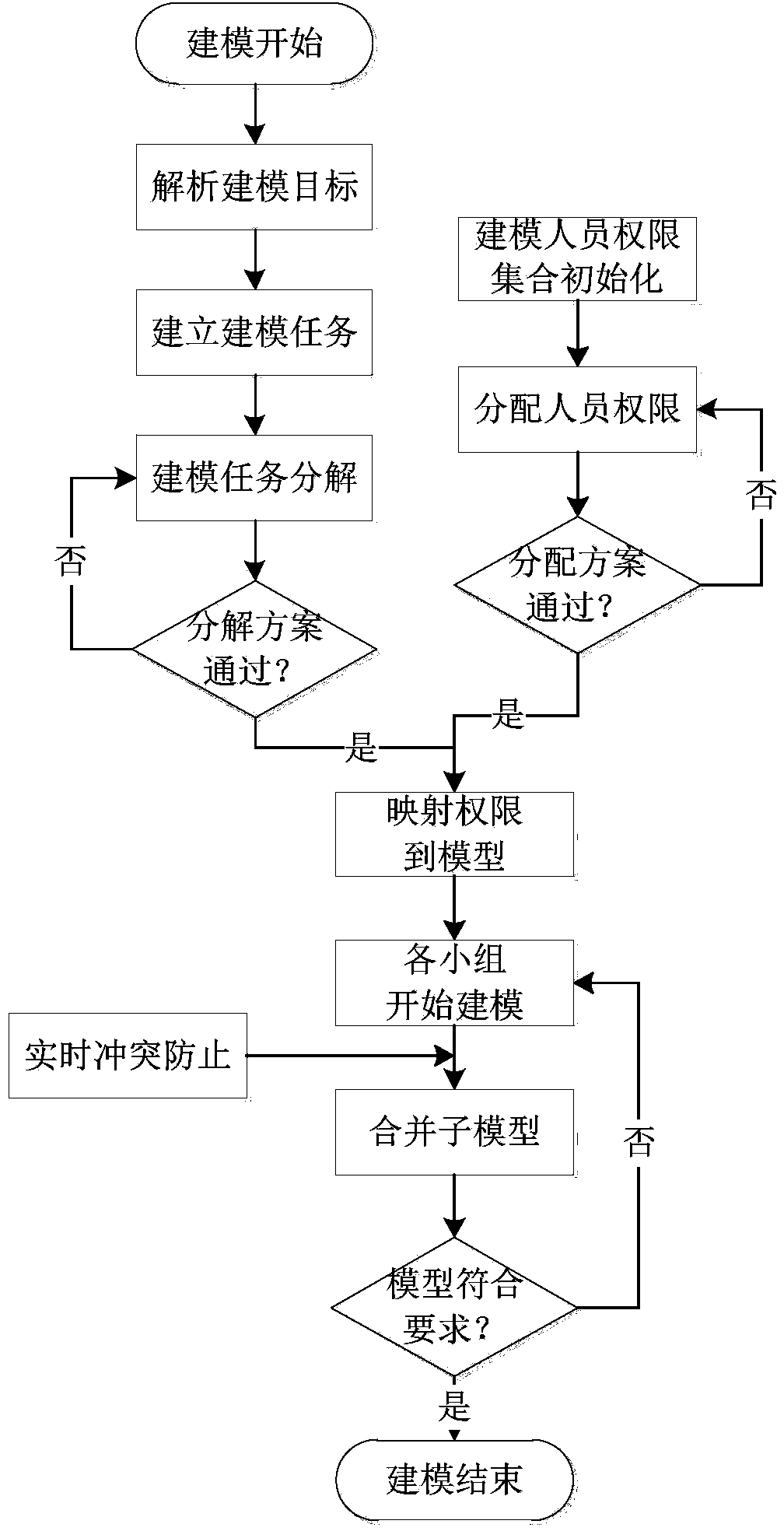

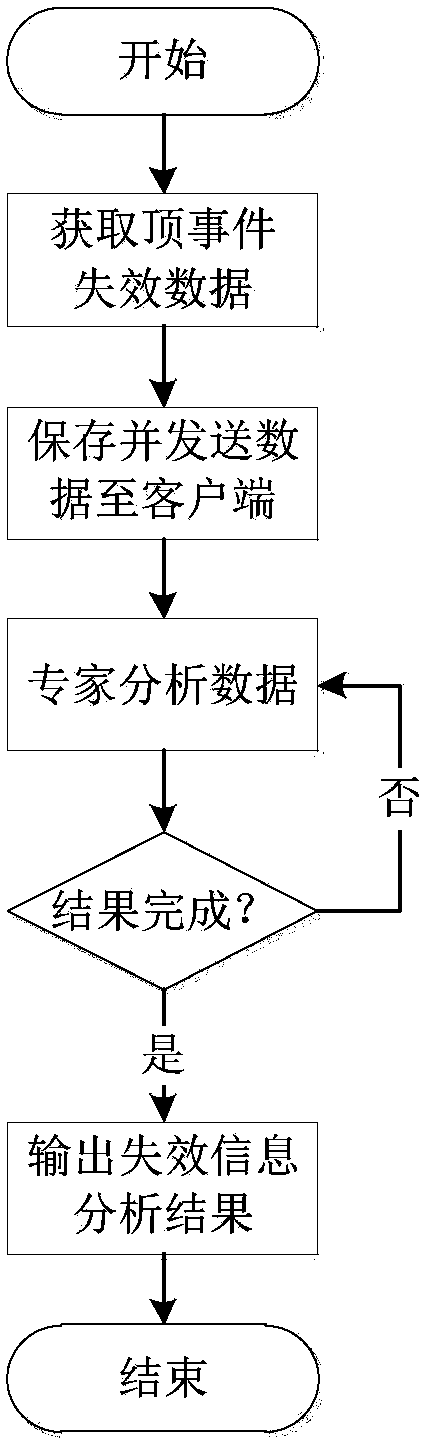

Fault tree collaborative analysis system based on authority management and model decomposition

InactiveCN104298825AIncrease workloadAvoid duplication of workSpecial data processing applicationsAviationNuclear power

The invention discloses a fault tree collaborative analysis system based on authority management and model decomposition. The system mainly comprises the following seven modules which include a modeling target resolver, a modeling task decomposer, an authority manager, an authority mapper, a conflict inhibitor, a model combiner and a model analyzer. According to the system, a collaborative technology is applied from modeling target analysis and task definition to specific modeling processes, and fault tree modeling analysis can be achieved by cooperation of multiple persons and multiple roles under the action of authority management and mapping mechanism; a collaboration platform is provided for fault tree modeling staff, and fault tree modeling tasks of large complicated systems in fields of navigation, aerospace, nuclear power energy and the like can be achieved; requirements in terms of model scale and multidisciplinary approach in fault tree modeling of current large complicated systems can be met, and the task of fault tree modeling analysis can be efficiently finished by cooperation of modeling staff with different knowledge backgrounds and professional skills.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Fault analysis rule extraction device, fault analysis rule extraction method and storage medium

InactiveUS9021304B2Less omissionHigh fault analysisFault responseHardware monitoringFault analysisData mining

The disclosed fault analysis rule extraction device includes: an event preprocessing section and a fault analysis rule extraction section. The event preprocessing section merges, with respect to event groups each of which is grouped every certain time period, event groups that can be presumed to occur from the same fault by a cluster analysis. The fault analysis rule extraction section extracts a fault analysis rule useful for a fault analysis by relating event logs to clusters. By the fault analysis rule extraction device of the above configuration, highly accurate fault analysis rule are automatically provided from the event logs of a system.

Owner:NEC CORP

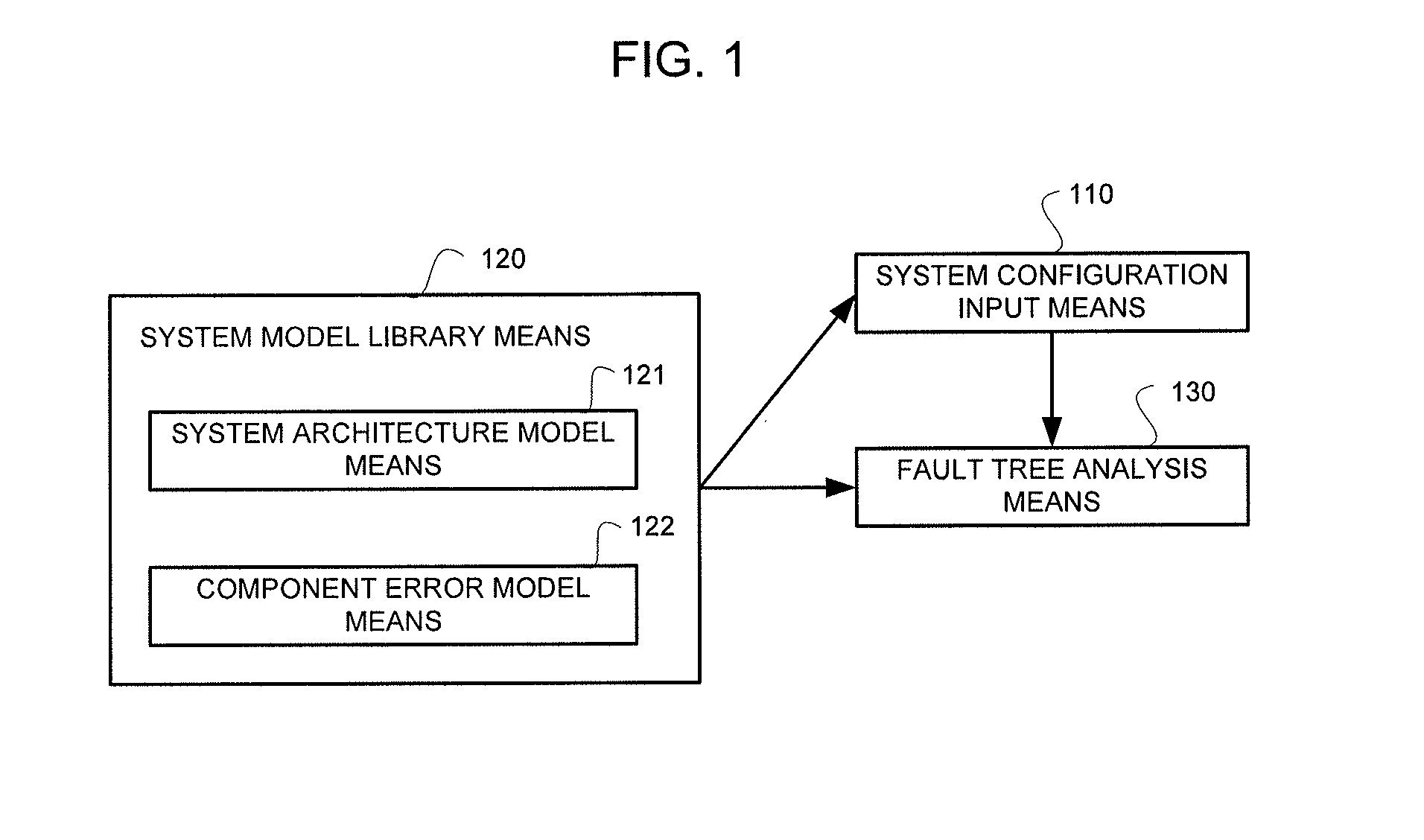

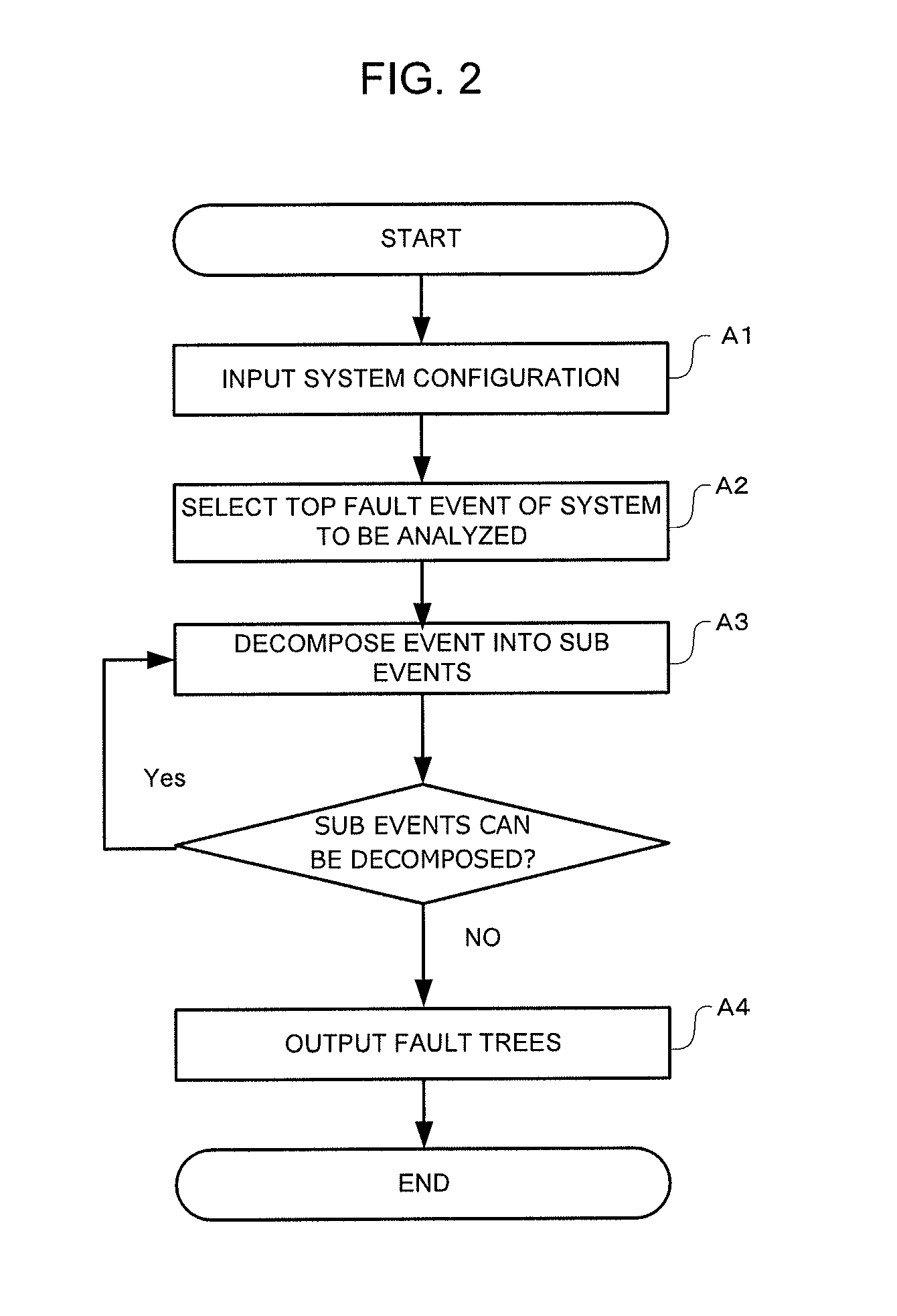

Static fault tree analysis system and method from system models

InactiveUS20130073271A1Error detection/correctionTesting/monitoring control systemsDecompositionComputer science

The present invention is a system for static fault tree analysis from system models comprising: system configuration input unit that inputs system configurations and top events of the systems to be analyzed; system model library that stores a set of system architecture models and component error models; and fault tree analyzer that analyzes fault trees of the system from the top events in terms of decomposition rules defined in the component error models. The system configurations and top events are instances of the system architecture models and the fault events of the component error models stored in the system model library, respectively. The system architecture models delimit classification of and definitions of physical and semantic relations between different components. The component error models define different fault events of components and their Boolean logic relationships called decomposition rules which cover both functional and sequential dependencies for fault tree analysis.

Owner:NEC CORP

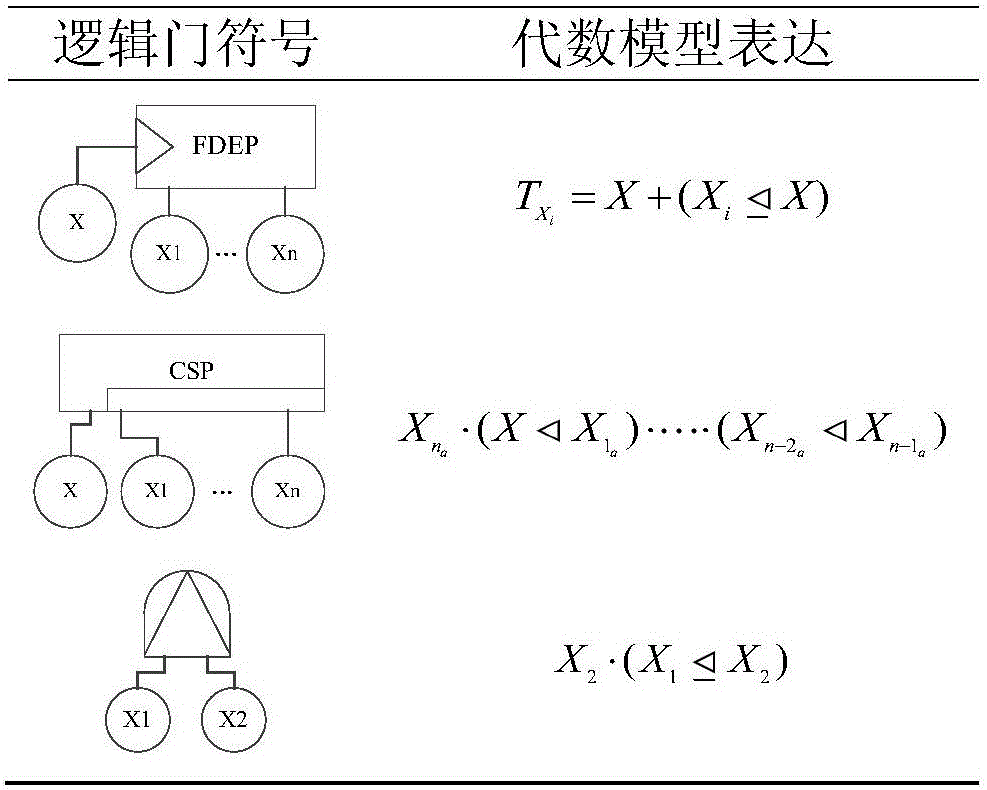

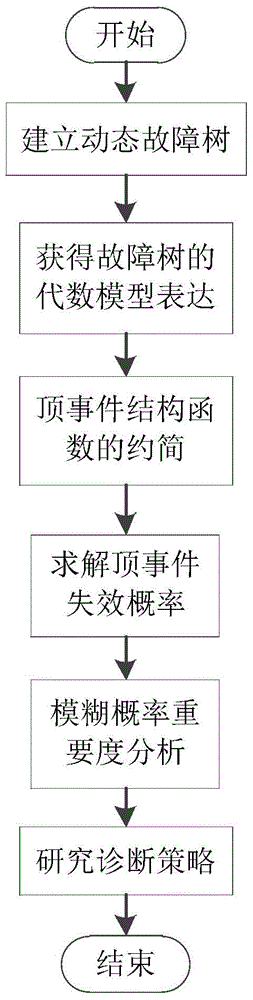

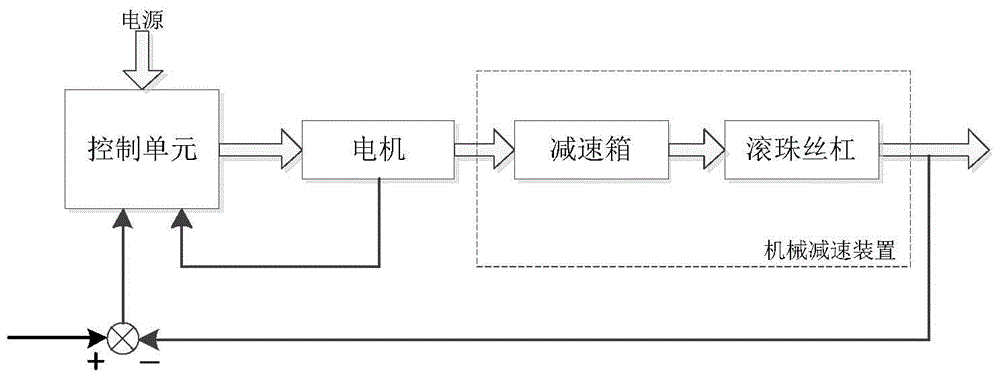

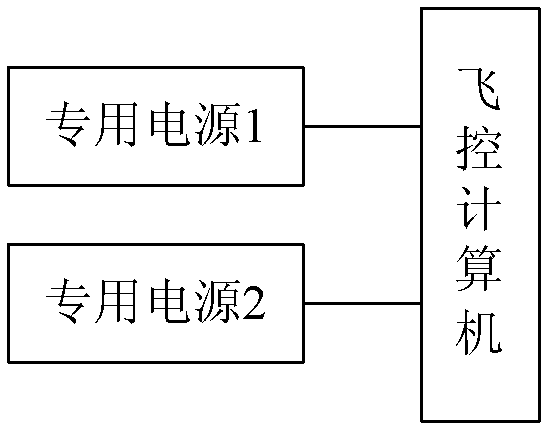

Reliability analysis method for electromechanical actuator based on fuzzy dynamic fault tree

InactiveCN105717912AConsistent failure mechanismIn line with engineering practiceProgramme controlElectric testing/monitoringFuzzy probabilityControl theory

The invention relates to a reliability analysis method for an electromechanical actuator based on a fuzzy dynamic fault tree. According to the method, top, intermediate and bottom events of the electromechanical actuator analyzed and determined to establish the dynamic fault tree, a dynamic logic gate is replaced with an algebraic operator, an algebraic model of the dynamic fault tree is converted into and solved, data of a triangular fuzzy set is used to represent the fuzzy reliability of the bottom event, the algebraic model is decomposed into a static subtree and a dynamic subtree for solution, the fuzzy probability of failure of an electromechanical actuator system is obtained via integration, and a weak link of the electromechanical actuator system is determined by analyzing the fuzzy importance degree. The method of the invention can be used to analyze the reliability of the electromechanical actuator effectively, solve the problem that traditional dynamic fault tree analysis is high in the computational complexity, and provides reference for fault positioning of the electromechanical actuator.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

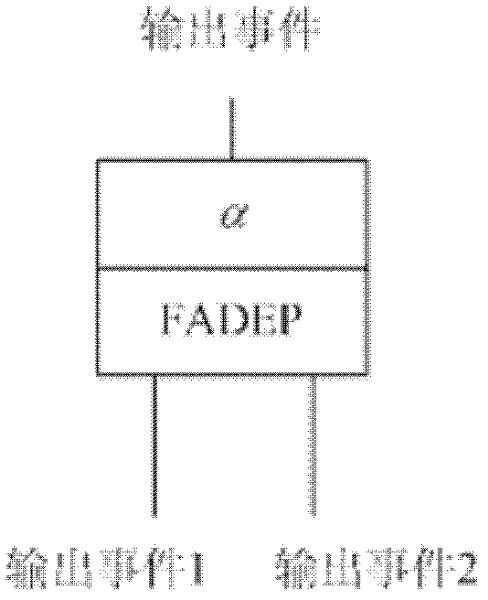

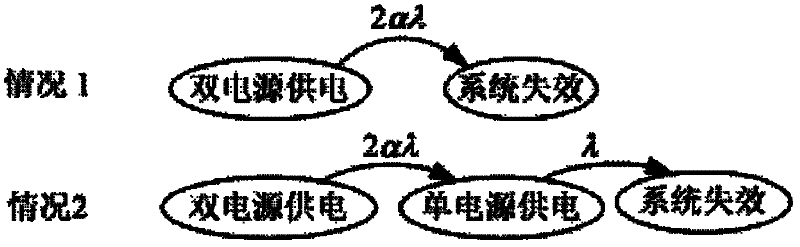

Dynamic fault tree analysis method for system with correlated failure mode

InactiveCN102542166AReduce repair and replacement costsGuaranteed reliabilitySpecial data processing applicationsMarkov chainAnalysis method

The invention relates to a dynamic fault tree analysis method for a system with a correlated failure mode, comprising the following steps of: 1, defining the correlated failure mode; 2, defining a correlated failure gate corresponding to the correlated failure mode; 3, solving the correlated failure gate through a Markov chain; 4, establishing a dynamic fault tree model of the system through the correlated failure gate; and 5, solving the dynamic fault tree model of the system to obtain the reliability of the system. The dynamic fault tree analysis method has the beneficial effects that the reliability of the correlated failure mode can be quantitatively calculated through analyzing and calculating the reliability of the correlated failure mode, so that the reliability of the system can be accurately obtained, and the maintenance and replacement costs of parts can be effectively reduced on the premise of ensuring the reliability of the system.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

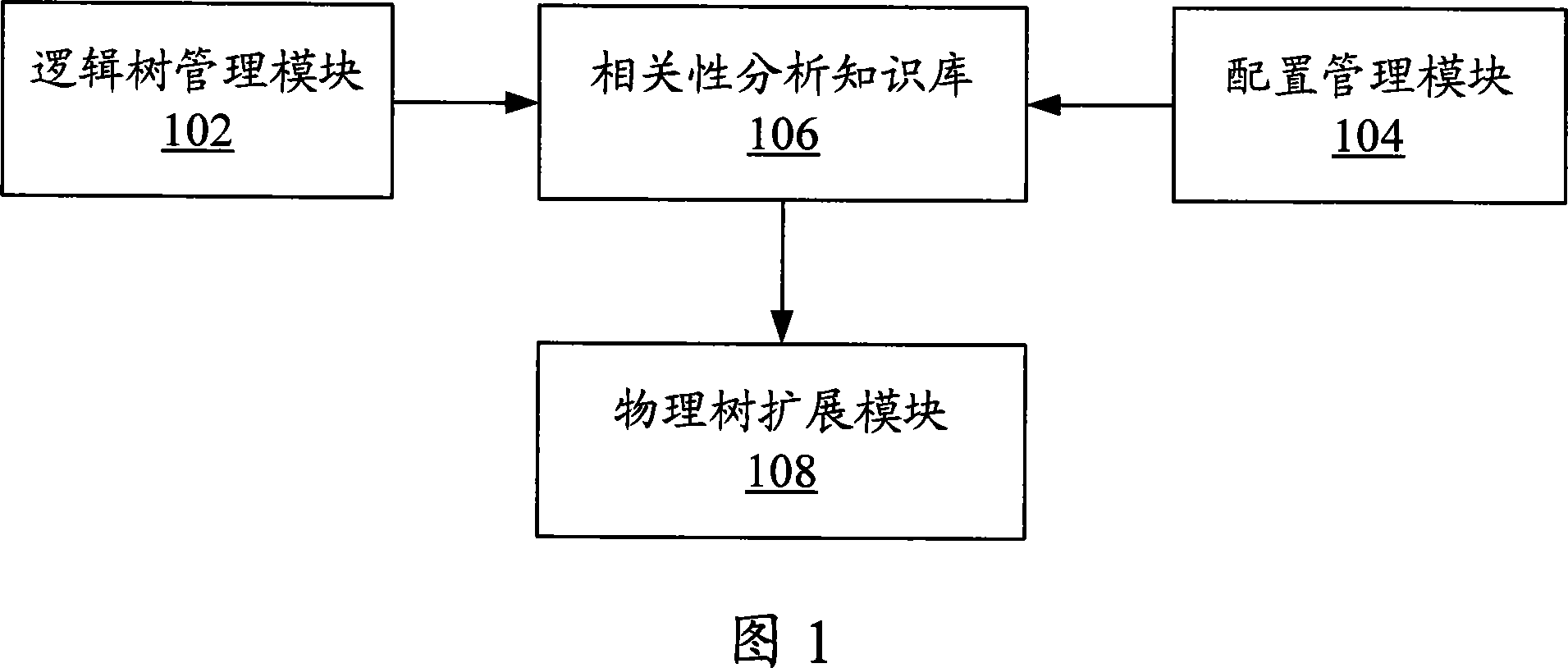

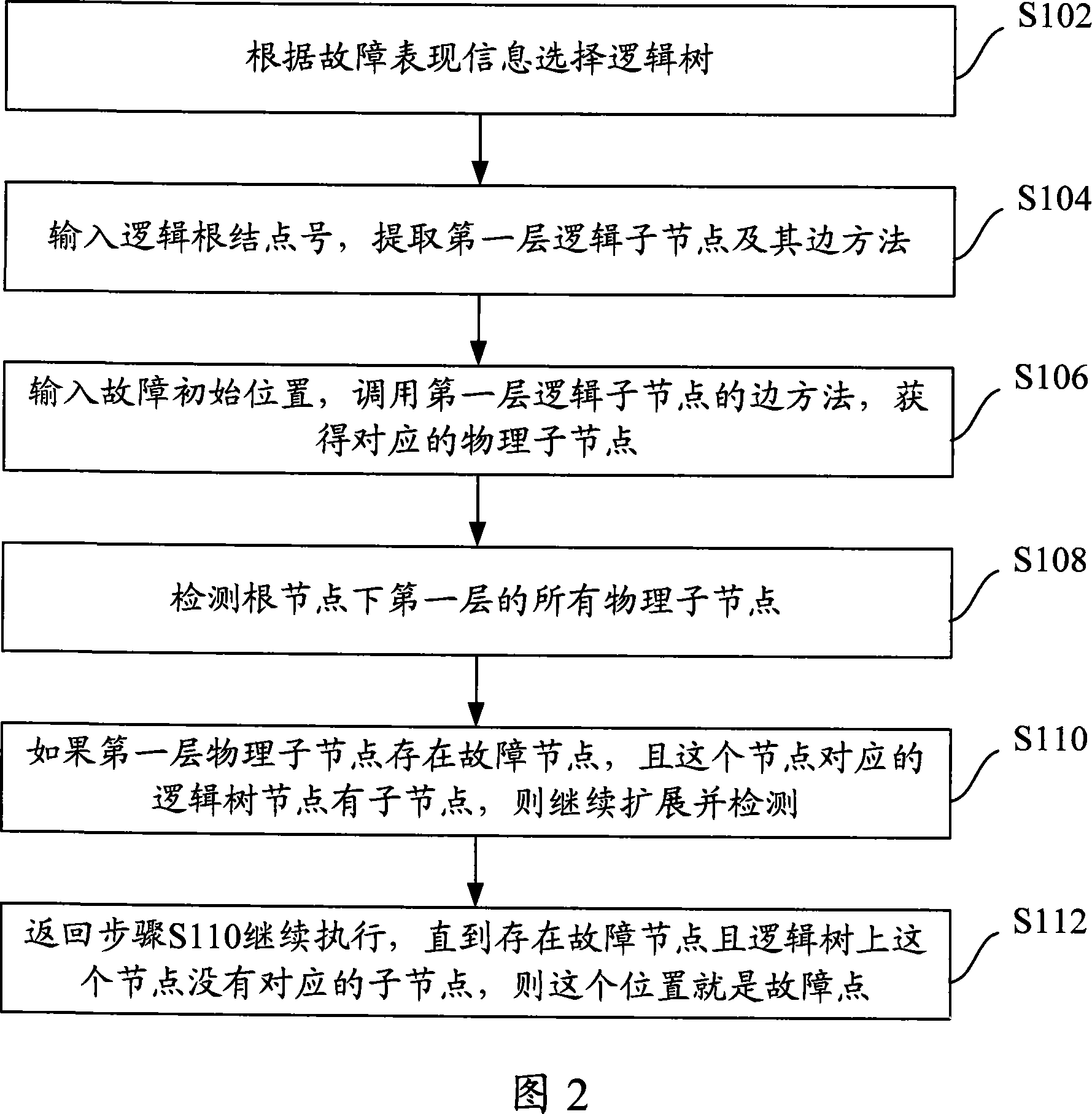

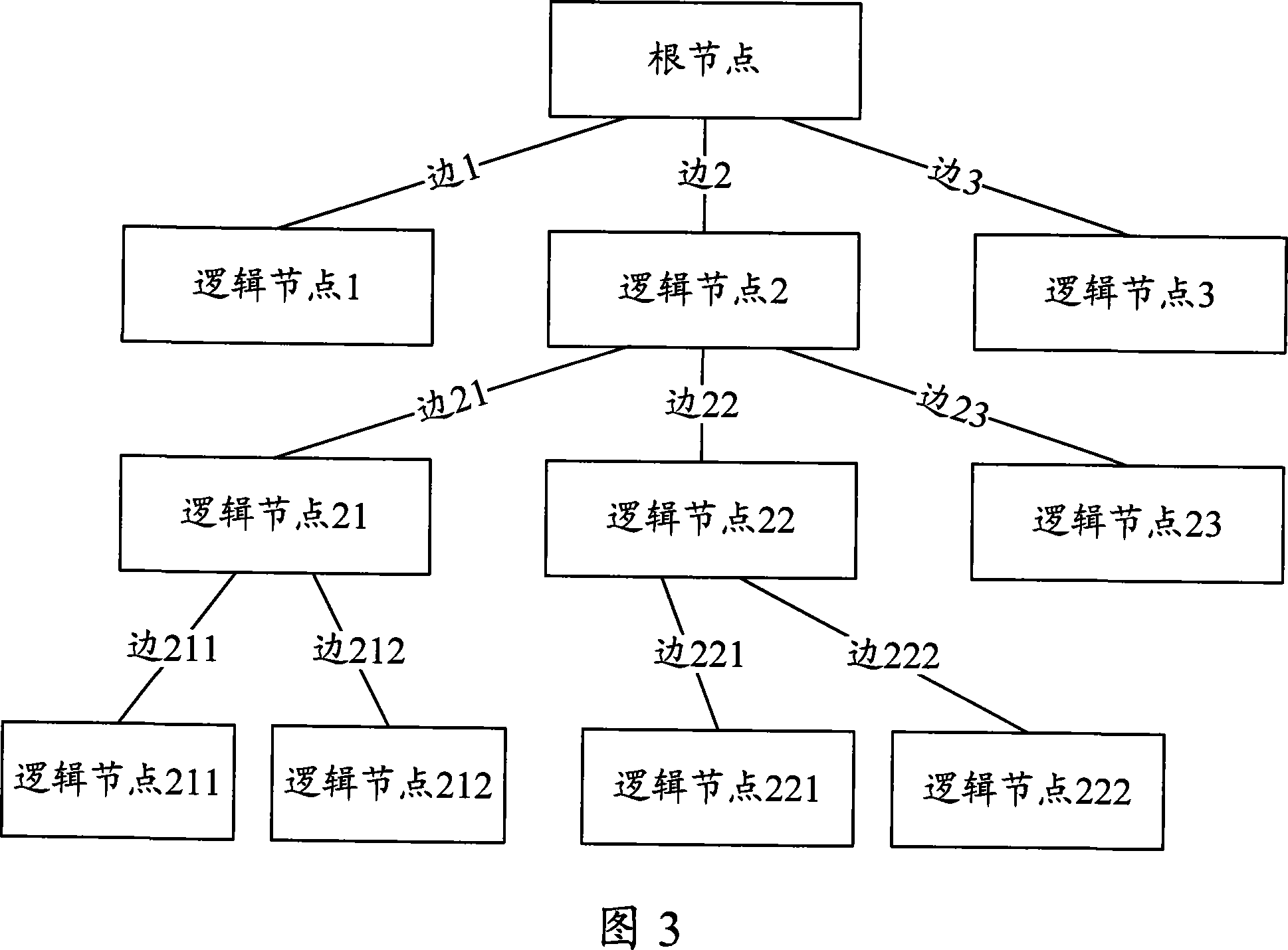

An expanding device and method from logic tree to physical tree in fault analysis

ActiveCN101217763AImprove efficiencyPrecise positioningRadio/inductive link selection arrangementsData switching networksExact locationTheoretical computer science

The invention discloses an extension device and a method from a logic tree to a physical tree in a malfunction analysis, which can realize the exact location to malfunction. The extension device comprises a logic tree management module used for arranging a malfunction detection point and establishing the logic tree which presents an equipment malfunction mode according to the malfunction detection point, a configuration management module used for establishing a configuration database according to the current configuration, a correlation analysis knowledge base which is connected with the logic tree management module and the configuration management module and used for achieving malfunction detection according to an analysis rule, and a physical tree extension module which is connected with the correlation analysis knowledge base and used for determining an edge method according to a node pair in the logic tree. Compared with the prior art, the device and the method of the invention can be smartly and self-adaptively extended from the logic tree to the physical tree, have high efficiency and exact positioning, and can be widely applied to mobile communication equipment malfunction analysis.

Owner:ZTE CORP

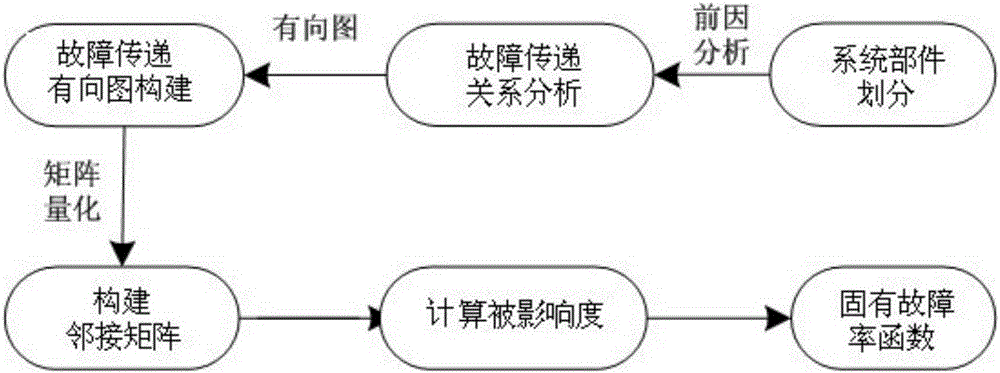

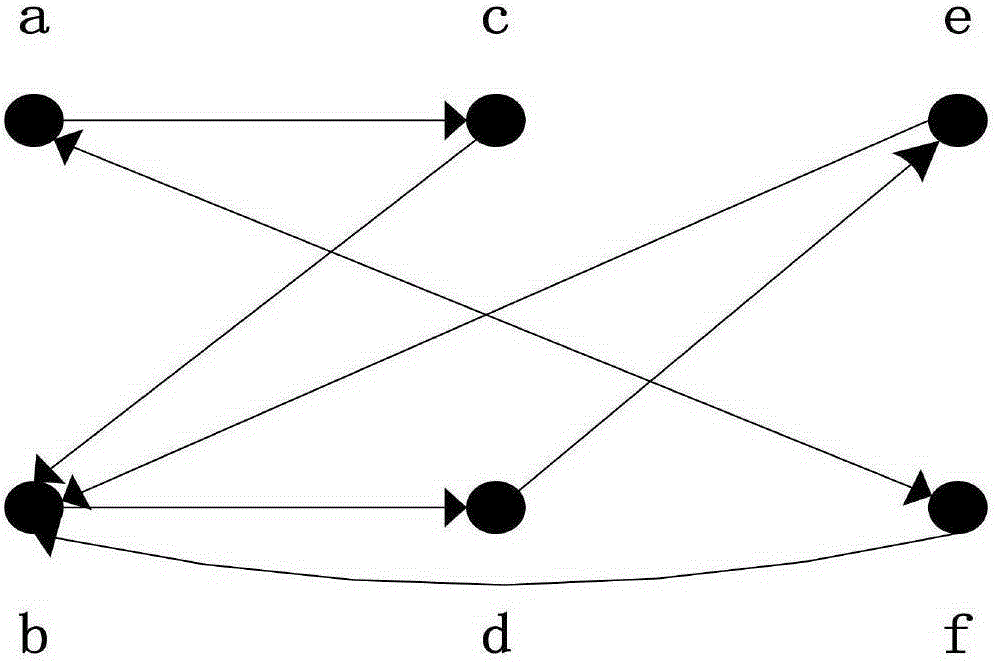

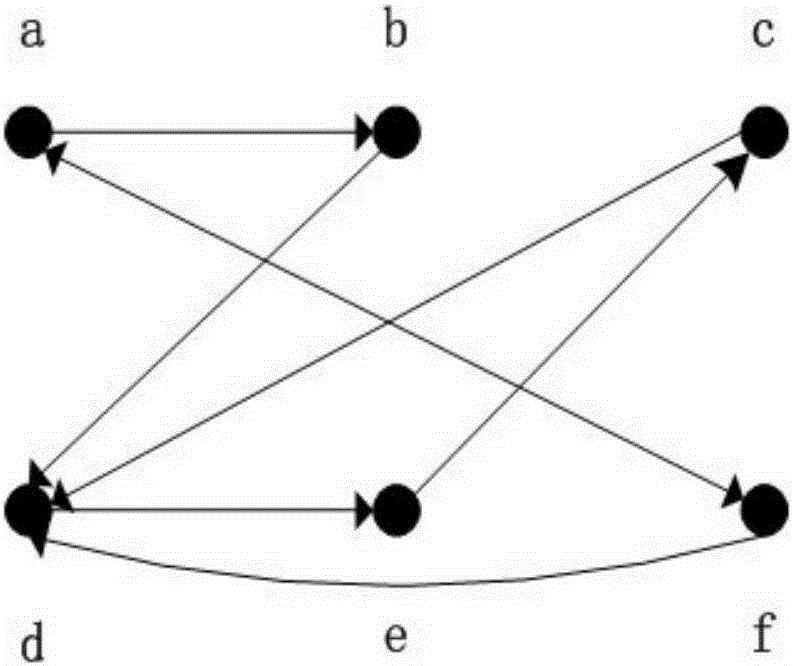

Numerical control machine tool system component reliability evaluation method based on cascading fault analysis

The invention relates to a numerical control machine tool system component reliability evaluation method based on cascading fault analysis. The method comprises the following steps that the entire numerical control machine tool system components are divided into multiple subsystems, and a fault transfer directed graph model is established according to the fault transfer relation between all the subsystems; the fault transfer directed graph model is described by using an adjacency matrix; a fault-correlation-based influence degree CK value of each subsystem is calculated; an inherent fault probability function of each subsystem is obtained according to the fault-correlation-based influence degree CK value of each subsystem and a comprehensive fault probability function through calculation; and reliability evaluation is performed on the numerical control machine tool system components by utilizing the inherent fault probability function. The cumulative fault process of the elements of the subsystems is considered by a reliability model, and fault correlation influence degree factors of other subsystem are also integrated so that the reliability model meets the reality further in comparison with the reliability model based on mutually independent assumption between systems.

Owner:JILIN UNIV

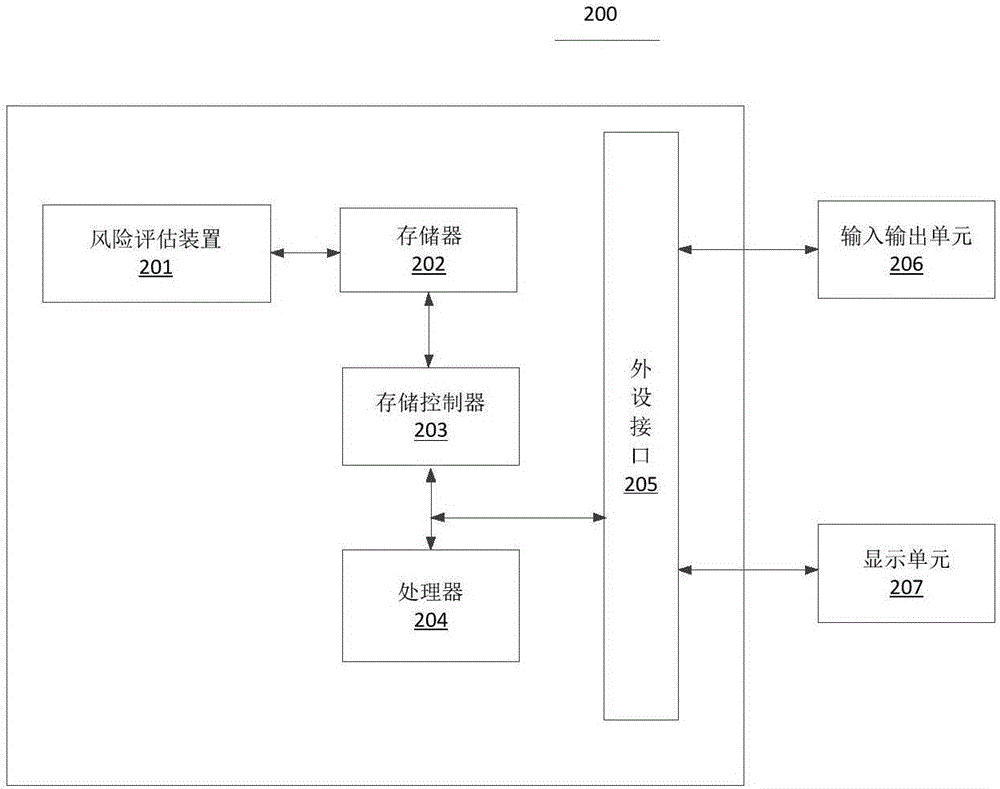

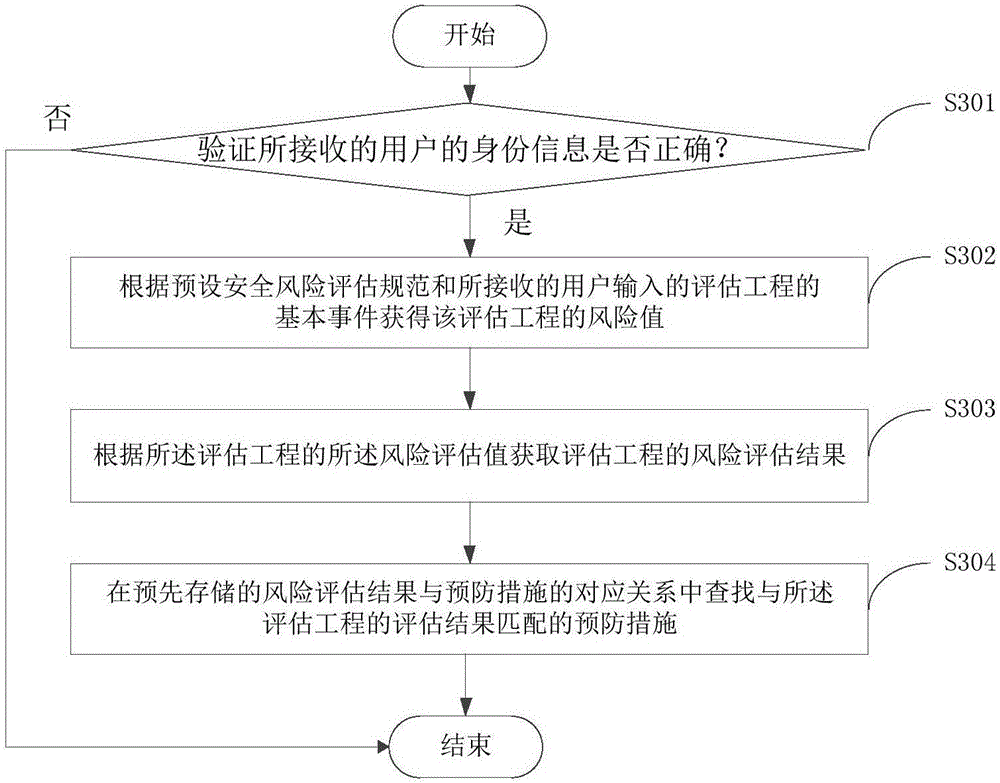

Risk assessment method and risk assessment device

The embodiment of the invention provides a risk assessment method and a risk assessment device, so as to solve technical problems that during a tunnel blasting project in the prior art, qualitative assessment is mainly carried out through an experienced person and an expert, the qualitative assessment is mainly subjective judgment and qualitative analysis, quantitative analysis is lacked, and thus, the stability and the accuracy of an assessment result are poor. According to the risk assessment method and the risk assessment device provided by the invention, after the identity of a user passes verification, basic events for project assessment inputted by the user are received, the risk values of the basic events are calculated quantitatively, and according to the risk values and the weight values of multiple basic events and a grahame assessment method and a fault tree analysis method, the risk value of the assessment project is acquired, and according to the risk value of the assessment project, the assessment result of the assessment project is acquired. Thus, the technical effects of quantitatively calculating the risk value of the assessment project and acquiring the risk assessment result according to the multiple basic events of the assessment project are achieved.

Owner:HAIWEI ENG CONSTR CO LTD OF FIRSTHIGHWAY ENG CO LTD OF CCCC

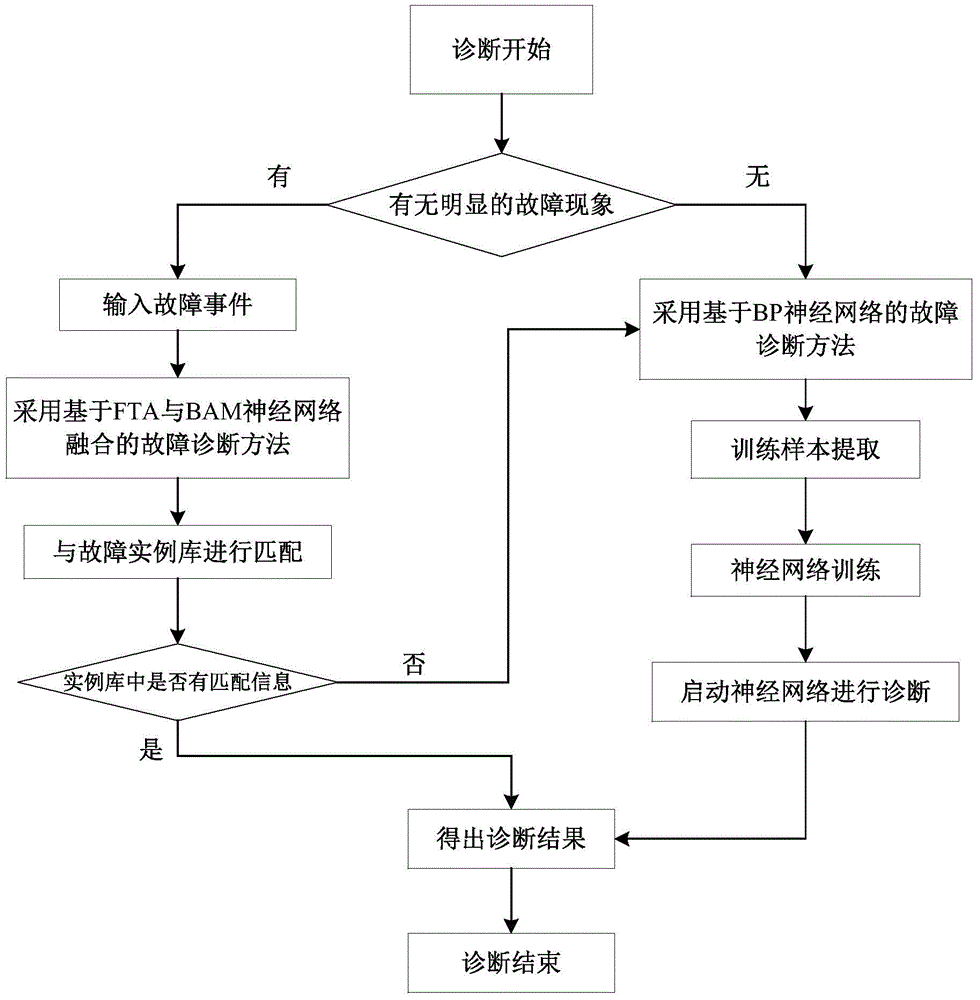

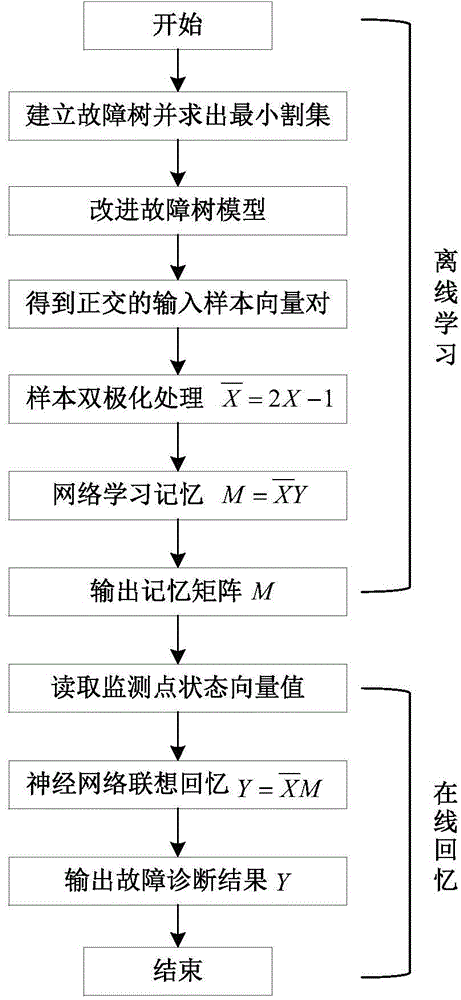

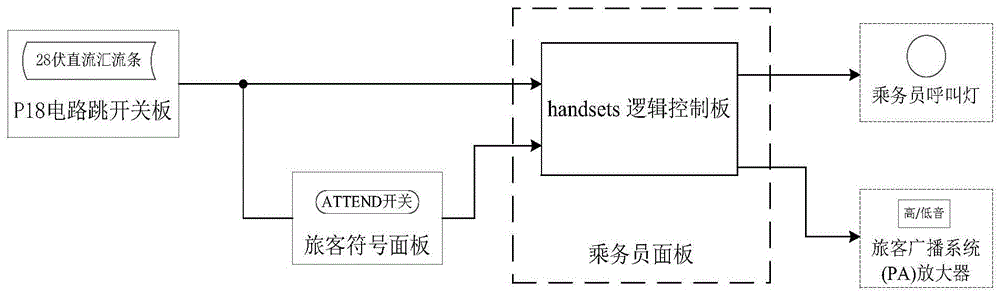

Multi-method combination avionics system fault diagnosis method

InactiveCN104915715ARapid positioningQuick and Intelligent DiagnosisBiological neural network modelsBidirectional associative memoryDiagnosis methods

The invention discloses an avionics system fault diagnosis method based on combination of three methods which are FTA (fault tree analysis), a BAM (bidirectional associative memory) neural network and a BP (back-propagation) neural network. According to the invention, a fault diagnosis model integrating FTA and the BAM neural network and a fault diagnosis model combining the BP neural network are established respectively. When a fault phenomenon is obvious, the fault diagnosis model integrating FTA and the BAM neural network is adopted. Firstly, a fault mode of the system is acquired by using FTA, a training sample of BAM is analyzed and summarized, and finally, BAM carries out parallel association through an associative memory matrix so as to acquire a diagnosis result. When a fault phenomenon is not obvious or a fault example base does not have such a fault, the fault diagnosis model combining the BP neural network is adopted. Learning is carried out on a training sample, that is, data such as voltage, temperature and the like, acquired by the BP neural network, and fault diagnosis is carried out by using the trained network in the end. The two fault diagnosis models have complementary advantages, and make up deficiencies of each other, thereby effectively solving problems existing in avionics system fault diagnosis, and improving the accuracy and the efficiency of fault diagnosis.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com