Modeling and graphical displaying method for causal relationship reasoning model of unusual working conditions of chemical process

A graphical display and abnormal working condition technology, which is applied in general control systems, control/adjustment systems, test/monitoring control systems, etc., can solve the problems of inaccurate judgment of the root cause of abnormal working conditions and poor graphical display effect, etc. Achieving a good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

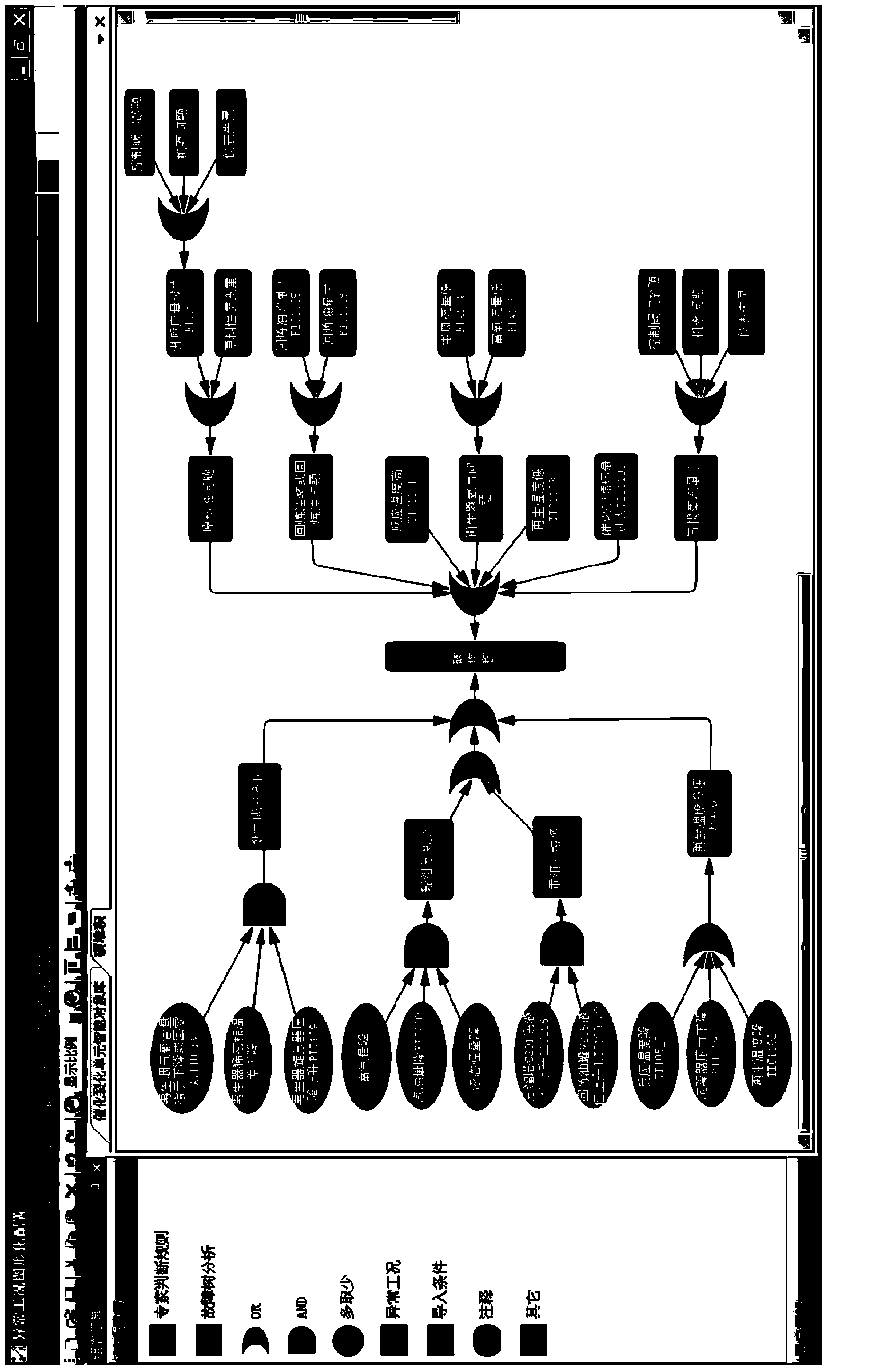

[0016] This patent focuses on the failure mode and performance characteristics of abnormal working conditions in the petrochemical production process, collects real-time data from the industrial control system, and establishes an expert rule model closely related to the judgment process of abnormal working conditions on the basis of an expert system. Based on the mode of root cause analysis of abnormal working conditions, a fault tree logical reasoning model for root cause analysis of abnormal working conditions is established, and a variety of intelligent calculation methods based on process mechanism and cluster analysis are adopted. Through threshold judgment and feature extraction of key safety technical parameters, It performs feature matching with the established expert rule model and fault tree analysis model to realize intelligent monitoring, early warning and root cause analysis of abnormal working conditions in the production process.

[0017] The judgment of abnormal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com