Numerical control machine tool system component reliability evaluation method based on cascading fault analysis

A technology of numerical control machine tools and fault analysis, which is applied in general control systems, control/regulation systems, program control, etc., and can solve problems such as deviations in evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

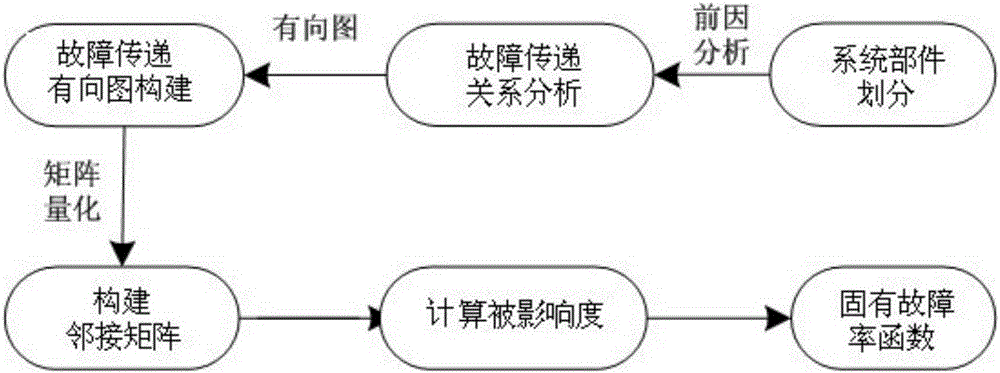

Method used

Image

Examples

Embodiment

[0102] Intrinsic Reliability Evaluation of Machining Center System Components

[0103] According to the statistical analysis of the field failure data of 109 VDL-1000 type machining centers collected, the frequency distribution of failures in each failure part (subsystem) of the machining center is calculated, as shown in Table 1.

[0104] Table 1 Frequency list of fault location factors

[0105]

[0106]

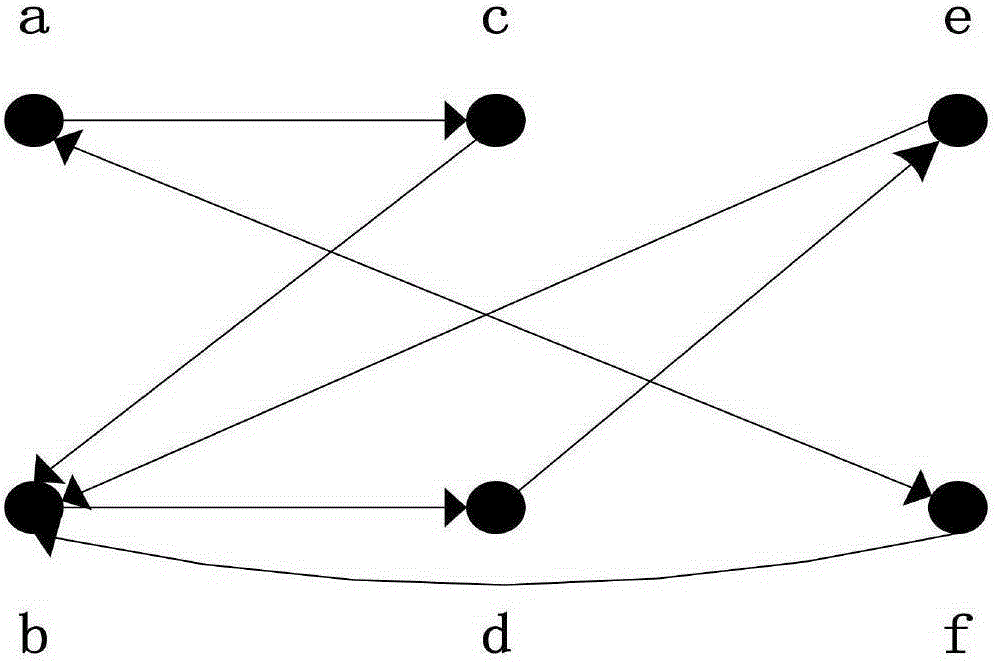

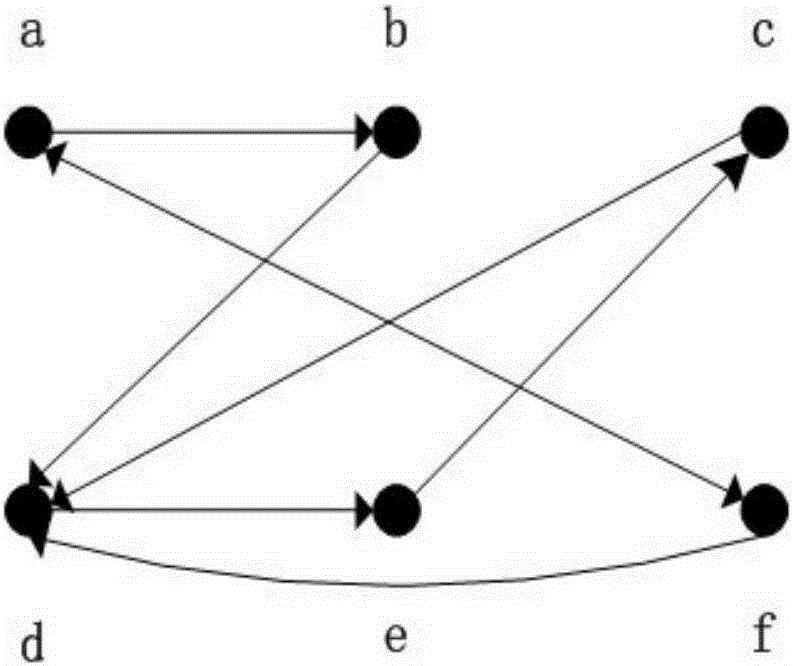

[0107] According to the associated fault analysis of the machining center and the directed graph theory, the fault transfer relation model and the fault transfer directed graph are constructed respectively as follows image 3 shown.

[0108] The fault transfer directed graph is matrixed, and the adjacency matrix C of the machining center and the corresponding probability transition matrix are constructed according to the serial numbers of the subsystems of the machining center in the table:

[0109] C = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com