Patents

Literature

37results about How to "Improve the quality of after-sales service" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

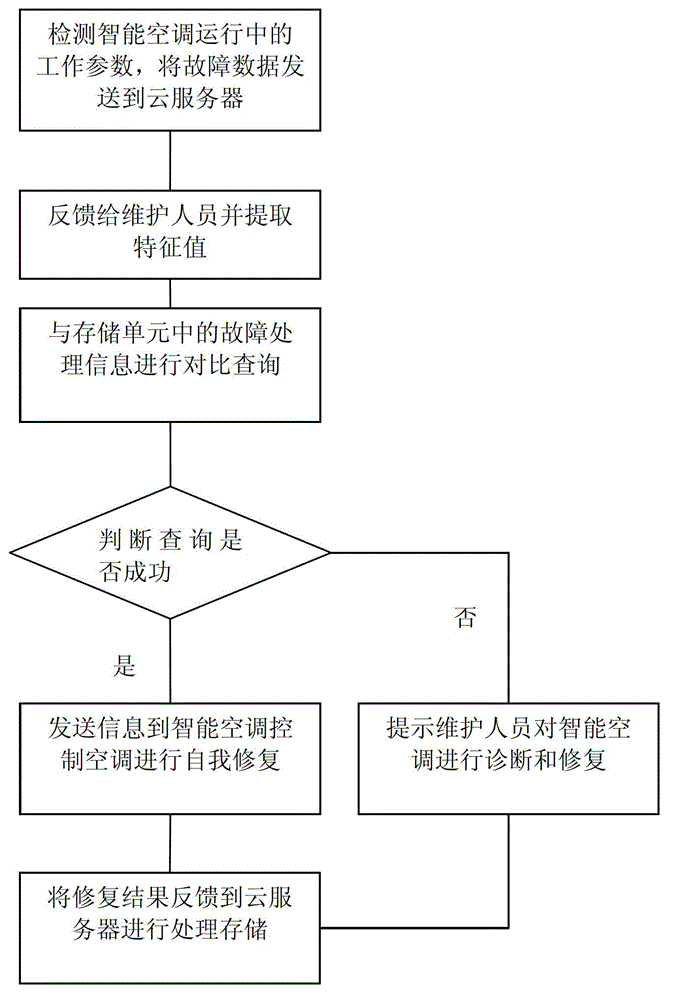

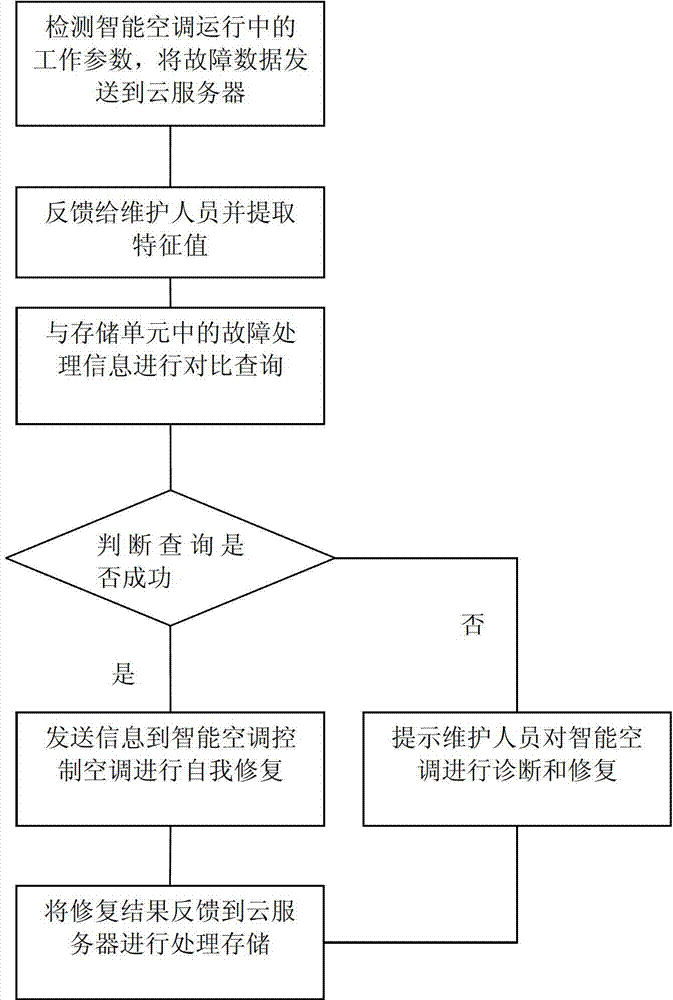

Remote fault processing method for intelligent air conditioner

ActiveCN103062862AImprove the quality of after-sales serviceLower service costsSpace heating and ventilation safety systemsLighting and heating apparatusComputer moduleFault analysis

The invention relates to the intelligent control technology, in particular to a remote fault processing method for an intelligent air conditioner. The remote fault processing method includes main steps that: fault data are analyzed through a detection module by detecting working parameters of the intelligent air conditioner and are transmitted to a cloud server; the cloud server performs comparison query according to characteristic values of the fault data and fault processing information in a storage unit, the intelligent air conditioner performs self repair according to contents of the fault processing information and feeds the repair result back to the cloud server if matched fault processing information is obtained, and maintainers perform fault analysis and repair for the intelligent air conditioner and input fault analysis and repair contents into the cloud server to be stored in the storage unit if the matched fault processing information is not obtained. The remote fault processing method for the intelligent air conditioner has the advantages of being an efficient and intelligent remote fault processing mode, being capable of effectively improving after-sale service quality of the intelligent air conditioner devices and saving service cost, and further is especially applicable to the intelligent air conditioner.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

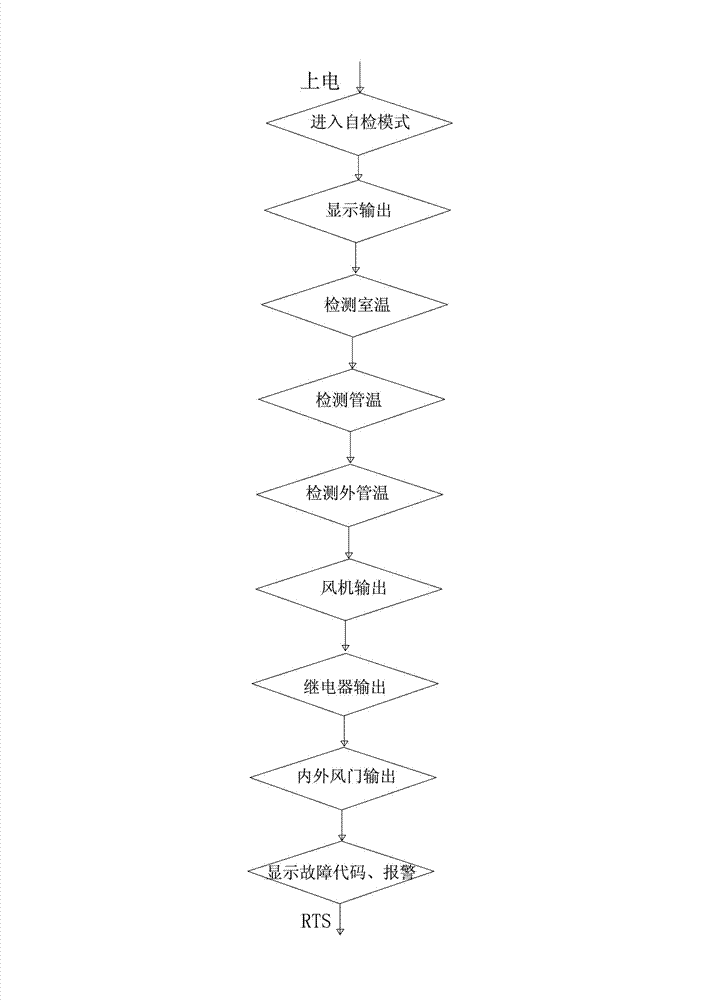

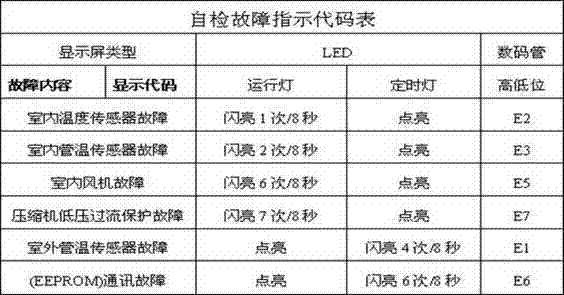

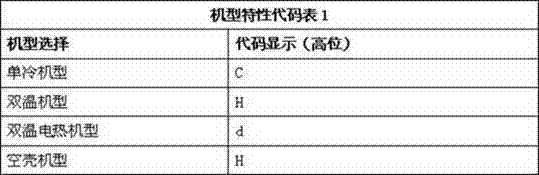

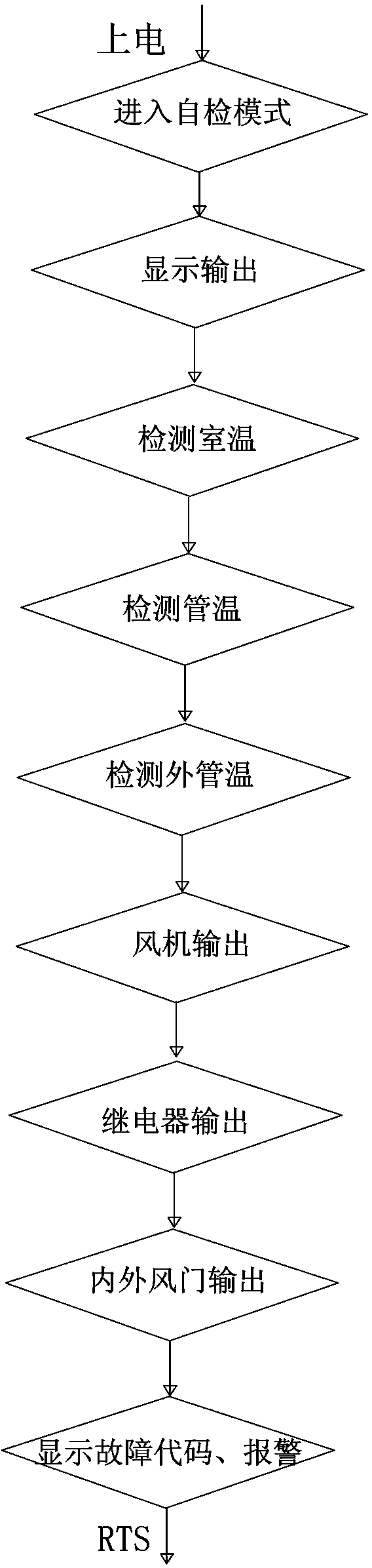

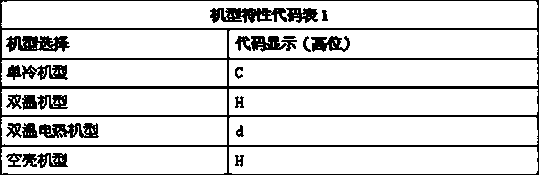

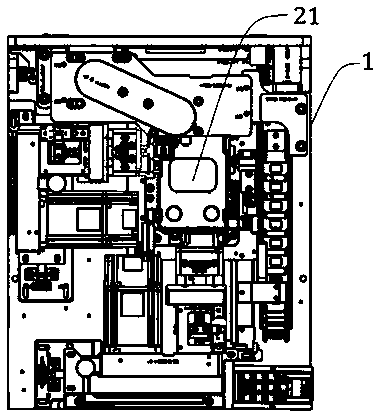

Intelligent self-checking method for air conditioner

ActiveCN102759176AGuarantee factory qualityNovel methodSpace heating and ventilation safety systemsLighting and heating apparatusLED lampSelf checking

The invention provides an intelligent self-checking method for an air conditioner. Firstly, under the condition that the air conditioner is electrified, a self-checking key is pressed down to enable the air conditioner to enter a self-checking mode, a buzzer sounds to confirm that the self-checking is started at the moment, each load begins to act, and according to software functional setting, the air conditioner outputs all of load information, including a display screen, a fan, a pressing machine, a fan, temperature signals and the like, in a sequence at intervals; and when the air conditioner quits the self-checking mode, all of input / output feedback information is collected, and if a fault appears, the air conditioner represents the fault in the form of the combination of a fault code and a buzzing alarm, and displays through an LED lamp and the fault code, so that a worker can rapidly find out the fault root according to the self-checking fault indication code and remove the fault to enable the air conditioner to return to the normal running state.

Owner:广东志高精密机械有限公司

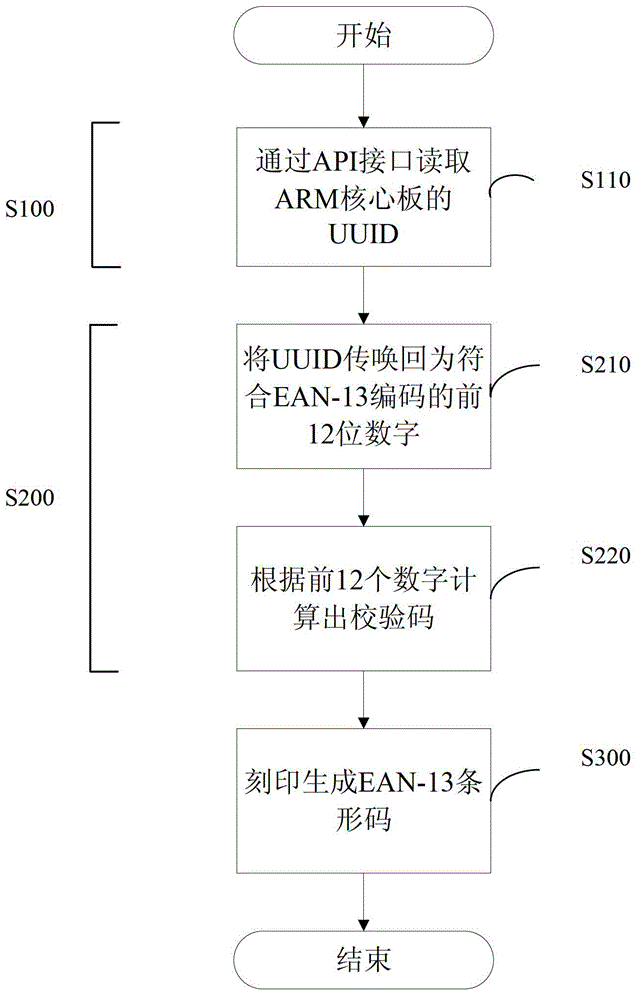

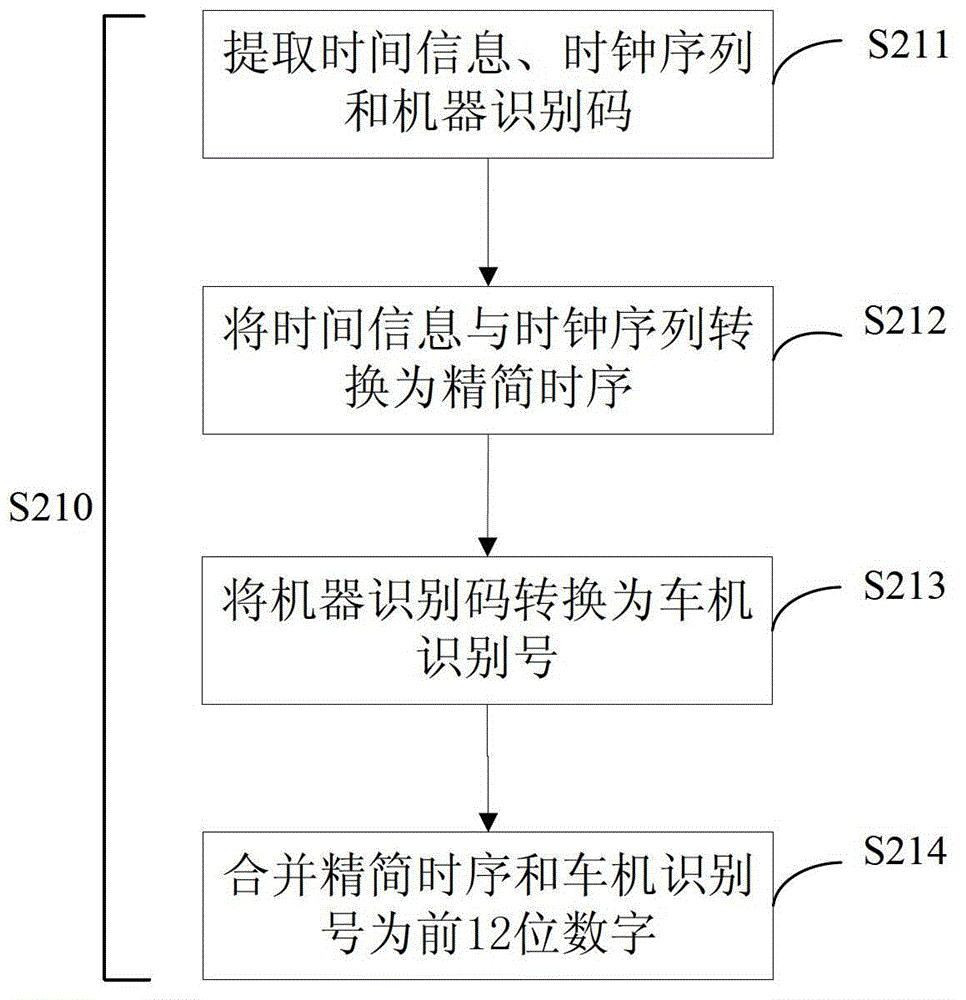

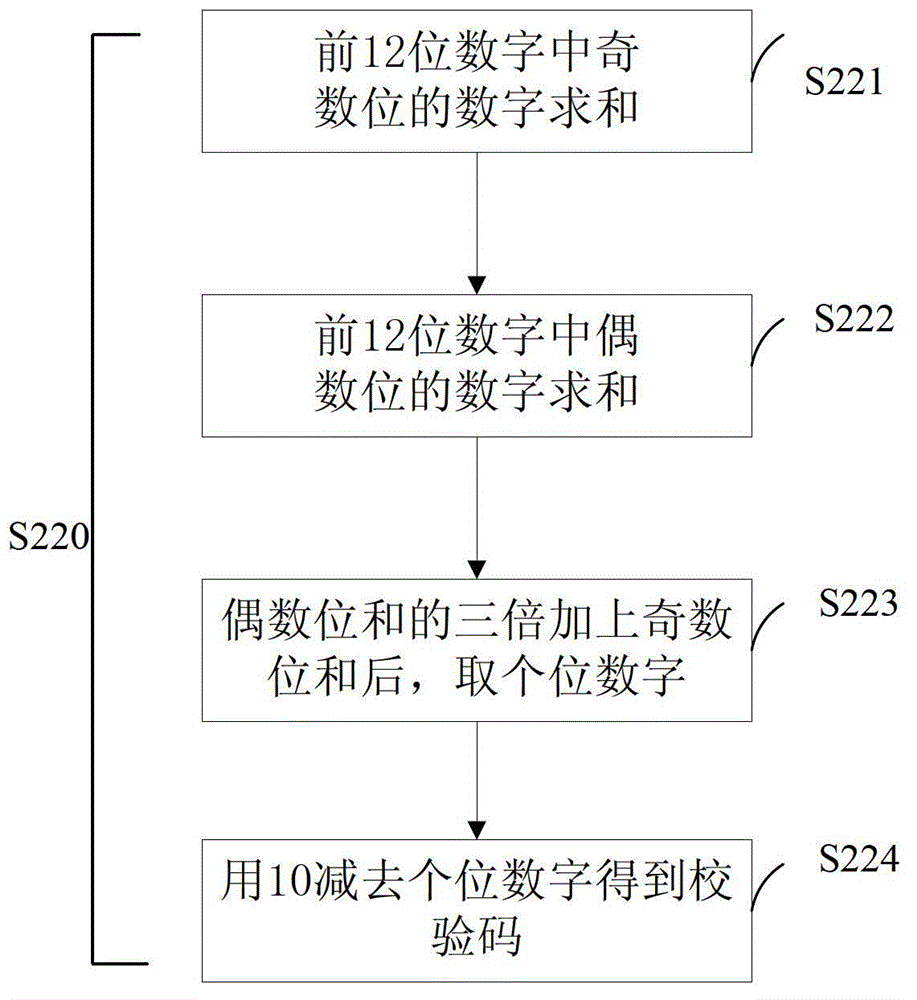

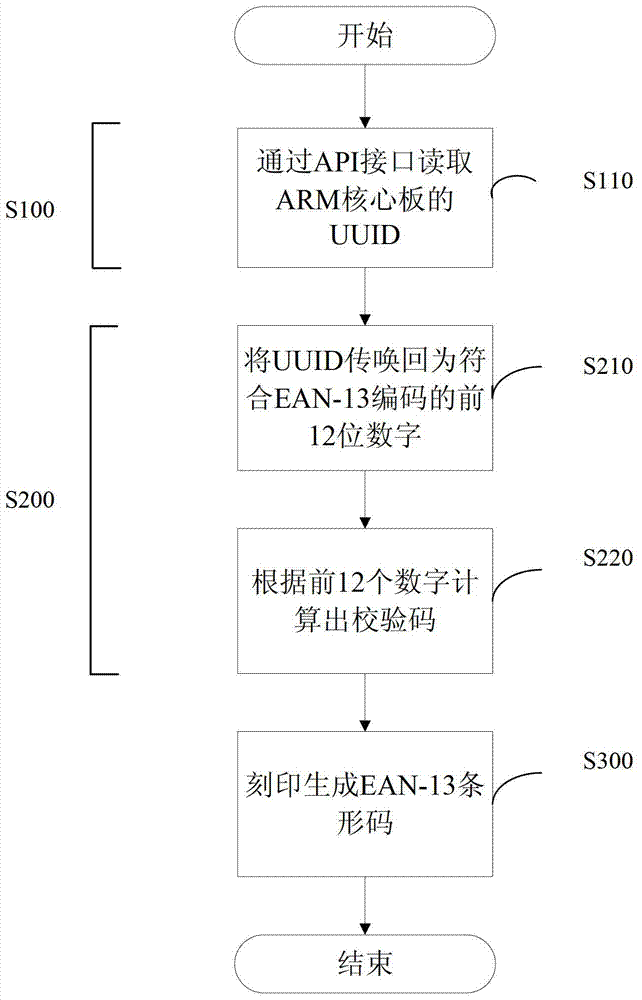

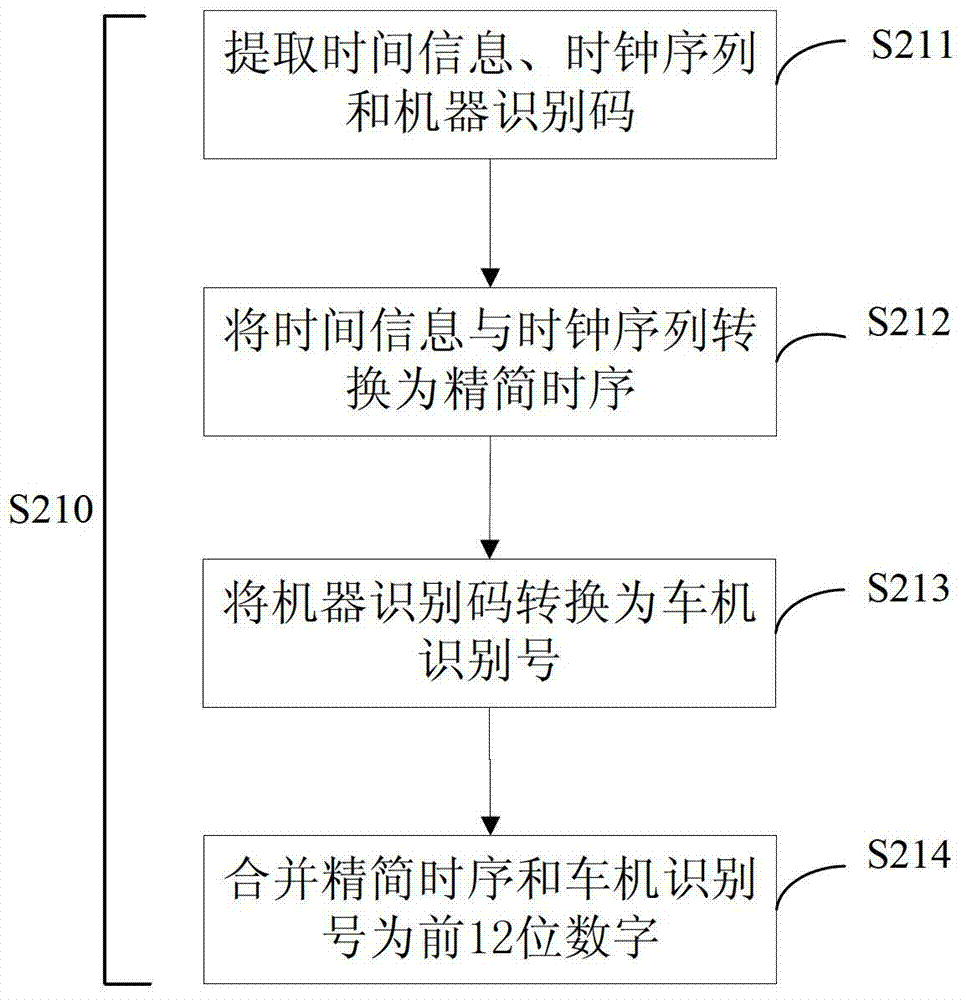

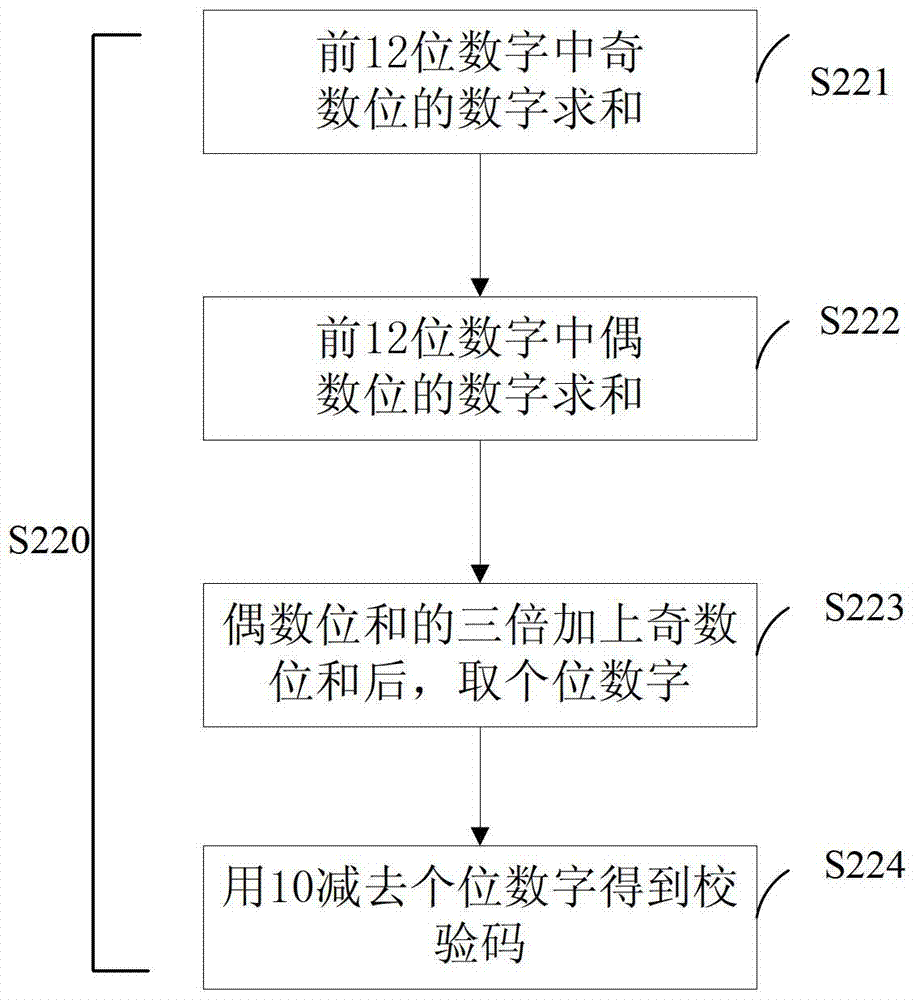

Universally unique identifier (UUID) conversion method for vehicle-mounted infotainment product

ActiveCN104376351AImprove the quality of after-sales serviceConvenient query and trackingRecord carriers used with machinesSensing by electromagnetic radiationUser identifierUnique identifier

The invention relates to a universally unique identifier (UUID) conversion method for a vehicle-mounted infotainment product. The conversion method comprises the following steps that a UUID is read; the UUID is converted into an EAN-13 barcode. By implementing the UUID conversion method, the complex UUID is converted into the EAN-13 barcode easy to identify; in this way, a user can determine whether the vehicle-mounted infotainment product is a counterfeit product or not according to the EAN-13 barcode imprinted on the vehicle-mounted infotainment product; besides, good query tracking and after-sales service can be provided for the user according to information obtained from the EAN-13 barcode through reverse derivation, and therefore the after-sales service quality of the product is improved.

Owner:SHENZHEN ZHONGHONG TECH

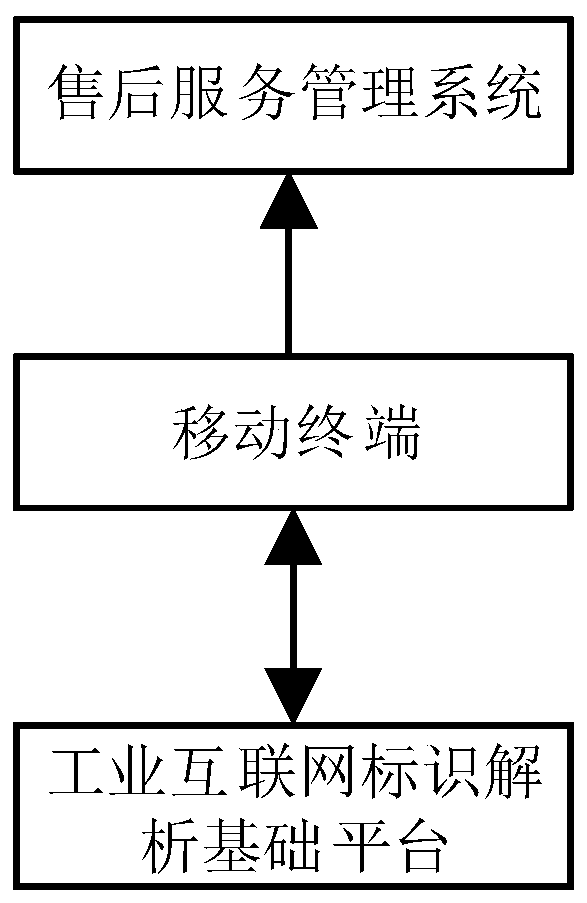

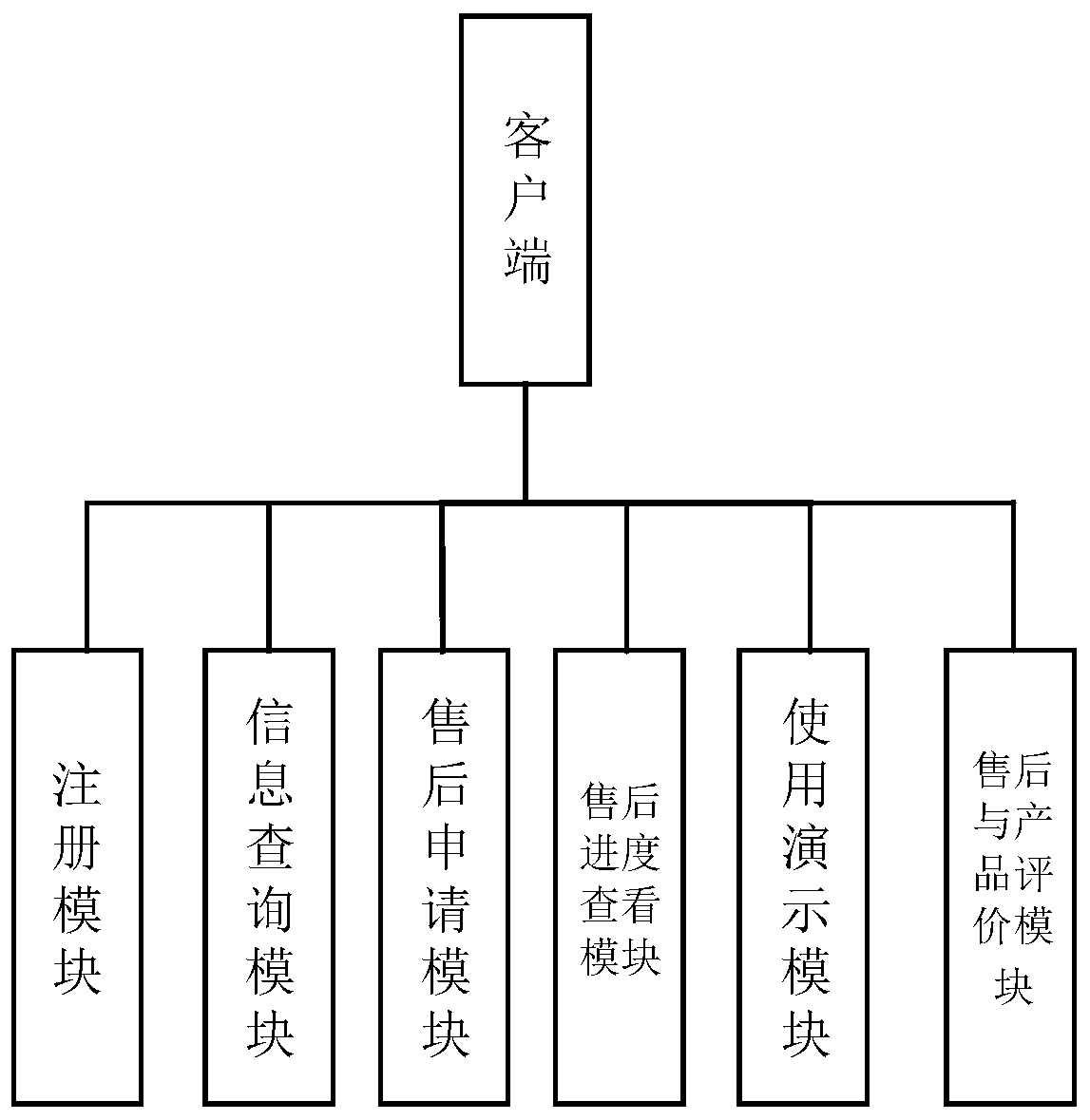

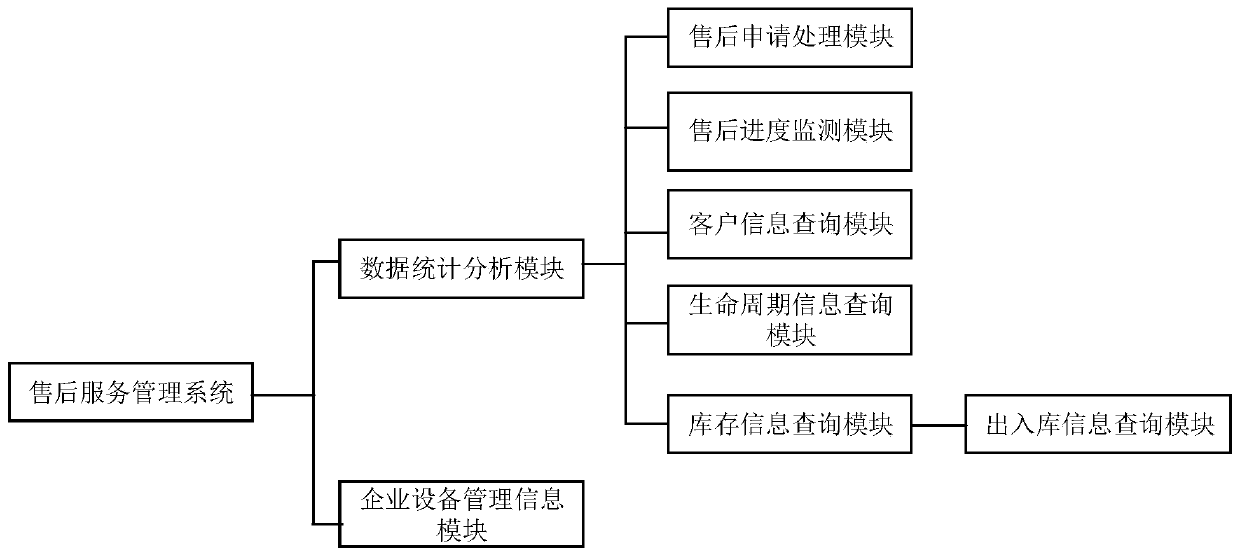

Product traceability and after-sales service system based on internet identification technology

InactiveCN110599204AReduce labor costsReduce after-sales operating costsCo-operative working arrangementsLogisticsOperational costsThe Internet

The invention discloses a product traceability and after-sales service system based on the Internet identification technology, and belongs to the technical field of Internet identifications, and the system comprises an industrial Internet identification analysis basic platform, an after-sales service management system, and a mobile terminal. The industrial Internet identifier analysis basic platform is in bidirectional connection with the mobile terminal through a wireless network and is used for analyzing the product unique identification code information uploaded by the mobile terminal. Themobile terminal is used for providing product traceability and after-sales service for a user, and information output by the mobile terminal is transmitted to the background management system througha wireless network. According to the invention, through the industrial Internet identifier analysis basic platform, the after-sales service management system and the mobile terminal, after-sales problems can be rapidly processed. The labor cost is reduced, and the after-sales service quality is improved. Meanwhile, products and spare and accessory parts of the products can be managed through the after-sales service system, meanwhile, replaced spare and accessory part return generated in the after-sales process is managed, the after-sales operation cost is effectively reduced, and value maximization is achieved.

Owner:工业云制造(四川)创新中心有限公司

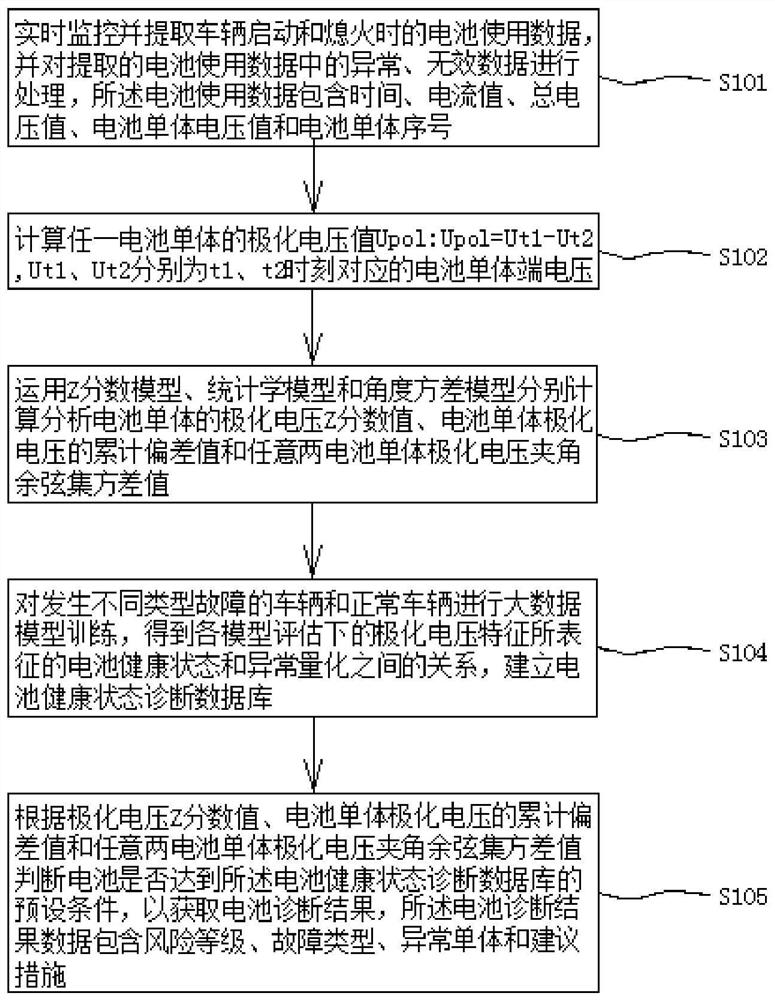

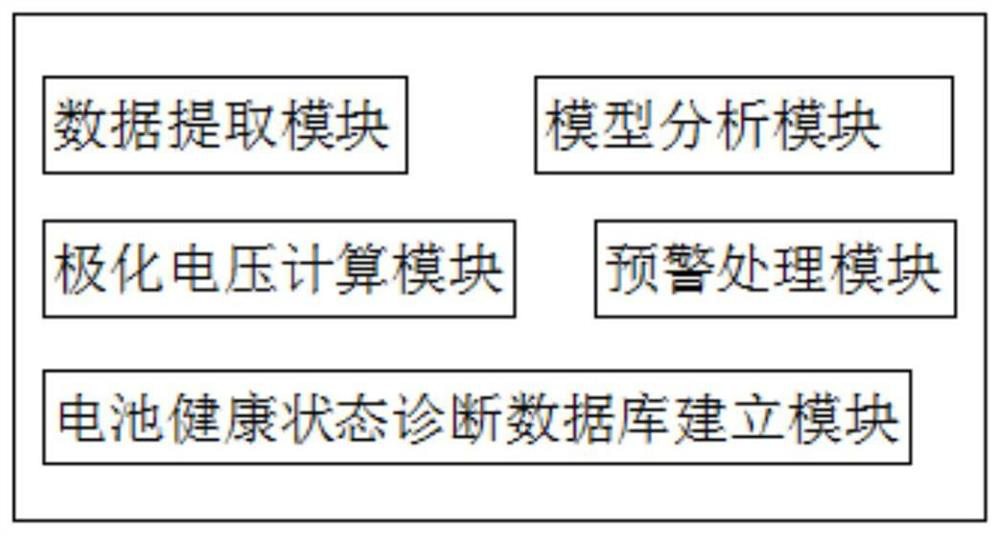

Automobile battery monomer abnormality estimation method and device

PendingCN112526376AAvoid lostImprove satisfactionElectrical testingSecondary cells testingPower batteryAutomotive battery

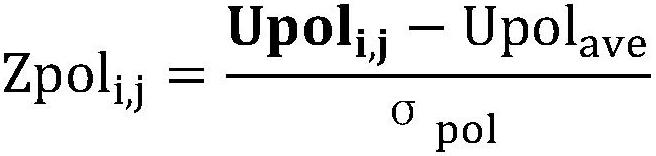

The invention provides an automobile battery monomer abnormality estimation method and device. The method comprises the following steps: monitoring and extracting battery use data when an automobile is started and shut down in real time; calculating a polarization voltage value of any battery monomer; calculating and analyzing a polarization voltage Z score value of each battery monomer, an accumulated deviation value of the polarization voltage of each battery monomer and a cosine set variance value of an included angle between any two battery monomers by using a Z score model, a statisticalmodel and an angle variance model; carrying out big data model training to obtain a relationship between a battery health state and abnormal quantification, and establishing a battery health state diagnosis database; and judging whether the battery reaches a preset condition of a battery health state diagnosis database or not according to three values so as to obtain a battery diagnosis result. According to the invention, the abnormal problem of the power battery system can be found in advance, early warning can be given, and accidents such as fire and explosion of an electric automobile can be reduced.

Owner:JIANGXI JIANGLING GRP NEW ENERGY AUTOMOBILE CO LTD

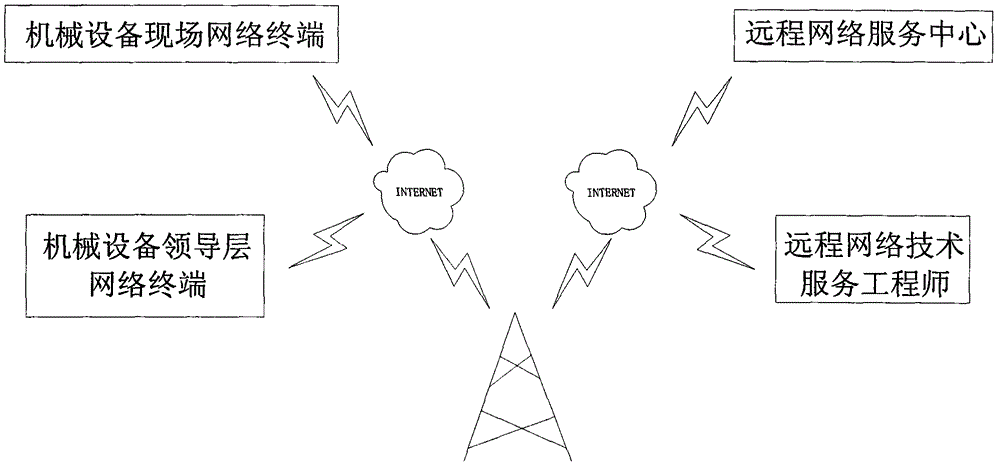

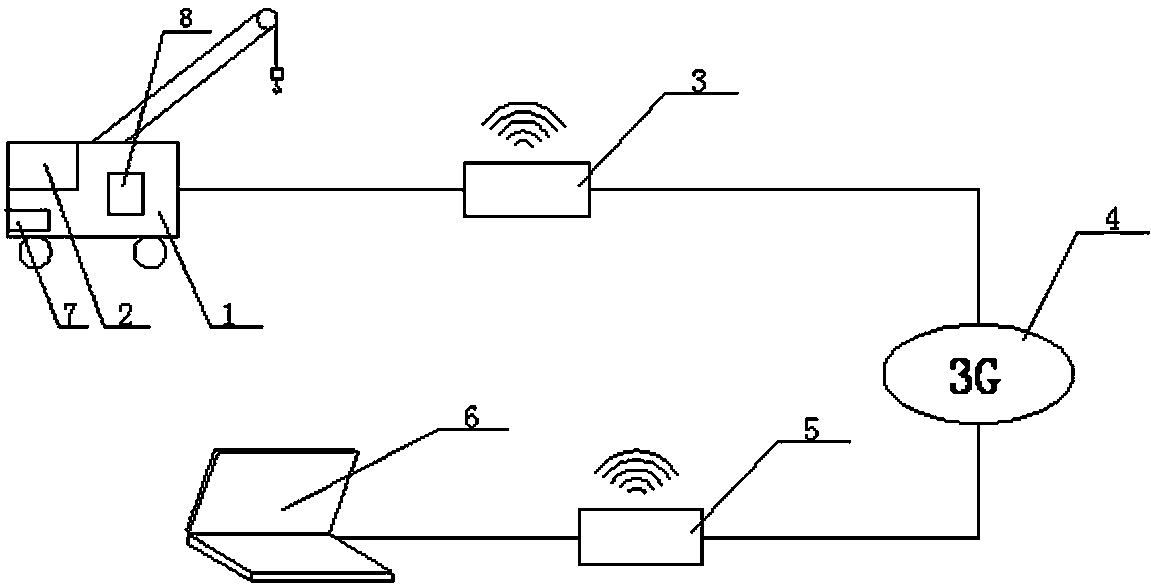

Device and method for remotely solving fault by utilizing handheld device

InactiveCN103048969ATroubleshootingReduced repair response timeTotal factory controlProgramme total factory controlControl engineeringWireless data

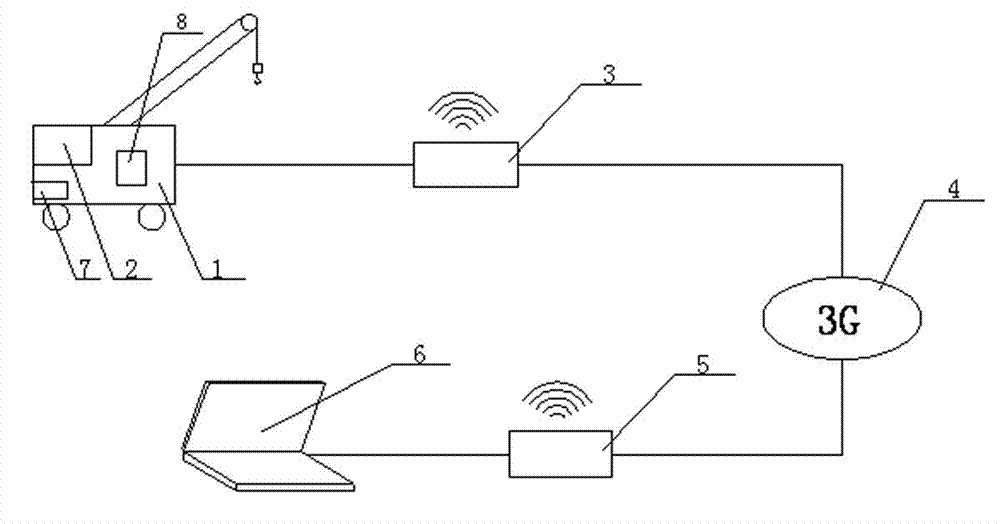

The invention relates to a device and a method for remotely solving a fault by utilizing a handheld device. The device comprises a sensor, a PID (proportion-integration-differential) controller and the handheld device, wherein the sensor which can be used for measuring characteristic parameters of an executive component in real time is positioned in engineering machinery and connected with the executive component of the engineering machinery; the PID controller is positioned in the engineering machinery and connected with the executive component; and a wireless data transmitter is fixed in the engineering machinery and connected with a wireless data receiver through a wireless network, and the wireless data receiver is connected with the handheld device. The invention further comprises a method for remotely solving the fault by utilizing the device for remotely solving the fault by utilizing the handheld device. According to the device and the method, the parameters of the remote engineering machinery in a operating process can be collected and transmitted in real time, the fault of the engineering machinery can be quickly determined, the engineering machinery is debugged and controlled by utilizing the remote handheld device, and the maintenance response time of the engineering machinery is shortened.

Owner:昆山航天智能技术有限公司

Unit maintenance demand determination method and device based on user tolerance conditions and air conditioner

ActiveCN110296500AImprove the quality of after-sales serviceGood compatibilityMechanical apparatusSpace heating and ventilation safety systemsQuality of serviceReliability engineering

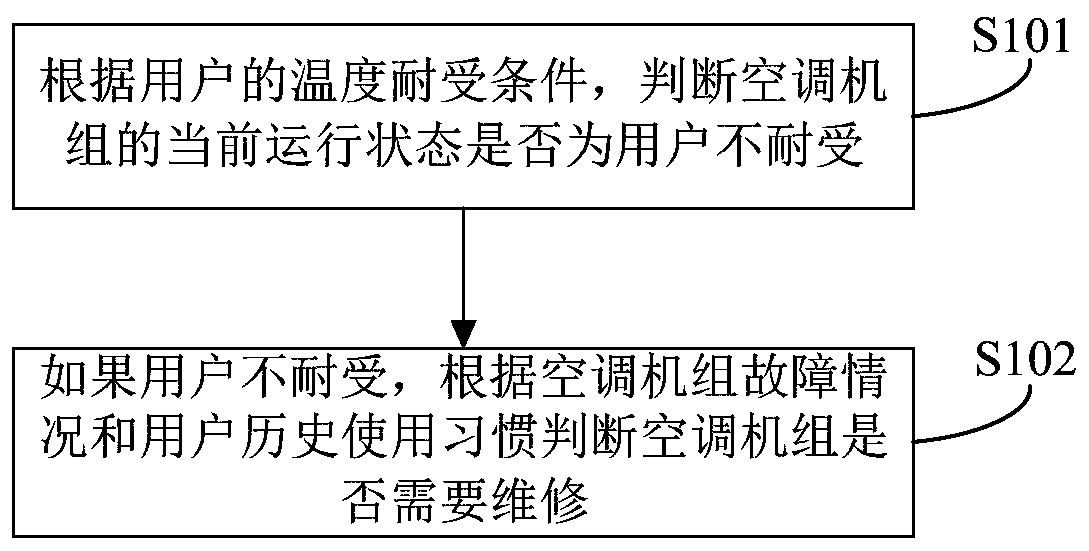

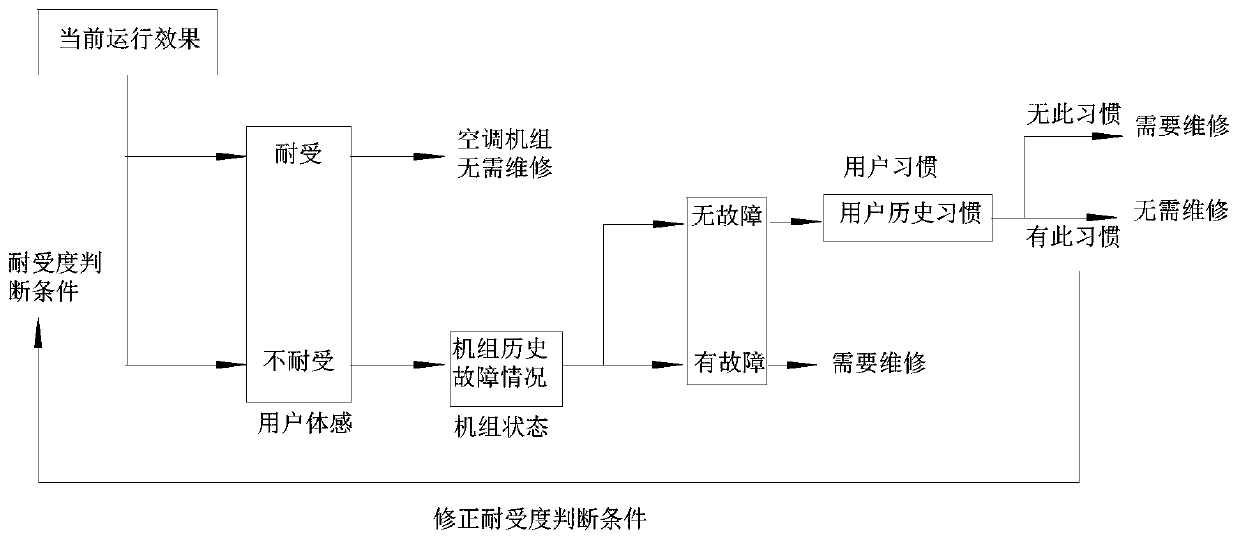

The invention discloses a unit maintenance demand determination method and device based on user tolerance conditions and an air conditioner. The method comprises the following steps that according tothe temperature tolerance conditions of a user, whether the current running state of an air conditioner unit is intolerant to the user or not is judged; and if the air conditioner unit is intolerant to the user, whether the air conditioner unit needs to be maintained or not is judged according to the fault condition of the air conditioner unit and the historical use habit of the user. According tothe method, whether the air conditioner unit needs to be maintained or not is judged according to the tolerance degree of the experiencing feeling of the user, the fault condition of the unit and thehistorical use habit of the user, the maintenance requirement is judged actively from the perspective of the user, the judgment result of whether the maintenance is needed or not is more practical, the matching performance with the actual maintenance needs of the user is high, ineffective maintenance is reduced, and the quality of the active after-sale service in the air conditioner industry is improved.

Owner:GREE ELECTRIC APPLIANCES INC

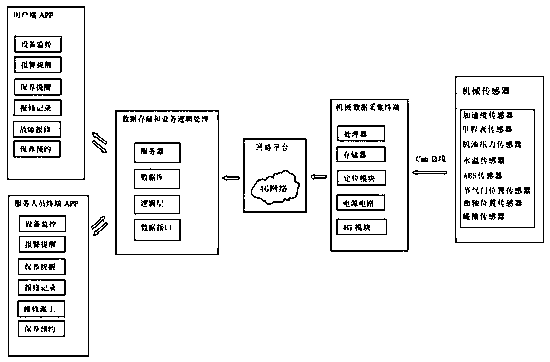

Engineering machinery maintenance information management system based on APP and Internet of Things big data

InactiveCN109615094AImprove the quality of after-sales serviceImprove work efficiencyInstrumentsService personnelData acquisition

The invention discloses an engineering machinery maintenance information management system based on APP and Internet of Things big data. The engineering machinery maintenance information management system comprises a machinery data acquisition terminal, a data storage and business logic processing module, a user terminal APP and a service personnel terminal APP. The mechanical data acquisition terminal is used for positioning and acquiring parameter data of each sensor and processing, packaging and transmitting the acquired data; the data storage and service logic processing module is mainly used for receiving the data transmitted by the mechanical data acquisition terminal, performing data analysis, storage and operation, performing data restorage, and performing logic judgment processingto form a readable data writing data interface; and the user terminal APP and the service personnel terminal APP are used for calling an interface to check data and submit data through a data interface provided by the data storage and business logic processing module. The problems of low equipment maintenance and repair efficiency, high cost and lack of remote alarm, fault prediction and remote active diagnosis are solved.

Owner:徐工汉云技术股份有限公司

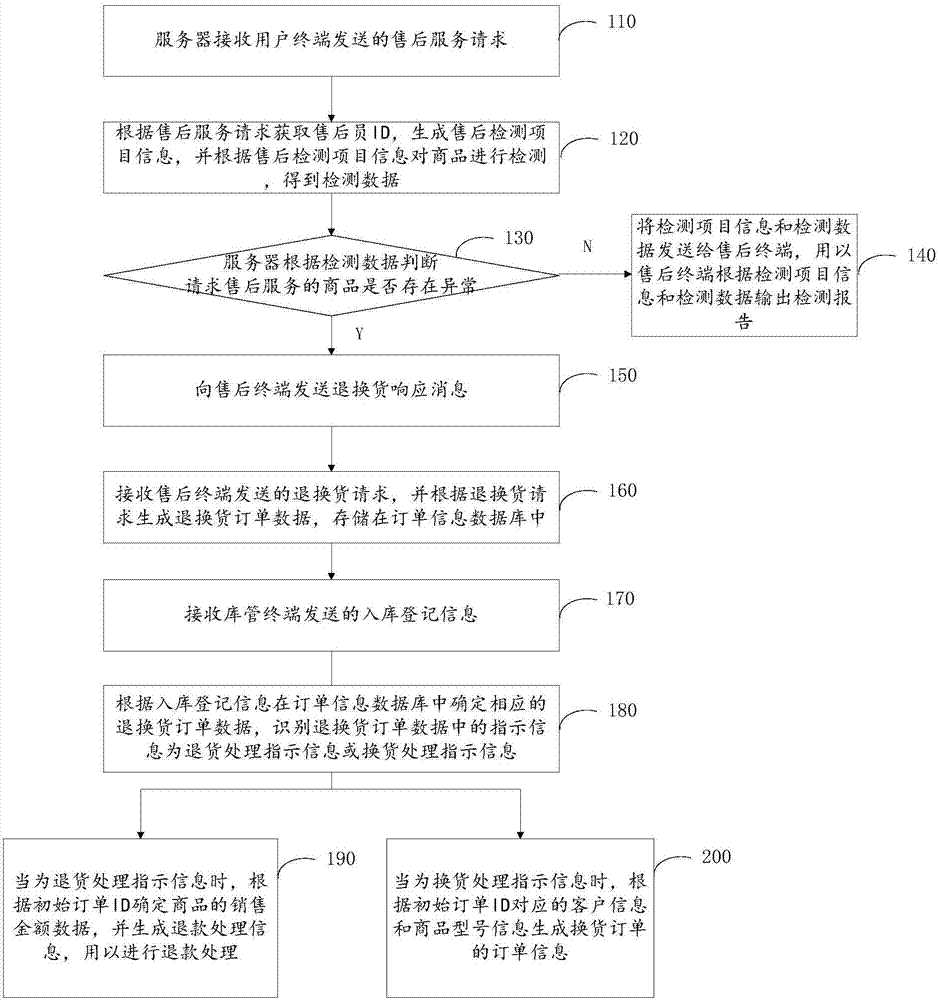

Equipment after-sales information processing method based on serial number

InactiveCN107153966AImprove satisfactionSave labor costBuying/selling/leasing transactionsInformation processingOrder form

The embodiment of the invention relates to an equipment after-sales information processing method based on a serial number, and the method comprises the steps: enabling a server to receive an after-sales service request sent by a user terminal; obtaining an after-sales worker ID according to the after-sales service request, and generating after-sales detection item information; receiving a changing or refunding request sent by an after-sales terminal, generating changing or refunding order data according to the changing or refunding request, and storing the changing or refunding order data in an order information database; receiving warehousing registration information transmitted by a warehouse management terminal; determining corresponding first changing or refunding order data in the order information database according to the warehousing registration information, and recognizing the indication information in the changing or refunding order data as the refunding processing indication information or changing processing indication information; determining the sales amount data of a commodity according to an initial order ID when the indication information is the refunding processing indication information, and generating refunding processing information; and generating the information of a changing order according to the customer information corresponding to the initial order ID and the commodity type information when the indication information is the changing processing indication information.

Owner:UNIVERSAL WISDOM TECH BEIJING CO LTD

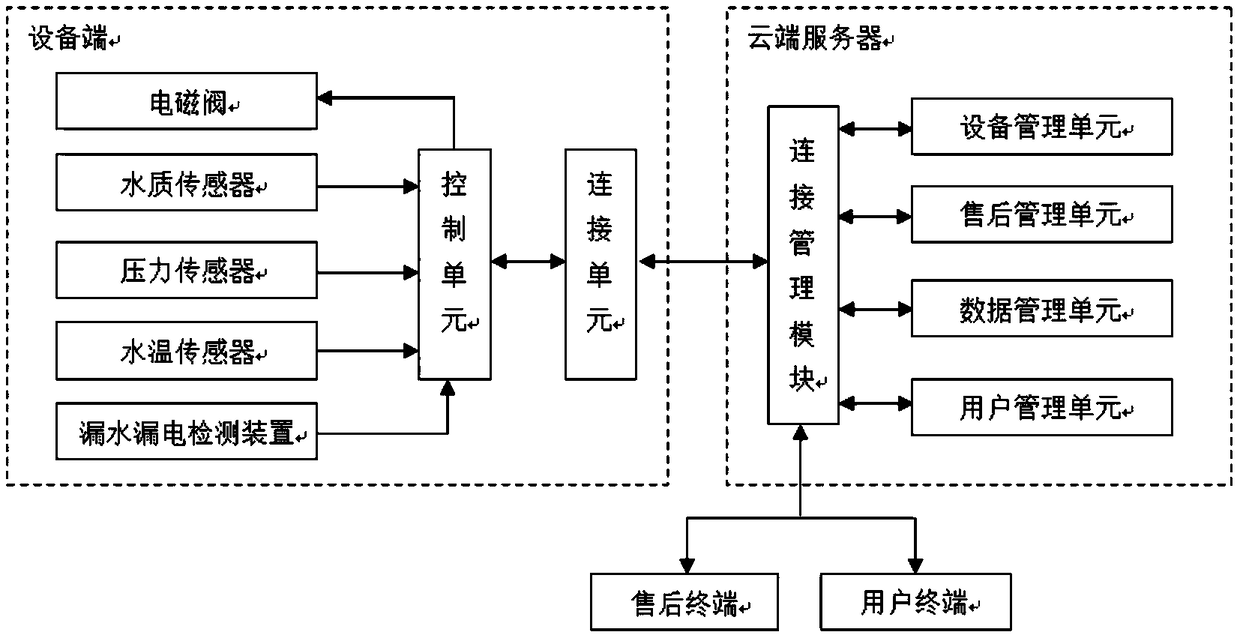

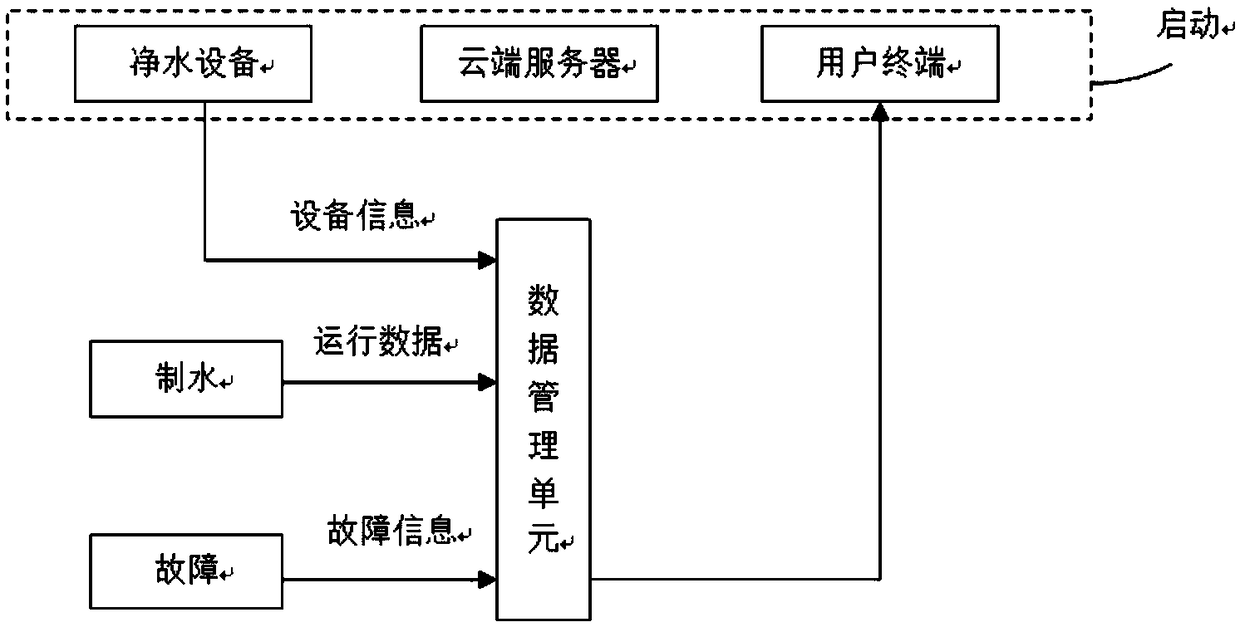

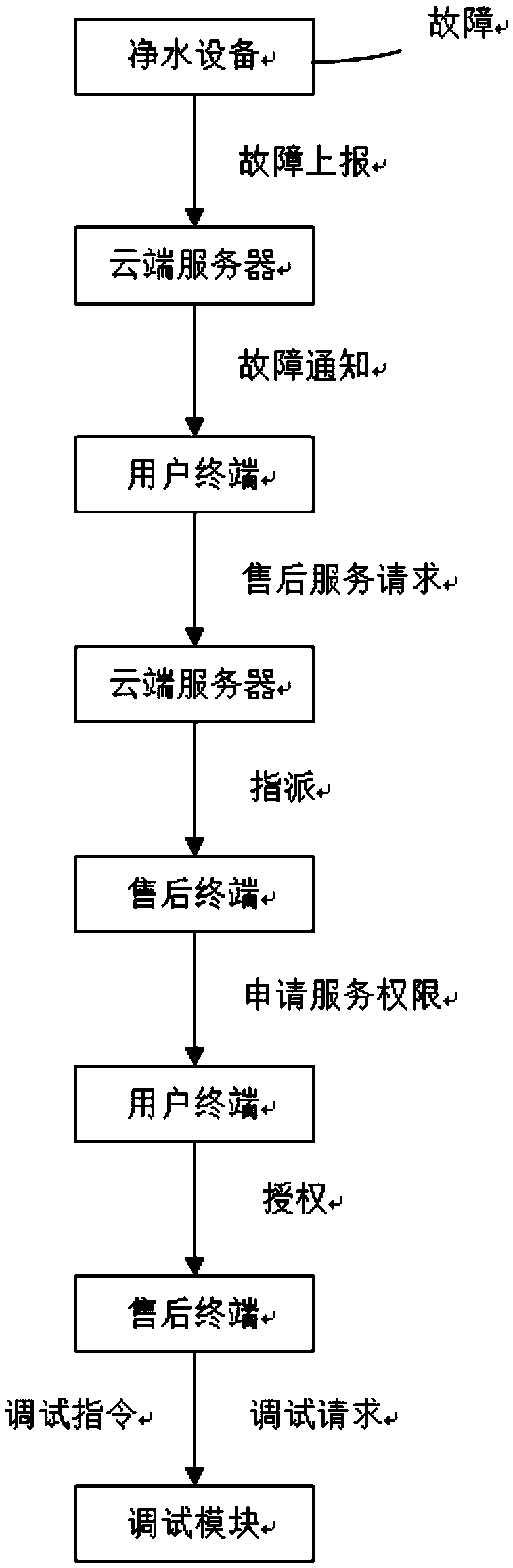

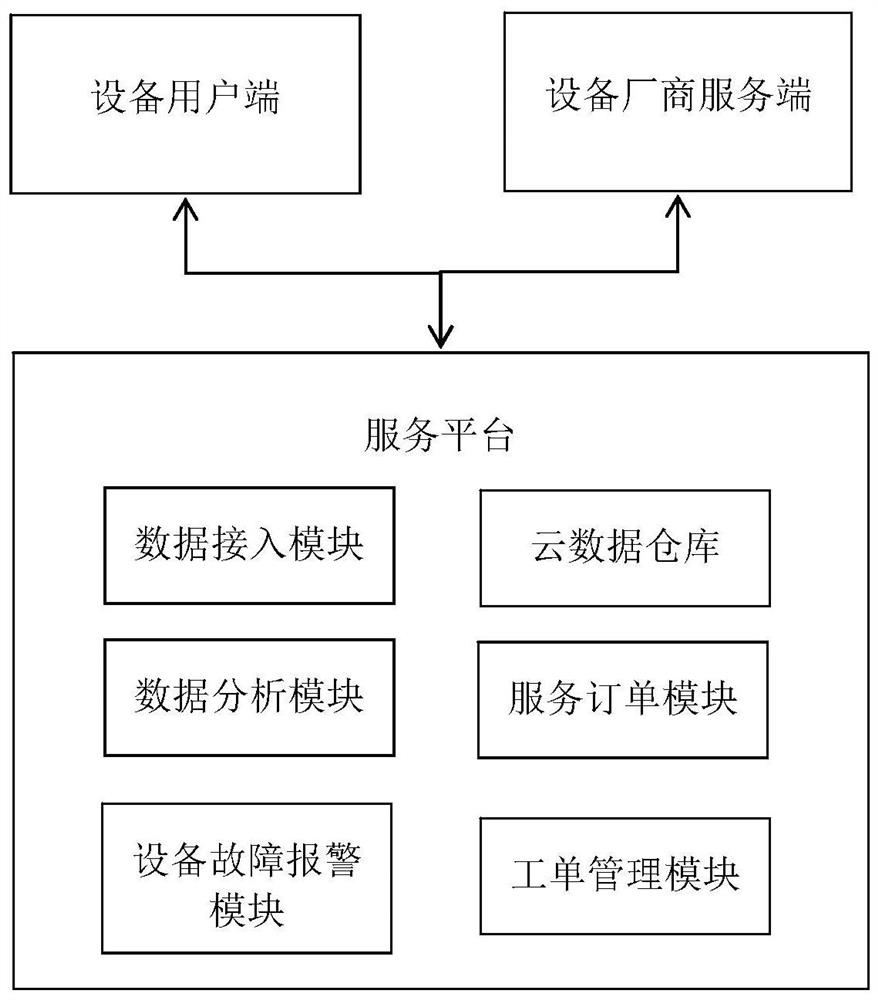

A cloud after-sales service system for water purification equipment

InactiveCN109377245AImprove the efficiency of after-sales serviceLower service costsTreatment involving filtrationCommerceSolenoid valveWater quality

A cloud after-sales service system for water purification equipment includes the equipment end, and the equipment end comprises a water treatment unit, a control unit and a connection unit. The outputend of the control unit is electrically connected with the input end of the solenoid valve through a relay, the out ends of a water quality sensor, a pressure sensor, a water temperature sensor and aleakage detection device are electrically connected with the input end of the control unit, and the connection unit is signally connected to the connection management module. The connection management module is electrically connected with the equipment management unit, the after-sale management unit, the data management unit and the user management unit respectively, and the connection managementmodule, the equipment management unit, the after-sale management unit, the data management unit and the user management unit constitute a cloud server, and the connection management module is connected with the after-sale terminal and the user terminal respectively by signal. The cloud after-sales service system of the invention adopts the mode of remote service, provides timely and efficient service for users, quickly handles faults, improves after-sales service quality, and makes users worry less.

Owner:肖卫方

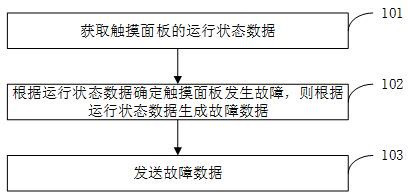

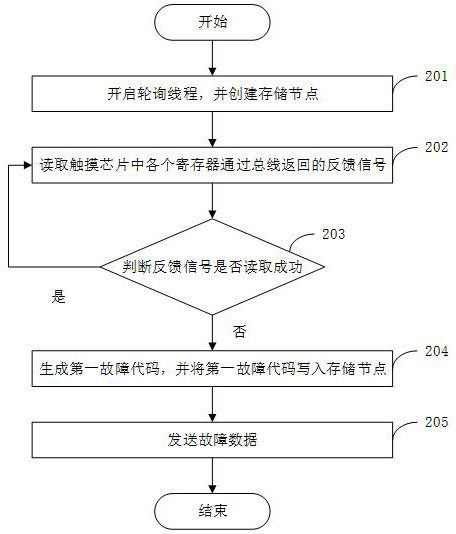

Fault detection method and device

PendingCN112114220AImprove the efficiency of after-sales serviceImprove troubleshooting efficiencyElectronic circuit testingCommerceData packQuality of service

The embodiment of the invention provides a fault detection method, device and system, equipment and a storage medium. The method comprises steps of obtaining operation state data of a touch panel; ifit is determined that the touch panel breaks down according to the operation state data, fault data being generated according to the operation state data, and the fault data comprising fault types; and sending the fault data. The method is advantaged in that troubleshooting efficiency of the touch panel after sale can be improved, the overall period of subsequent troubleshooting is greatly shortened, and then the after-sale service quality and the merchant use experience are effectively improved.

Owner:SHANGHAI SUMI TECH CO LTD +1

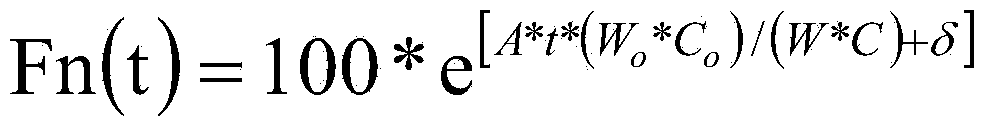

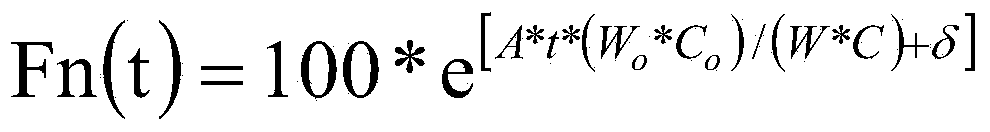

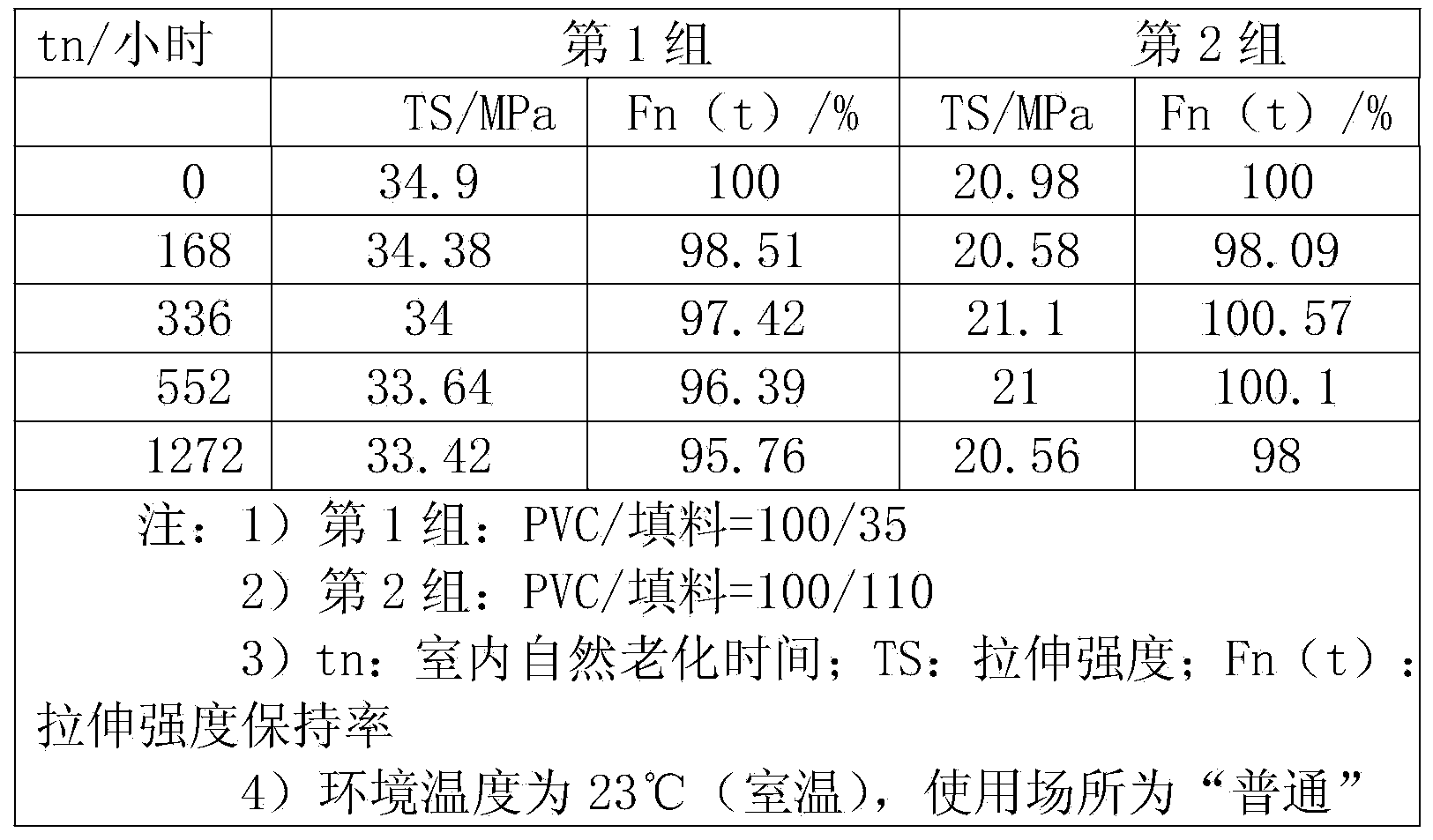

Modeling method of mathematical model used for predicting plastic pipeline aging tendency

InactiveCN104008280ASmall relative errorFor easy referenceSpecial data processing applicationsModel methodMathematical model

The invention relates to the technology of analysis of building plastic pipeline aging performance, and discloses a modeling method of a mathematical model used for predicting a plastic pipeline aging tendency. The tensile strength conservation rate of a plastic pipeline is measured according to the determined temperature impact factor, the place impact factor and the time impact factor, and the index function relation between the tensile strength conservation rate and the temperature impact factor, the place impact factor and the time impact factor can be referred to in the instruction. According to the method, an indoor aging mathematical model formula has a smaller relative error value, the variation tendency of indoor natural aging tensile performance of plastic pipe materials used for buildings can be well fit, and the modeling method provides a good reference basis for predicting the plastic pipeline aging situation.

Owner:ZHEJIANG INST OF QUALITY INSPECTION SCI

Grain after-cloud market service cloud platform and method thereof

PendingCN112734447AImprove the quality of after-sales serviceEffective supervisionDigital data information retrievalCo-operative working arrangementsQuality of serviceData access

The invention discloses a grain after-cloud market service cloud platform and a method thereof; the grain after-cloud market service cloud platform comprises a service platform, an equipment user side and an equipment manufacturer server side, and the equipment user side and the equipment manufacturer server side are both in communication connection with the service platform; the service platform comprises a data access module, a cloud data warehouse, a data analysis module, an equipment fault alarm module, a service order module and a work order management module. And the data analysis module, the equipment fault alarm module, the service order module and the work order management module synchronously send the processed data information to the cloud data warehouse for storage. The after-sales service quality can be improved, and in the whole after-sales service process, a client can track the service process in the whole process according to the equipment number. Manufacturers can also effectively supervise the whole service process, and the whole after-sales service resources are optimized and allocated through the system.

Owner:江苏禾之谷科技发展有限公司

Storage battery information management system

InactiveCN103377418AClear distributionOptimize allocationResourcesCommerceWork distributionCentral database

The invention provides a storage battery information management system which comprises a central database used for storing product information of storage batteries, and an input computer connected with the central database. The product information comprises sales information and after-sale information of the storage batteries. According to the storage battery information management system, the network information is collected, input, and marked, connected and separated on a map, so that the information of the sales network is perfected and channels are distributed clearly. The basis is provided for system and implementation of brand strategies, area distribution of salesmen can be carried out according to the basis, and therefore popularization efficiency is improved. The clear connecting and separating information of the sales network and the sales channels in an area brings convenience to work distribution of the salesmen, and timing and quantitative analysis can be carried out on actual working conditions and workloads of the salesmen so that the salesmen can be assessed and supervised.

Owner:SANBORNS ENERGY TECH HANGZHOU

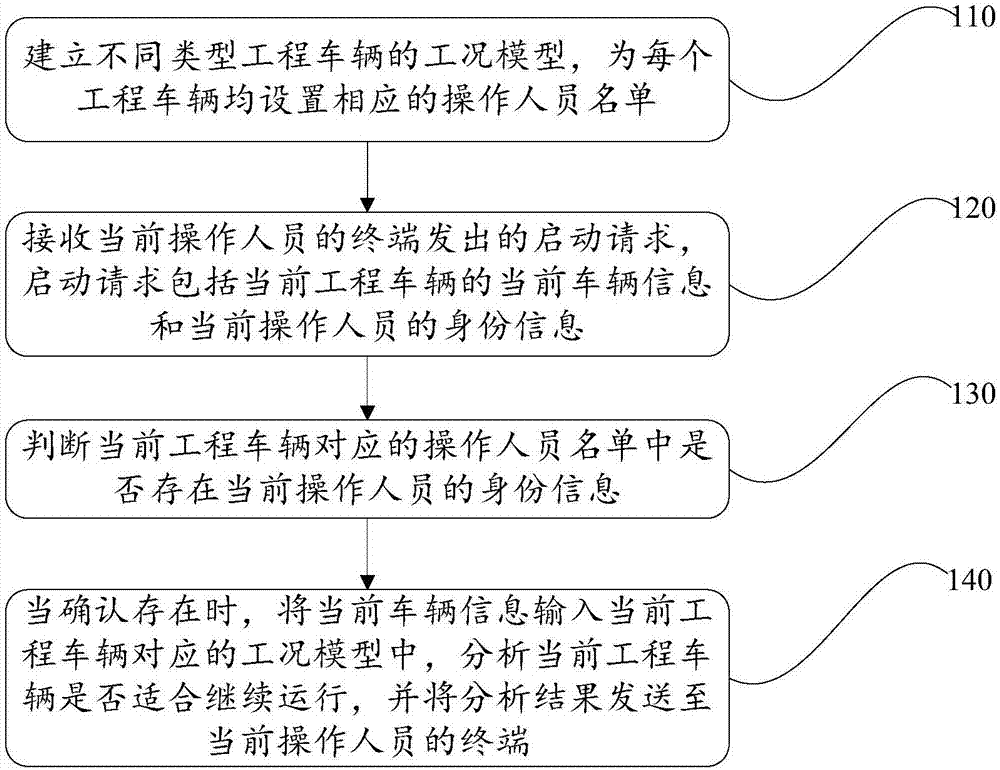

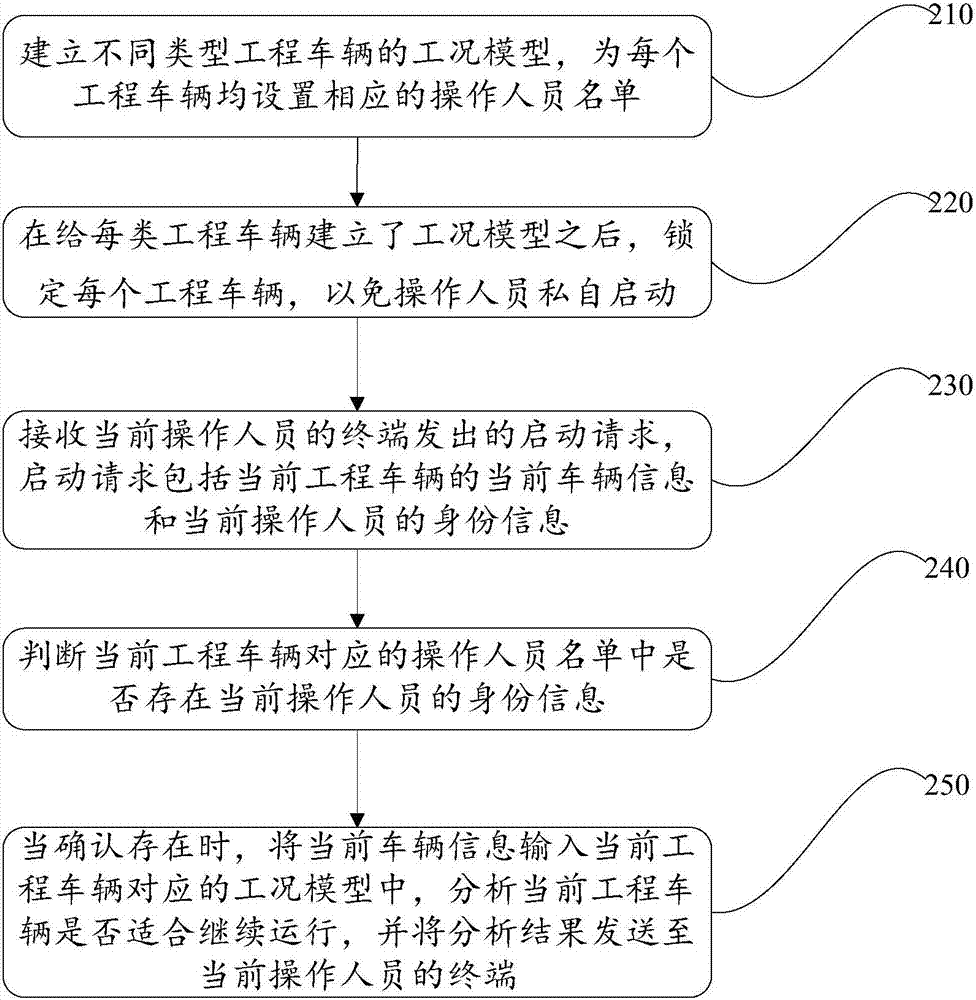

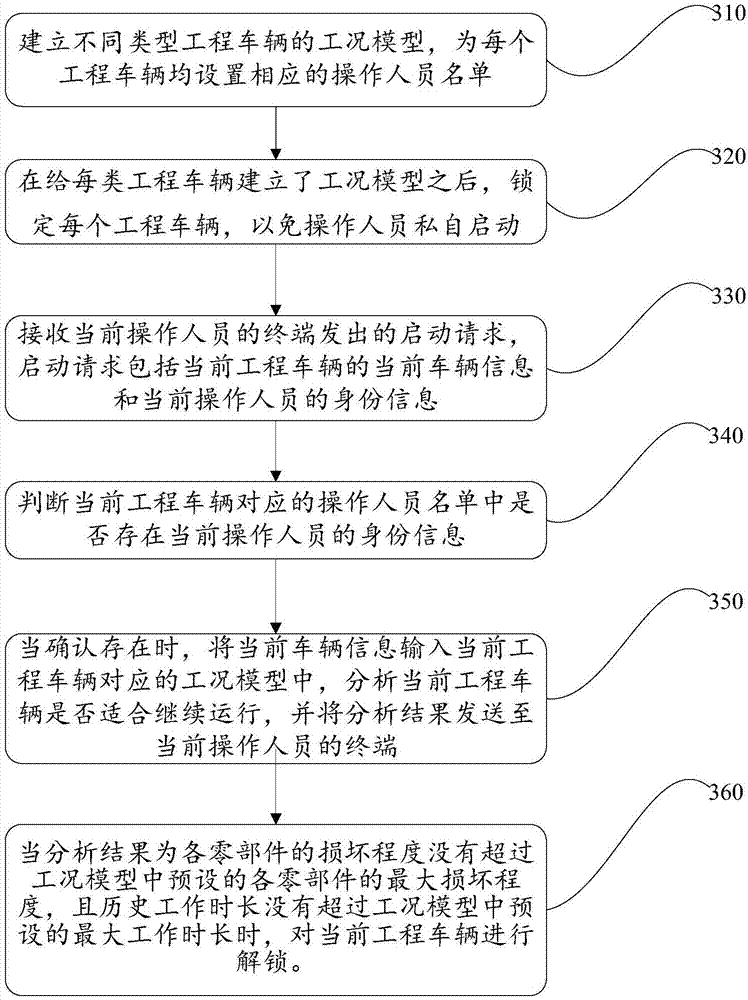

Intelligent comprehensive management method and system for engineering vehicle

InactiveCN107423827AAfter-sales service scienceEfficient after-sales serviceResourcesCommerceEngineeringService mode

The invention provides an intelligent comprehensive management method and a system for an engineering vehicle. The method comprises the steps of establishing working condition models for different types of engineering vehicles, and setting a corresponding operator list for each engineering vehicle; receiving a starting request sent by a terminal of a current operator, wherein the starting request comprises the current vehicle information of a current engineering vehicle and the identity information of the current operator; judging whether the identity information of the current operator exists in an operator list corresponding to the current engineering vehicle or not; if the identity information of the current operator is judged to exist in the operator list corresponding to the current engineering vehicle, inputting the current vehicle information into a working condition model corresponding to the current engineering vehicle, analyzing whether the current engineering vehicle is suitable for continuous operation or not, and sending the analysis result to the terminal of the current operator. According to the method and the system, an engineering vehicle system in a traditional mode is broken through in the brand new manner, so that the after-sales service mode of engineering vehicles can be quickly added into the after-sales service industry of engineering vehicles. The after-sales service quality of engineering vehicles is greatly improved.

Owner:SHENZHEN SHENGLU IOT COMM TECH CO LTD

Remote fault processing method for intelligent air conditioner

ActiveCN103062862BImprove the quality of after-sales serviceLower service costsSpace heating and ventilation safety systemsLighting and heating apparatusComputer moduleFault analysis

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Packaging box bulk transport remote network service system

InactiveCN105892415ASolve labor costsReduce maintenance costsTotal factory controlProgramme total factory controlWireless routerQuality of service

The invention discloses a packaging box bulk transport remote network service system. The packaging box bulk transport remote network service system includes a 3G wireless router, a VIPA 314ST type PLC, an industrial personal computer, a Cisco 3925 type switch, a telecommunication optic fiber network platform and a power source output module, wherein the industrial personal computer is connected with the Cisco 3925 type switch, the 3G wireless router and the VIPA 314ST type PLC through an Ethernet. With the packaging box bulk transport remote network service system of the invention adopted, the problem of high labor cost and maintenance cost caused by manual on-site maintenance can be solved, labor force can be saved, work efficiency can be improved, and the quality of after-sales services of equipment can be improved.

Owner:HUANGSHI LANSHU TECH & TRADE

Intelligent self-checking method for air conditioner

ActiveCN102759176BGuarantee factory qualityNovel methodSpace heating and ventilation safety systemsLighting and heating apparatusLED lampSelf checking

The invention provides an intelligent self-checking method for an air conditioner. Firstly, under the condition that the air conditioner is electrified, a self-checking key is pressed down to enable the air conditioner to enter a self-checking mode, a buzzer sounds to confirm that the self-checking is started at the moment, each load begins to act, and according to software functional setting, the air conditioner outputs all of load information, including a display screen, a fan, a pressing machine, a fan, temperature signals and the like, in a sequence at intervals; and when the air conditioner quits the self-checking mode, all of input / output feedback information is collected, and if a fault appears, the air conditioner represents the fault in the form of the combination of a fault code and a buzzing alarm, and displays through an LED lamp and the fault code, so that a worker can rapidly find out the fault root according to the self-checking fault indication code and remove the fault to enable the air conditioner to return to the normal running state.

Owner:广东志高精密机械有限公司

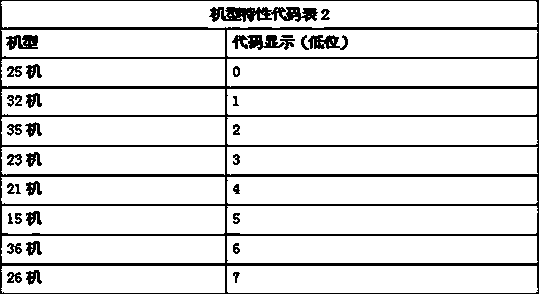

Intelligent remote assistance service system for mining truck

InactiveCN110874653AImprove the quality of after-sales serviceRealize interconnectionTransmissionInstrumentsTruckComputer science

The invention discloses an intelligent remote assistance service system for a mining truck. The system comprises a manufacturer service terminal, a mining truck terminal and a technician terminal, themanufacturer service terminal, the mining truck terminal and the technician terminal are interconnected through a network, and the mining truck terminal comprises a voice intercom system, a maintenance countdown system, a fault detection system and a warning and reminding system. In the intelligent remote assistance service system for a mining truck, interconnection and intercommunication among the mining truck terminal, the technician terminal and the manufacturer service terminal can be realized. A user of the mining truck can demand services of technicians and manufacturers in real time through the mining truck terminal; a manufacturer can monitor the maintenance and fault conditions of all sold mining trucks in real time, technicians can obtain related tasks in real time and deploy accessories, the after-sales service quality of the mining trucks is greatly improved, and large economic losses cannot be caused to using units and the manufacturer.

Owner:徐州筑之邦工程机械有限公司

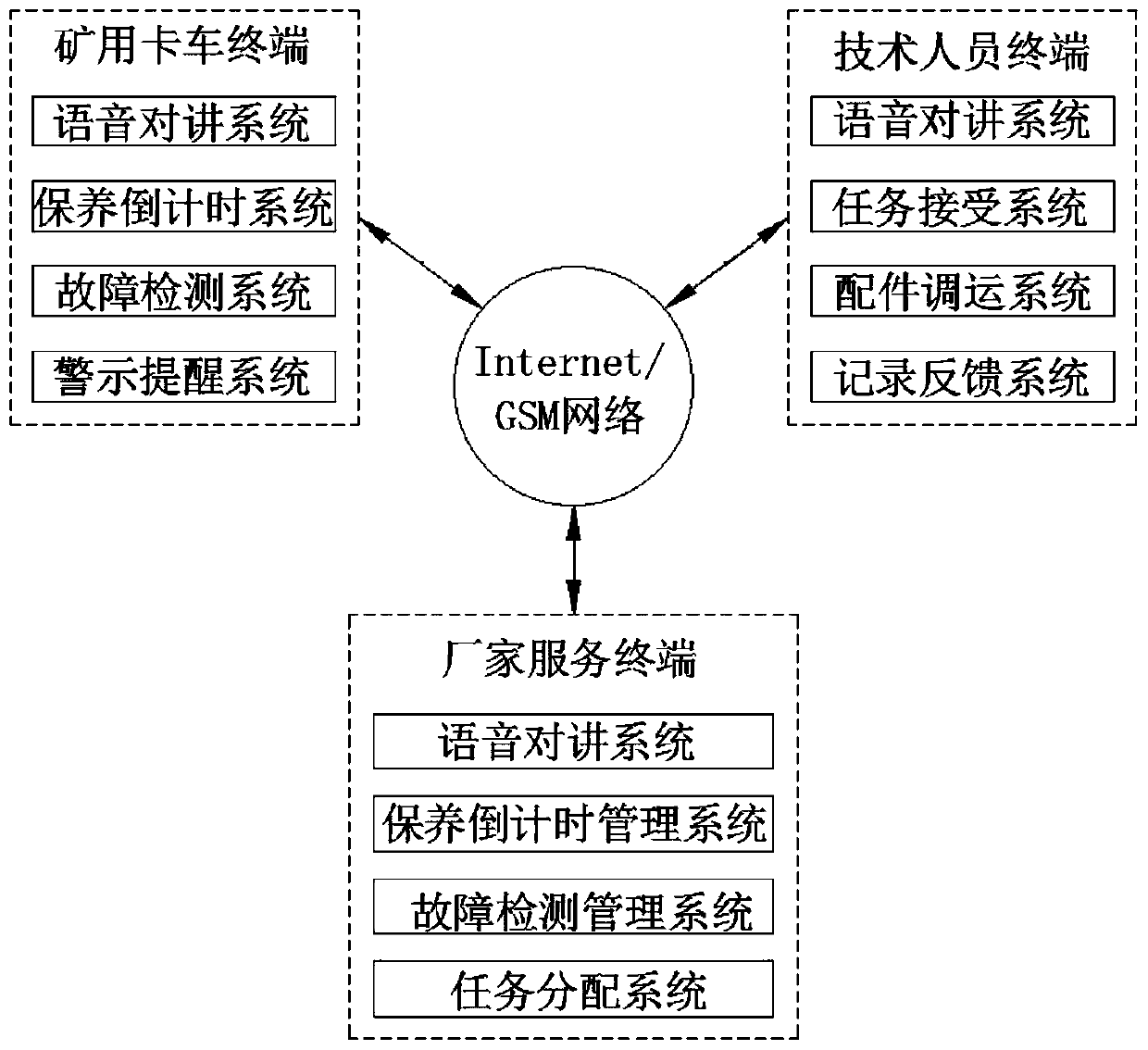

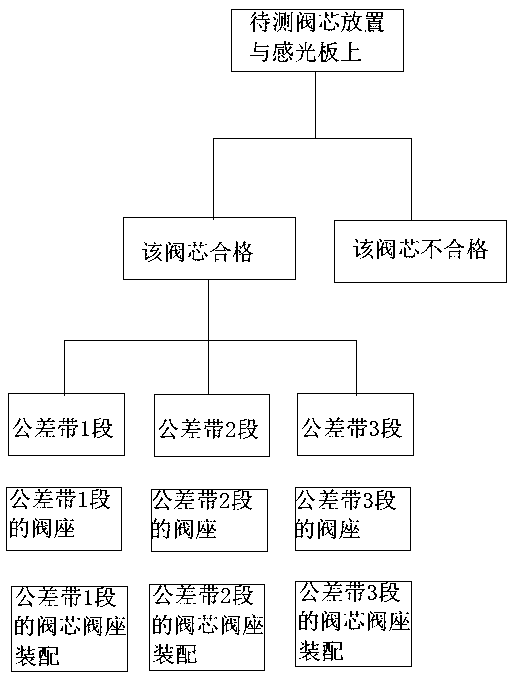

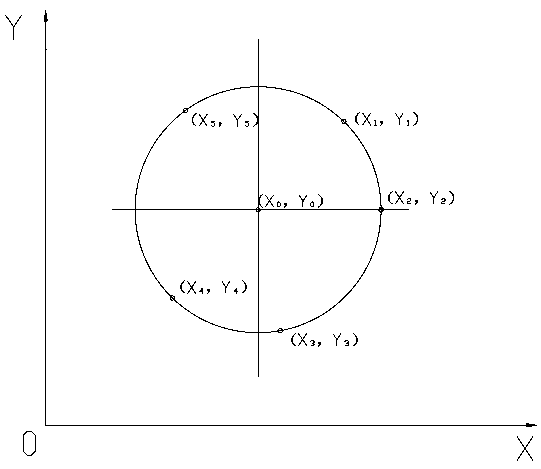

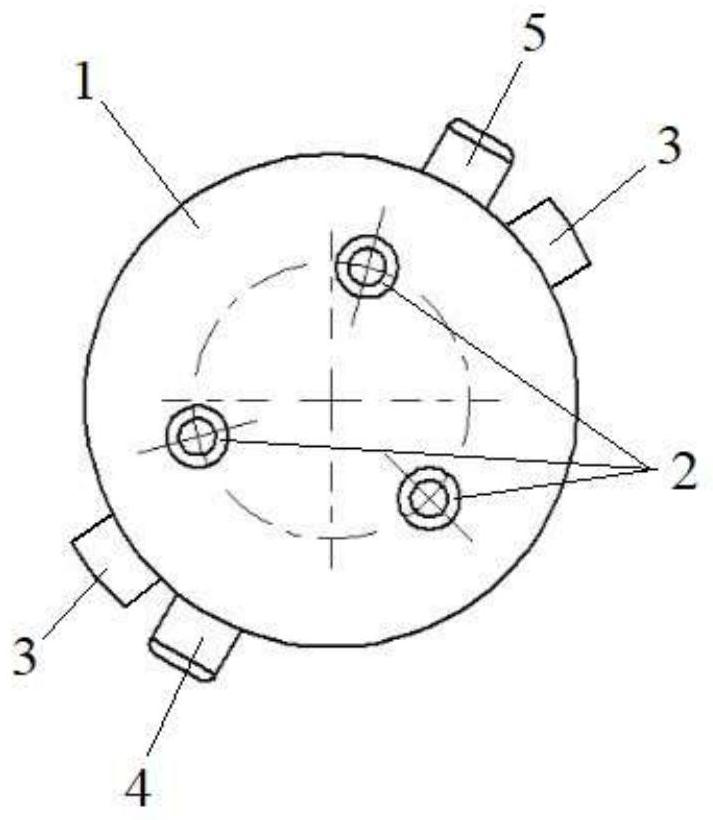

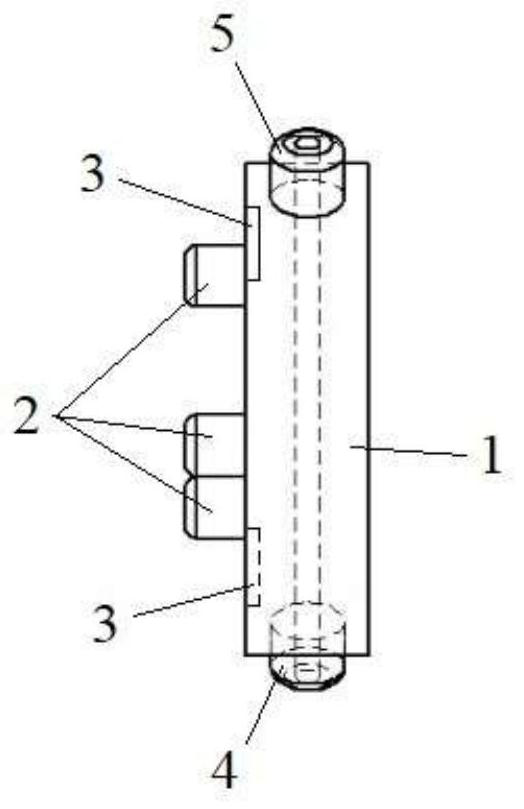

A sorting device and sorting method for segmentally assembled valve core and valve seat

The invention discloses a sorting device and a sorting method for segmentally assembling valve cores and seats, relates to the field of quality inspection, and solves the problem of low assembly precision of valve cores and seats, which includes a photosensitive device, a light source device, and a sorting mechanism And a control computing system connected with the above three devices, the light source device is arranged directly above the center of the photosensitive device, and the sorting mechanism includes a lifting universal joint that can rotate 360 degrees and is arranged at the center of the photosensitive device , the photosensitive device is provided with a feeding channel for transporting the spool to be sorted to the sorting mechanism and several sorting channels corresponding to each tolerance section, and the feeding channel and the sorting channel are both connected to the The center of the photosensitive device is connected. The invention has the advantages of sorting the valve core and the valve seat with the closest size to the same section, allowing the valve core and valve seat to achieve the maximum utilization rate, and improving the qualified rate of assembly.

Owner:WENZHOU UNIVERSITY

Metering pump head capable of being mounted and dismounted quickly

PendingCN113090488ASimple structureEasy to usePump testingPositive displacement pump componentsControl engineeringPump head

The invention discloses a metering pump head capable of being mounted and dismounted quickly. The metering pump head capable of being mounted and dismounted quickly comprises a pump head body, wherein the pump head body is used for being mounted on a metering pump body, a fixing column and a clamping piece are arranged on the pump head body, a positioning groove and a clamping groove are formed in the metering pump body, the fixing column is used for being matched with the positioning groove, and the pump head body and the metering pump body can rotate relatively after matching, so that a clamping sheet is clamped into the clamping groove. According to the metering pump head capable of being mounted and dismounted quickly, the pump head body and the metering pump body are limited in one direction through knob type embedded matching of the fixing column and the positioning groove, and the pump head body and the metering pump body are limited in the other direction through buckling type matching of the clamping sheet and the clamping groove; the pump head body can be simply and quickly dismounted and mounted, time-consuming and labor-consuming bolt dismounting is not needed, after-sales service time can be greatly shortened, after-sales service quality is improved, and the metering pump head is simple in structure, convenient to use and good in effect.

Owner:四川卓滤环保技术有限公司

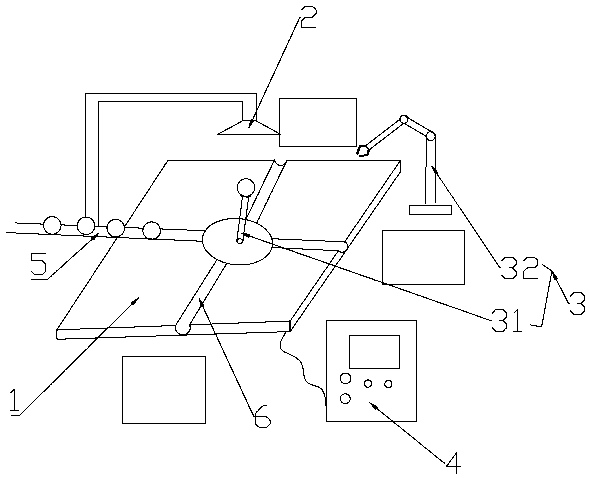

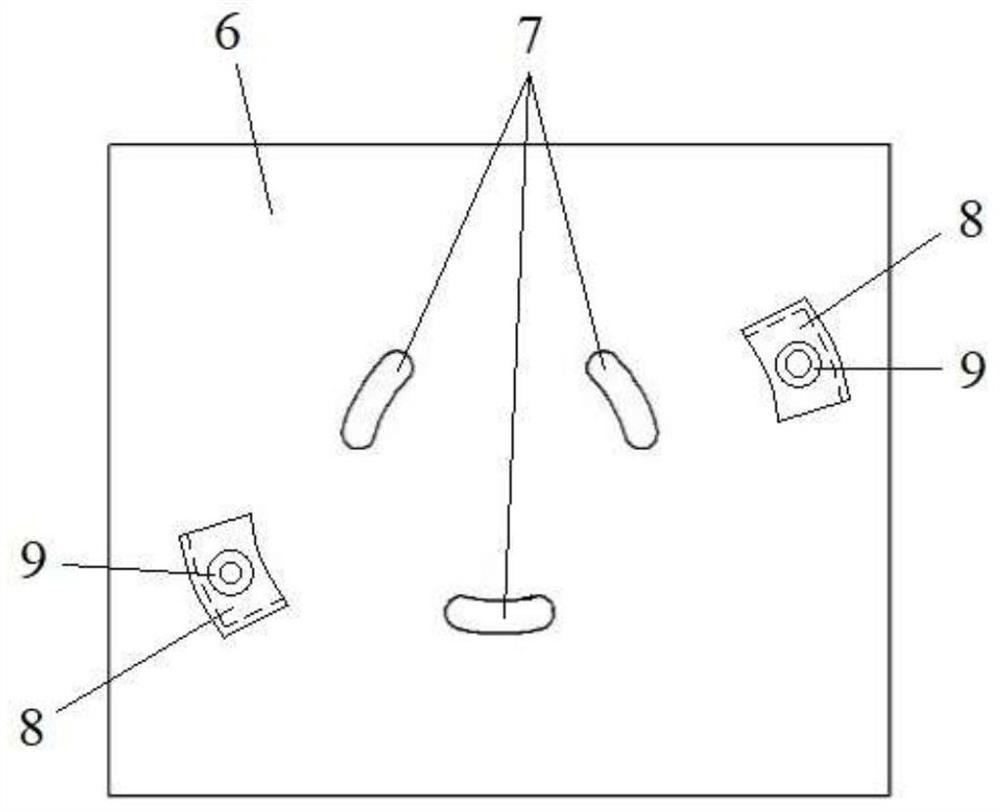

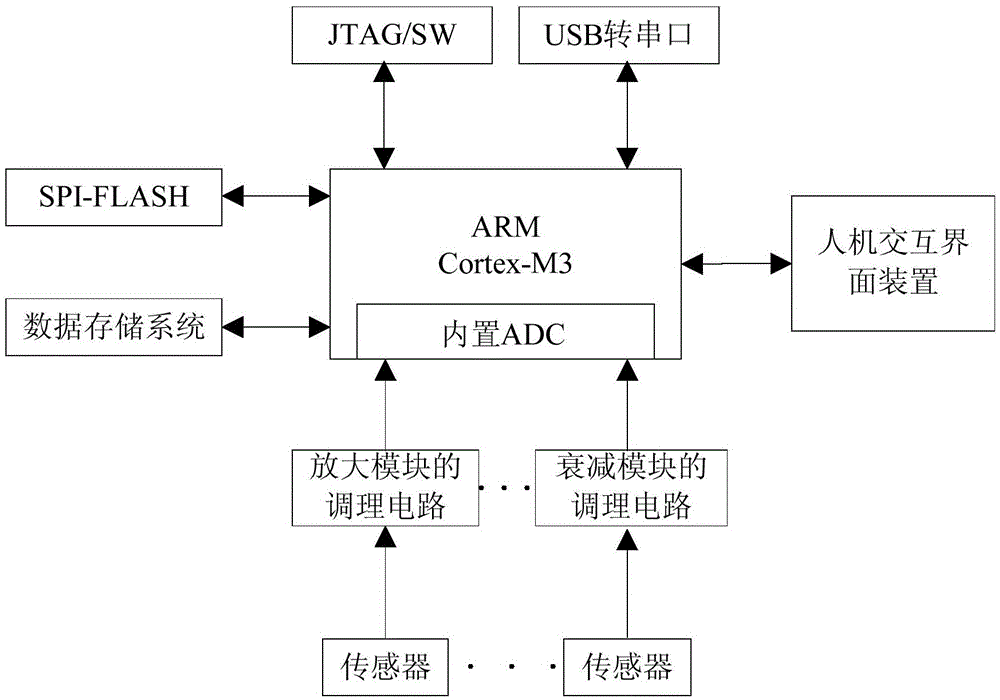

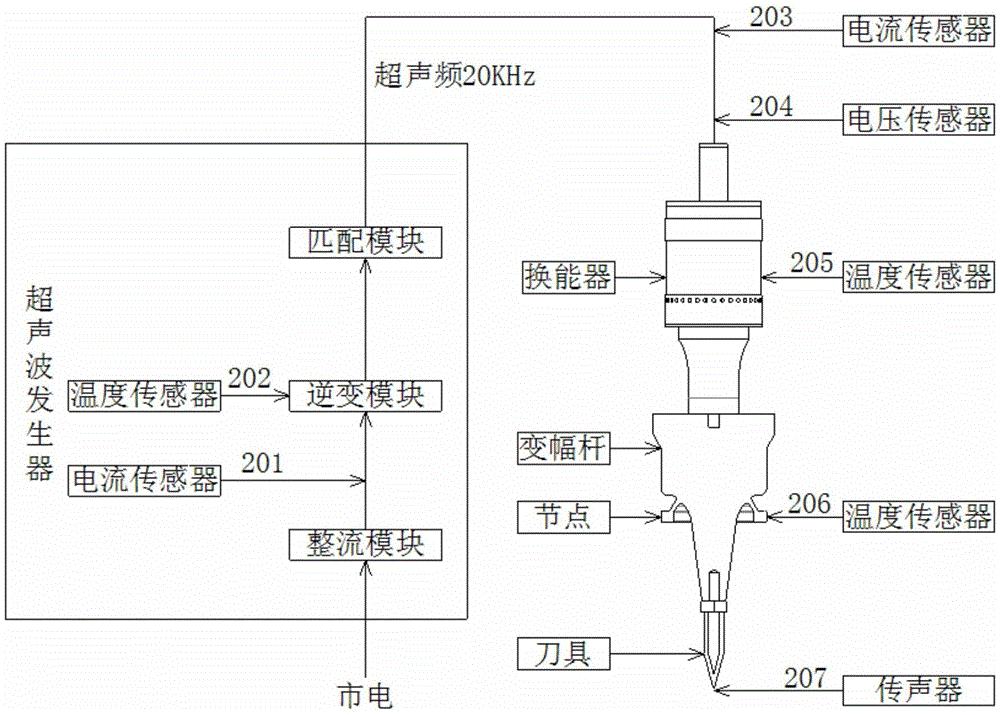

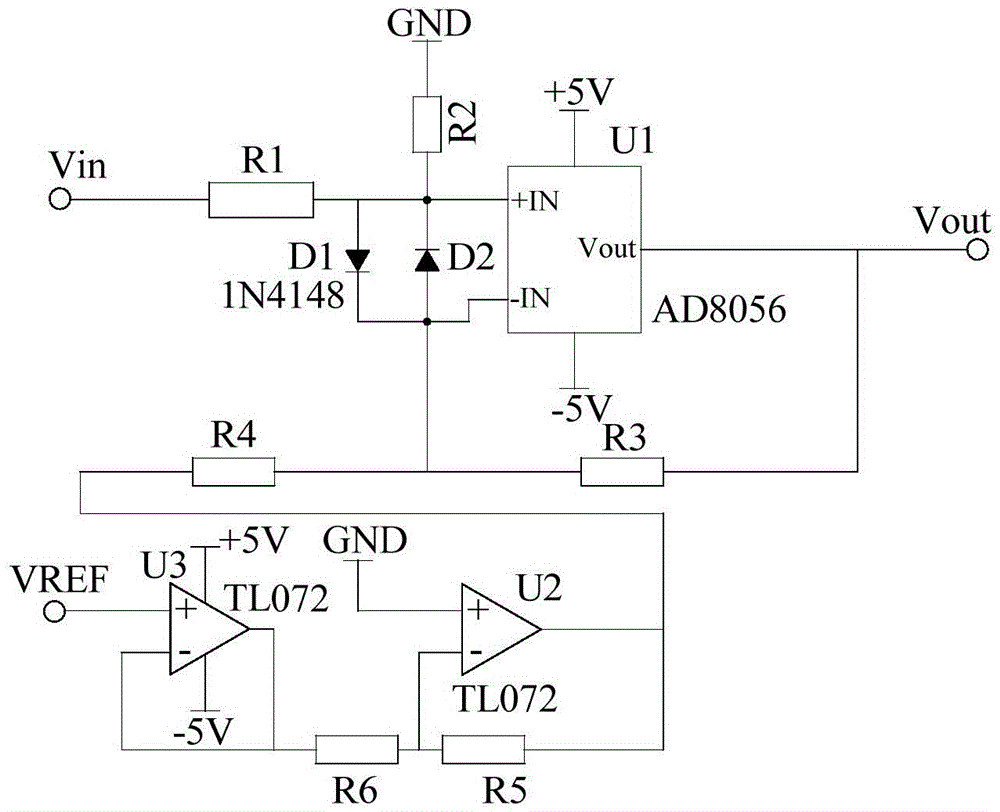

A state monitoring system and method for ultrasonic cutting acoustic spindle

InactiveCN103760819BMonitoring Common Fault ParametersSuppress interferenceProgramme controlComputer controlSonificationInteraction interface

The invention discloses a system and method for monitoring an ultrasonic cutting sound main shaft state. The system comprises a main control MCU, a human-computer interaction interface device, a data collection system and a data storage system. The output interface of a sensor is connected with the input interface of a conditioning circuit through Dupont lines, the output interface of the conditioning circuit is connected with a GPIO port of a built-in ADC of the main control MCU, the human-computer interaction interface device is connected with the main control MCU through a 16-bit 8080 bus, and the data storage system is connected with the main control MCU through an SPI bus. A USB port is formed in the main control MCU for power supply, a 2MSPI-FLASH is arranged for storing a font library, and a JTAG / SW port is formed for downloading data collection programs. When all fault parameters of the system in a processing process exceed a working tolerance range, sound-light alarm prompts are given out, the reliability and safety of processing are improved, enterprise competitiveness is enhanced, and the system and method for monitoring the ultrasonic cutting sound main shaft state are more suitable for engineering practical application.

Owner:HANGZHOU DIANZI UNIV

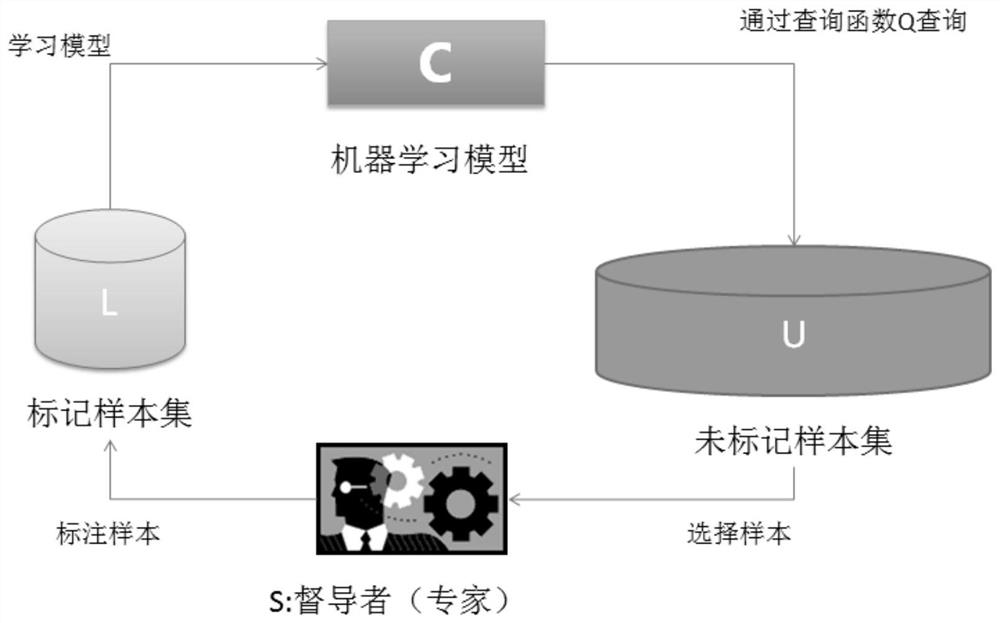

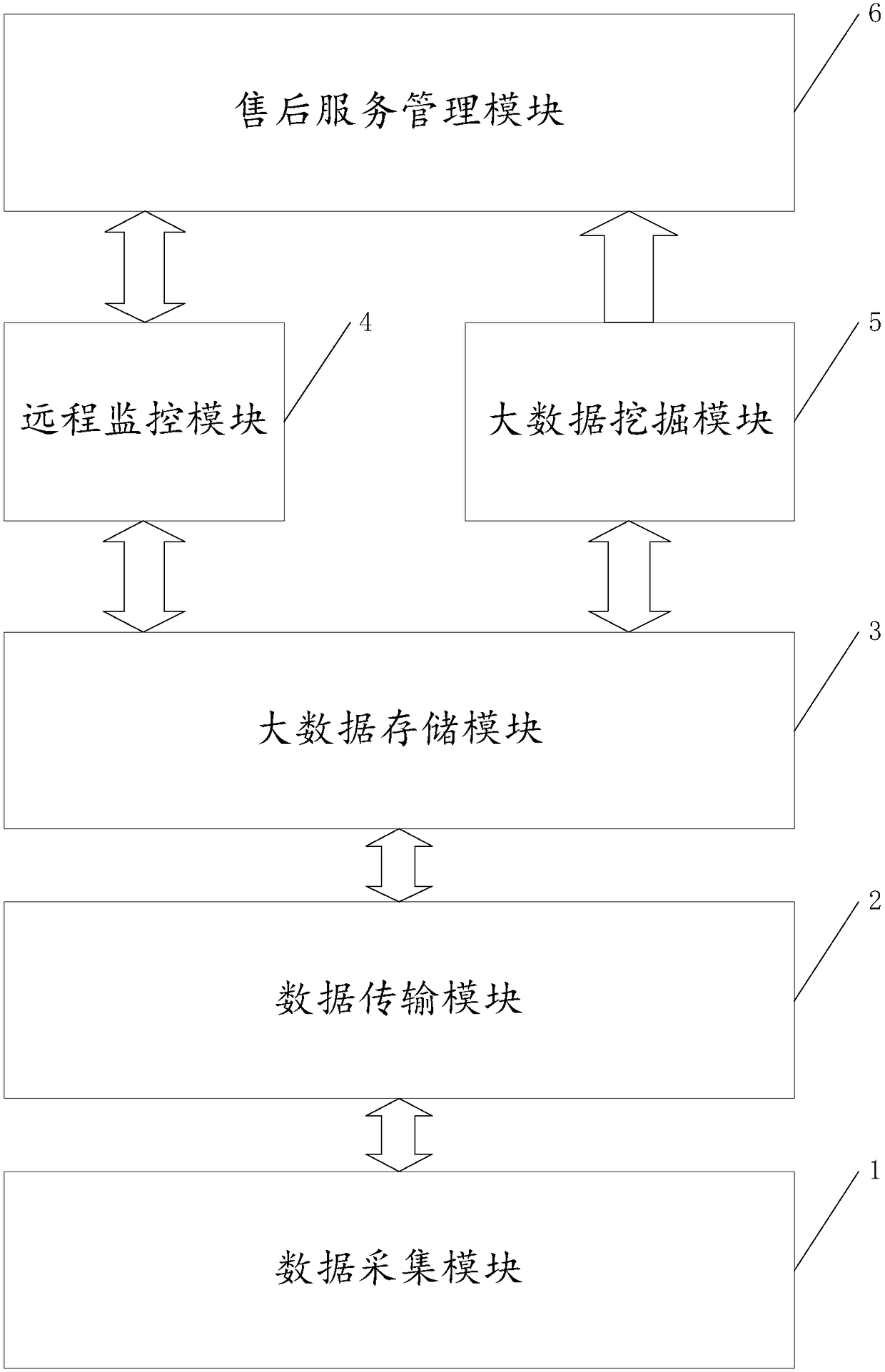

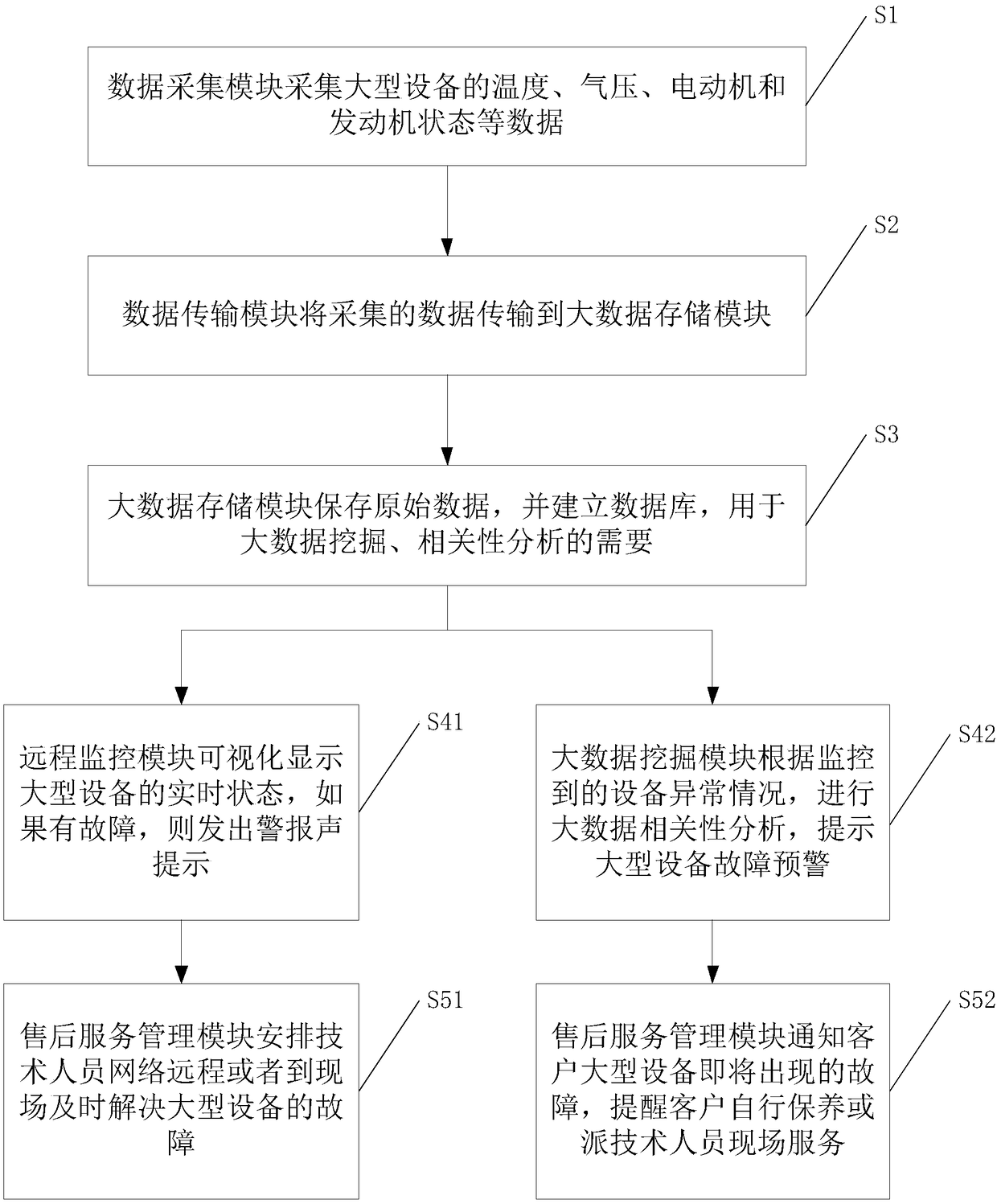

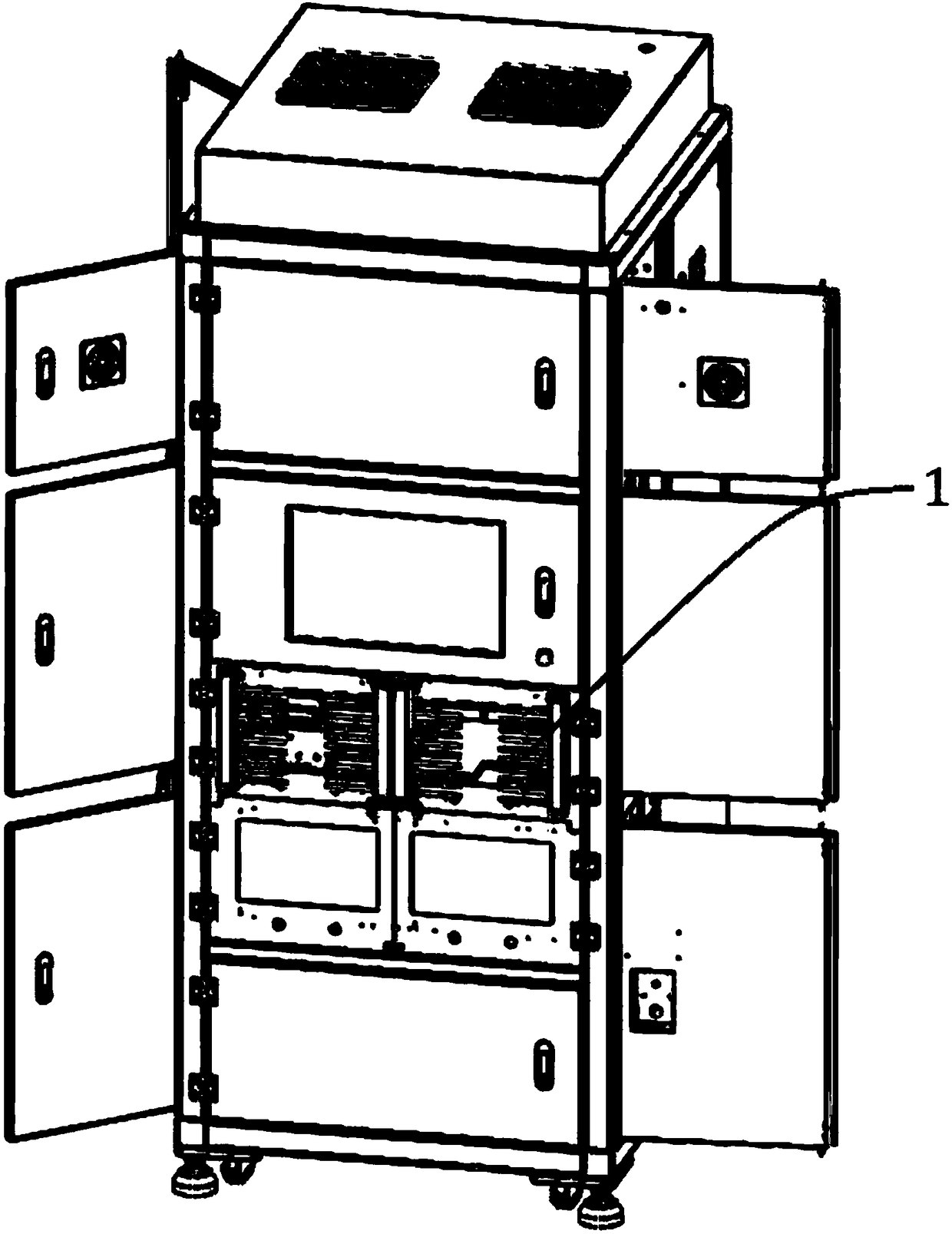

Active after-sale service system for large-scale equipment based on big data mining

PendingCN109459942AImprove the quality of after-sales serviceProgramme control in sequence/logic controllersData acquisitionData visualization

The invention discloses an active after-sale service system for large-scale equipment based on big data mining, which comprises a data acquisition module, a data transmission module, a big data storage module, a remote monitoring module, a big data mining module and an after-sale service management module. The data acquisition module is used for acquiring data of the large-scale equipment; the data transmission module transmits the data acquired by the data acquisition module to the big data storage module; the big data storage module stores the data; the remote monitoring module is communicated with the big data storage module, and visually displays the state of the large-scale equipment according to the data, and gives an alarm prompt to the fault which already occurs; the big data mining module analyzes the data so as to carry out fault early warning on the fault to be generated; the after-sale service management module arranges remote or on-site services for failures that already occur and prompts users of the large-scale equipment to maintain or arrange on-site services on their own for failures to be generated. Early warning can be analyzed and faults can be quickly solved.

Owner:SHENZHEN CIMC SECURITY & SMART TECH

Vehicle-machine universal unique identification code conversion method

ActiveCN104376351BConvenient query and trackingConvenient after-sales serviceRecord carriers used with machinesSensing by electromagnetic radiationProgramming languageUniversally unique identifier

The invention relates to a method for converting a vehicle-machine universal unique identification code, comprising the following steps: reading the universal unique identification code; converting the universal unique identification code into an EAN‑13 barcode. Implement the universal unique identification code conversion method of the present invention, by converting the complex universal unique identification code into an easily identifiable EAN-13 barcode. Users can determine whether the car is a counterfeit product through the EAN-13 barcode engraved on the car. In addition, the reverse deduced information based on the EAN-13 barcode can also provide users with good query tracking and after-sales service, and improve the quality of after-sales service of the product.

Owner:SHENZHEN ZHONGHONG TECH

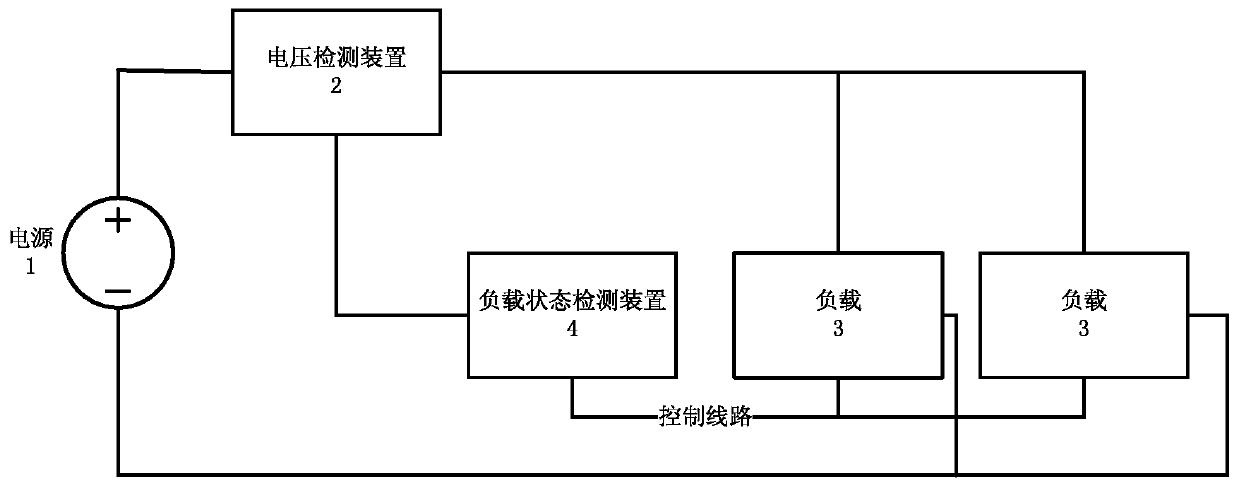

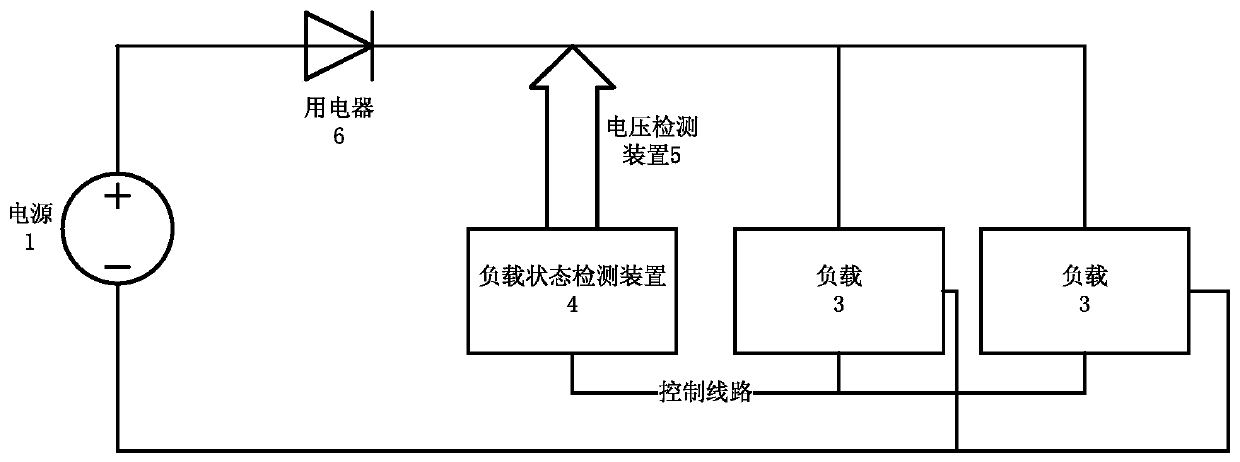

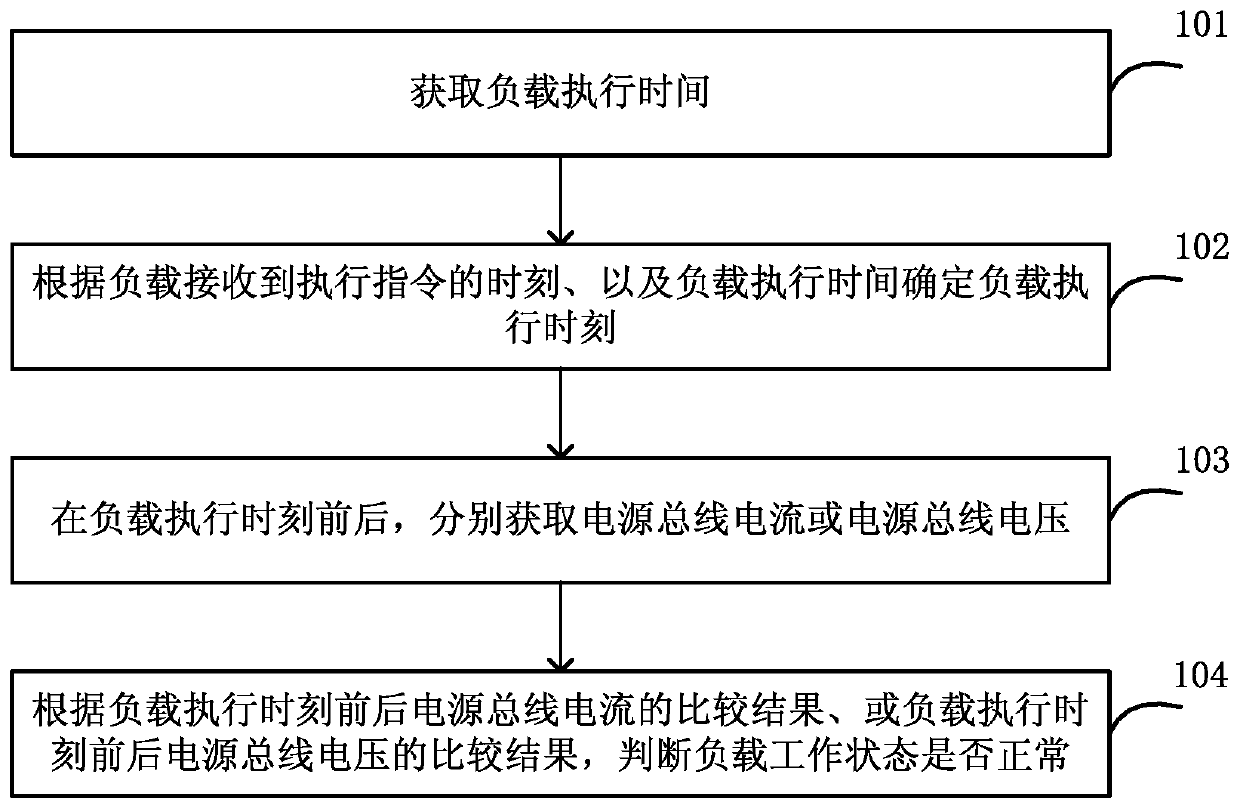

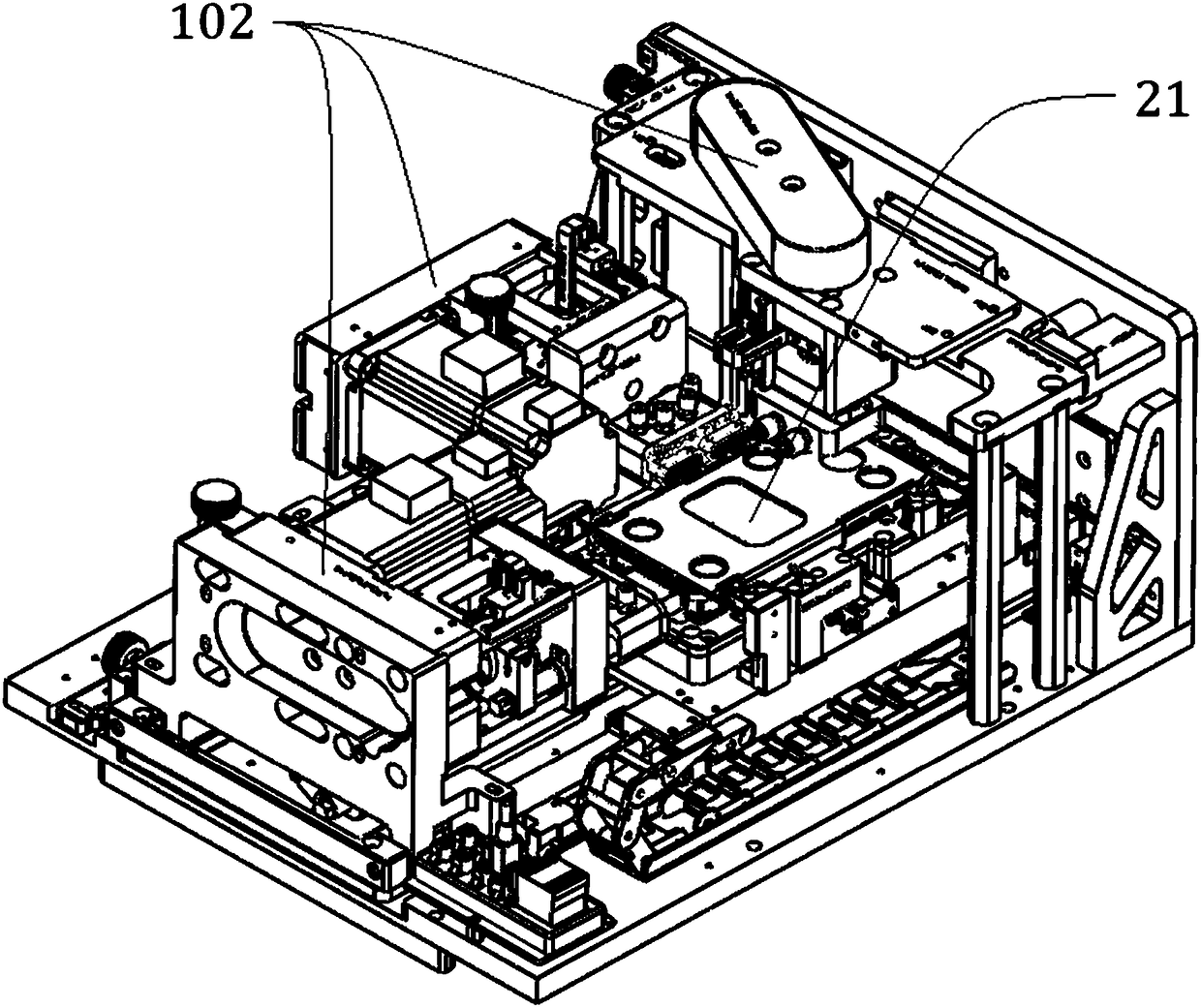

Load state detection method, device and circuit, air conditioner controller

ActiveCN108332353BAccurately locate faultsSave manpower and material resourcesMechanical apparatusSpace heating and ventilation safety systemsParallel computingBus voltage

A load state detection method, device and circuit, and an air conditioner controller. The method comprises: acquiring a load execution time (101); determining a load execution moment according to a moment when a load receives an execution instruction and the load execution time (102); respectively acquiring a power supply bus current or a power supply bus voltage both before and after the load execution moment (103); and according to a comparison result of the power supply bus current before and after the load execution moment or a comparison result of the power supply bus voltage before and after the load execution moment, determining whether the working state of the load is normal (104). When a fault occurs in an air conditioner controller device, the fault can be quickly and accurately located.

Owner:GREE ELECTRIC APPLIANCES INC

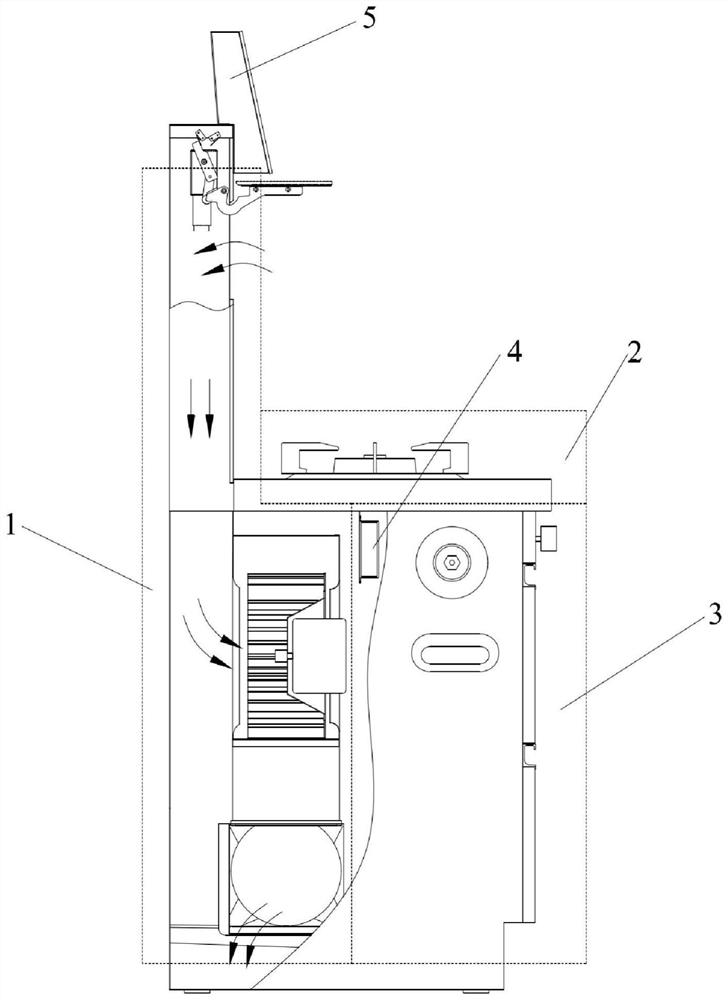

A remote-controlled integrated cooker and a fault diagnosis method for the integrated cooker

ActiveCN109725623BRealize self-diagnosisAvoid inconvenienceElectric testing/monitoringServerOperations management

The invention relates to a remote-controlled integrated stove and a fault diagnosis method for the integrated stove, belonging to the technical field of integrated stoves. The remote-controlled integrated stove includes an information collection component connected to a host, and the information collection component communicates with a server. Each host of the integrated stove is connected to the information collection component, so that the information collection component can collect the status of each host of the integrated stove in real time. When each host of the integrated stove fails, the information collection component sends the fault information to the server. The server understands the fault information in real time, and by sending repair instructions to the server, the after-sales personnel can get the fault information at the first time and contact the user for on-site maintenance, so as to realize the self-diagnosis of the integrated stove and reduce the fault from discovery to on-site diagnosis by after-sales service personnel , Troubleshooting time, avoiding the inconvenience caused by the fault of the integrated stove to the user, and improving the quality of after-sales service.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD

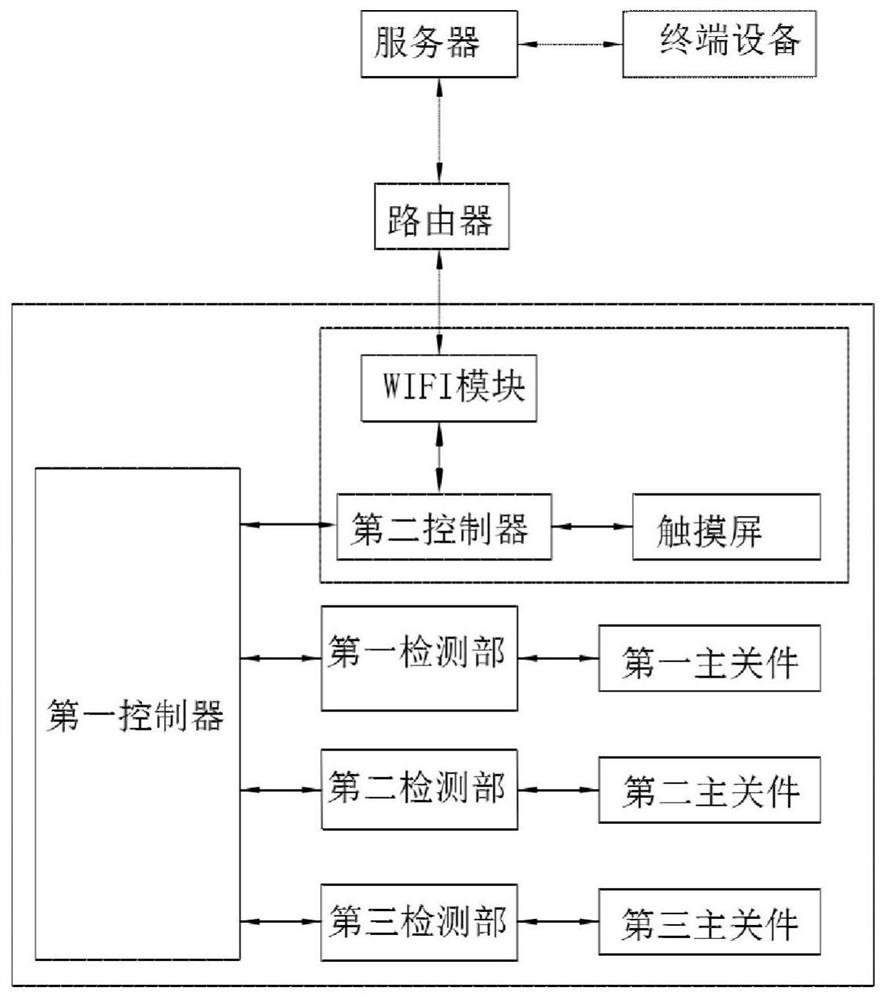

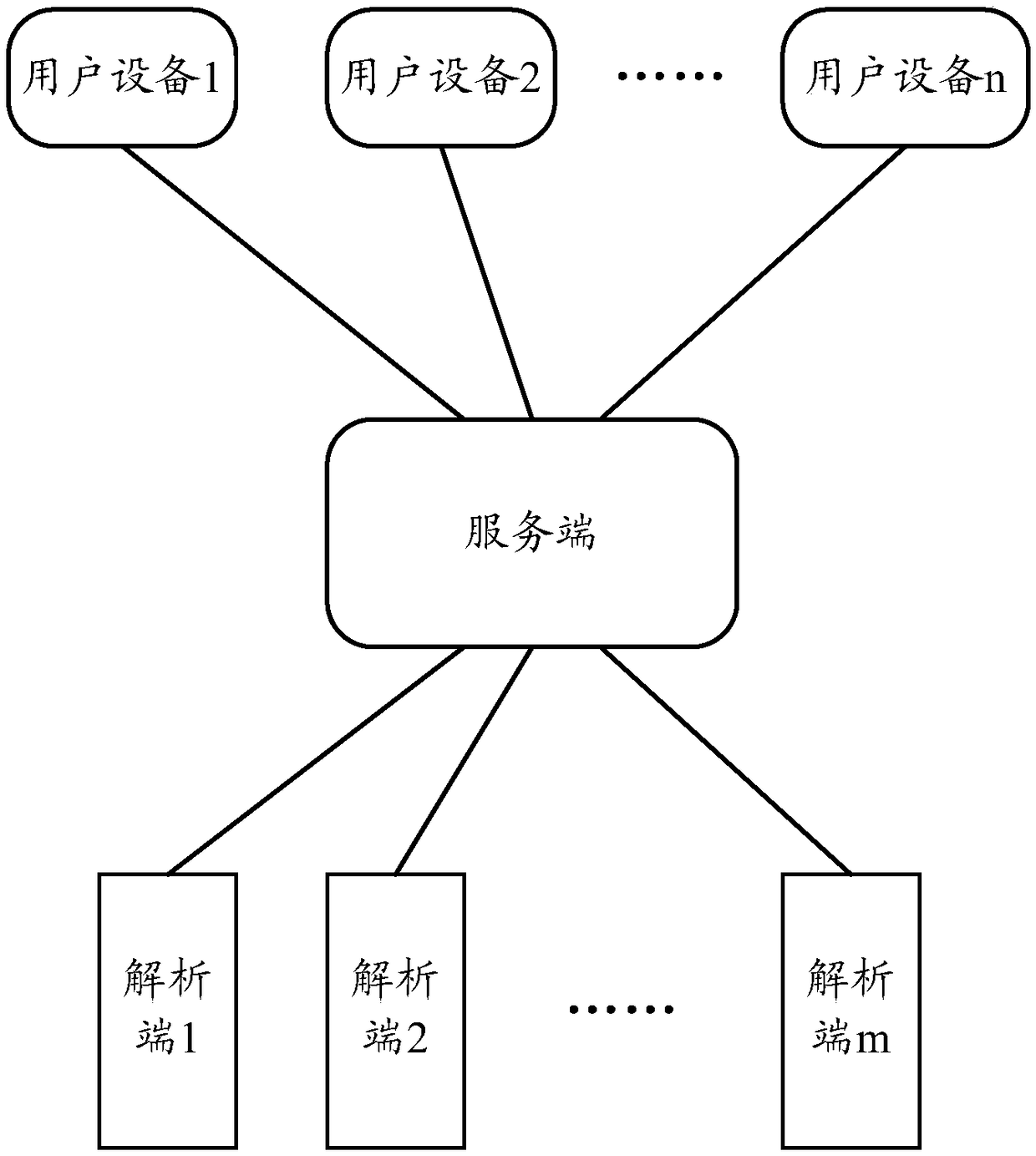

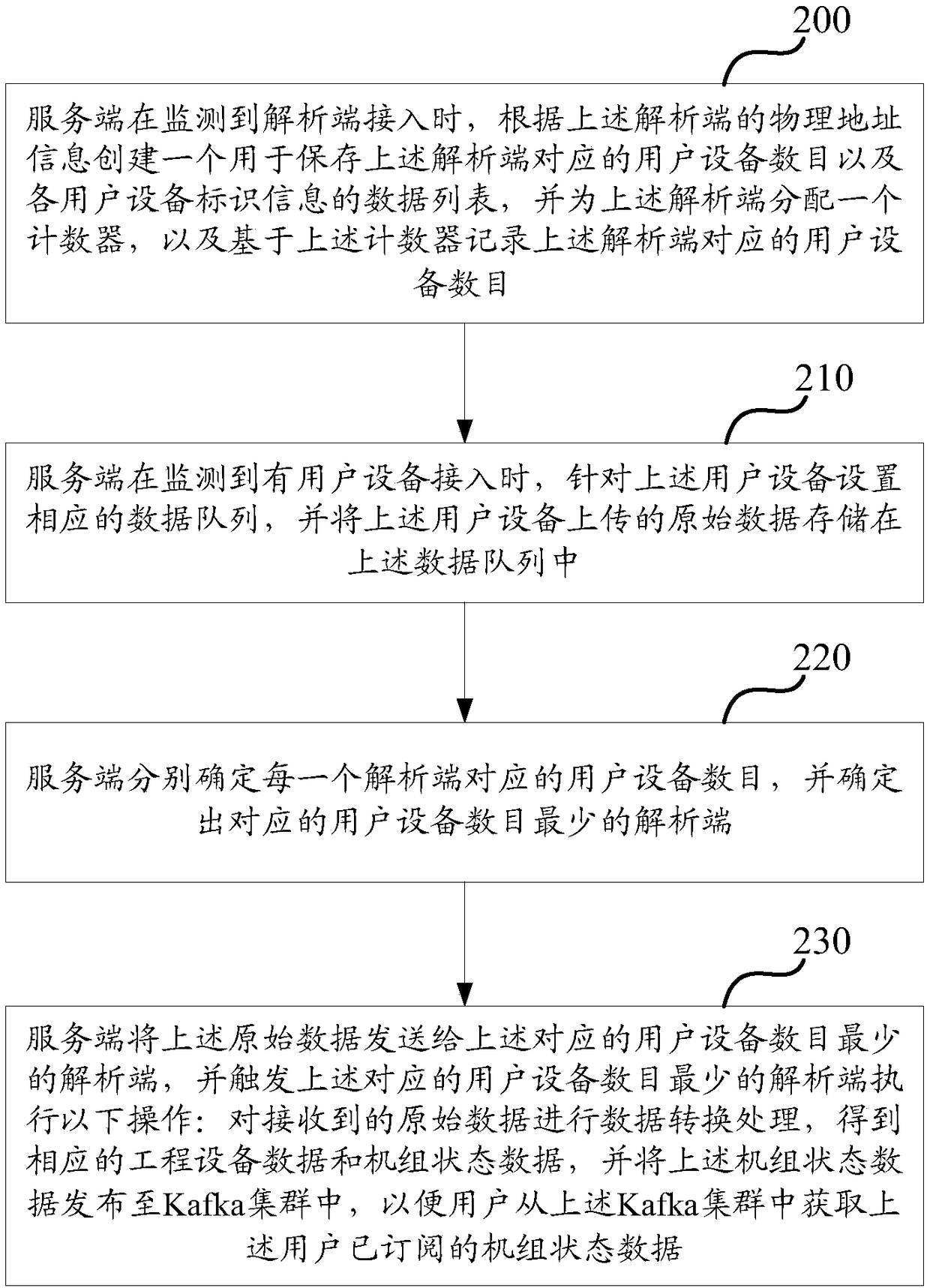

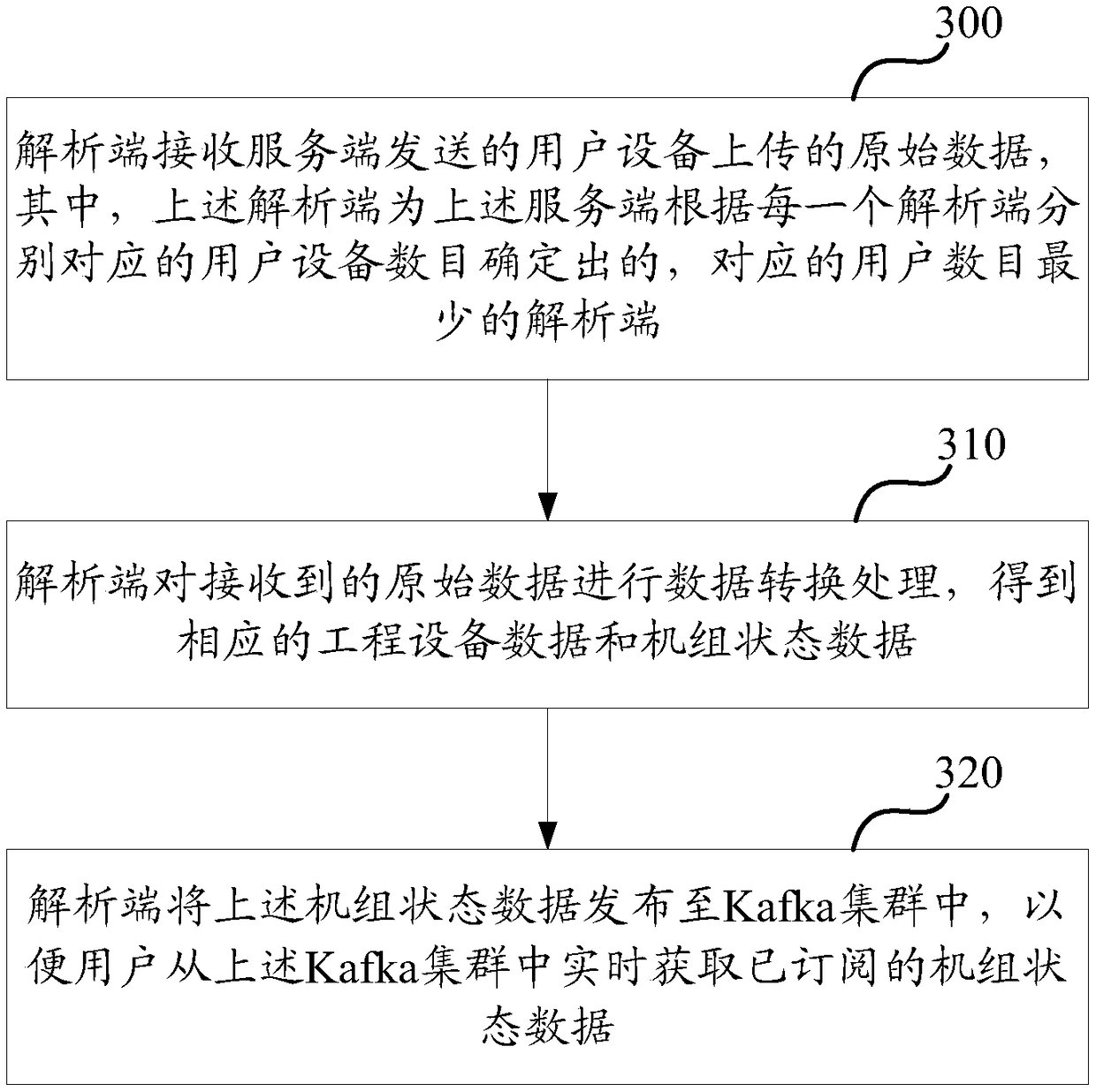

A big data processing method, device and system

ActiveCN107423316BDynamic Load BalancingImprove experienceRelational databasesTransmissionFailure rateUser device

The present invention relates to the technical field of data analysis, in particular to a big data processing method, device and system. The method is: according to the number of user equipment corresponding to each analysis terminal, determine the analysis terminal with the least number of corresponding user equipment, send the original data to the analysis terminal, and trigger the analysis terminal to perform the following operations: The original data is converted and processed to obtain the corresponding unit status data, and the unit status data is published to the Kafka cluster, so that users can obtain the subscribed unit status data from the Kafka cluster. Using the above method, the dynamic load balancing between the analysis terminals is realized. Further, the user can obtain the unit status data corresponding to each user equipment in real time, and pre-detect each unit status data according to the unit status data corresponding to each user equipment. Whether there is any user equipment running abnormally in the user equipment, so as to reduce the failure rate of the user equipment and improve user experience.

Owner:GREE ELECTRIC APPLIANCES INC

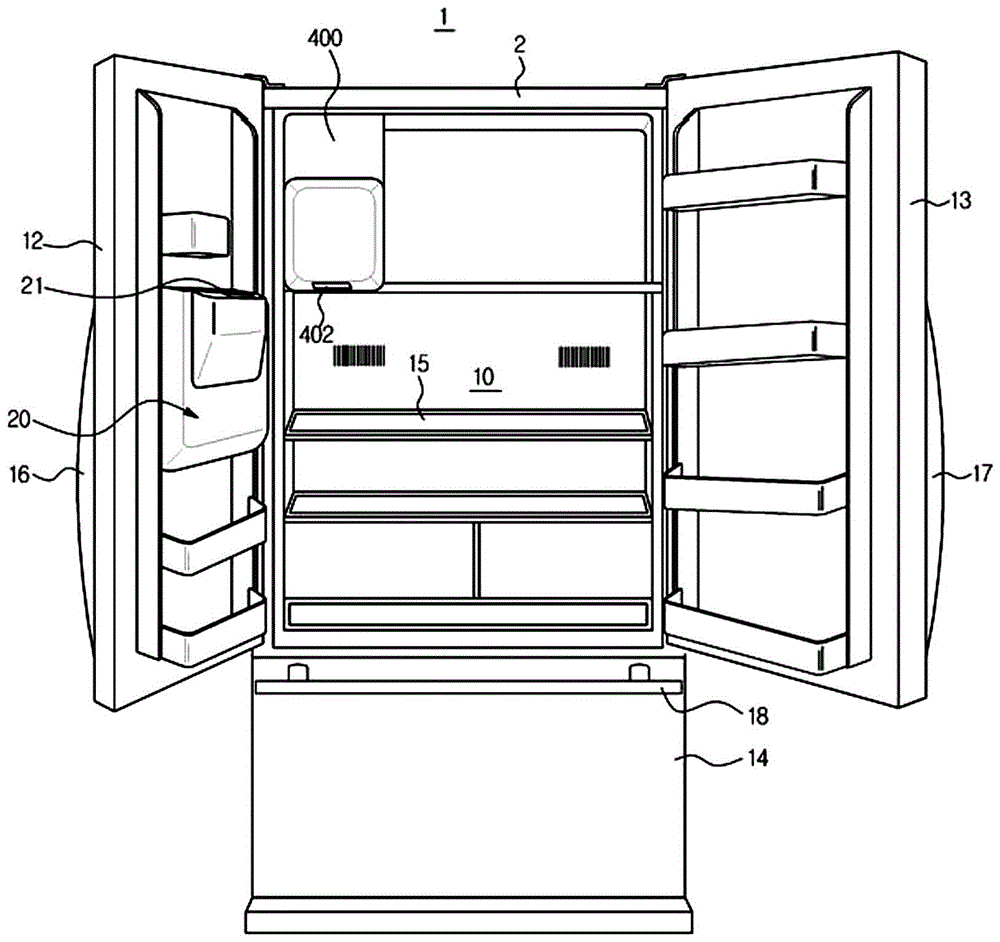

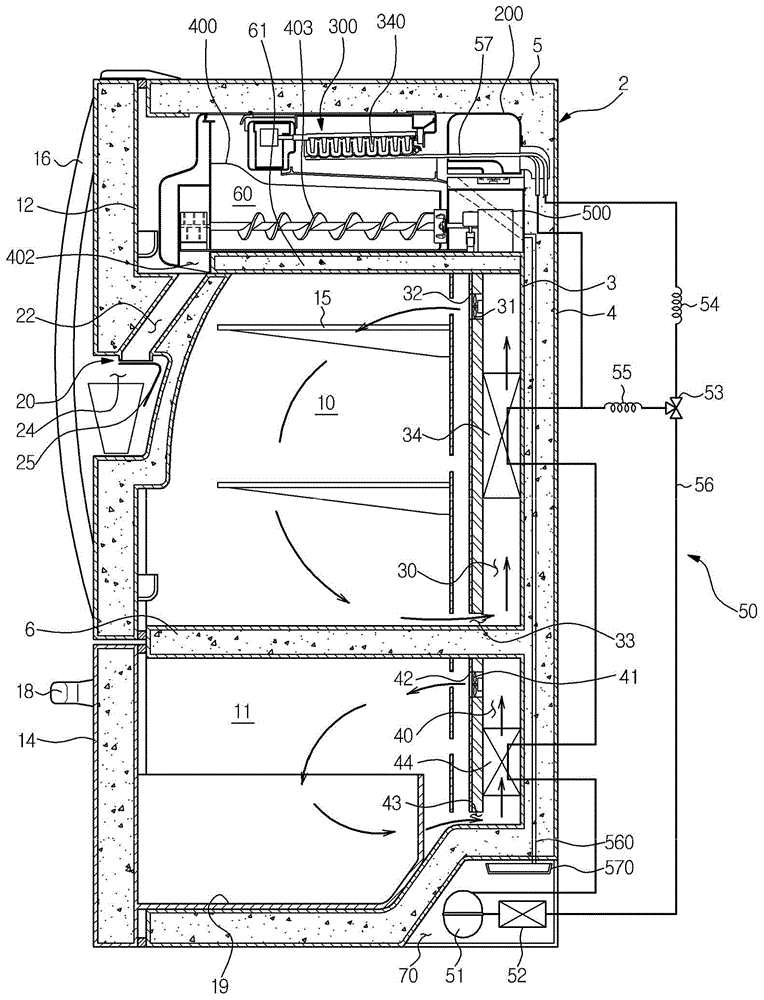

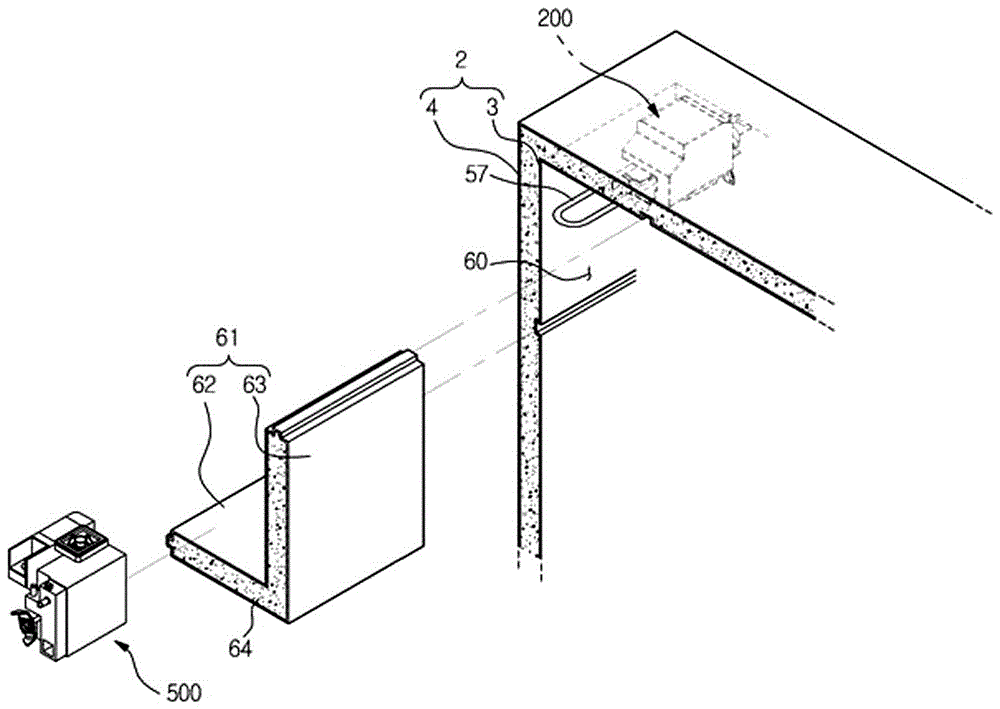

refrigerator

ActiveCN103185431BImprove assembly qualityImprove the quality of after-sales serviceLighting and heating apparatusIce productionSolenoid valveRefrigerated temperature

The invention provides a refrigerator. The structure of the auger motor assembly of the refrigerator can easily install the auger motor, solenoid valve, ice-making compartment fan and drain hose. The auger motor drives the auger located inside the ice-making compartment. The ice-box fan makes the air in the ice-making room flow, and the drain hose discharges the defrosted water of the ice-making tray to the outside of the ice-making room, so that the auger motor assembly is inserted through the open front surface of the ice-making room in a sliding manner. To the inside of the ice making compartment and is easily installed into the inside of the ice making compartment.

Owner:SAMSUNG ELECTRONICS CO LTD

Device and method for remotely solving fault by utilizing handheld device

InactiveCN103048969BReduced repair response timeImprove the quality of after-sales serviceTotal factory controlProgramme total factory controlControl engineeringWireless data

The invention relates to a device and a method for remotely solving a fault by utilizing a handheld device. The device comprises a sensor, a PID (proportion-integration-differential) controller and the handheld device, wherein the sensor which can be used for measuring characteristic parameters of an executive component in real time is positioned in engineering machinery and connected with the executive component of the engineering machinery; the PID controller is positioned in the engineering machinery and connected with the executive component; and a wireless data transmitter is fixed in the engineering machinery and connected with a wireless data receiver through a wireless network, and the wireless data receiver is connected with the handheld device. The invention further comprises a method for remotely solving the fault by utilizing the device for remotely solving the fault by utilizing the handheld device. According to the device and the method, the parameters of the remote engineering machinery in a operating process can be collected and transmitted in real time, the fault of the engineering machinery can be quickly determined, the engineering machinery is debugged and controlled by utilizing the remote handheld device, and the maintenance response time of the engineering machinery is shortened.

Owner:昆山航天智能技术有限公司

Single-point waterproof testing tool and testing system for electronic product

PendingCN108120572AEasy to checkEasy to handleMeasurement of fluid loss/gain rateAxial displacementEngineering

The invention provides a single-point waterproof testing tool and testing system for an electronic product, belonging to the technical field of airtightness testing. The single-point waterproof testing tool comprises a testing station which is used for spacing a to-be-tested part, and at least one pressure-sealing mechanism including a first axial displacement driving component, a transmission component and a first axial displacement component, wherein the first axial displacement component is connected with the first axial displacement driving component through the transmission component, andmoves in a first axial direction; a sealing pressure head is arranged at the end part of the first axial displacement component, and a fluid passage is formed in the sealing pressure head and comprises a fluid inlet and a fluid outlet; and the sealing pressure head is pressed on the to-be-tested part and is introduced with a fluid with set pressure for water-proof testing. The testing tool can beused for carrying out water-proof testing in local area on an electronic product, and is convenient for checking water-proof failed reasons in researching, developing and manufacturing processes, sothat the design is improved to eliminate the potential risk leakage or reinforce a water-proof weak part, and the water-proof performance of the local part can be improved.

Owner:BOZHON PRECISION IND TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com