Packaging box bulk transport remote network service system

A remote network and service system technology, applied in the field of after-sales service systems, can solve the problems of increased failure processing time for mechanical equipment users, low after-sales service work efficiency, and increased after-sales service expenses, so as to improve after-sales service quality, save labor, and solve problems The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

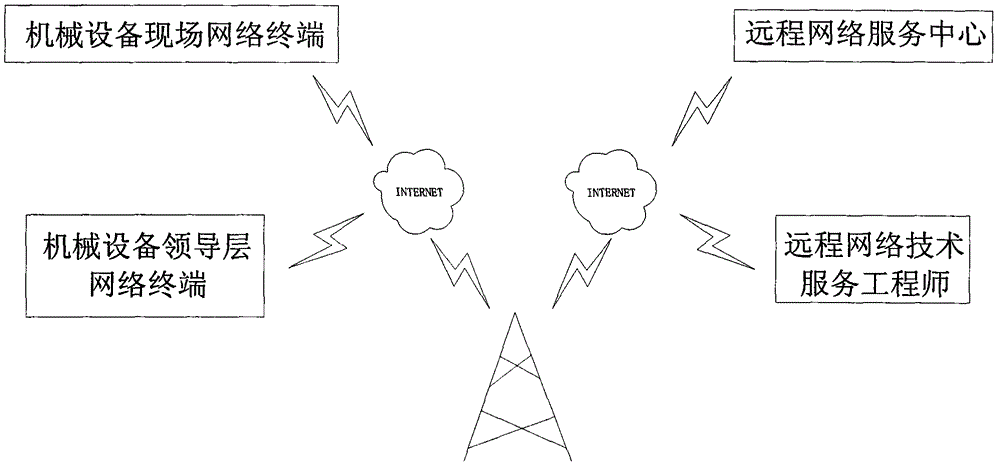

[0012] A remote network service system for batch transportation of packing boxes of the present invention comprises 3G wireless router, VIPA314ST type PLC, industrial computer, Cisco 3925 switch, telecommunication optical fiber network platform and power output module, and said industrial computer communicates with said Cisco 3925 type switch, the 3G wireless router and the VIPA 314ST type PLC are connected. The 3G wireless router is an InRouter417 router.

[0013] The 3G wireless router is InRouter417, which is an industrial-grade 3G wireless router that integrates functions such as wireless 3G network, secure routing, industrial Ethernet switching, industrial serial port, system management interface and intelligent protocol processing. Meet the requirements of remote networking in industrial sites. And its shell is a metal structure with EMC characteristics. Anti-shock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com