Silicon material cleaning method

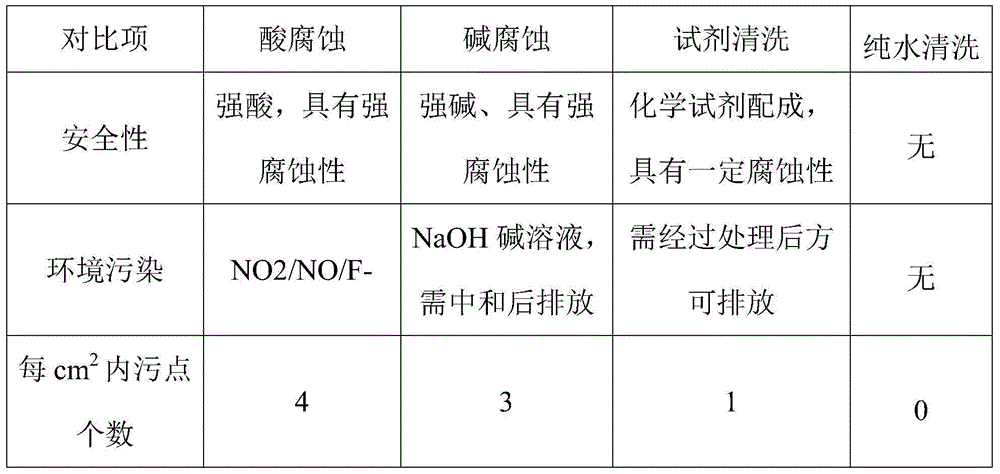

A silicon material and pre-cleaning technology, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, silicon compounds, etc., can solve the problems of unstable cleaning quality and high cleaning cost, so as to avoid silicon material loss, improve cleaning quality, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A silicon material cleaning method provided by the present invention specifically includes the following steps:

[0031] Step 1) Collect the edge leather produced after being cut in a whole piece, put it into a washing bowl filled with water to scrub all its surfaces, and then transfer it to a container to dry;

[0032] Step 2) Put the dried edge leather into the sandblasting work box, and use silicon particles with an average particle size of 0.2mm-0.6mm as the medium to perform sandblasting to ensure that the surface of the edge leather is completely peeled off and transferred to a clean In the material box;

[0033] Step 3), transfer the sandblasted edge leather to a washing basin filled with pure water, and scrub all sides of the edge leather with a clean dust-free cloth;

[0034] Step 4), place the scrubbed edge material in an ultrasonic machine filled with pure water for ultrasonic cleaning. The ultrasonic cleaning time is 10 minutes and the temperature is 70°C;

[0035] S...

Embodiment 2

[0038] A silicon material cleaning method provided by the present invention specifically includes the following steps:

[0039] Step 1) Collect the edge leather produced after being cut in a whole piece, put it into a washing pot filled with water to scrub all its sides, scrub it and transfer it to the container to dry;

[0040] Step 2) Put the dried edge leather into the sandblasting work box, and use silicon particles with an average particle size of 0.2mm-0.6mm as the medium to perform sandblasting to ensure that the surface of the edge leather is completely peeled off and transferred to a clean In the material box;

[0041] Step 3), transfer the sandblasted edge leather to a washing basin filled with pure water, and scrub all sides of the edge leather with a clean dust-free cloth;

[0042] Step 4), the scrubbed edge material is placed in an ultrasonic machine filled with pure water for ultrasonic cleaning, the ultrasonic cleaning time is 12 minutes, and the temperature is 55°C;

[...

Embodiment 3

[0046] A silicon material cleaning method provided by the present invention specifically includes the following steps:

[0047] Step 1), collect the edge leather produced after being cut in one piece, put it into a washing basin filled with tap water to scrub all its surfaces, and then transfer it to a container to dry;

[0048] Step 2) Put the dried edge leather into the sandblasting work box, and use silicon particles with an average particle size of 0.2mm-0.6mm as the medium to perform sandblasting to ensure that the surface of the edge leather is completely peeled off and transferred to a clean In the material box;

[0049] Step 3), transfer the sandblasted edge leather to a washing basin filled with pure water, and scrub all sides of the edge leather with a clean dust-free cloth;

[0050] Step 4), the scrubbed edge material is placed in an ultrasonic machine filled with pure water for ultrasonic cleaning, the ultrasonic cleaning time is 15 minutes, and the temperature is 40°C;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com