Continuous-rolling silicon steel high-detergency rolling oil and preparation method thereof

A technology of detergency and rolling oil, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of high lubricity requirements, and achieve the effects of ensuring emulsifying ability, good anti-rust and oil burning, and anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

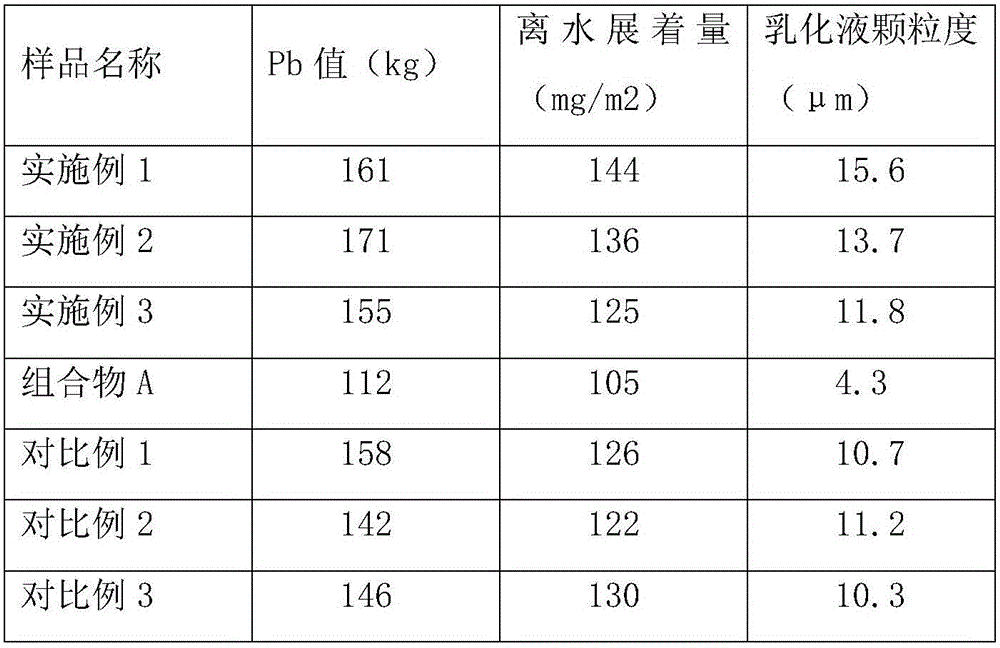

Examples

Embodiment 1

[0031] The present embodiment provides a kind of rolling oil with high cleanliness for continuous rolling of silicon steel, including each component of the following quality: secondary hydrogenated palm oil 40g, trimethylolpropane oleate 50g, BASF L1350.5g, Irganox 1010 0.5g, T501 0.5g, hexadecenyl succinic acid 2g, sulfurized olefin 1g, ethylene glycol phosphite 2g, octadecyldimethylamine salt 2g, nonionic polymer surfactant 1g, C18 Fatty alcohol polyoxyethylene ether 0.5g. The nonionic high molecular polymer is a polymer of hexyl alcohol, oleic acid and polyethylene glycol-4000.

[0032] The preparation method is as follows: mix the components in proportion, and stir at 50-70°C for 0.5-2 hours until they dissolve into a transparent and uniform liquid to obtain the rolling oil.

Embodiment 2

[0034] The present embodiment provides a kind of rolling oil with high cleanliness for continuous rolling silicon steel, including each component of the following quality: secondary hydrogenated palm oil 35g, trimethylolpropane oleate 52.5g, BASF1350.5g, Irganox 1010 0.5g, T501 0.5g, hexadecenyl succinic acid 1g, sulfurized olefin 2g, ethylene glycol phosphite 4g, octadecyldimethylamine salt 1g, nonionic polymer surfactant 2g, C18 Fatty alcohol polyoxyethylene ether 1g. The nonionic high molecular polymer is a polymer of hexyl alcohol, oleic acid and polyethylene glycol-4000.

[0035] Its preparation method is identical with embodiment 1.

Embodiment 3

[0037] The present embodiment provides a kind of rolling oil with high cleanliness for continuous rolling silicon steel, including each component of the following quality: secondary hydrogenated palm oil 35g, trimethylolpropane oleate 56.5g, BASF1350.5g, Irganox 1010 0.5g, T501 0.5g, hexadecenyl succinic acid 1g, sulfurized olefin 2g, octadecyl dimethylamine salt 1g, nonionic polymer surfactant 2g, C18 fatty alcohol polyoxyethylene ether 1g. The nonionic high molecular polymer is a polymer of hexyl alcohol, oleic acid and polyethylene glycol-4000.

[0038] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com