Organic coated steel sheet, manufacturing method and application thereof

An organic coating, steel plate technology, applied in coatings, anti-corrosion coatings, conductive coatings, etc., can solve the problems of uneven enamel layer, enamel assembled tanks do not have anti-corrosion performance requirements, etc. strength, the effect of increasing overall mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

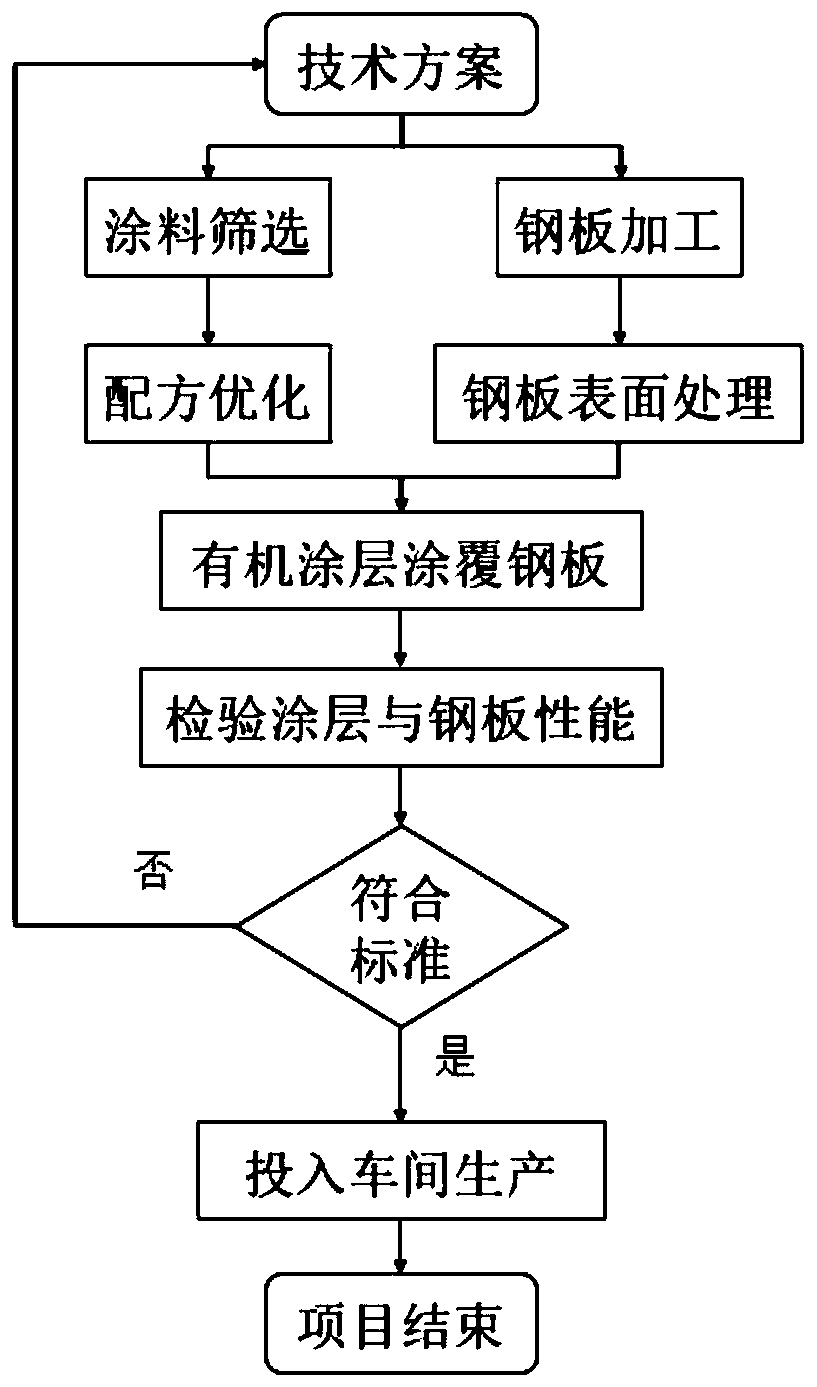

Method used

Image

Examples

Embodiment Construction

[0031] The technical scheme of the present invention will be explained and illustrated in detail below in conjunction with specific embodiments, so that those skilled in the art can better understand and implement the present invention.

[0032] Ordinary carbon structural steel or low-alloy structural steel is selected as the base material, and the base material is subjected to shape treatment, surface treatment, coating and curing of the organic coating in sequence to obtain an organic coated steel plate.

[0033]The choice of steel plate material includes Q235, Q275, Q345, SRT480, etc. The length of a steel plate is 2-6m, the height is 1-3m, and the thickness is 3mm-35mm.

[0034] The shape treatment includes three steps of flattening, punching, and corner cutting; the surface treatment process includes two steps of cleaning the oxide skin and dust on the metal surface and increasing the roughness of the metal surface.

[0035] For shape processing, Kaiping improves the flat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com