Automatic lifting monitoring device equipped with invar level staff and used for monitoring ground surface settlement as well as method

An automatic lifting and monitoring device technology, applied in measuring devices, mapping and navigation, height/level measurement, etc., can solve the problems of limited scope, huge cost, long subway tunnel mileage, etc., to achieve convenient and fast operation, saving manpower and cost and efficiency improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention is not limited to this embodiment. In order to provide the public with a thorough understanding of the present invention, specific details are specified in the following preferred embodiments of the present invention.

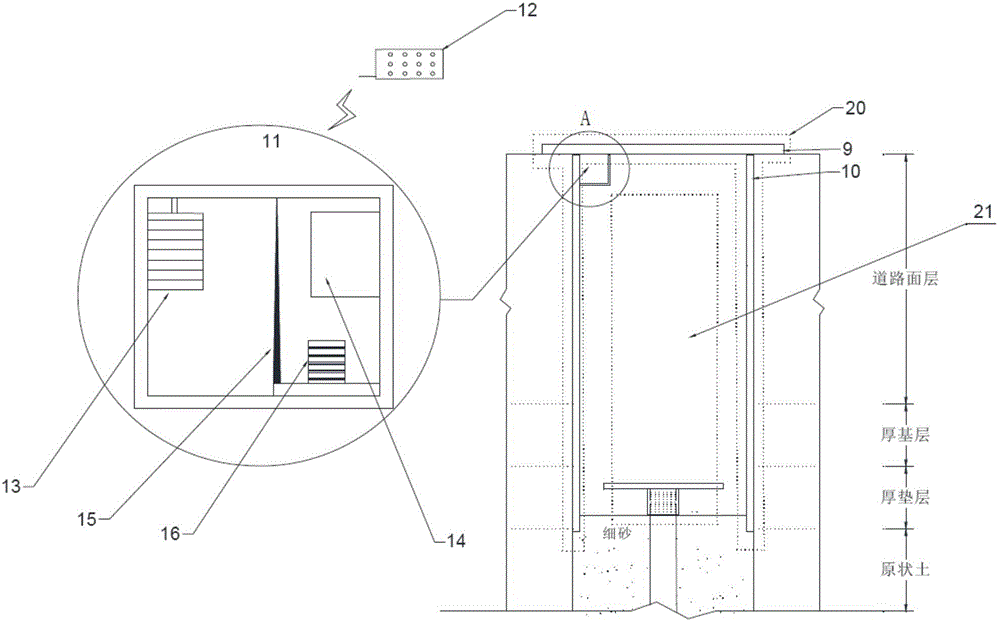

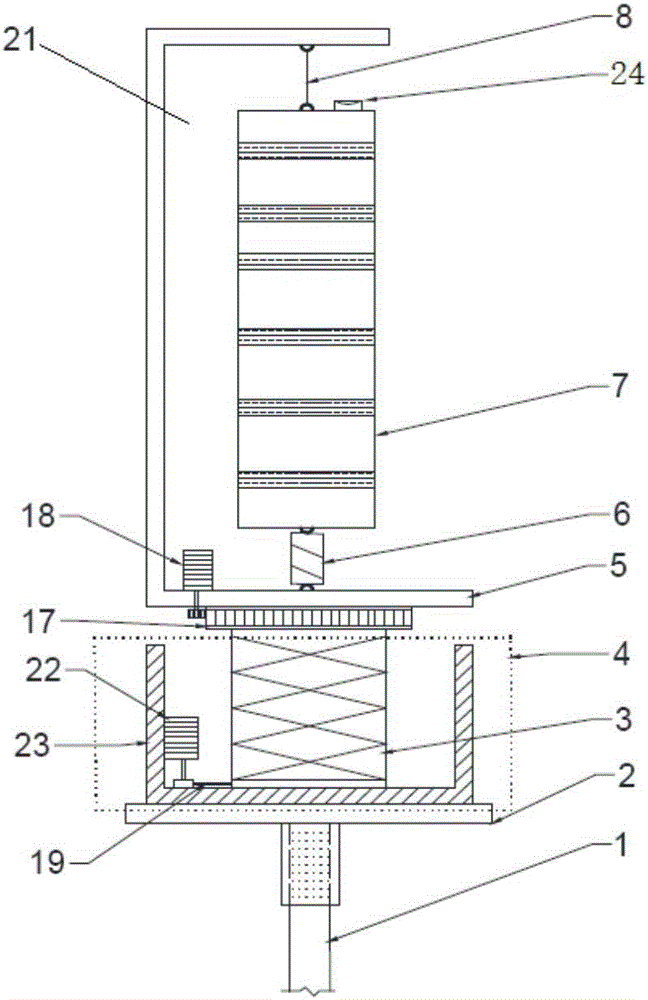

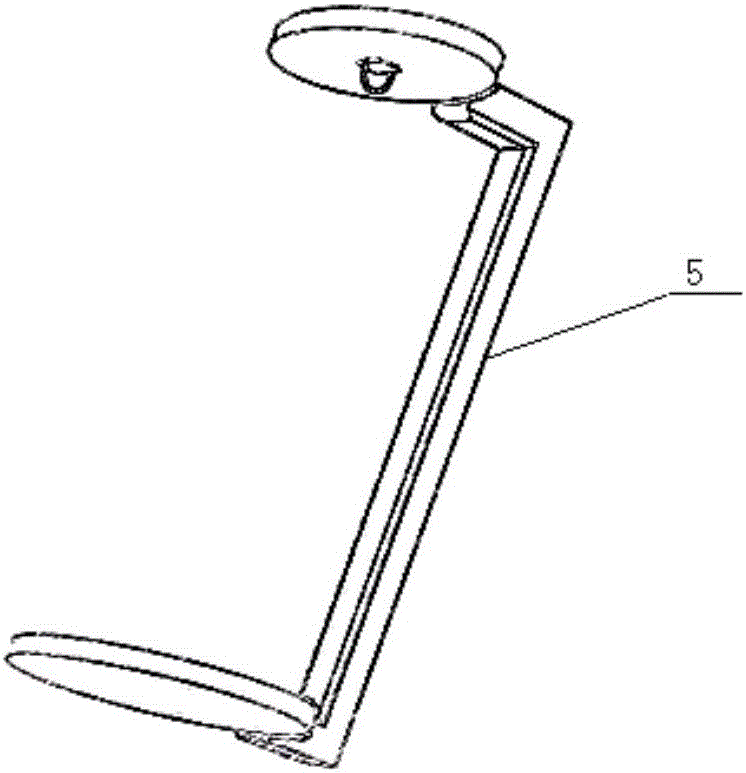

[0050] Such as figure 1 As shown, the present invention is an indium steel ruler automatic lifting monitoring device for surface subsidence monitoring. The device at least includes: a measuring point protection device 20, a single-chip microcomputer control box 11, an indium steel ruler lifting device 21, and a ZigBee remote controller 12.

[0051] The measuring point protection device 20 is composed of a protective cover 9 and a protective wall steel cylinder 10. The protective wall steel cylinder 10 is fixed on the inner wall of the monitoring and measuring hole, and the part between the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com