Fault detection method and device

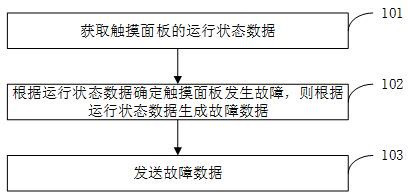

A technology of fault detection and fault data, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., it can solve the problems of inability to accurately check the touch failure after after-sales service, users unable to check the cause of the failure by themselves, and prone to touch failure. The effect of improving user experience with merchants, improving troubleshooting efficiency, and improving after-sales service efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

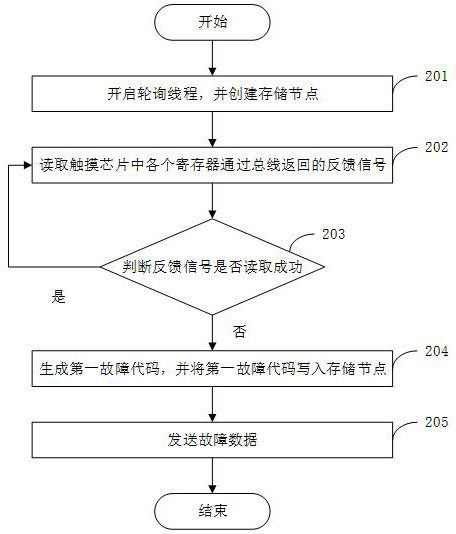

[0071] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application. It should be understood by those skilled in the art that the described embodiments are some, but not all, embodiments of the present invention. Based on the embodiments in the present application, those skilled in the art can make any appropriate modification or variation to obtain all other embodiments.

[0072] At present, most cash registers are controlled by touch screens, among which capacitive touch panels are mainly used for control. However, cash registers with capacitive touch functions are prone to touch failure during use. Currently, when a touch failure occurs in a cash register, the user cannot troubleshoot the cause by himself, and the after-sales service cannot accurately troubleshoot the touch failure remotely. Professional after-sales engineers are required to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com