A sorting device and sorting method for segmentally assembled valve core and valve seat

A technology of segmented assembly and sorting device, applied in sorting and other directions, can solve the problems of valve core and valve seat size mismatch, assembly problems, valve core deformation, etc., to improve the assembly qualification rate, avoid damage, and improve enthusiasm. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

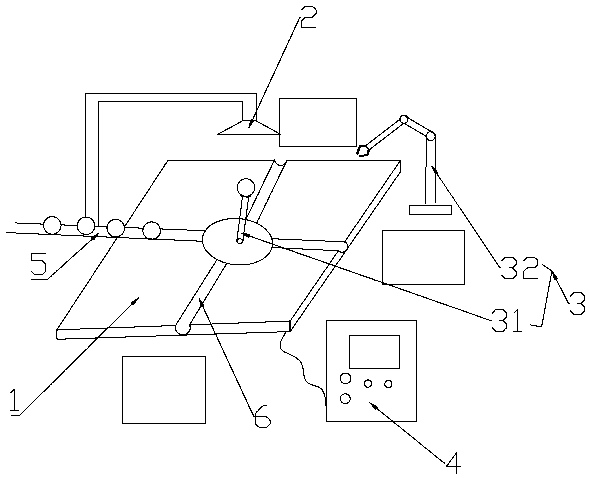

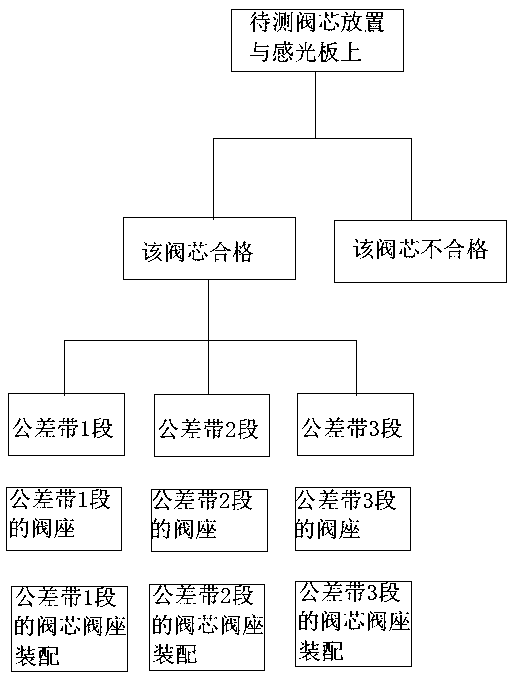

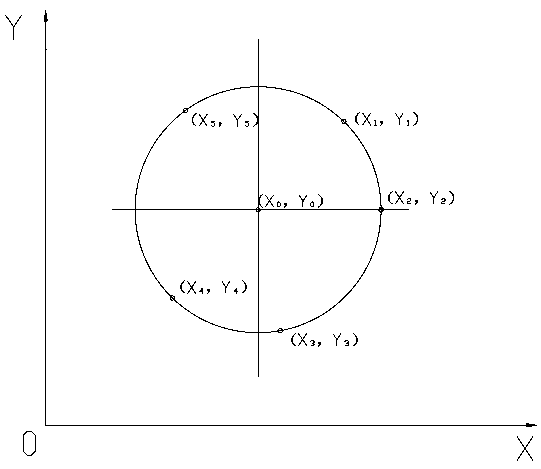

[0043] As shown in the figure, a sorting device for segmentally assembling the valve core and valve seat includes a photosensitive device 1, a light source device 2, a sorting mechanism 3, and a control computing system 4 connected to the above three devices. The light source device 2 is arranged directly above the center of the photosensitive device 1, the sorting mechanism 3 includes a lifting universal joint 31 that can rotate 360 degrees and is arranged at the center of the photosensitive device 1, and the photosensitive device 1 is provided with a The sorting spool is transported to the feeding channel 5 of the sorting mechanism 3 and several sorting channels 6 corresponding to each tolerance section, and the feeding channel 5 and the sorting channel 6 are connected to the center of the photosensitive device 1 Connected, combining computer image proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com