New piler cargo quick stock-taking technique based on RFID

A stacker, a new technology, applied in the direction of computer parts, instruments, induction recording carriers, etc., can solve the problems of low efficiency of goods inventory, achieve the effect of improving low efficiency, reducing enterprise management costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, illustrate the new technology that the present invention proposes based on the automated three-dimensional warehouse stacker goods rapid stocktaking of RFID technology, its technical principle and specific implementation method are as follows:

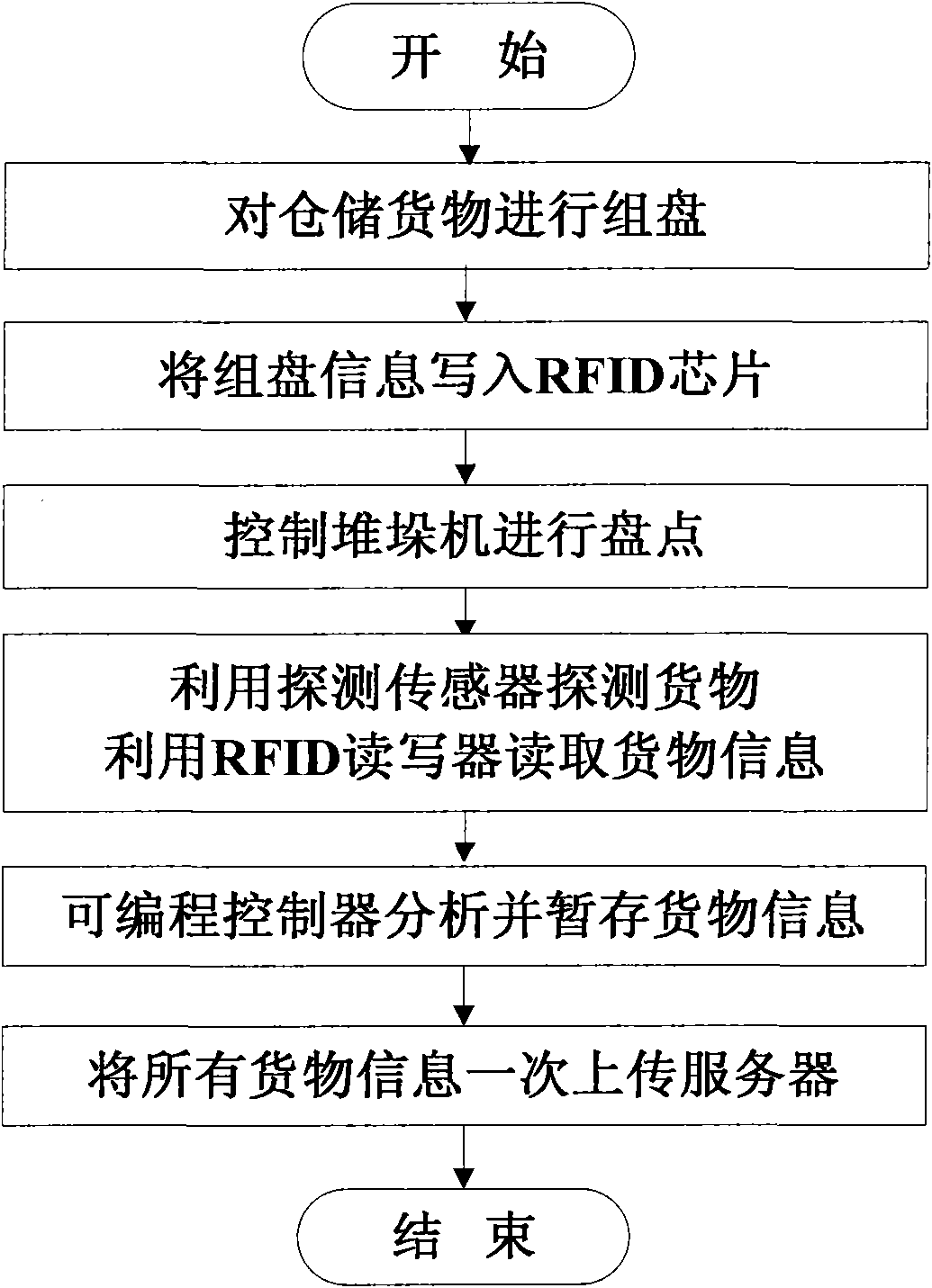

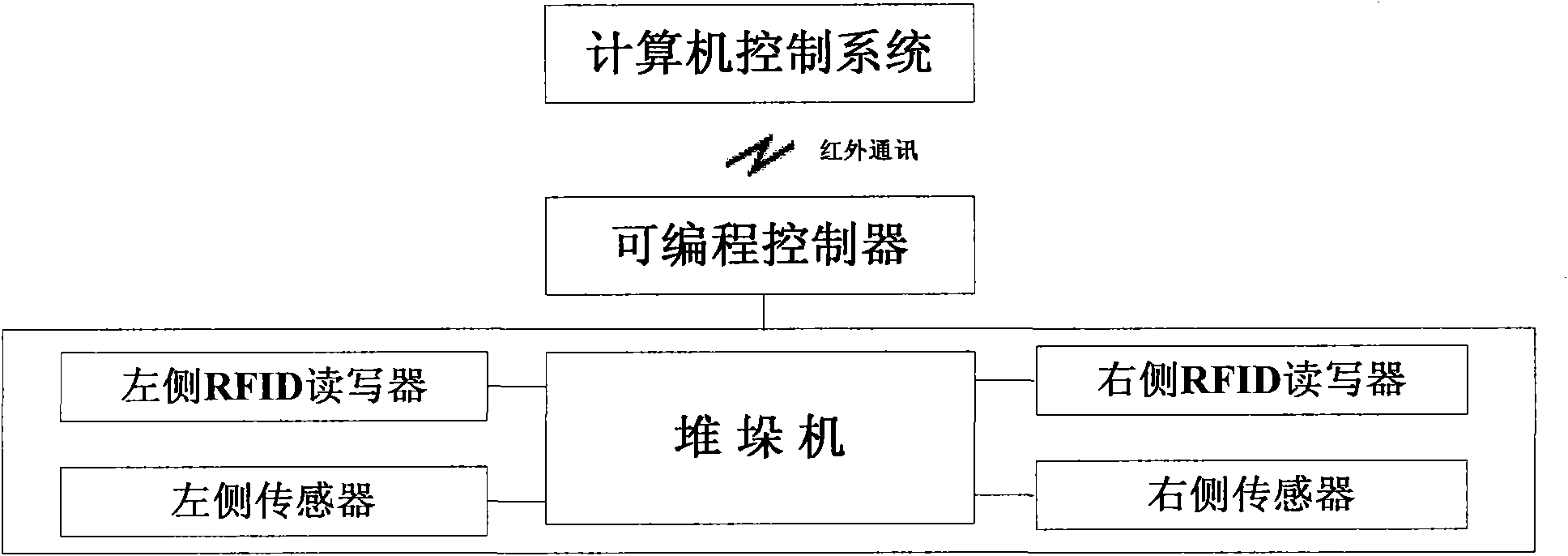

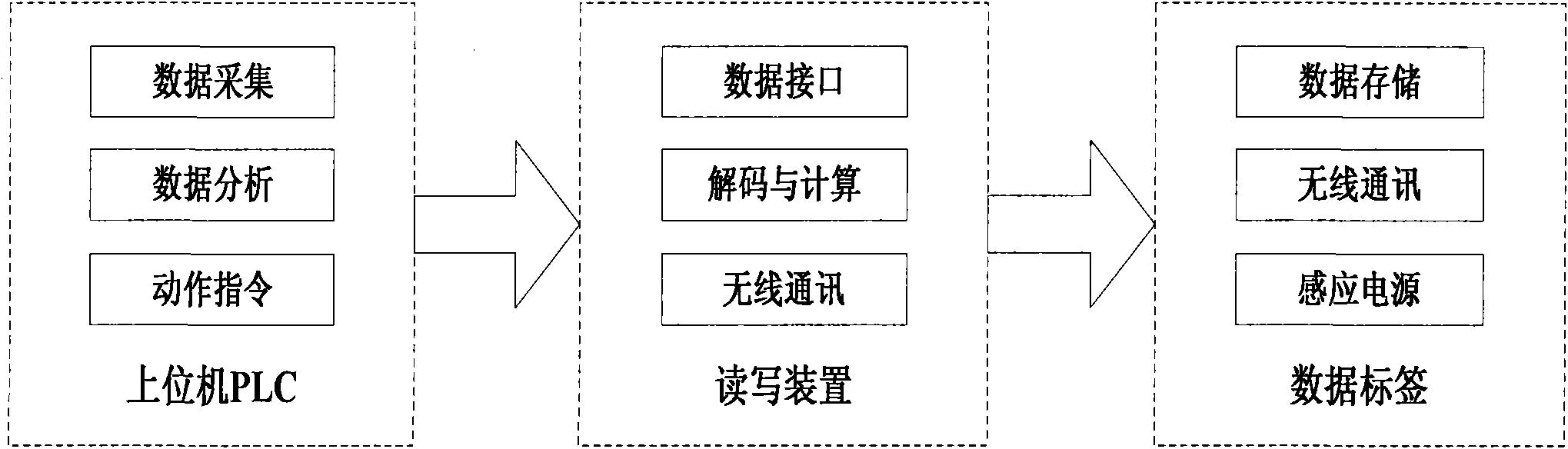

[0015] figure 1 It is an application flow chart of the new technology of rapid stocktaking of stacker goods based on RFID. When applying the invention of the present invention to carry out stocktaking of goods in an automated three-dimensional warehouse, firstly paste one-dimensional codes or two-dimensional codes that can identify their own attributes on the pallets and goods The bar code is scanned separately when the tray is assembled to establish the corresponding relationship between the pallet and the goods; then the information of the tray is written into the RFID chip pasted on both sides of the tray, and put into the automatic storage system; in the stacking Detection sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com