Condiment Dispensing System

a dispenser and liquid technology, applied in the field of dispensers, can solve the problems of reducing efficiency, reducing operational speed, reducing efficiency, etc., and achieve the effects of minimizing waste and potentially damaging the package during use, reducing the time required to insert the bag, and increasing the accuracy of insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

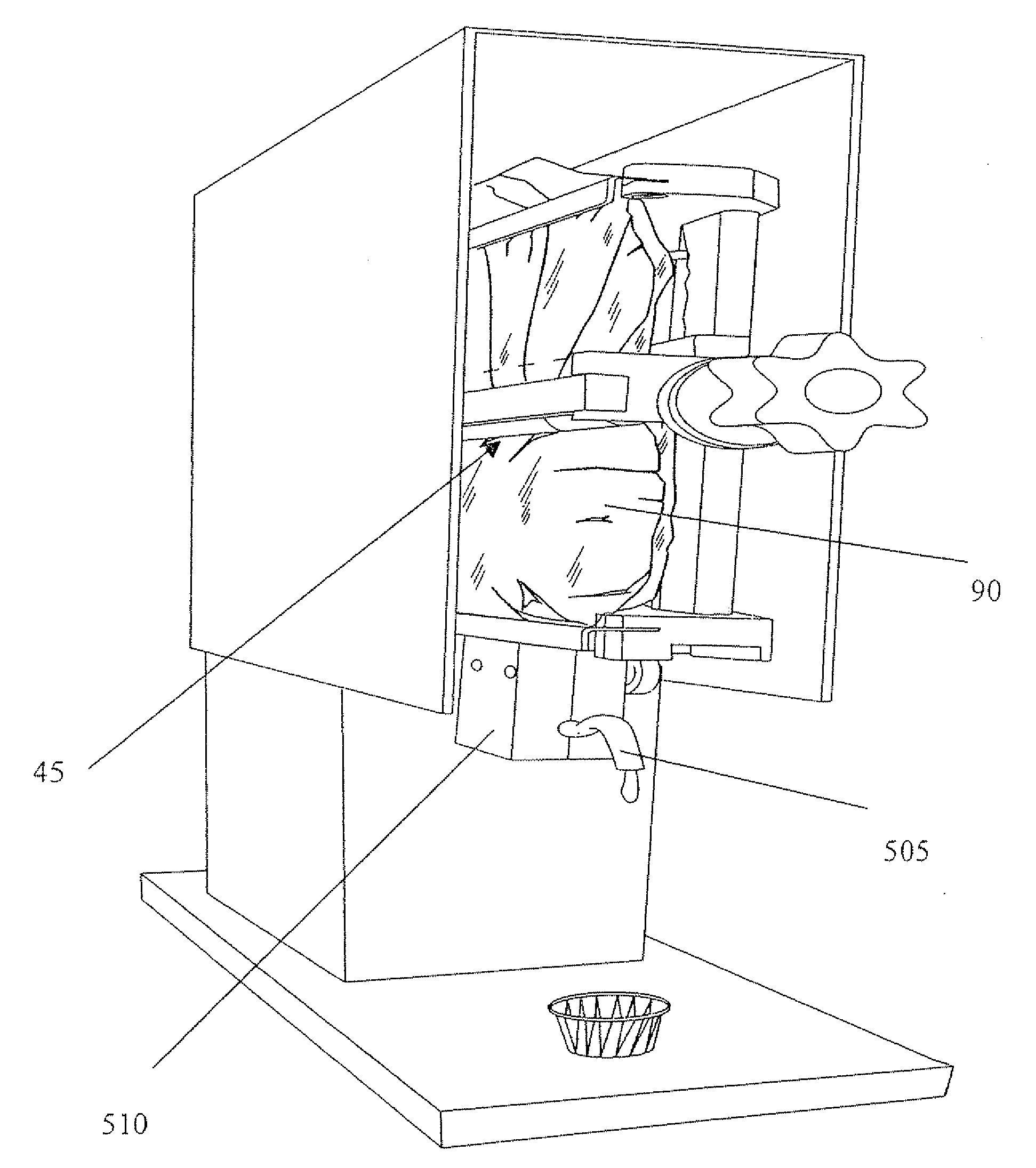

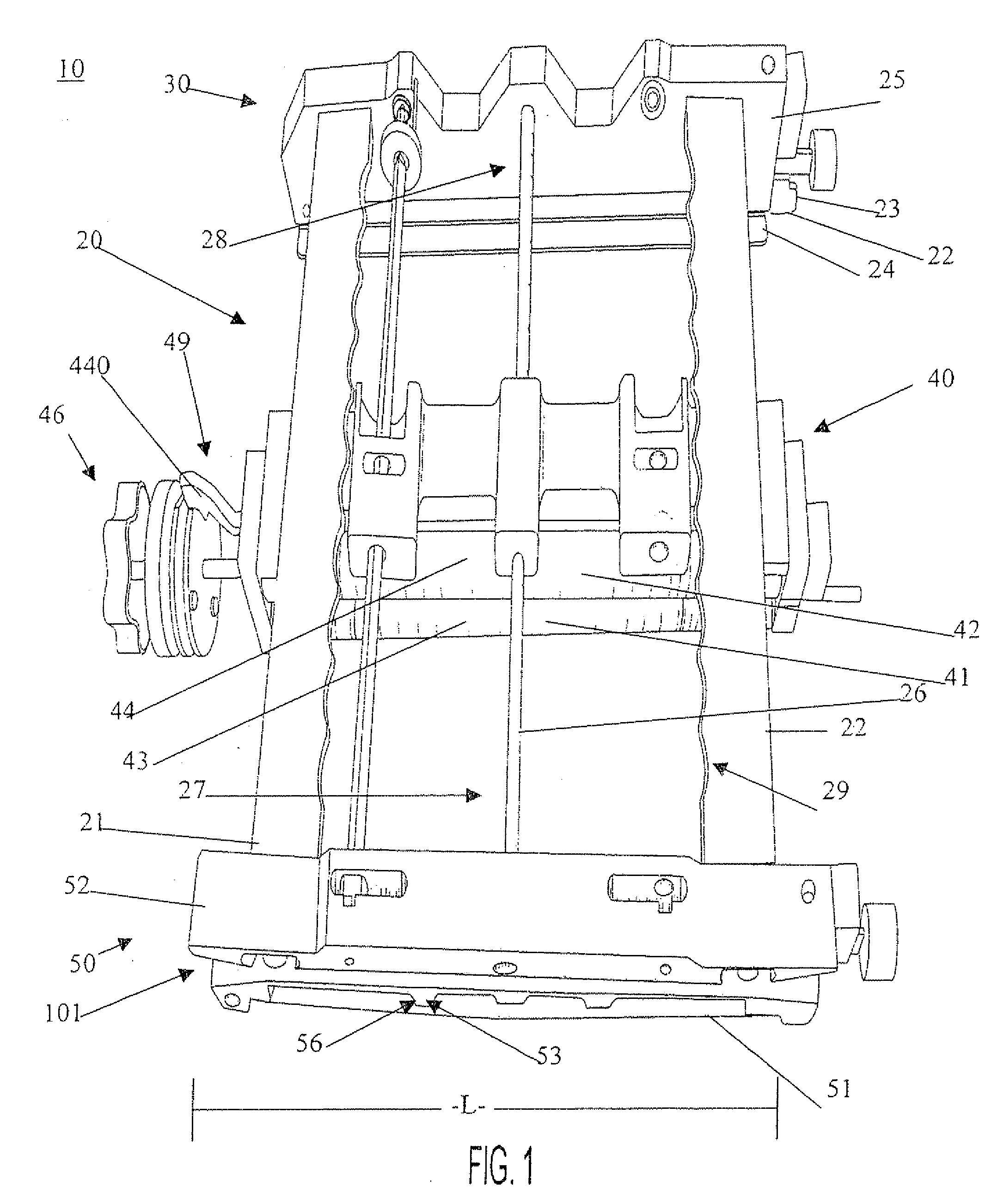

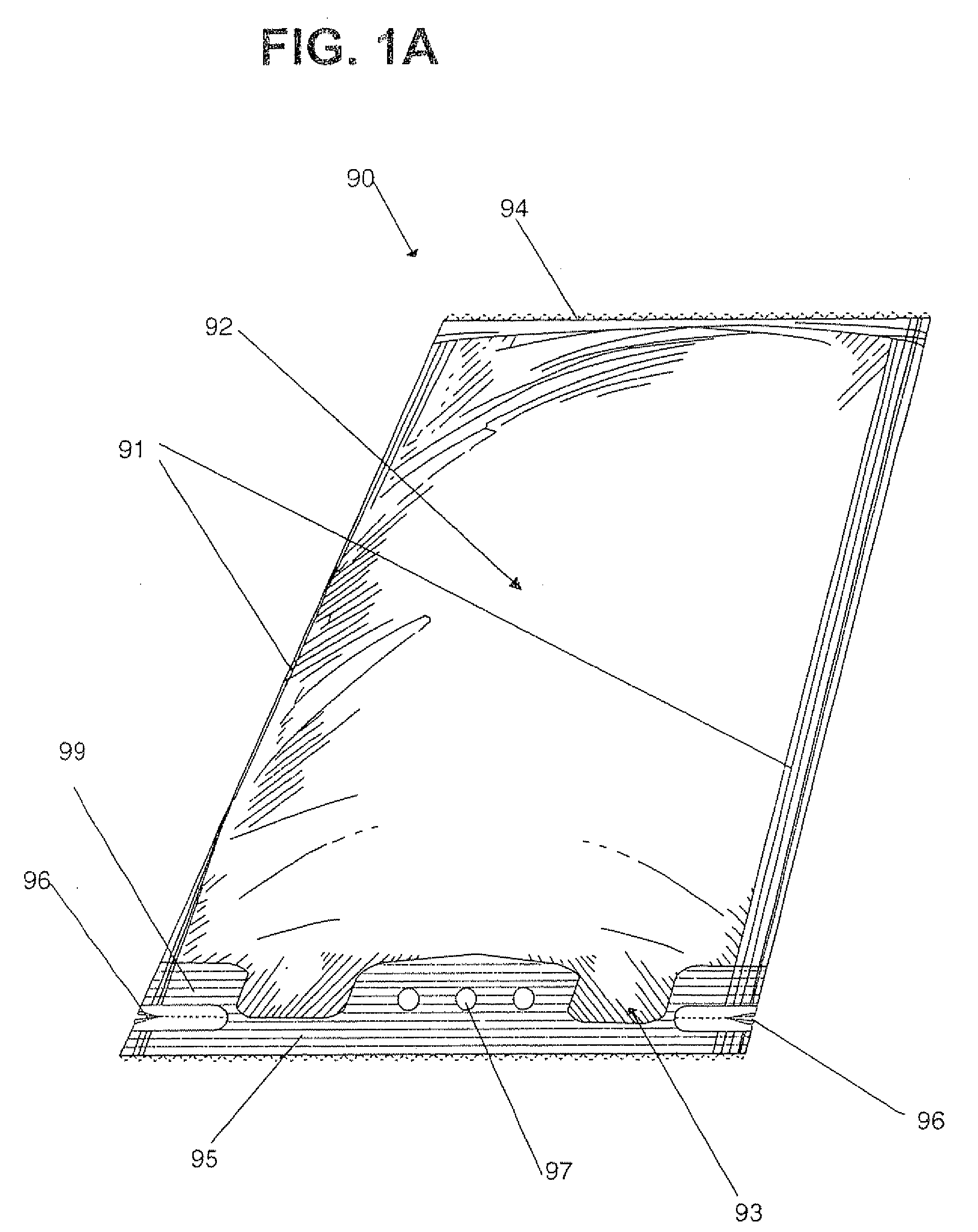

[0047]FIG. 1 illustrates a system 10 in accordance with one embodiment of the invention. System 10 includes a frame 20, top clip 30, roller frame 40, and valve assembly 50. System 10 further includes housing 5 (see FIG. 6) and dispenser 310 (see FIGS. 3A and 3B). In one embodiment, flexible bag 90 is retained and supported, at least in part, by top clip 30 and held within roller assembly 40.

[0048] Housing 5 is operable to support frame 20. In one embodiment, housing 5 is a freestanding unit, configurable to rest upon, for example, a tabletop. In another embodiment, housing 5 is configured as a wall-mounted unit. In one embodiment, frame 20 includes a male adaptor configured to mate with a female adaptor in housing 5 for a sliding engagement between frame 20 and housing 5. In one embodiment, frame 20 includes a female adaptor configured to mate with a male adaptor in housing 5 for a sliding engagement between frame 20 and housing 5. Embodiments with a female adaptor on the frame 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com