Method for producing soluble composite microorganism fertilizer

A technology of composite microorganisms and composite microbial agents, which is applied in the direction of organic fertilizers, fertilizer mixtures, sewage/sludge fertilizers, etc., can solve the problems of reduced number of viable bacteria, difficulty in utilization, and high return production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

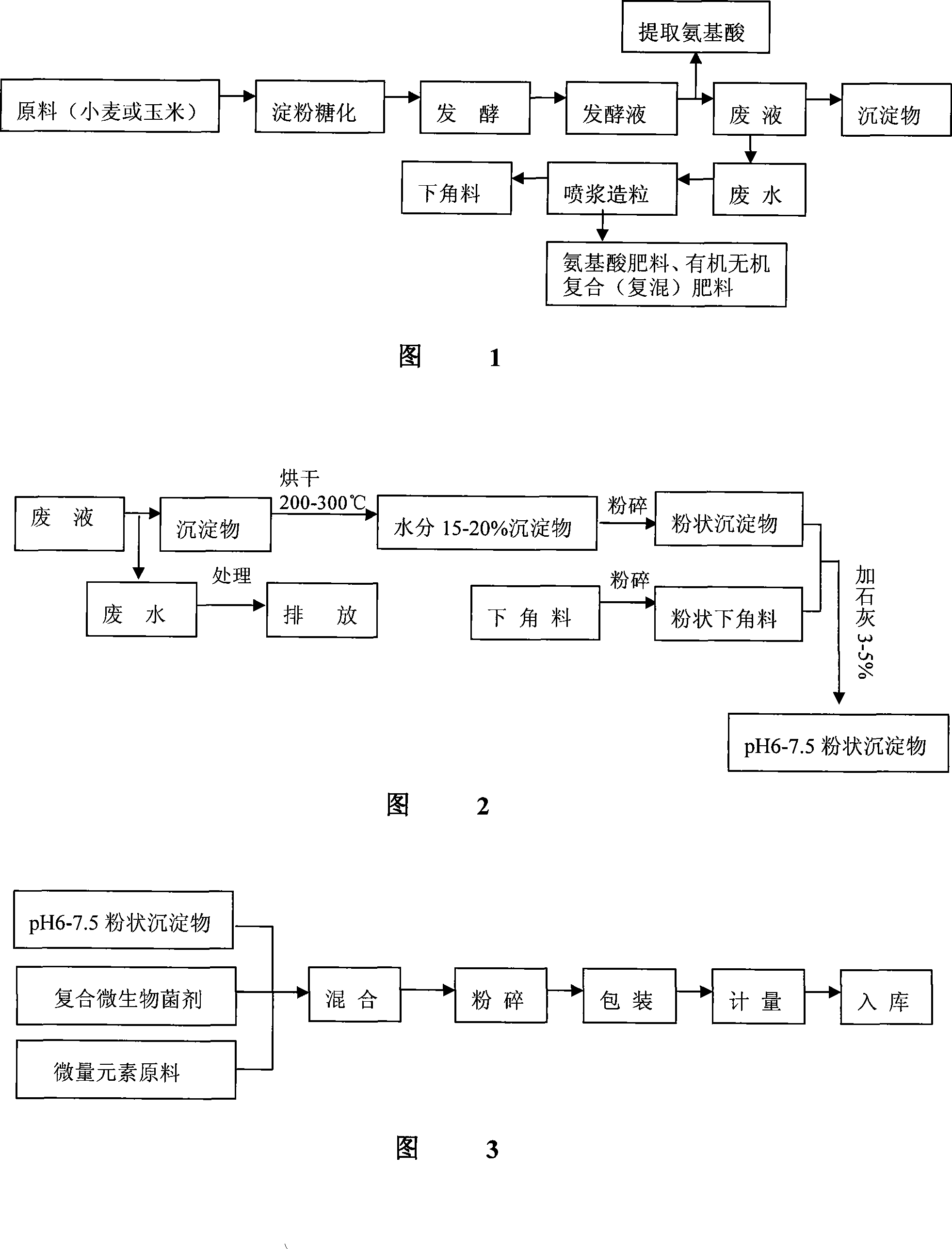

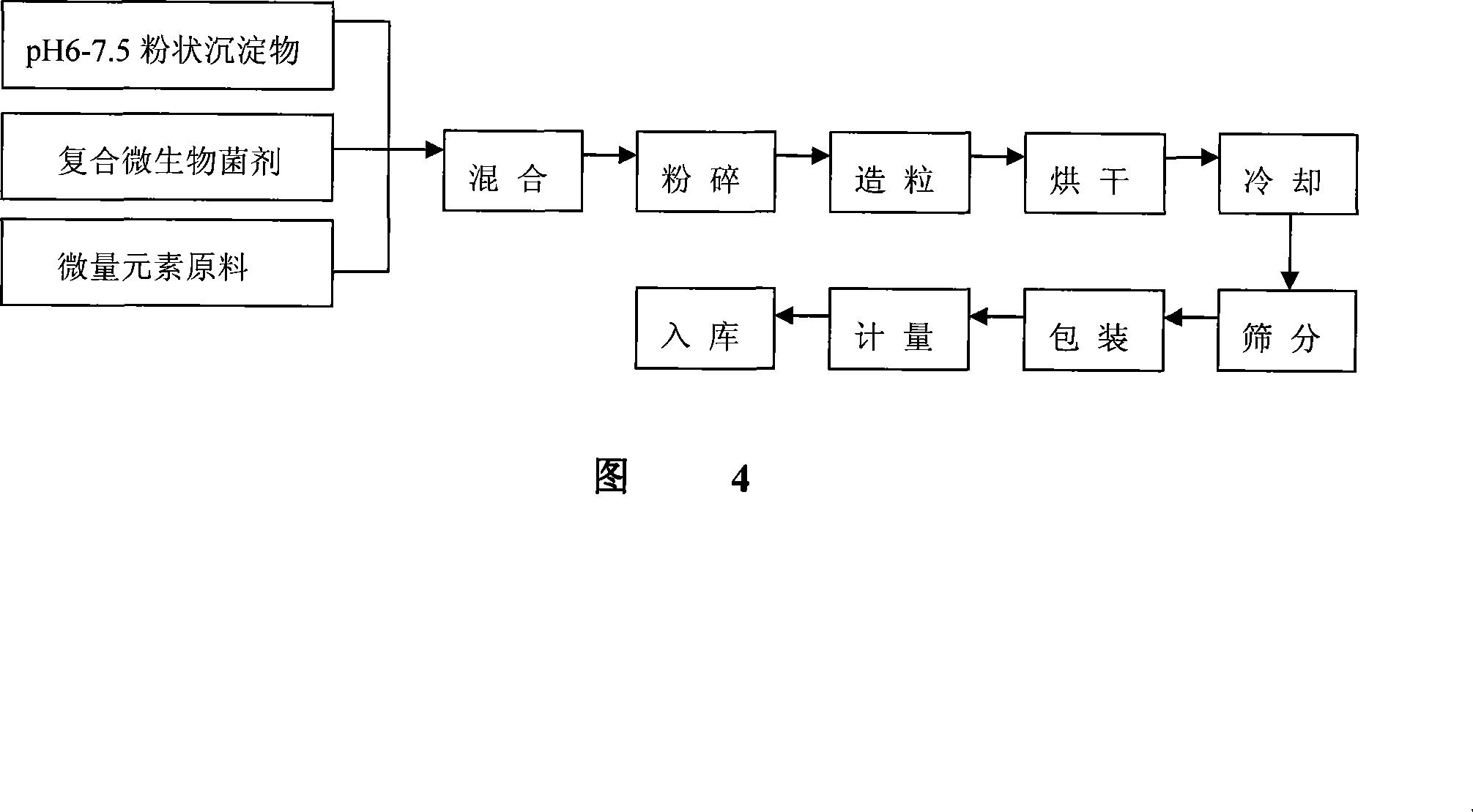

Method used

Image

Examples

Embodiment 1-1

[0045] 1. Sampling. The raw material of waste liquid sediment produced in the amino acid production process was obtained from Henan Lianhua Monosodium Glutamate Co., Ltd.

[0046] 2. Dry. The sediment with a water content of about 50% is dried by cold air at a low temperature at 250-300°C, and the moisture of the sediment reaches 15%-20% after drying.

[0047] 3. Crush. After pulverizing the waste liquid sediment raw material, the fineness reaches 60-80 mesh, and the pulverized sediment is measured. The basic properties are shown in Table 4. The heavy metals are far below the industry standard for compound microbial fertilizers (arsenic≤75mg / kg, cadmium ≤10mg / kg, lead ≤100mg / kg, chromium ≤150mg / kg, mercury ≤5mg / kg), so no determination was performed.

[0048] The basic character of table 4 amino acid production waste liquid sediment

[0049] item

head

(%)

pH

total nutrients

(N+P 2 o 5 +K 2 O)

(%) ...

Embodiment 1-2

[0062] Except following process, other is the same as embodiment 1-1, makes the compound microbial fertilizer produced with waste liquid sediment.

[0063] The temperature of the low temperature cold air drying is controlled at 220°C-260°C.

[0064] Bacillus subtilis (Bacillus subtilis), Bacillus megaterium (Bacillus megaterium) and gelatin-like Bacillus (Bacillus mucilagimosus krassilm) are fermented separately, and the fermented bacterial liquid is carried out with peat according to the ratio of bacterial liquid: peat = 1:5 adsorption. Mix and pulverize the three adsorbed single bacteria agents according to the ratio of 1:1.2:1.2, so that the total number of viable bacteria of the three strains after mixing reaches 5×10 8 More than one per gram, the moisture is kept at 22-25%.

[0065] The crushing fineness in steps 3 and 8 is 40-60 mesh.

[0066] The ingredients are: 228kg of powdery sediment, 15kg of compound microbial agent. Magnesium sulfate 3kg, zinc sulfate 4kg.

...

Embodiment 1-3

[0069] Except following process, other is the same as embodiment 1-1, makes the compound microbial fertilizer produced with waste liquid sediment.

[0070] The temperature of the low temperature cold air drying is controlled at 260°C-295°C.

[0071] Bacillus subtilis (Bacillus subtilis), Bacillus megaterium (Bacillus megaterium) and gelatinous bacillus (Bacillus mucilagimosus krassilm) were produced by separate fermentation, and the fermented bacterial liquid was adsorbed by peat charcoal. Mix and pulverize at a ratio of 1:0.9:1.2, so that the total number of live bacteria of the three strains after mixing reaches 5×10 8 more than one per gram, the water content is kept at 20-25%.

[0072] The crushing fineness in steps 3 and 8 is 80-100 mesh.

[0073] The ingredients are: 207kg of powdery sediment, 18kg of compound microbial agent, 10kg of magnesium sulfate, 5kg of zinc sulfate, 5kg of borax, and 5kg of iron sulfate.

[0074] The total nutrient of the obtained compound mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com