Briquette as material for steel making and method for production thereof

a technology of briquettes and steel, which is applied in the direction of presses, manufacturing tools, furnaces, etc., can solve the problems of increased costs, difficulty in achieving the desired strength, and causing phreatic explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

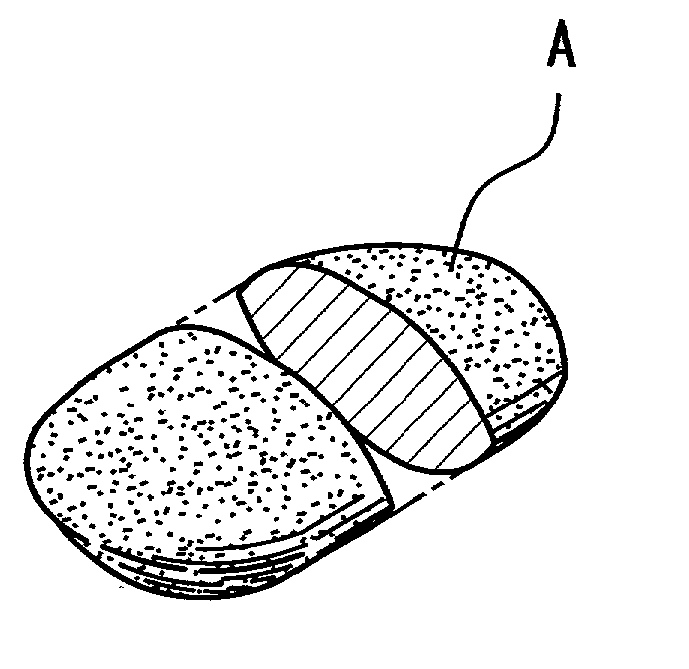

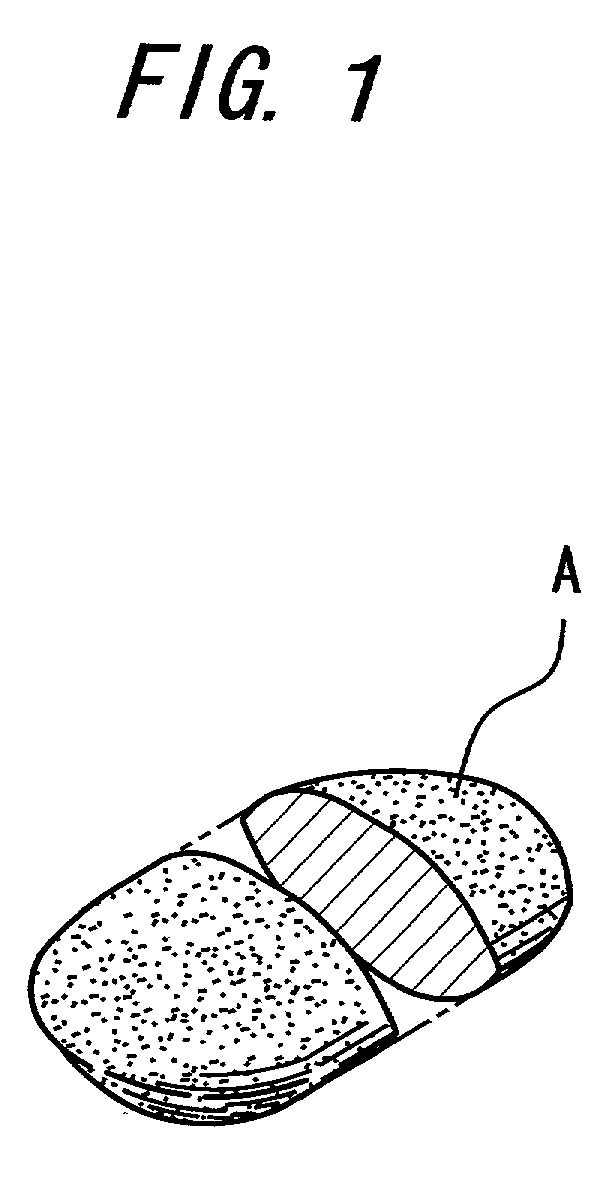

[0039] FIG. 1 is a partially cut-away perspective view showing a briquette for use as steelmaking material according to one embodiment of the invention. The briquette A contains powdery pure iron and oil, and is formed by solidifying powder using a solidification assistant, the powder obtained by finely shearing cotton-like aggregates containing grinding chips from an iron-based metal and a grinding fluid containing oil and water; and drying the solidified product for removal of the water. The briquette A is substantially shaped like a pillow.

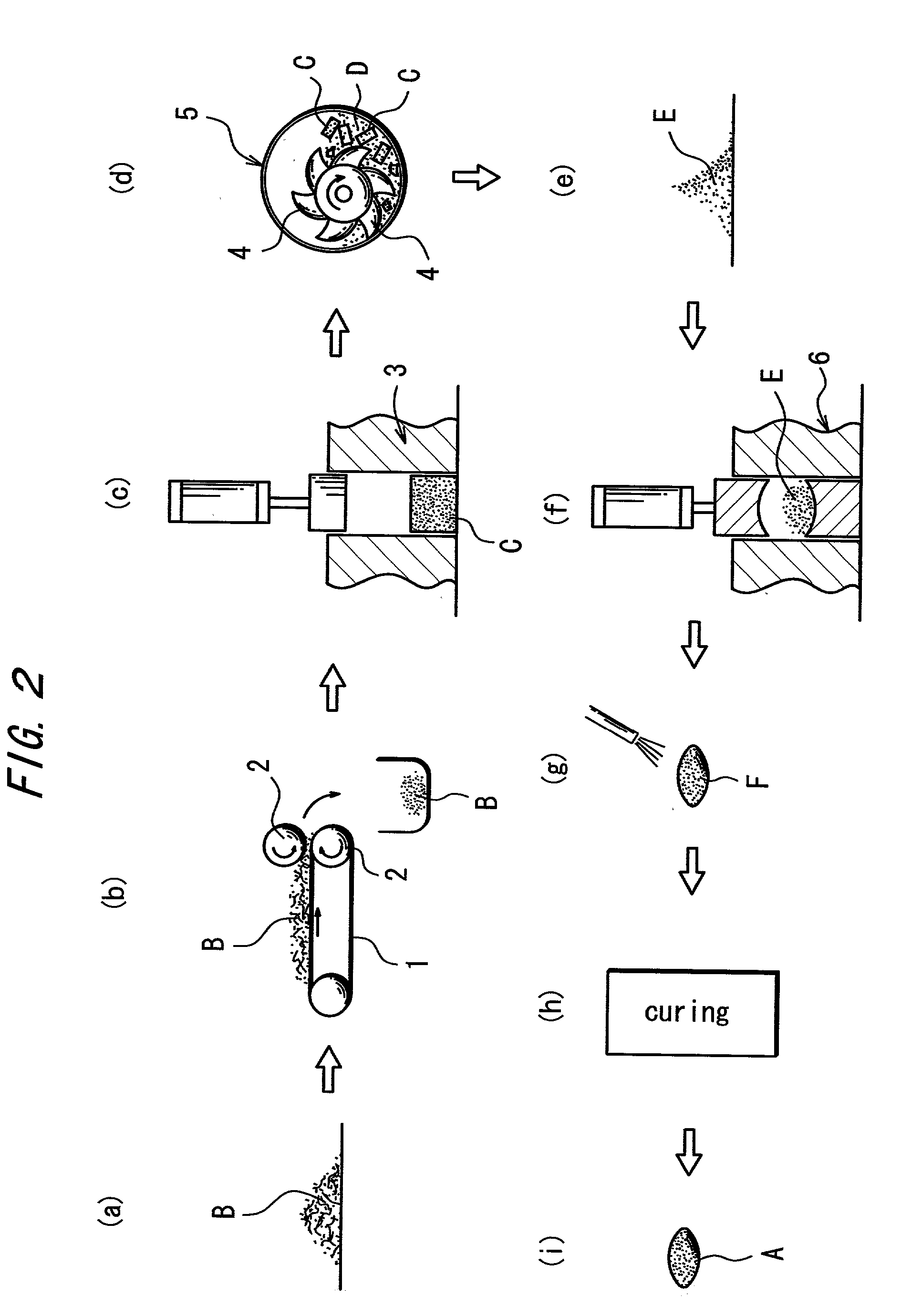

[0040] FIG. 2 is a group of diagrams showing steps of a method for forming the briquette A. In the forming of the briquette A, cotton-like aggregates B (see FIG. 2(a)) of grinding chips produced by machining an iron-based metal are first compressed for preparatory adjustment of contents of water and oil which are components of the grinding fluid contained in the cotton-like aggregates B. The cotton-like aggregates B are compressed by, for examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brittleness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com