Aqueous ink waste water disposal process

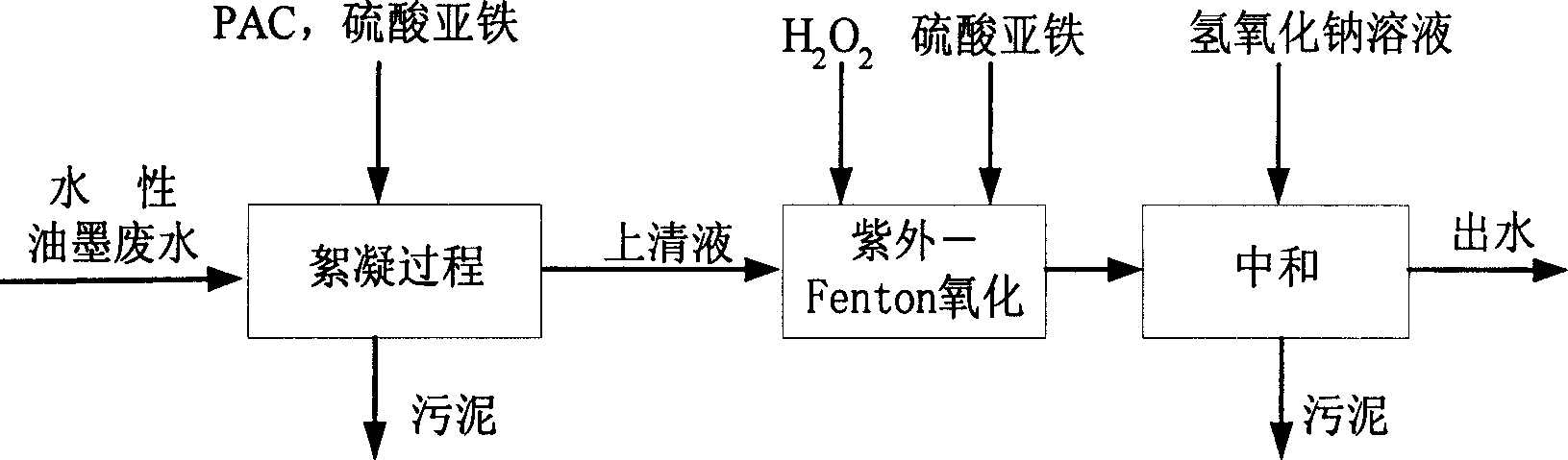

A technology for water-based ink and wastewater treatment, applied in water/sewage treatment, light water/sewage treatment, neutralized water/sewage treatment, etc. Solid-liquid separation, fast floc formation and rapid sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Add 100kg polyaluminum chloride to 200000L water-based ink wastewater (COD=3484mg / L, light transmittance 0), stir at a speed of 150rpm for 3min; then add 100kg of ferrous sulfate, stir at a speed of 50rpm for 5min, and let stand After precipitation, the supernatant is pumped into the oxidation tank, and the sludge is dehydrated and compressed. The light transmittance of the supernatant after flocculation treatment was 95.5%, COD=319mg / L, and the COD removal rate reached 90.8%. Adjust the pH of the supernatant to 3 with dilute hydrochloric acid, add 40kg of ferrous sulfate and 220L of 30% hydrogen peroxide solution, and adjust the pH with sodium hydroxide solution after UV / Fenton oxidation for 5 hours under aeration conditions After the iron ions are completely precipitated, take the supernatant to measure the light transmittance and COD value. After oxidation treatment, the light transmittance of the water sample is close to 100%, and the COD is 169mg / L. The total rem...

example 2

[0021] Add 120kg polyaluminum chloride to 300000L water-based ink wastewater (COD=2571mg / L, light transmittance 0), stir at a speed of 150rpm for 5min; then add 90kg of ferrous sulfate, stir at a speed of 50rpm for 4min, and let stand After precipitation, the supernatant is pumped into the oxidation tank, and the sludge is dehydrated and compressed. The light transmittance of the supernatant after flocculation treatment was 96.5%, COD=319mg / L, and the COD removal rate reached 87.6%. Adjust the pH of the supernatant to 3 with dilute hydrochloric acid, add 60kg of ferrous sulfate and 240L of 30% hydrogen peroxide solution, and adjust the pH with sodium hydroxide solution after UV / Fenton oxidation for 6 hours under aeration conditions After the iron ions are completely precipitated, take the supernatant to measure the light transmittance and COD value. After oxidation treatment, the light transmittance of the water sample is close to 100%, and the COD is 175mg / L. The total remo...

example 3

[0023] Add 75kg polyaluminum chloride to 100000L water-based ink wastewater (COD=6968mg / L, light transmittance 0), stir at a speed of 150rpm for 4min; then add 60kg of ferrous sulfate, stir at a speed of 50rpm for 6min, and let stand After precipitation, the supernatant is pumped into the oxidation tank, and the sludge is dehydrated and compressed. The light transmittance of the supernatant after flocculation treatment was 97%, COD=463mg / L, and the COD removal rate reached 93%. Use dilute hydrochloric acid to adjust the pH value of the supernatant to 3, add 25kg of ferrous sulfate and 110 L of 30% hydrogen peroxide solution, and adjust it with sodium hydroxide solution after UV / Fenton oxidation for 5 hours under aeration conditions When the pH value reaches neutral, after the iron ions are completely precipitated, take the supernatant to measure the light transmittance and COD value. After oxidation treatment, the light transmittance of the water sample is close to 100%, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

| Translucent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com