Method for in-situ removal of nitrogen pollutants in biomass fuel gas in biomass gasifier

A biomass and gasifier technology, applied in the direction of nitrous oxide capture, chemical instruments and methods, gasification process, etc., to achieve the effect of reducing emission concentration, efficient removal, widespread promotion and use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

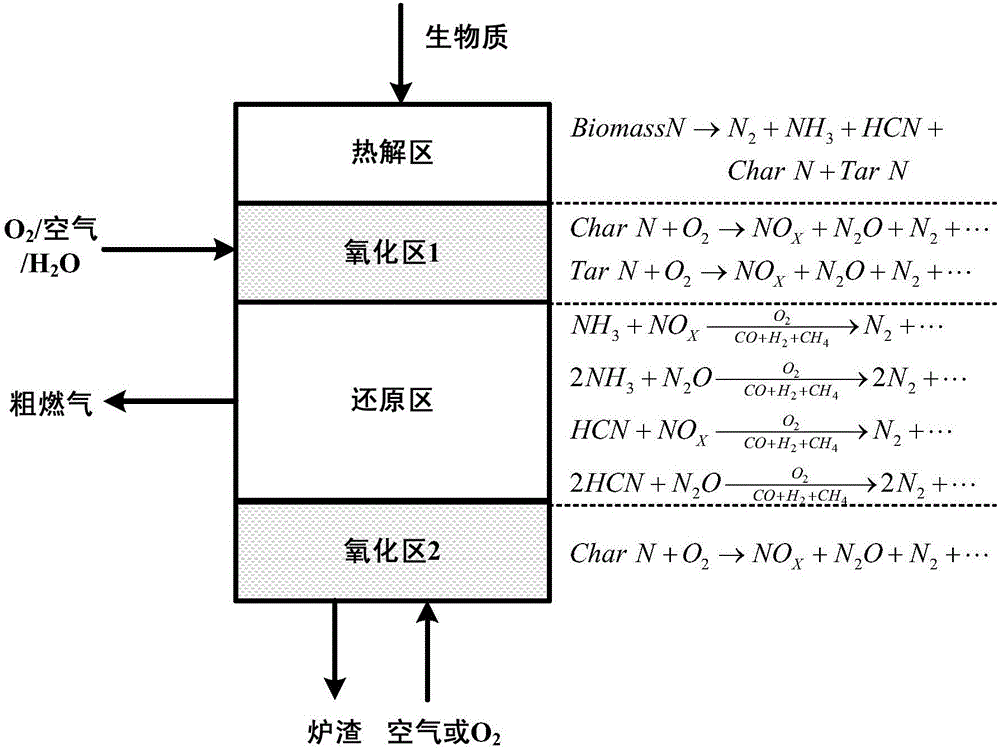

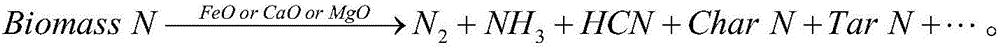

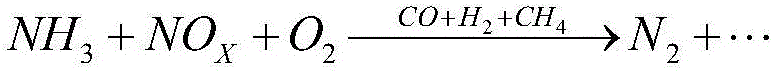

Embodiment 1

[0050] The biomass gasifier adopts a fixed-bed gasifier, the biomass uses corn stalks (N mass content is 0.83%), and the exogenous metal-based catalyst (Ca(OH) 2 ) to corn stalks to prepare metal-doped corn stalks or metal-impregnated corn stalks rich in extrinsic metal salts, Ca(OH) 2 The mass ratio of corn stalks is 2%. The gasification agent uses air for gasification, the feeding amount of corn stalks is 250kg / h, and the total air flow rate is 300Nm 3 / h, respectively set air inlets in the furnace and the bottom of the furnace, and the air flow in the furnace is 180Nm 3 / h, the bottom air flow rate is 120Nm 3 / h, the gas flow direction and biomass flow direction of this gasification method take part in the attached figure 1 , the obtained raw gas is drawn from the reduction zone (also the biomass gasification zone). The temperatures of pyrolysis zone, oxidation zone 1, reduction zone and oxidation zone 2 are 500°C, 850°C, 750°C, and 900°C, respectively. The raw gas tem...

Embodiment 2

[0061] The biomass gasifier adopts a fixed-bed gasifier, using soybean straw (3.2% N by mass) as raw material, and exogenous metal-based catalyst Ca(OH) by solution impregnation. 2 , Fe 2 (SO 4 ) 3 , Mg(OH) 2 Adding to bean straw, the metal-soaked bean straw rich in extrinsic Ca salt, Fe salt, Mg salt, Ca(OH) 2 , Fe 2 (SO 4 ) 3 The mass ratio of soybean straw is 2%, 5%, 20%, Mg(OH) 2 The mass ratio of bean straw to bean straw is 20%, the gasification agent uses air for gasification, the feeding amount of bean straw is 250kg / h, and the total air flow rate is 300Nm 3 / h, respectively set air inlets in the furnace and the bottom of the furnace, and the air flow in the furnace is 180Nm 3 / h, the bottom air flow rate is 120Nm 3 / h, crude gas is drawn from the gasification zone. The temperatures of pyrolysis zone, oxidation zone 1, reduction zone and oxidation zone 2 are 500°C, 850°C, 750°C, and 900°C, respectively. The raw gas temperature is 550°C.

[0062] NH in the ra...

Embodiment 3

[0068] The biomass gasifier adopts a fixed-bed gasifier, using corn stalks (N mass content of 0.83%) as raw material, and exogenous metal-based catalyst Fe by solution impregnation. 2 (SO 4 ) 3 Added to corn stover to make metal-impregnated corn stover rich in extrinsic Fe salts, Fe 2 (SO 4 ) 3 The mass ratio of corn stalks is 2%, the gasification agent uses air for gasification, the feeding amount of corn stalks is 250kg / h, and the total air flow rate is 300Nm 3 / h, respectively set air inlets in the furnace and the bottom of the furnace, and the air flow in the furnace is 180Nm 3 / h, the bottom air flow rate is 120Nm 3 / h, crude gas is drawn from the gasification zone. The temperatures of pyrolysis zone, oxidation zone 1, reduction zone and oxidation zone 2 are 500°C, 850°C, 750°C, and 900°C, respectively. The raw gas temperature is 550°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com