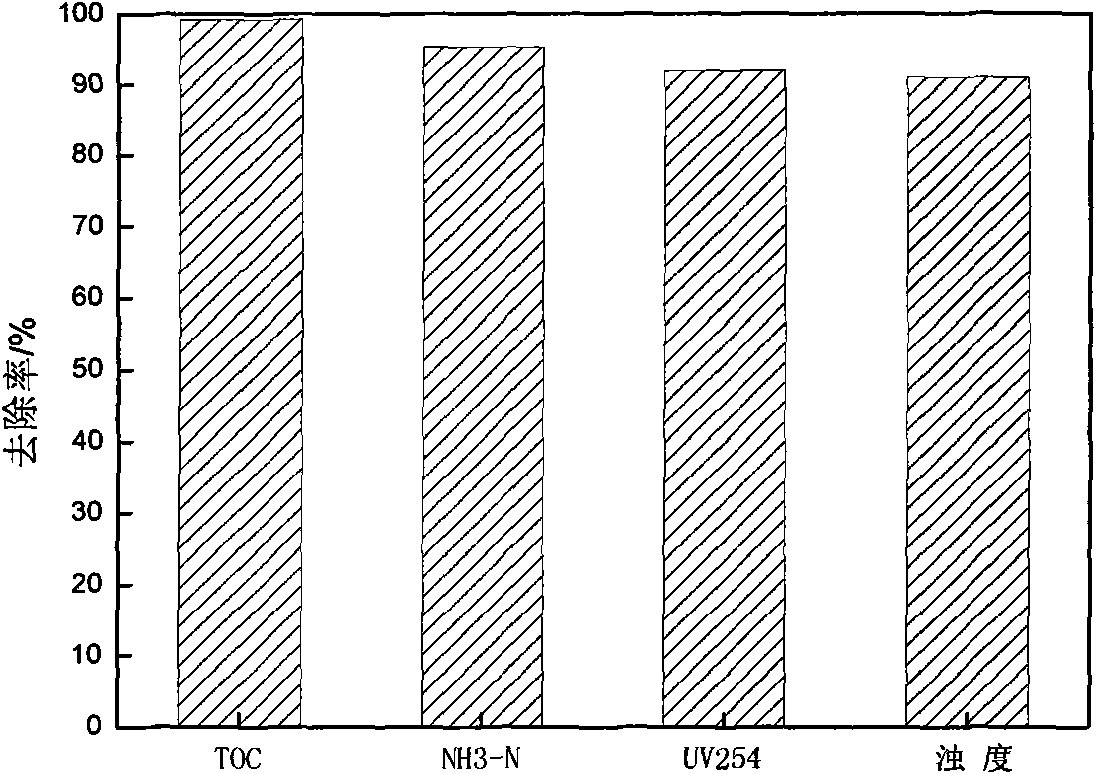

Catalyzed ozonation film reactor with total removal rate of organic carbon over 99%

A total organic carbon and membrane reactor technology, applied in the field of catalytic ozonation membrane reactor, can solve the problems of selectivity in the degradation of organic matter, low solubility in water, insufficient oxidation capacity, etc., and achieve enhanced ozone utilization, increased contact area, Avoid sinking and draining effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

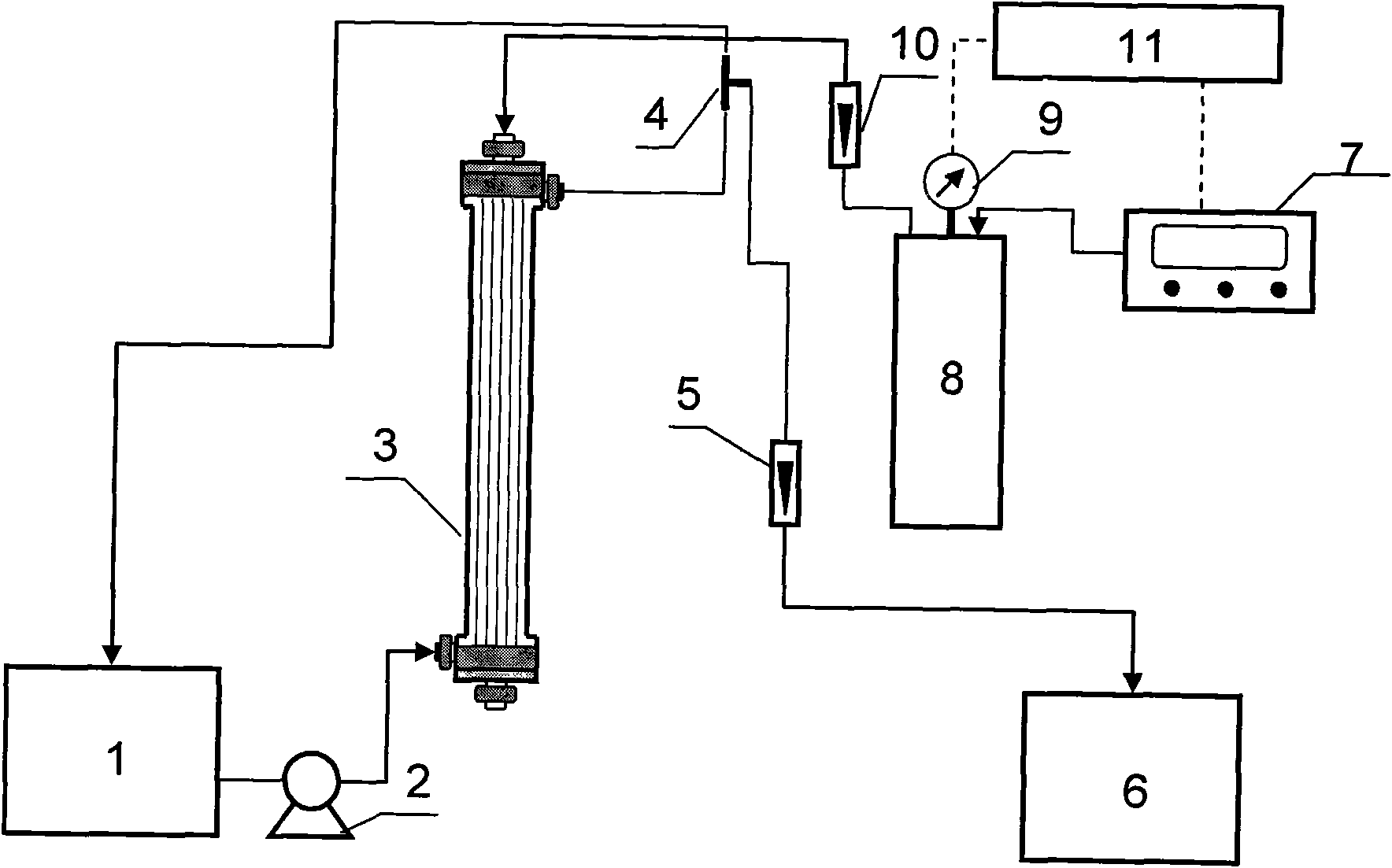

[0023] from figure 1 It can be seen that a catalytic ozonation membrane reactor with a TOC removal rate exceeding 99% of the present invention mainly includes a raw water tank 1, a treatment water tank 6, and an ozone generator 7, and is characterized in that the outlet of the raw water tank 1 passes through the pipeline and its upper The metering pump 2 is connected to the inlet at the lower part of the newly installed membrane module 3 side; the outlet of the ozone generator 7 is connected to the inlet at the top of the buffer tank 8 through a pipeline, and the outlet at the top of the buffer tank 8 is connected through the pipeline and the gas flow meter on it 10. The inlet on the top of the membrane module 3 is connected to the inner cavity of the hollow fiber membrane; the water outlet on the upper part of the membrane module 3 is divided into two paths through the pipeline and the tee pipe 4 on it, one of which is connected to the raw water tank 1, and the other through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com