Method for pre-removing arsenic in arsenic-containing soot

A soot and pre-removal technology, applied in the direction of improving process efficiency, etc., can solve the problems of high cost and incomplete arsenic removal of arsenic-containing soot, and achieve the effects of reducing leaching rate, realizing separation and recovery, and reducing alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

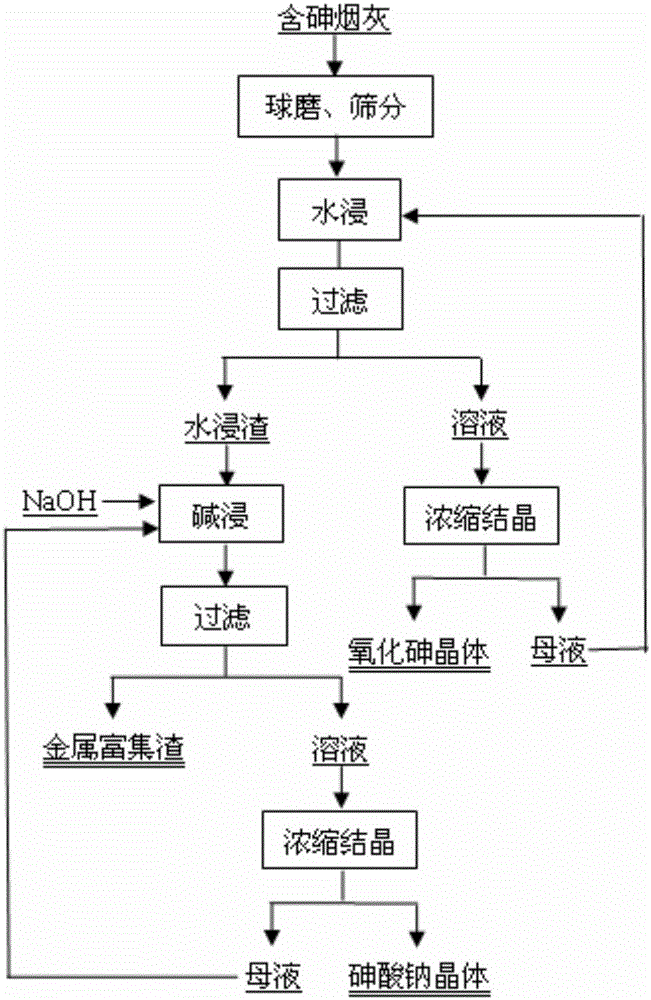

Image

Examples

Embodiment 1

[0023] Get 100Kg copper smelting soot (specific composition is As: 18.14%, Zn: 9.61%, Sn: 1.49%, Pb: 15.08%, Cu: 4.07%, Bi: 7.00%, In: 0.11%; Arsenic phase: arsenic oxide : 12.73%, arsenate: 4.96%, arsenic sulfide: 0.11%, arsenopyrite: 0.36%) for hydrothermal leaching, leaching process control temperature 85 ℃, liquid-solid ratio 8:1, reaction time 20min, stirring speed 200rpm, After the reaction is over, the liquid-solid separation is carried out while it is hot, the leaching rate of arsenic reaches 75.68%, the concentrated crystallization precipitates arsenic oxide, the arsenic precipitation rate is 92.37%, and the crystallization mother liquor returns to the water immersion process. The water leaching residue is further subjected to alkaline leaching. During the leaching process, the concentration of sodium hydroxide is controlled at 1.5mol / L, the temperature is 90°C, the liquid-solid ratio is 5:1, the reaction time is 1h, and the stirring speed is 200rpm. After the reaction...

Embodiment 2

[0025] Get 100Kg lead smelting soot (specific composition is As: 48.50%, Sb: 12.1%, Fe: 1.24%, Pb: 8.45%, Bi: 0.513%, In: 0.24%; Arsenic phase: arsenic oxide: 39.41%, arsenic salt: 4.67%, elemental arsenic: 1.56%, others: 2.87%) for hydrothermal leaching, the leaching process is controlled at a temperature of 95°C, a liquid-solid ratio of 8:1, a reaction time of 30min, and a stirring speed of 200rpm. The liquid-solid separation is carried out, the leaching rate of arsenic reaches 80.62%, the concentration and crystallization precipitates arsenic oxide, the arsenic precipitation rate is 91.05%, and the crystallization mother liquor returns to the water immersion process. The water leaching residue is further subjected to alkaline leaching. During the leaching process, the concentration of sodium hydroxide is 2mol / L, the temperature is 90°C, the liquid-solid ratio is 6:1, the reaction time is 1h, and the stirring speed is 250rpm. After the reaction is completed, the liquid-solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com