Method for separating and comprehensively utilizing gases in carbon black tail gas and device for realizing method

A technology of gas separation and carbon black, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of long working cycle of temperature swing adsorption, secondary pollution, high energy consumption, etc., shorten the working cycle, improve heat value, the effect of simplifying the separation step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

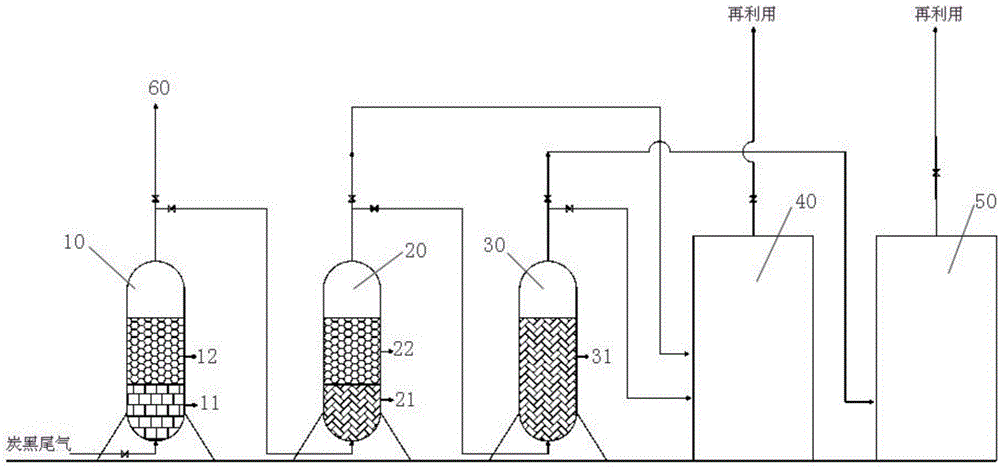

[0029] The separation method of carbon black tail gas comprises the steps:

[0030] 1) The carbon black tail gas first enters the first-stage pressure swing adsorption tower for H 2 For the adsorption of O gas and sulfur-containing gas, the adsorption material at the bottom of the tower is activated alumina, and the upper layer is 5A and 13X molecular sieves. The operating pressure in the tower is 0.1-0.5MPa, and the temperature is 10-30°C.

[0031] 2) depressurize in the first-stage pressure swing adsorption tower to depressurize H 2 O gas and sulfur-containing gas enter the H through the top of the tower 2 O gas and sulfur-containing gas collection device, the tail gas after the first stage pressure swing adsorption (adsorbed H 2 O gas and sulfur-containing gas) enter the second-stage adsorption tower to absorb N 2 , CO, CO 2 , the operating pressure in the tower is 2.0-2.3MPa, and the temperature is 60-80°C. The adsorption materials are activated carbon and molecular si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com