Method for degrading trichloroethylene by virtue of biological carbon immobilized microorganism co-metabolism

A technology for immobilizing microorganisms and trichloroethylene, which is applied to the restoration of polluted soil fixed on or in an inorganic carrier, can solve the problems of ecological environment damage, no pollutant removal, etc., and achieves improved tolerance, The effect of strong feasibility and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Example: Biochar-immobilized Pseudomonas fluorescens Co-metabolic degradation of TCE

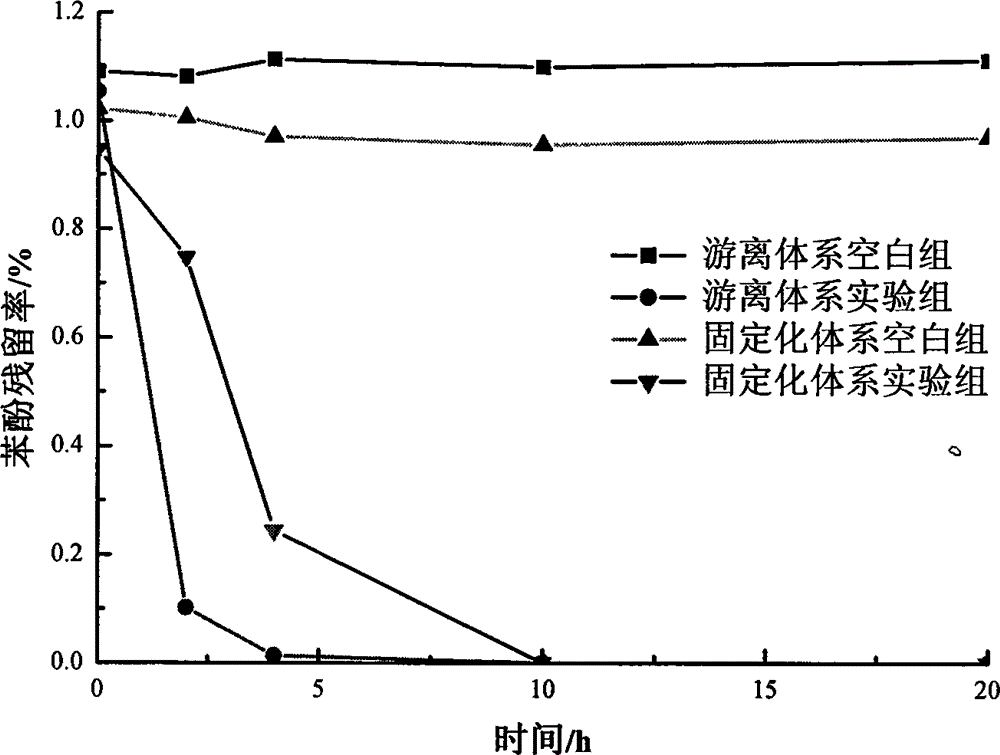

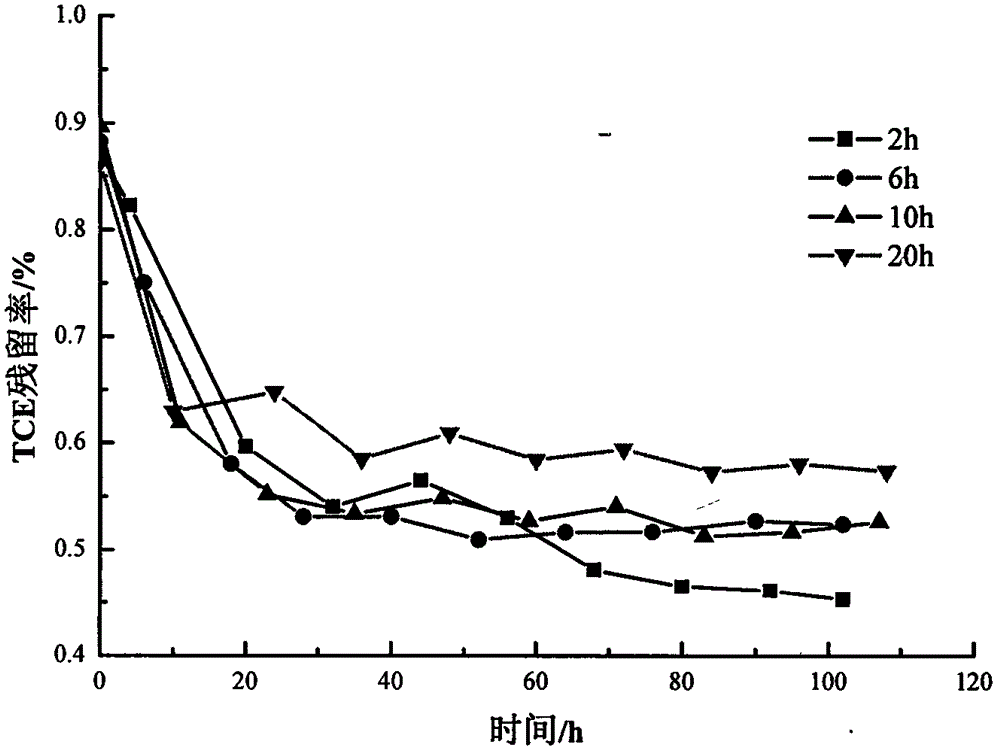

[0021] Biochar was selected as the immobilized carrier, phenol with a concentration of 100 mg / L was used as the co-metabolized substrate, the concentration of TCE was selected as 2 mg / L, and the residual rate of TCE was determined by selecting different adsorption times, pH, TCE concentration, salinity, and the amount of bacteria added.

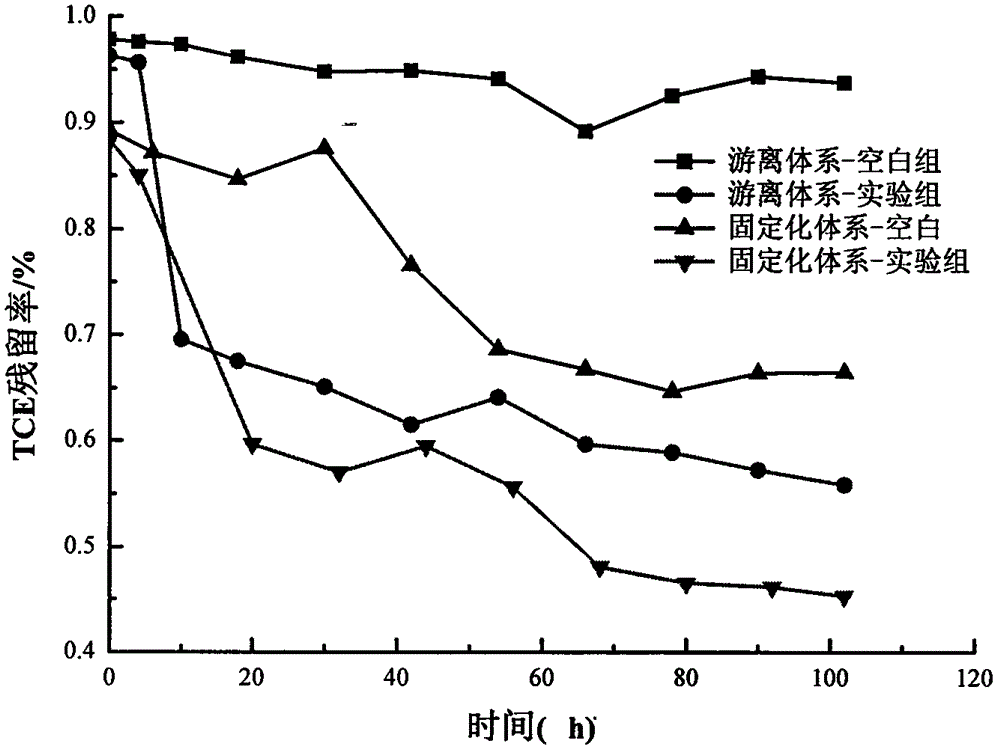

[0022] Depend on figure 1 It can be seen that the equilibrium is basically reached after 72 hours of reaction; the removal rate of TCE in the free system after equilibrium is 39% to 41%, and that of the immobilized system is 55% to 58%; compared with the free system, the overall TCE removal rate of the immobilized system is The removal rate increased by 15% compared with the free system. About 30% of the TCE removed in the immobilization system was co-metabolized and degraded by Pseudomonas fluorescens adsorbed on the biochar, and about 25% was adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com