Profile correction machining method for high-precision plane of optical part

A technology of optical parts and processing methods, applied in metal processing equipment, machine tools for surface polishing, manufacturing tools, etc., to achieve the effects of high processing efficiency, low cost, and small removal allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

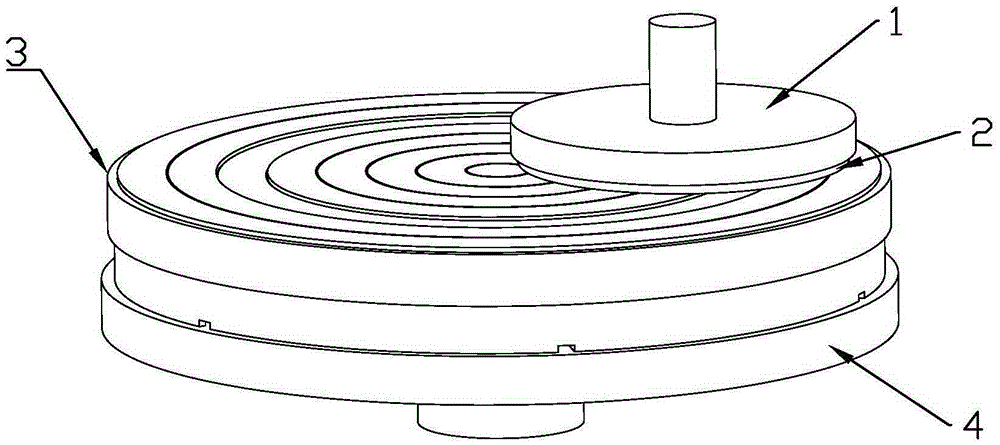

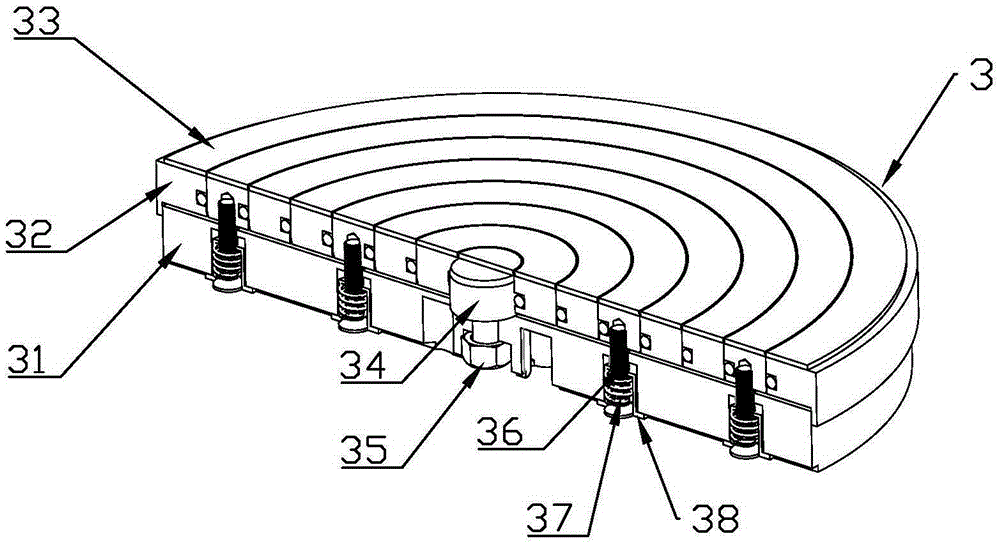

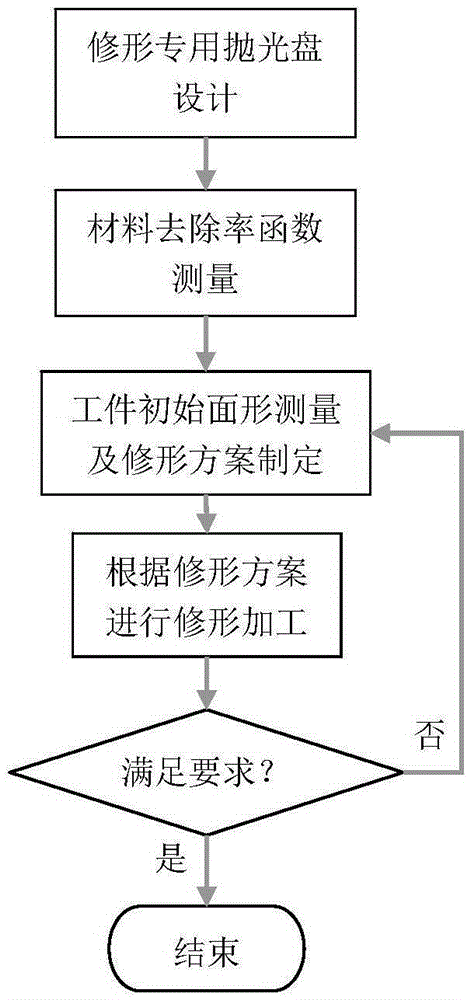

[0030] The invention provides a method for modifying and processing high-precision planes of optical parts. The method of the invention is mainly aimed at processing flat optical parts and can realize deterministic global modification processing of the surface of the optical parts. In this method, on the basis of traditional chemical mechanical polishing or mechanical polishing, the integral polishing disc on the grinding and polishing machine is replaced by a special polishing disc for modification, by removing the polishing pads located in different radial positions on the special polishing disc for modification Process conditions are controlled to obtain different material removal rate functions, and according to the deviation of the initial surface profile of the surface of the workpiece 2 to be processed, the processing time corresponding to the process conditions for various material removal characteristics is designed to realize the modification process of the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com