Deterministic local physical deliquescing device capable of being applied to polishing KDP (potassium dihydrogen phosphate) crystal as well as polishing method thereof

A processing device, a deterministic technology, applied in grinding devices, metal processing equipment, manufacturing tools, etc., can solve the problems of long processing cycle of KDP crystal, tool marks on the machined surface, low pass rate, etc., to achieve stable and controllable deliquescence process, Achieve deterministic machining, high-precision surface quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

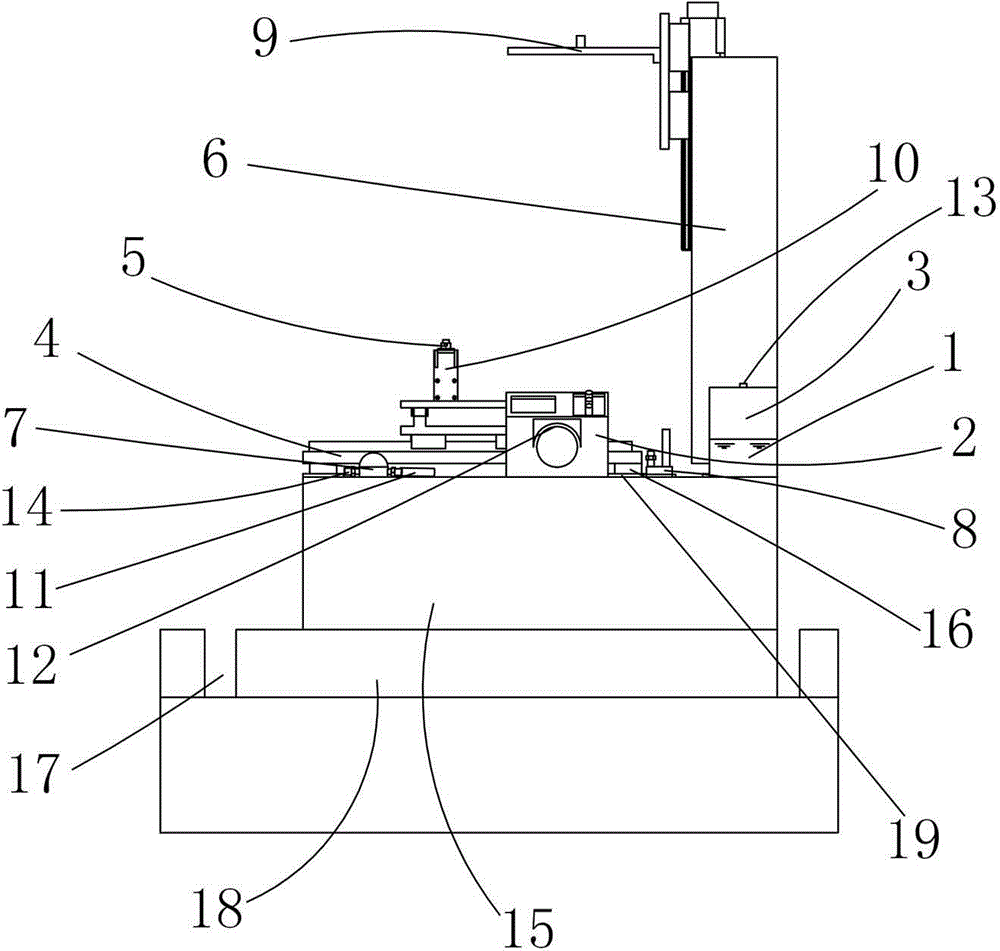

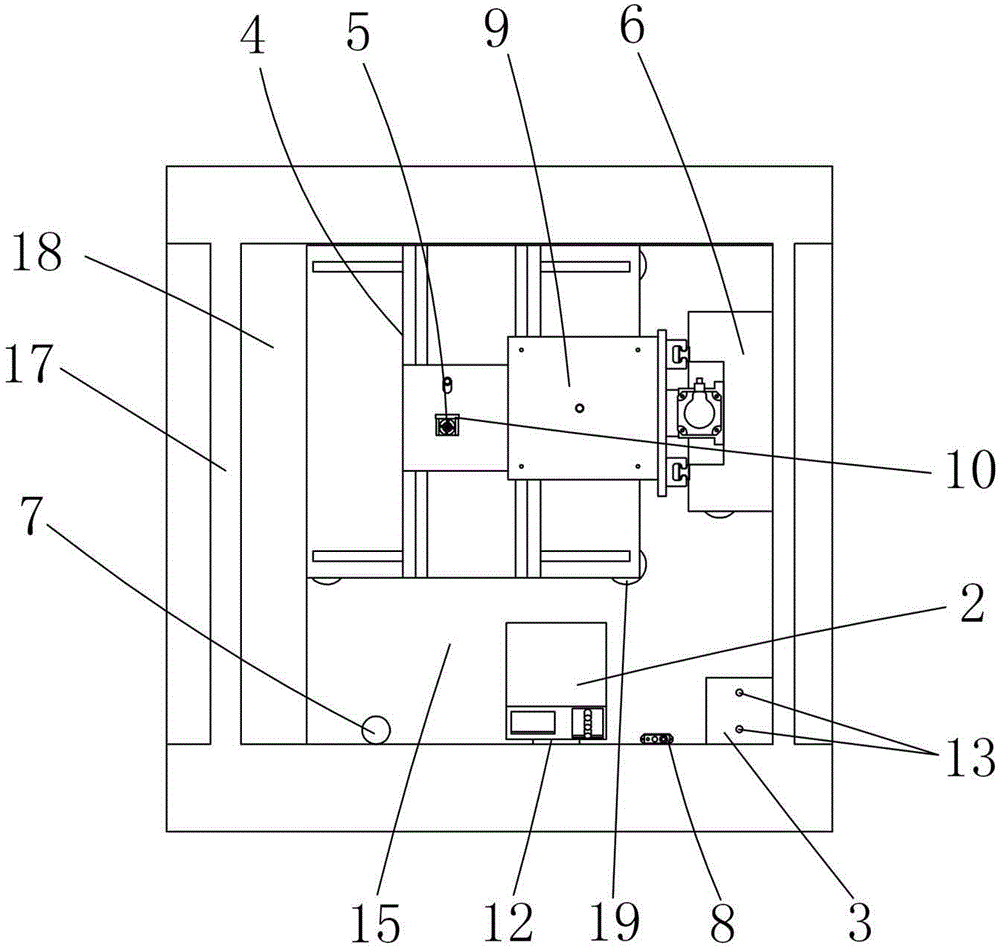

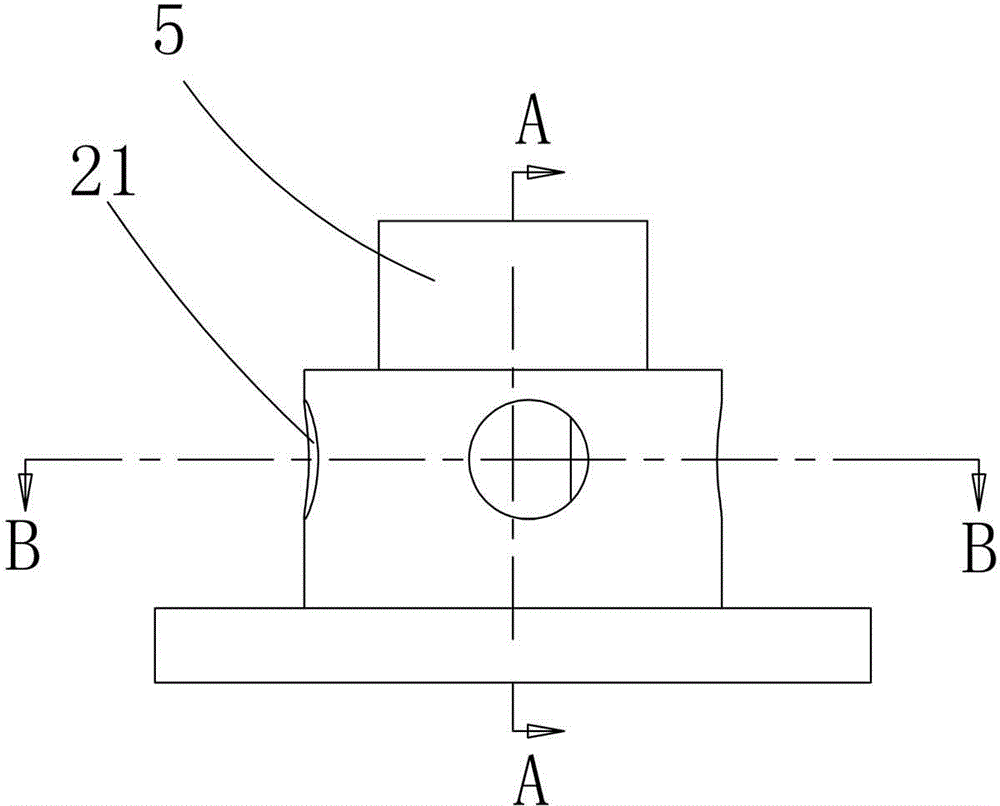

[0031] a kind of like Figure 1 to Figure 5 The shown deterministic partial physical deliquescence processing device for KDP crystal polishing process, the processing device includes a Z-axis lifting table 6 and an XY-axis motion platform 4 provided with a nozzle fixing table 10, and a fixed waiting table is installed on the Z-axis lifting table 6. The vacuum chuck 9 for polishing the KDP crystal, the top of the nozzle fixing table 10 is provided with a nozzle 5, the nozzle 5 is connected with the liquid storage tank 3 filled with the reaction solution 1 through the liquid delivery pipeline, and the liquid delivery pipeline is provided with a liquid storage tank. The reaction solution 1 in 3 is delivered to the peristaltic pump 2 at the nozzle 5 . The liquid delivery pipeline in this embodiment includes a liquid delivery hard tube 11 and a liquid delivery hose 12 , the liquid delivery hose 12 is mainly used on the peristaltic pump 2 , and the liquid delivery hard tube 11 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com