Preparation and application of palygorskite/graphite phase carbon nitride compound composite material

A composite material, palygorskite technology, applied in the direction of silicon compound, special compound water treatment, chemical/physical process, etc., can solve the problem that the degradation performance of organic pollutants is not ideal, cannot provide reactive sites, and is difficult to uniformly Covering and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

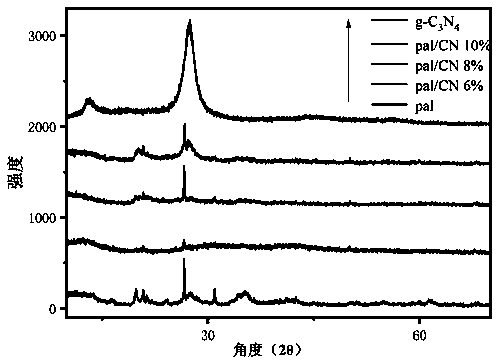

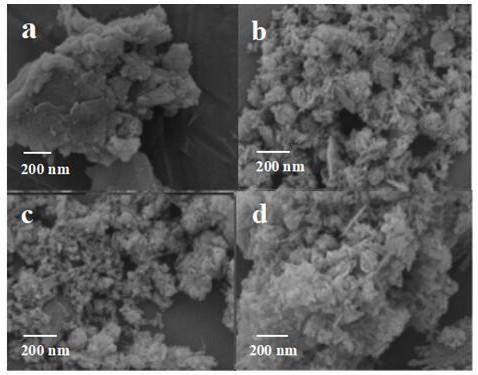

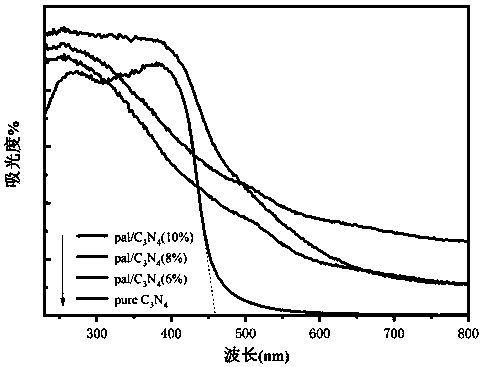

Embodiment 1

[0037] (1) Preparation of exfoliated palygorskite: Grind 10 g of raw ore palygorskite into powder, add 1 L of deionized aqueous solution to a large beaker and mechanically stir for 1 hour, stop stirring, let stand for 24 hours, remove the supernatant liquid, and extract The upper layer was precipitated, dried overnight at 100°C, added to 4 mol / L hydrochloric acid and stirred for 24 hours, washed five times with water, dried and ground for later use;

[0038] (2) pal / g-C 3 N 4 Preparation of (6%): Take 0.12 g of palygorskite prepared in step (1), add it to 100 ml of distilled water, ultrasonicate for 01 hour, then add 4 g of dicyandiamide, stir evenly, ultrasonicate for 1 hour, heat to 50°C and continue stirring Evaporate completely to dryness, grind into powder, calcined at 550°C for 4 hours, and grind into powder after cooling down to room temperature, which is pal / g-C 3 N 4 (6%) samples;

[0039] (3) Degradation performance of tetracycline hydrochloride: Degradation expe...

Embodiment 2

[0041] (1) Preparation of exfoliated palygorskite: same as in Example 1;

[0042] (2) pal / g-C 3 N 4 (8%) preparation: Take 0.16 g of palygorskite prepared in step (1) and add it to 100 ml of distilled water, ultrasonic for 1 hour, then add 4 g of dicyandiamide and stir evenly, then ultrasonic for 1 hour, heat to 50°C and continue stirring until Completely evaporated to dryness, ground into powder, calcined at 550°C for 4 hours, and ground into powder after cooling down to room temperature, which is the pal / g-C3N4 (8%) sample;

[0043] (3) Degradation performance of tetracycline hydrochloride: Degradation experiment was done under 800 watt xenon lamp, pal / g-C 3 N 4 (8%) The total removal rate of tetracycline hydrochloride reached 78%.

Embodiment 3

[0045] (1) Preparation of exfoliated palygorskite: same as in Example 1;

[0046] (2) pal / g-C 3 N 4 Preparation of (10%): Take 0.2 g of palygorskite prepared in step (1) and add it to 100 ml of distilled water, sonicate for 1 hour, then add 4 g of dicyandiamide, stir evenly, sonicate for 1 hour, heat to 45~50°C and continue Stir until completely evaporated to dryness, ground into powder, calcined at 550°C for 4 hours, and ground into powder after cooling down to room temperature, which is the pal / g-C3N4 (10%) sample;

[0047] (3) Degradation performance of tetracycline hydrochloride: Degradation experiment was done under 800 watt xenon lamp, pal / g-C 3 N 4 (10%) The total removal rate of tetracycline hydrochloride reached 57%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com