A preparation method, product and application of hexadecyltrimethylammonium bromide modified bismuth molybdate photoelectrode

A technology of cetyltrimethylammonium bromide and bismuth molybdate is applied in chemical instruments and methods, light water/sewage treatment, water/sludge/sewage treatment, etc. Unsatisfactory photocatalytic activity, limited popularization and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Preparation of bismuth molybdate powder by hydrothermal method

[0034] Take 1mol / L Na 2 MoO 4 2H 2 O solution 50ml and 2mol / L Bi(NO 3 ) 3 ·5H 250ml of O solution was thoroughly mixed to obtain a bismuth molybdate precursor solution, adjusted to a pH value of 9 with NaOH, placed in a hydrothermal reaction kettle, and subjected to a hydrothermal reaction at 120°C for 24 hours, and filtered after the hydrothermal reaction was completed. Dry and grind at 60°C to obtain bismuth molybdate powder;

[0035] Step 2: Preparation of bismuth molybdate photoelectrode

[0036] Add 0.15g of bismuth molybdate powder prepared in step 1 to 10ml of water to make a bismuth molybdate suspension, add 2mL of polyethylene glycol 400 and stir evenly, then add 0.1g of ethanol, heat and stir at 70°C until completely dissolved, and obtain a viscous Suspension, the suspension is evenly scraped onto the FTO conductive glass, the thickness of the film layer is 45 μm, placed in an oven...

Embodiment 2

[0038] The preparation process is the same as that in Example 1, except that 0.04 mol of CTAB is added to the uniformly mixed bismuth molybdate precursor solution in step 1 to obtain a CTAB-modified bismuth molybdate photoelectrode (BMO-1);

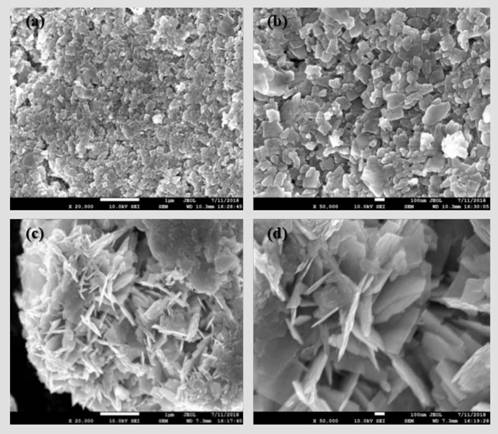

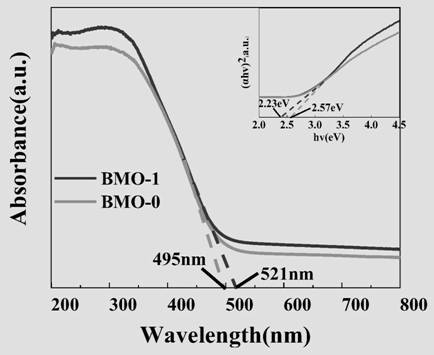

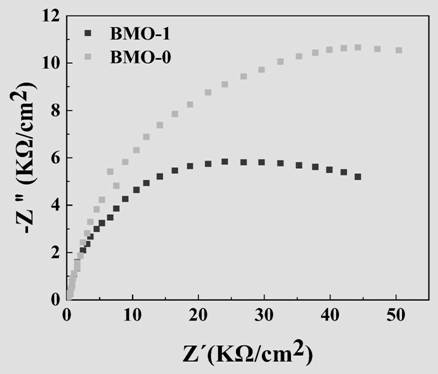

[0039] The photoelectrode prepared in embodiment 1 and embodiment 2 is carried out structure and morphology analysis, and the X-ray diffraction spectrum (XRD) of implementing 1 photoelectrode and embodiment 2 photoelectrode is as follows figure 1 As shown, several groups of enhanced diffraction peaks 2θ=28.24°, 32.59°, 33.07°46.72°, 55.45°, 56.16° and 58.42° can be observed in the spectrum, corresponding to (131), (002), (060) , (202), (331), (262) crystal planes, the positions of the diffraction peaks and Bi 2 MoO 6 The XRD standard card (JCPDS 21-0102) matches, all belong to the orthorhombic crystal phase, and no other impurity phases appear, indicating that the purity is high. After calcination in the muffle furnace, compared with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| photocurrent | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com