Integrated physical chemistry purification method for treating complex industry organic waste gas, device and application

A technology of organic waste gas and physical chemistry, applied in the direction of chemical instruments and methods, separation methods, solid separation, etc., can solve the problems of reduced photocatalyst life, photocatalytic purification efficiency, ozone secondary pollution, etc., to reduce shading and Poisoning effect, elimination of secondary pollution problem, effect of elimination of shading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

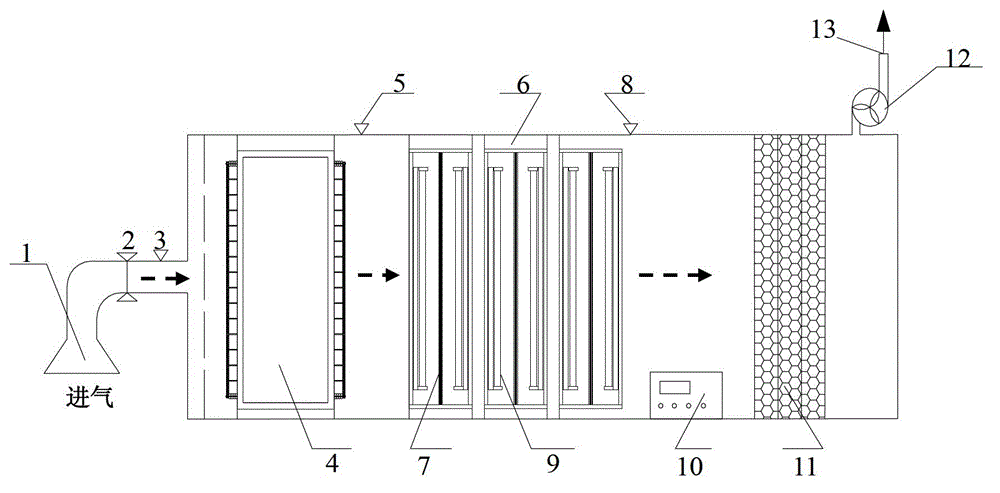

[0035] Equipment that realizes an integrated physical and chemical purification method for complex industrial organic waste gas: such as figure 1As shown, it includes a gas collecting hood 1, a reaction box and a fan 12 for extracting gas that are connected in sequence; an electrostatic precipitator 4, a photocatalytic reaction device 6, an ozone generator 10 and The adsorption bed 11; according to the gas direction, the gas inlet of the reaction box, the electrostatic precipitator 4, the photocatalytic reaction device 6, the ozone generator 10, the adsorption bed 11 and the gas outlet of the reaction box are arranged in sequence; the ozone generation Between the device 10 and the adsorption bed 11 is an ozone oxidation zone, and the adsorption bed 11 is provided with an adsorbent. The gas collection hood 1 is connected to the gas inlet of the reaction box through a pipeline, and a valve 2 for controlling the gas flow is arranged on the pipeline; the gas outlet of the reaction...

Embodiment 2

[0039] Use the equipment that embodiment 1 provides, wherein, photocatalyst is the nano-commercial TiO that is supported on the nickel foam 2 As a photocatalyst, the adsorbent on the adsorption bed is Au-loaded activated carbon and molecular sieve, and its preparation process is: HAuCl 4 Make an impregnating liquid with a concentration of 0.01g / L with water, then add 2.5g of activated carbon and 2.5g of SBA-15 molecular sieve into 1L of impregnating liquid, and then adjust the pH of the impregnating liquid to 7 with 0.1mol / L NaOH solution. After reacting at 40°C for 5min, filter, wash with deionization, dry naturally at room temperature, and calcinate at 200°C for 12h to obtain Au-loaded activated carbon and molecular sieve adsorbent.

[0040] (1) Electrostatic precipitator: collect organic waste gas (benzene series organic waste gas) through the gas collection hood 1, and the organic waste gas is treated by the electrostatic precipitator 4 to remove the total suspended partic...

Embodiment 3

[0045] The difference between the equipment used in this embodiment and the equipment used in Example 2 is that the photocatalyst of this embodiment is the nano ZnO-SnO supported on the nickel foam 2 Composite oxide photocatalyst (invention patent: ZL 03126662.2), the adsorbent is Au-loaded activated carbon and molecular sieve, and the ozone generation is 15g / h. The preparation process of Au-loaded activated carbon and molecular sieve is as follows: HAuCl 4 Make an impregnating solution with a concentration of 0.1g / L with water, then add 1g of activated carbon and 4g of SBA-15 molecular sieve into 1L of the impregnating solution, and then adjust the pH value of the impregnating solution to 7 with 0.1mol / L NaOH solution. After reacting at ℃ for 120min, filter, wash with deionization, dry naturally at room temperature, and calcinate at 400℃ for 1h to obtain Au-loaded activated carbon and molecular sieve adsorbent.

[0046] The research results of organic waste gas degradation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com