Method for recycling butyric acid by treating butanol and octanol waste lye

A waste lye, adsorption treatment technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of low CODCr removal rate, environmental friendliness and economic benefits. , the extraction technology is difficult to achieve the effect and other problems, to achieve the effect of significant environmental and economic benefits, increase product value, and low investment and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0051] Use 98% concentrated sulfuric acid to acidify the waste lye, adopt the method of standing and floating to separate layers, recover the upper organic phase, and measure the COD of the lower acidic water phase Cr . See the specific treatment effect

[0052] Table 1:

[0053] Table 1 Acidification treatment effect of butyl octanol waste lye

[0054]

Embodiment 6

[0056] COD with 30% waste sulfuric acid Cr Acidify the spent lye with a concentration of 104651mg / L. The pH after acidification is 3. After standing and floating for 2 hours, the upper organic phase is recovered, and the COD of the lower acidic aqueous phase is measured. Cr 27137mg / L, COD Cr The removal rate was 74.1%.

Embodiment 7~12

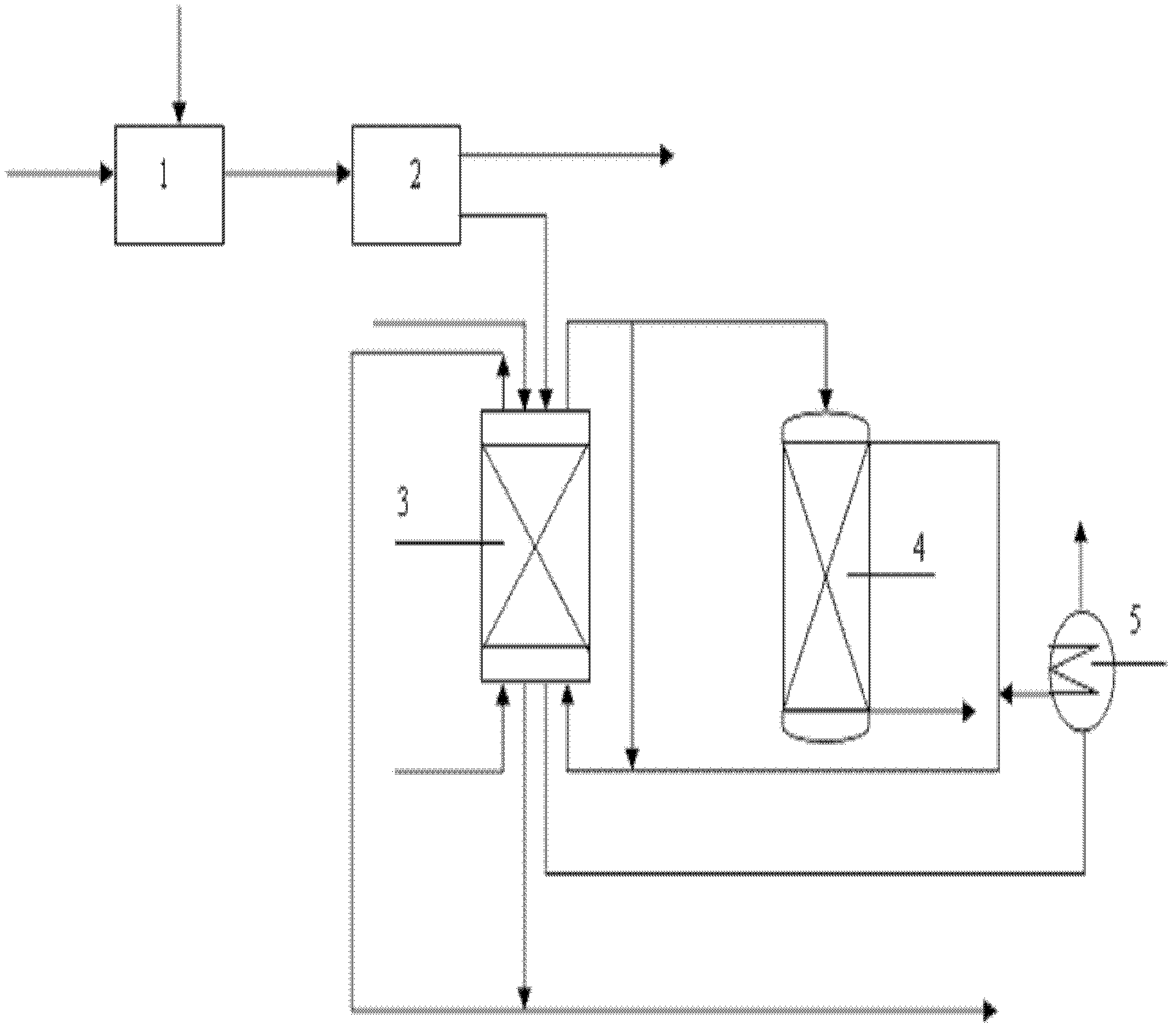

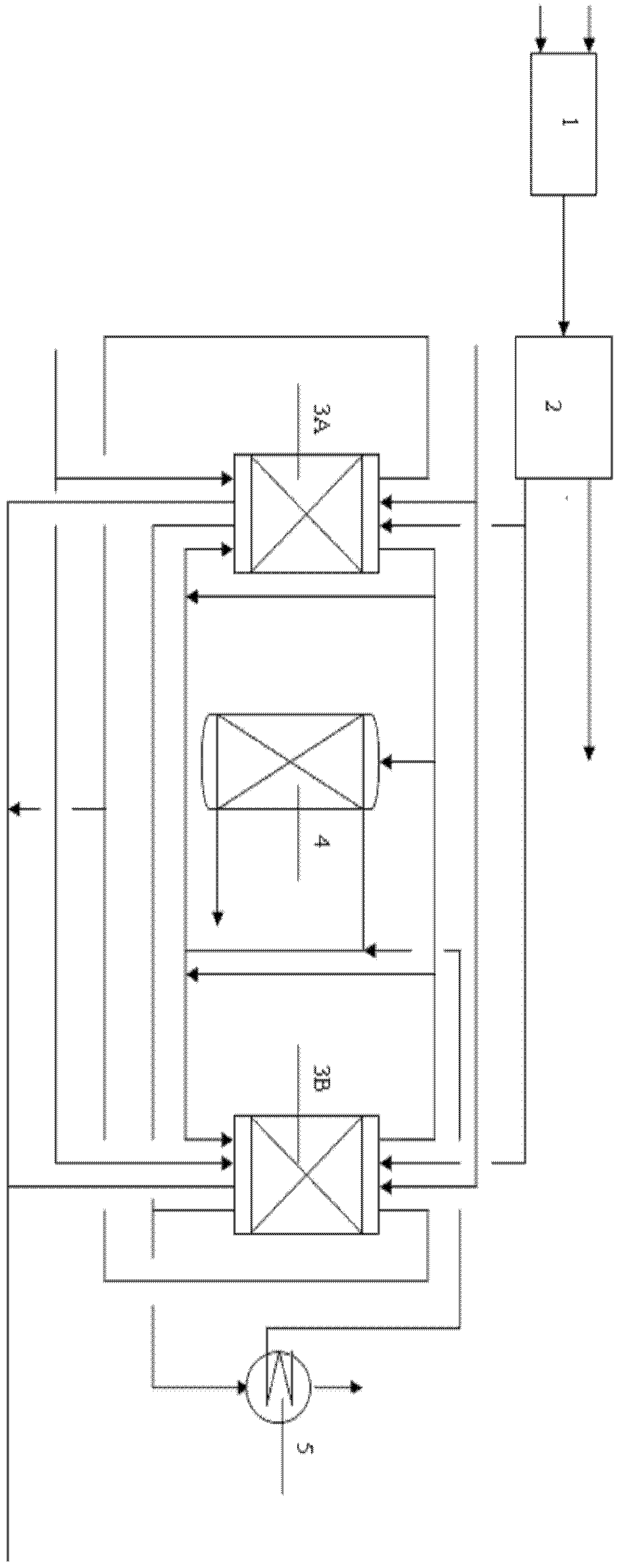

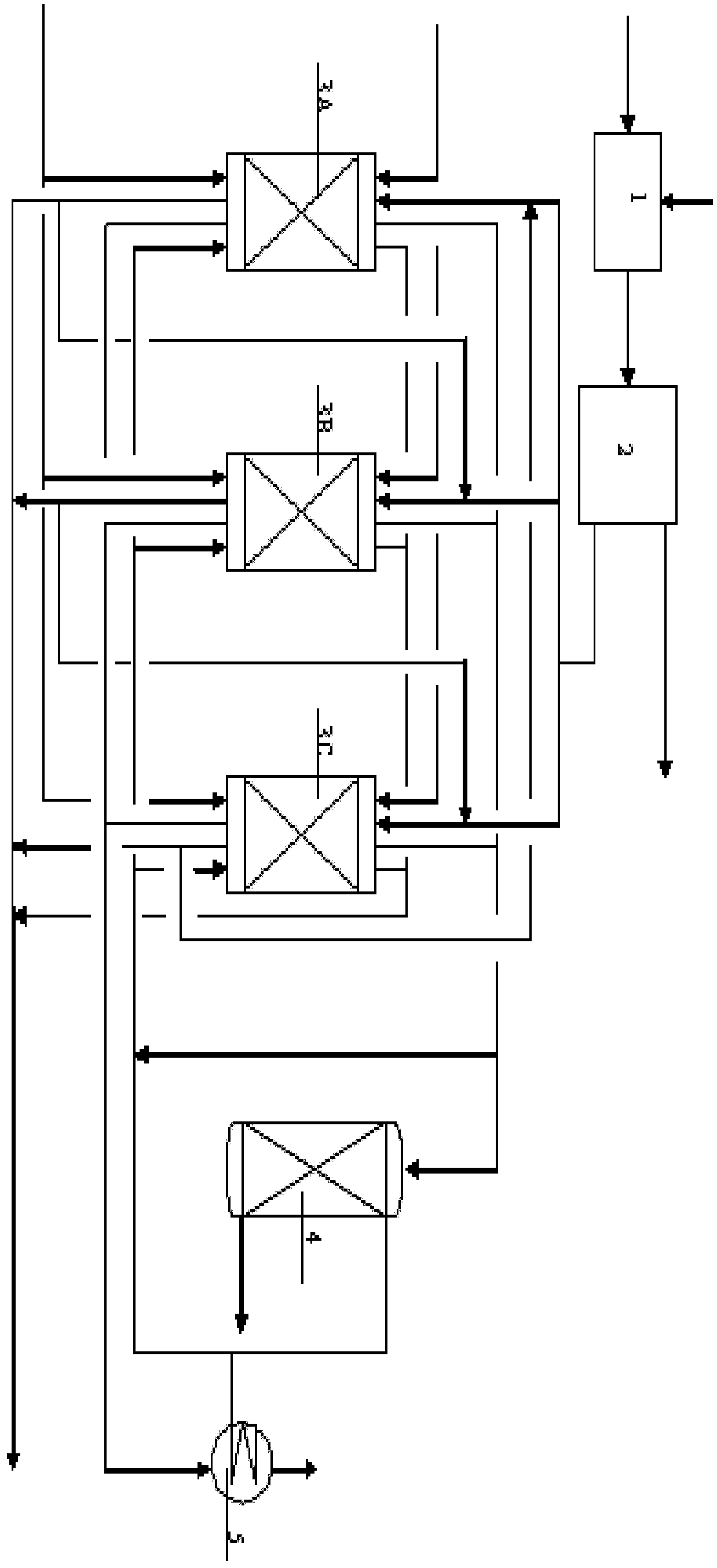

[0058] Use 98% concentrated sulfuric acid for COD Cr Carry out acidification treatment for 104651 mg / L octanol waste lye, adjust pH=3, adopt static floatation method to stratify for 2 hours, recover the upper organic phase, and the lower acidic water phase enters the resin tower for adsorption treatment, and the adsorption adopts resin tower 3A and resin tower 3B two towers alternate adsorption regeneration operation form (see figure 2 ). The specific treatment effect is shown in Table 2:

[0059] Table 2 Effect of two towers alternate adsorption treatment

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com