Bentonite compounded porous material and preparation method thereof

A technology of porous materials and bentonite, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve the difficulty of controlling the polycondensation reaction of dicyandiamide and formaldehyde, the difficulty of mass production of products, and the difficulty of complete removal, etc. problem, to achieve the effect of low production cost, easy to remove, and easy to obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

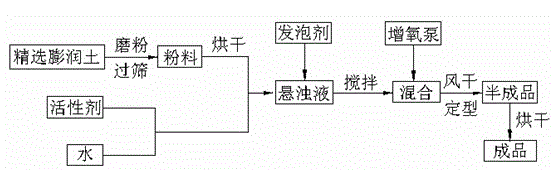

Method used

Image

Examples

Embodiment 1

[0025] ① Grind the artificially selected calcium-based bentonite raw ore and pass through a 200-mesh sieve to make bentonite powder. Put the bentonite powder in an oven at 100°C for 1.5 hours, and put the dried bentonite powder into a dryer to wait Use, control moisture ≤ 12%. The oven adopts an electric blast drying oven.

[0026] ② Add the active agent octadecyltrimethylammonium chloride into distilled water and stir until dissolved. If it is difficult to dissolve, heat it slightly to make an active agent solution. Pour the active agent solution into the bentonite powder and use a high-speed stirrer Mix and stir evenly without agglomeration to make a bentonite suspension. The speed of the high-speed stirrer should be above 1000r / min.

[0027] ③ Add the plant foaming agent to the bentonite suspension, and stir with a high-speed mixer until it is evenly mixed while adding it, then penetrate the porous air outlet of the aeration pump into the bentonite suspension and stir at ...

Embodiment 2

[0030] ① Grind the artificially selected calcium-based bentonite raw ore and pass through a 200-mesh sieve to make bentonite powder. Put the bentonite powder in an oven at 105°C for 2 hours, and put the dried bentonite powder into a dryer for use , control moisture ≤ 12%. The oven adopts an electric blast drying oven.

[0031] ② Add the active agent cetyltrimethylammonium bromide into distilled water and stir until dissolved. If it is difficult to dissolve, heat it slightly to make an active agent solution. Pour the active agent solution into the bentonite powder and use a high-speed stirrer Mix and stir evenly without agglomeration to make a bentonite suspension. The speed of the high-speed stirrer should be above 1000r / min.

[0032] ③ Add the plant foaming agent to the bentonite suspension, and stir with a high-speed mixer until it is evenly mixed while adding it, then penetrate the porous air outlet of the aeration pump into the bentonite suspension and stir at high speed...

Embodiment 3

[0035] ① Grind the artificially selected calcium-based bentonite raw ore and pass through a 200-mesh sieve to make bentonite powder. Put the bentonite powder in an oven at 110°C for 2.5 hours, and put the dried bentonite powder in a dryer for Use, control moisture ≤ 12%. The oven adopts an electric blast drying oven.

[0036] ② Add the active agent lauryl dimethyl amine oxide into distilled water and stir until dissolved. If it is difficult to dissolve, heat it slightly to make an active agent solution. Pour the active agent solution into the bentonite powder and mix with a high-speed stirrer Stir evenly without agglomeration to make a bentonite suspension. The speed of the high-speed stirrer should be above 1000r / min.

[0037] ③ Add the plant foaming agent to the bentonite suspension, and stir with a high-speed mixer until it is evenly mixed while adding it, then penetrate the porous air outlet of the aeration pump into the bentonite suspension and stir at high speed for 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com