Crude oil degrading bacterium for producing lipid biosurfactant and application

A crude oil degrading bacteria, biological surface technology, applied in microorganism-based methods, microorganisms, biochemical equipment and methods, etc., can solve the problems of high cost, large investment, low yield, etc., and achieve long-lasting effect, obvious emulsification and increase. effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

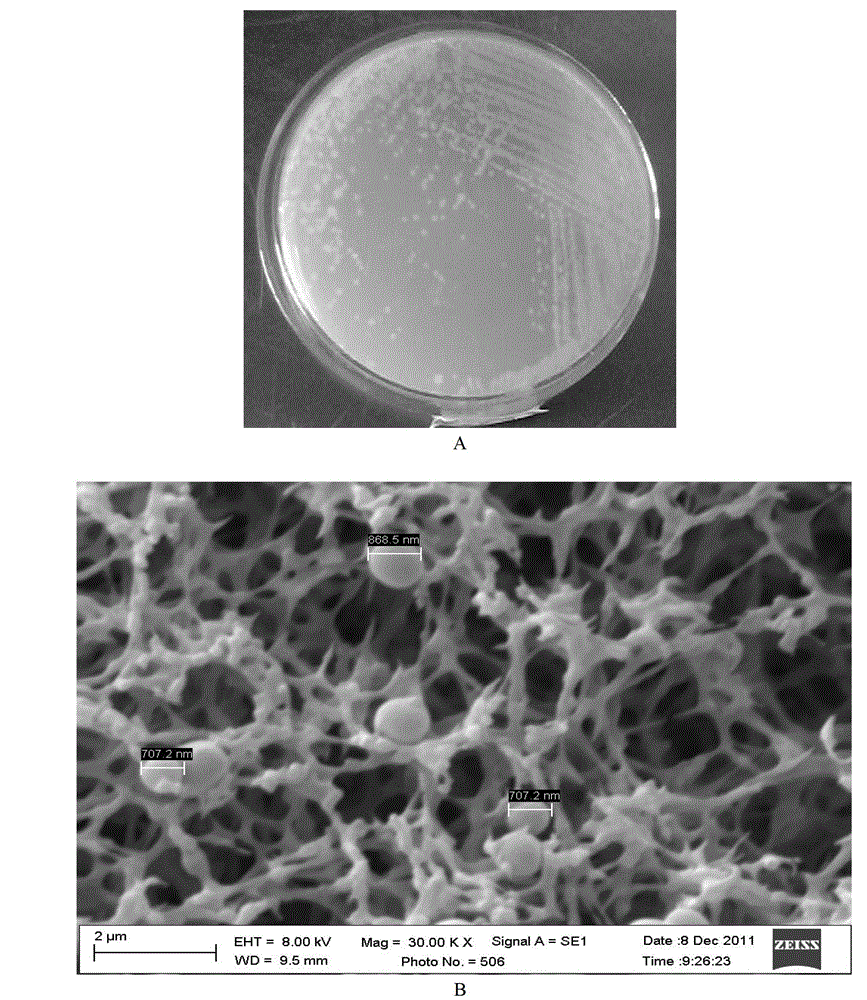

[0022] Screening isolation of MZ01.

[0023] Oil-contaminated soil near an oil refinery in Guangzhou was collected, 2g of the soil was added to medium A, and placed in a shaker at 30°C and 150rpm overnight. Add crude oil as the only carbon source to medium A to repeatedly acclimatize and cultivate the strains in the soil (place at 30°C, shake at 150rpm for 5 days, and then inoculate again into medium A containing 2g of fresh crude oil after 5 days, repeat this step three times acclimation to the strains in the soil), the amount of crude oil (from Guangzhou Sinopec Company) added was 2g of crude oil per liter of medium A.

[0024] The composition of medium A (the composition of medium A used below is the same as here) is to add 1ml of trace elements to each liter of enrichment medium, and the pH value is 7.0;

[0025] Contains per liter of enrichment medium: 0.5 g MgSO 4 .7H 2 O, 0.02 g CaCl 2 .2H 2 O, 1 g NH 4 NO 3 , 1g NaCl, 3g yeast extract, 1.5g KH 2 PO 4 , 2 grams...

Embodiment 2

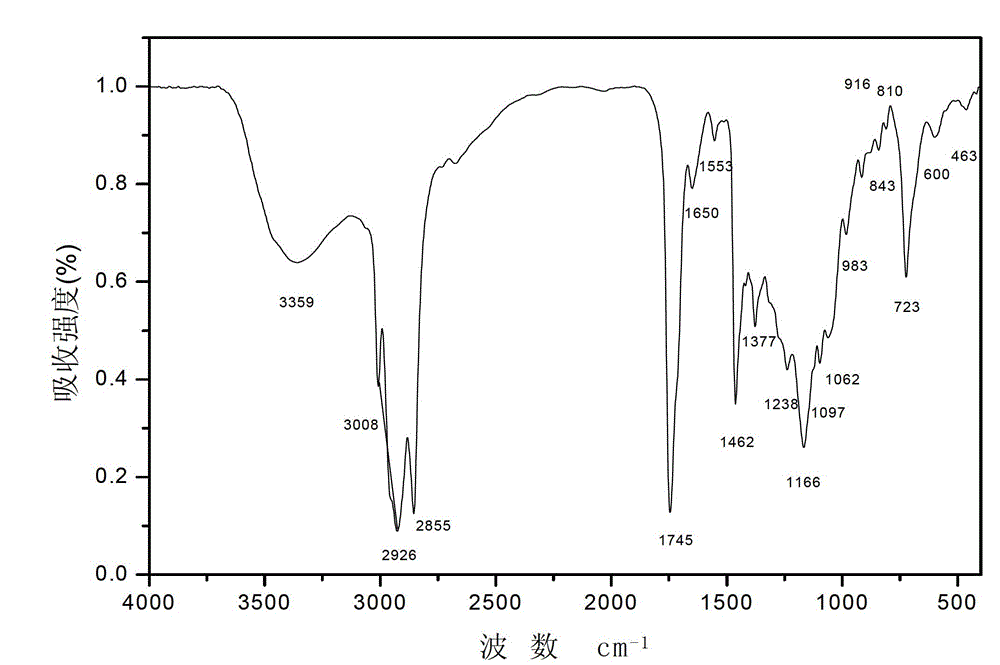

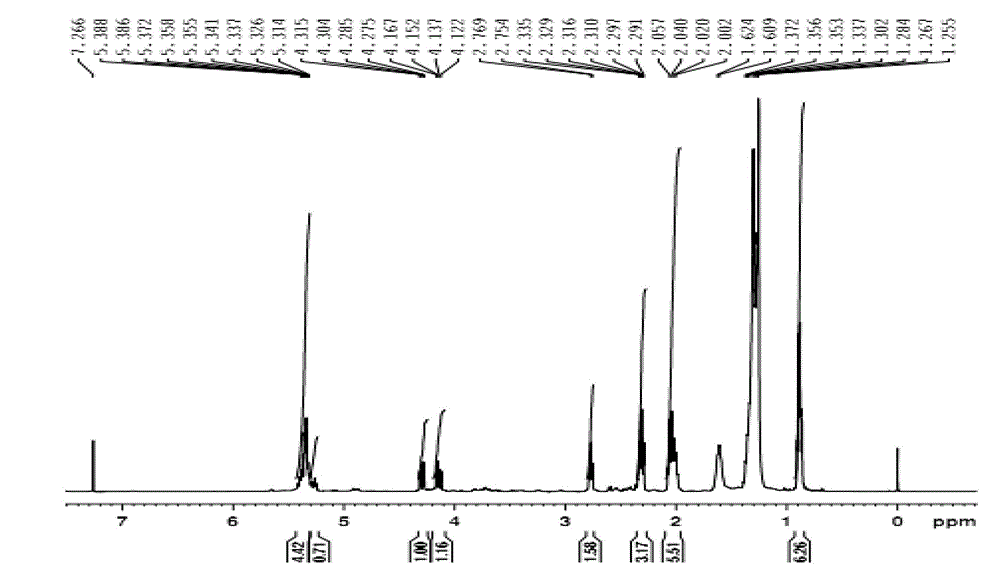

[0066] Embodiment 2: the identification of surfactant bacterial strain

[0067] Purification of biosurfactants

[0068] Add corn oil to medium A (the amount of corn oil added is 2 g of corn oil per liter of medium A) to ferment the strain MZ01. After 7 days, adjust the pH value of the obtained bacterial liquid to 8.0 with 2N NaOH. Then centrifuge at 10000rpm for 15min, collect the supernatant, adjust the pH value of the supernatant to 2.0 with 12N HCl, and put it in a refrigerator at 4°C overnight. Then the solution was centrifuged at 10000rpm for 15min to collect the precipitate. The precipitate was extracted three times with chloroform:methanol solution at a ratio of 2:1 by volume, the lower layer was removed, filtered with a 0.22 μm filter membrane, the filtrate was taken, and the desired product was obtained by rotary evaporation (45°C). After measurement, at 25°C, the initial pH value is 7, and the medium A containing 2g / L corn oil is used for fermentation and culture. ...

Embodiment 3

[0079] Embodiment 3: the surfactant CMC value determination that bacterial strain MZ01 produces

[0080] The tensio-active agent after purifying and drying according to Example 2 is prepared into a series of aqueous solutions whose concentration is 0.025, 0.04, 0.05, 0.1, 0.2, 0.25, 0.3g / l, using the QBZY-1 type surface active agent produced by Shanghai Fangrui Instrument Co., Ltd. The tensiometer measures its surface tension at 25°C, and the results are as follows Figure 5 shown. According to the figure, the surfactant produced by strain MZ01 has a CMC value of 0.1g / l, which can reduce the surface tension of water from 72mN / m to 30mN / m. The results showed that the surfactant had a good emulsifying and solubilizing effect on hydrophobic organic compounds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com