Method for extracting phytic acid

A phytic acid and extraction technology, applied in the chemical industry, can solve the problem of high content of inorganic phosphorus in phytic acid, and achieve the effect of less process, wide industrial application prospect and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

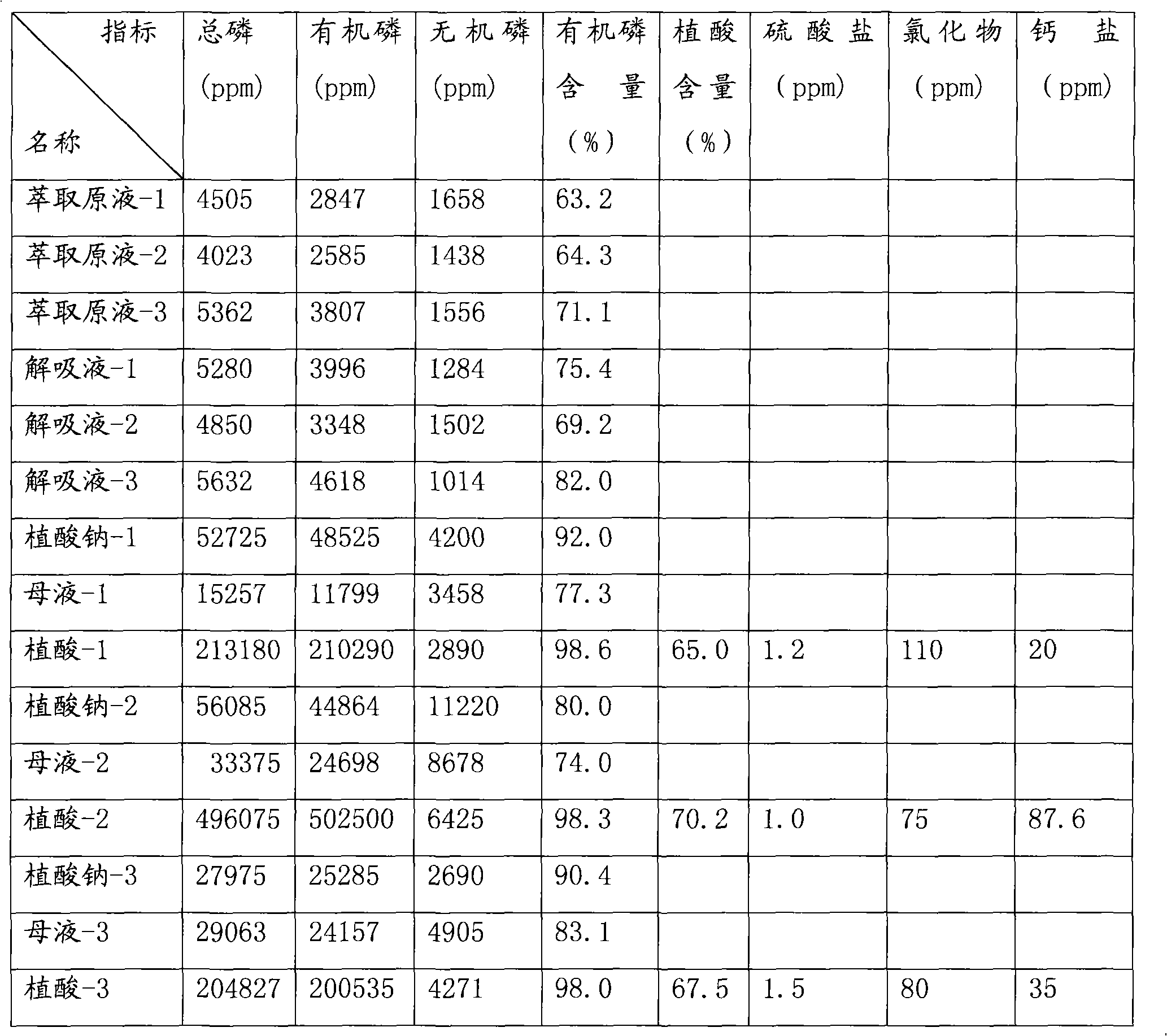

Image

Examples

Embodiment 1

[0033] (1) After removing impurities from the corn, mix it with water at a weight ratio of 1:3, and then pass SO 2 The gas adjusts the pH to 3.0. After soaking at a temperature of 50°C for 48 hours, the liquid obtained after separating the solids is the extraction stock solution corn soaking water.

[0034] (2) Add 1‰ cationic polyacrylamide to 200L corn soaking water for flocculation, and obtain the filtrate after filtering the precipitate, and the filter residue can be used for feed processing.

[0035] (3) Add hydrochloric acid to adjust the pH of the filtrate to 2.5, and the filtrate is passed through at a speed of 30L / h. It is that 100L is equipped with 50Kg polyacrylic acid D318 anion exchange resin (produced by Jiangsu Suqing Water Treatment Engineering Group Co., Ltd.) to absorb the phytic acid therein, and flow out The liquid is returned to the branch factory for reuse. After testing, the adsorption rate of organic phosphorus in corn soaking water can reach 90%.

[0...

Embodiment 2

[0045] (1) After removing impurities from the bran, mix it with water at a weight ratio of 1:2, add hydrochloric acid to adjust the pH to 5.0, soak it at a temperature of 45°C for 72 hours, separate the solid and obtain the liquid as the extraction stock solution for later use. The filter residue can be used for feed processing.

[0046] (2) Add 0.1‰ non-ionic organic polymer flocculant to 200L of the extraction stock solution obtained in step (1) for flocculation, and filter the precipitate to obtain the filtrate for later use.

[0047] (3) Add hydrochloric acid to adjust the pH of the filtrate to 5.0, and the filtrate is passed through at a speed of 40L / h. It is that 100L is equipped with 50Kg polyacrylic acid D318 anion exchange resin (produced by Jiangsu Suqing Water Treatment Engineering Group Co., Ltd.) to absorb the phytic acid therein, and flow out The liquid is returned to the branch factory for reuse. After testing, the adsorption rate of organic phosphorus in this s...

Embodiment 3

[0054] (1) After removing impurities from the rice bran, mix it with water at a weight ratio of 1:5, and then pass through SO 2 The gas is adjusted to pH 4.5, and after soaking at a temperature of 30°C for 70 hours, the solid is separated to obtain an extraction stock solution for later use, and the filter residue can be used for feed processing.

[0055] (2) Add 0.5‰ anionic polyacrylamide to 200L of the extraction stock solution obtained in step (1) for flocculation, and filter the precipitate to obtain the filtrate for later use.

[0056] (3) Add hydrochloric acid to adjust the pH of the filtrate to 2.8, and the filtrate is passed through at a speed of 35L / h. It is that the polyacrylic acid D318 anion exchange resin produced by 50Kg Jiangsu Su Qing Water Treatment Engineering Group Co., Ltd. is installed in a volume of 100L to absorb the phytic acid therein, and the effluent Return to the branch factory for reuse. After testing, the adsorption rate of organic phosphorus in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com