Preparation method of polycarboxylic acid water reducing agent compound

A technology of polycarboxylate and water reducer, which is applied in the field of preparation of polycarboxylate water reducer compound, to achieve the effect of improving compoundability, improving function, and improving internal plastic protection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

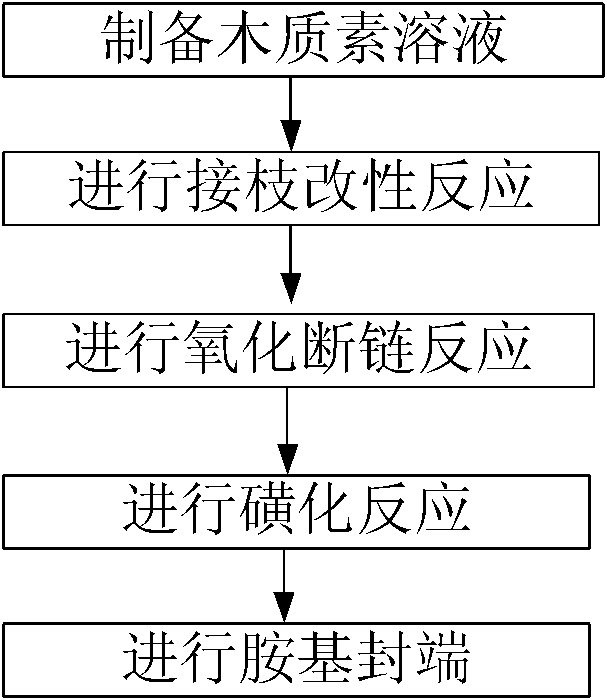

[0046] The preparation method of a kind of polycarboxylate water-reducer compound agent that the present invention proposes, such as figure 1 As shown, the preparation process of carrying out the grafting modification reaction first, and then carrying out the oxidative chain scission reaction specifically includes the following steps:

[0047] Step 1: Prepare lignin solution:

[0048] Weigh 1000g of lignin with a purity greater than or equal to 60% and place it in a reaction vessel, add 429-9000mL of water, and stir to completely dissolve the lignin in the water to form a lignin solution.

[0049] The lignin is preferably alkaline lignin, hydrochloric acid lignin, acid lignin, Larsen lignin, high-purity lignin prepared by solvent extraction, steam cracking lignin, milling lignin , 1,4-dioxane lignin or lignosulfonate.

[0050] Step 2: heating the reaction vessel in a water bath to react:

[0051] (1) Carry out graft modification reaction:

[0052] When the temperature of ...

Embodiment 1

[0080] In this example, the preparation method of the polycarboxylate-based water-reducer compounding agent that first undergoes the graft modification reaction and then undergoes the oxidative chain scission reaction, specifically includes the following steps:

[0081] Step 1: Prepare lignin solution:

[0082] Weigh 1000g of alkaline lignin with a purity equal to 60% and place it in a reaction vessel, add 1000mL of water and stir to completely dissolve the lignin in the water to form a lignin solution.

[0083] Step 2: heating the reaction vessel in a water bath to react:

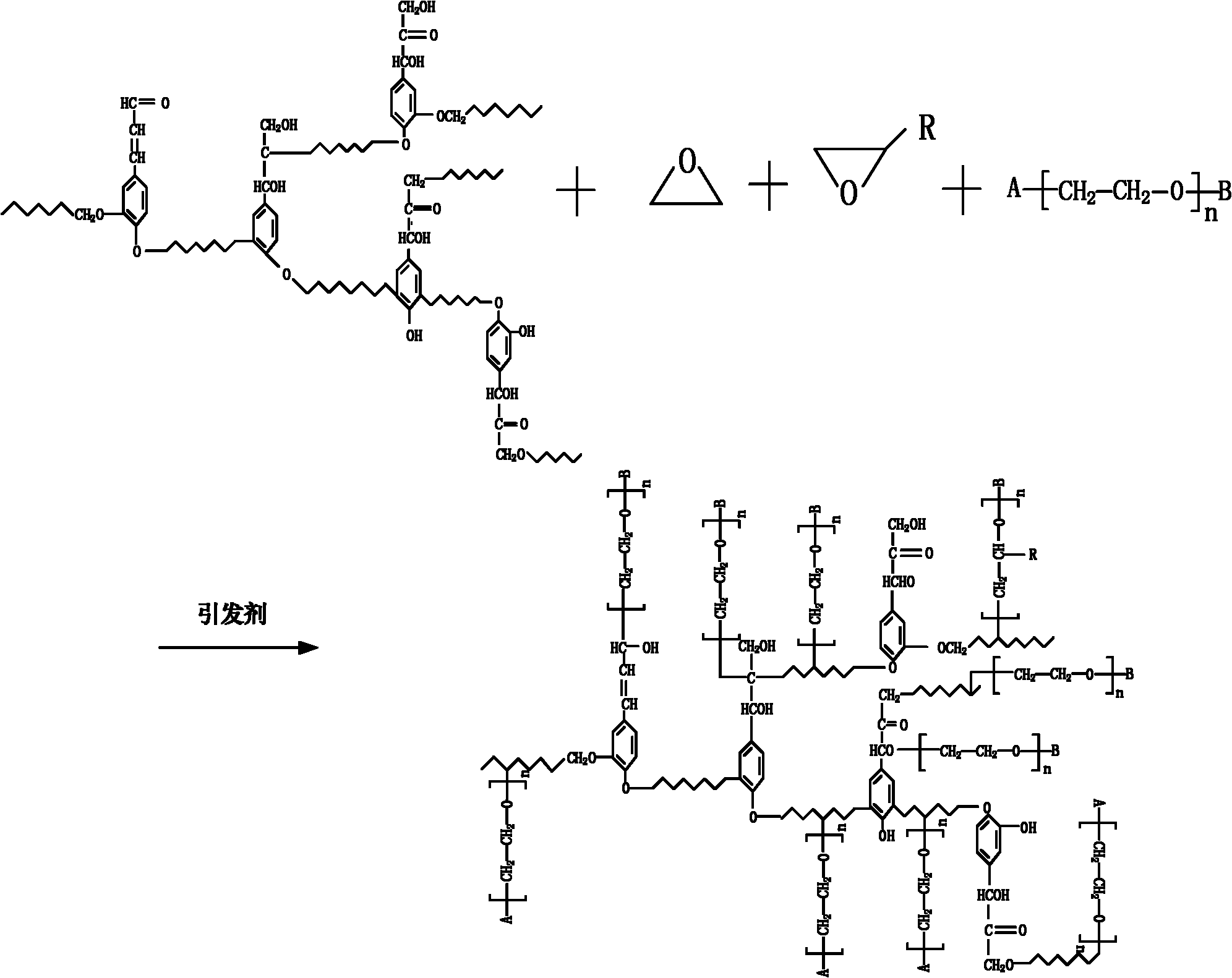

[0084] (1) Carry out graft modification reaction:

[0085] When the temperature of the lignin solution in the reaction vessel is raised to 70°C, slowly add a mass of 20g active monomer—propylene oxide and 500g oligomer allyl polyethylene glycol (APEG) into the reaction vessel Molecular weight is 600, then adding the initiator ammonium persulfate (NH 4 ) 2 S 2 o 8 , and continue to insulate and react ...

Embodiment 2

[0097] In this example, the oxidative chain scission reaction is carried out first, and then the graft modification reaction is carried out. The specific preparation method of the polycarboxylate water reducer compound includes the following steps:

[0098] Step 1: Prepare lignin solution:

[0099] 1000g of alkaline lignin with a purity of 60% was weighed and placed in a reaction vessel, 2000mL of water was added and stirred to completely dissolve the lignin in the water to form a lignin solution.

[0100] Step 2: heating the reaction vessel in a water bath to react:

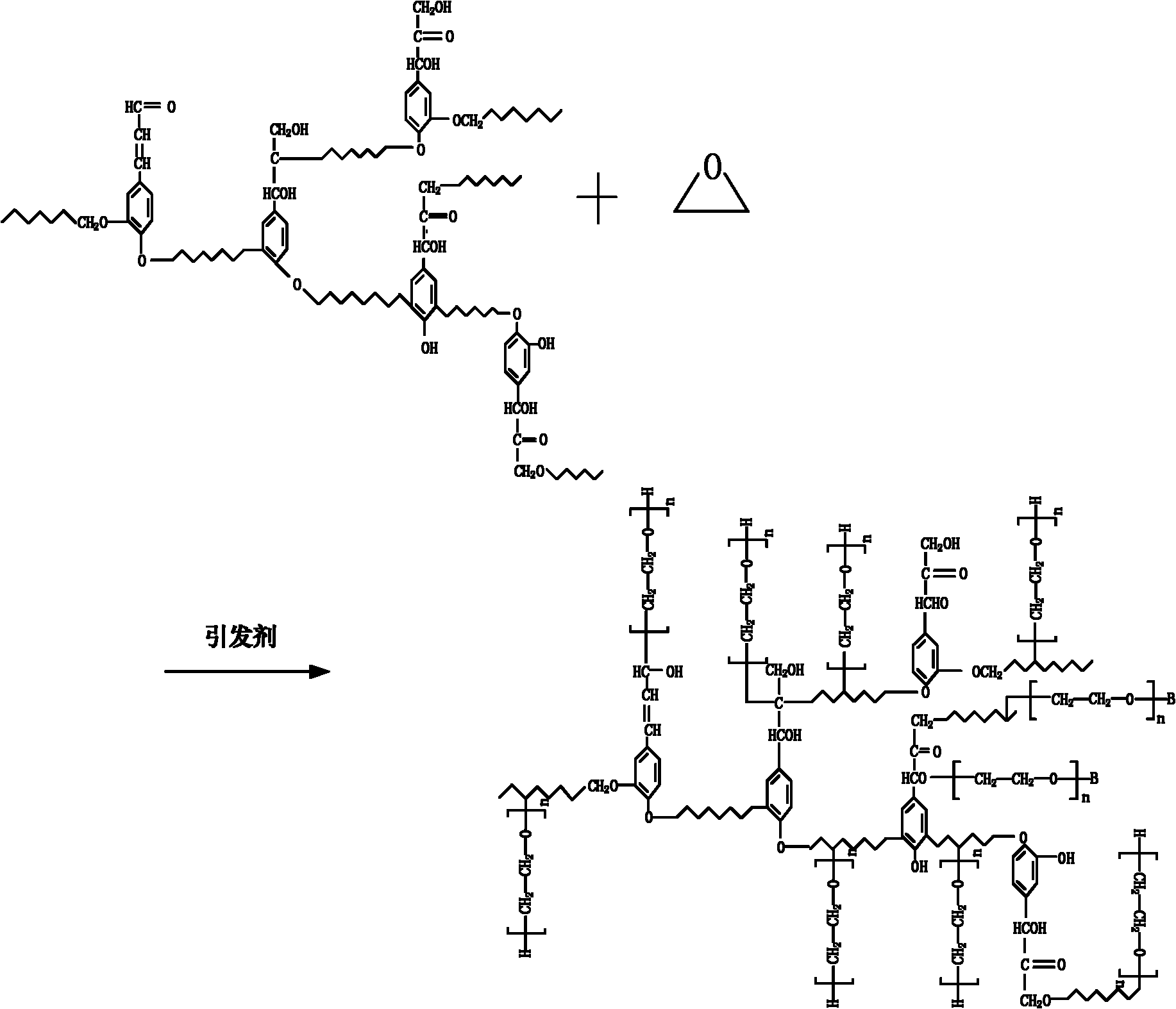

[0101] (1) Carry out oxidative chain scission reaction:

[0102] The solution temperature of the lignin solution in the reaction vessel is maintained at 80° C., and the compressed air and the composite catalyst solution whose flow rate is 60 mL / min are passed into the reaction vessel, and the addition amount of the composite catalyst solution meets the catalytic effect in the composite catalyst. The concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com