Machine vision-based system for detecting abnormal state of scraper

A technology of abnormal state and detection system, applied in the direction of instruments, computer parts, character and pattern recognition, etc., can solve the problems of unfavorable installation and maintenance, cumbersome use process, low processing efficiency, etc., to achieve easy installation and maintenance, improve efficiency, structure scientifically sound effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

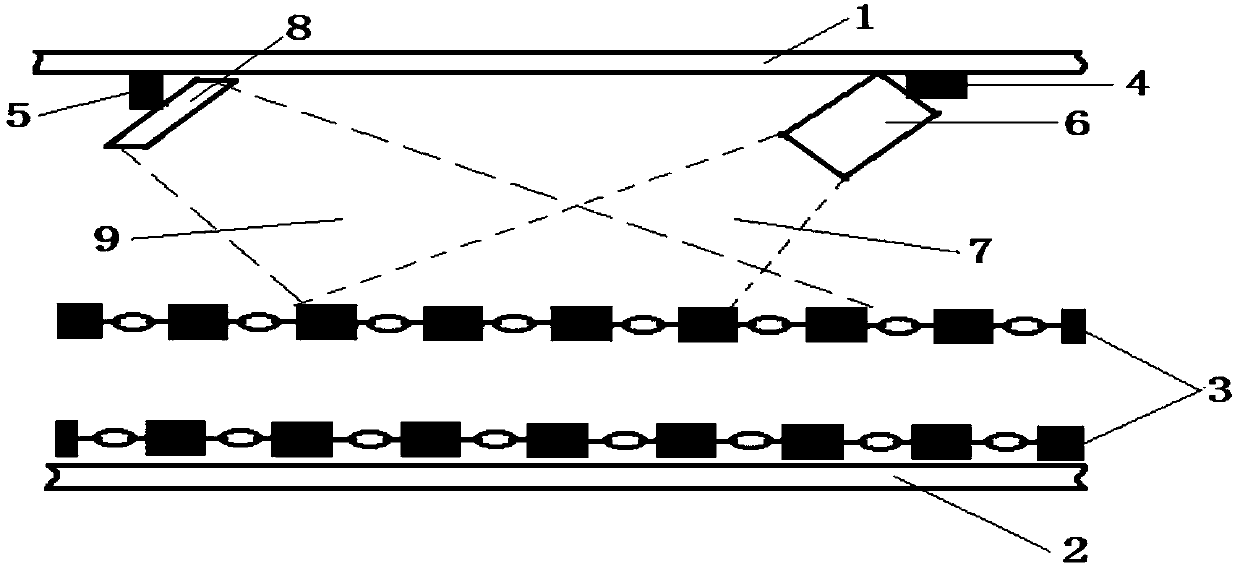

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

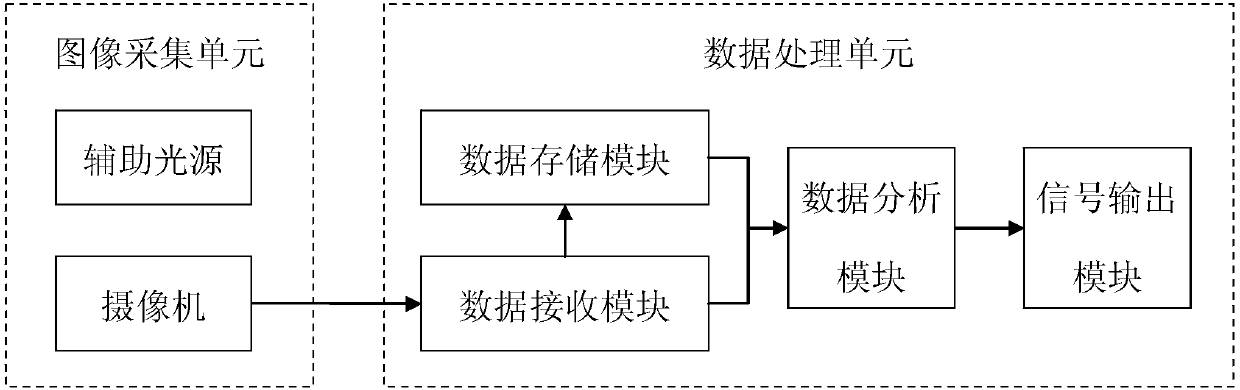

[0022] see figure 1 , one A machine vision-based abnormal state detection system for scraper machines, including:

[0023] Image acquisition unit: the image acquisition unit includes a camera and an auxiliary light source, the camera is used to collect video images of the operation of the scraper, and the auxiliary light source is used to illuminate the surface of the scraper to improve the accuracy of image segmentation and recognition;

[0024] Data processing unit: receiving and processing the video image data collected by the image acquisition unit, when the scraper machine is tilted or the chain is broken and shut down, the on-site video picture is recorded, and a fault alarm signal is sent.

[0025] The data processing unit uses the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com