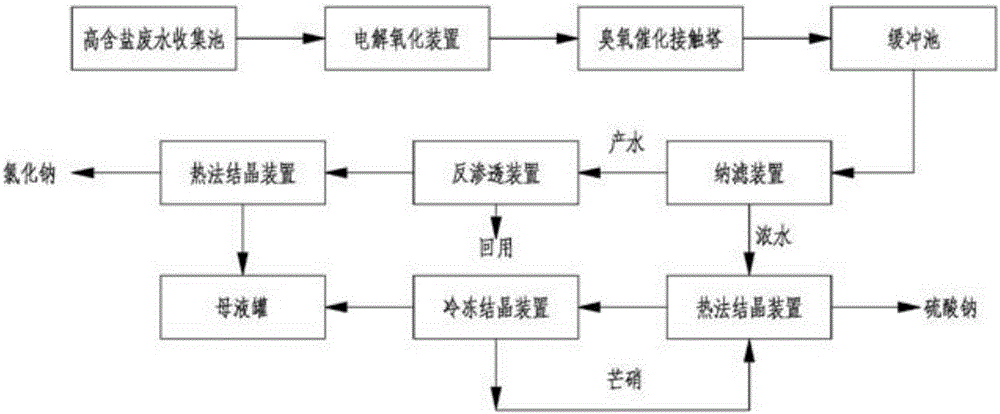

Quality-divided resourceful treatment method for coal chemical industry high-salt-content wastewater

A treatment method and high-salt technology, applied in the directions of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of low whiteness, high chromaticity and high concentration of wastewater, and reduce organic matter. Pollution, removal effect is good, water volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

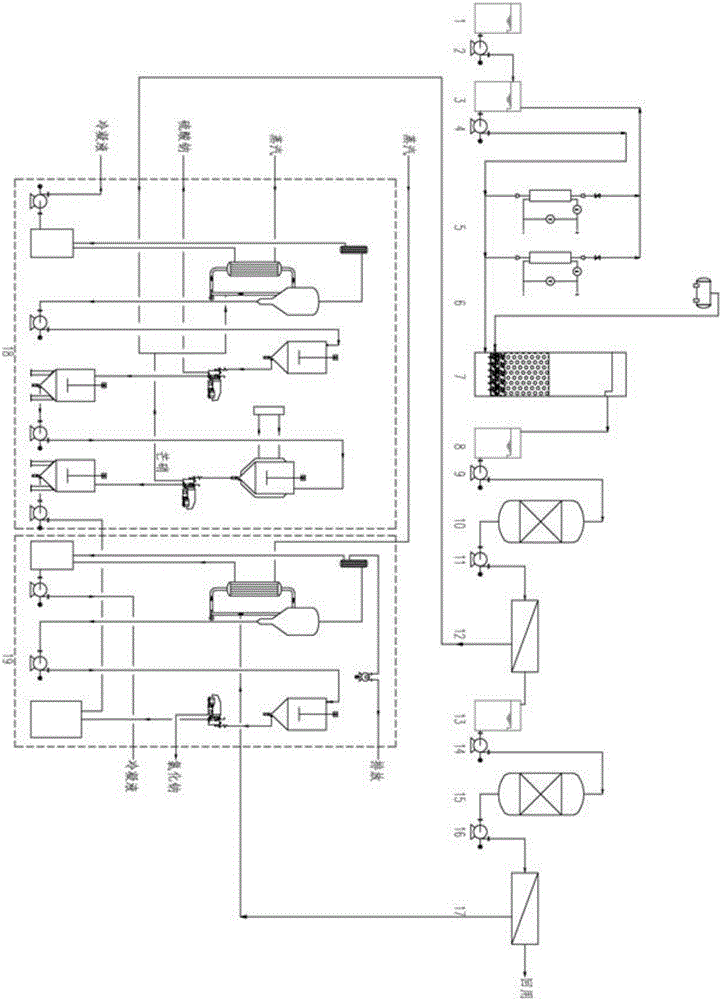

[0017] The embodiment of the present invention is implemented in a Lurgi furnace coal-to-urea chemical plant. The coal chemical enterprise adopts the process of "biochemical treatment + reclaimed water + membrane concentration" to treat production and domestic wastewater, and has been running stably for about two years. The raw water of the embodiment of the present invention is taken from the reverse osmosis concentrated water tank of the concentrated brine station, the water volume is 3 m3 / h, the water quality: COD 600-900 mg / L, TDS 50000-60000 mg / L, Cl-18000-21000 mg / L, SO42- 9000-12000 mg / L, Na+ 16000-20000 mg / L, chromaticity 450-500 degrees.

[0018] First, the lifting pump 2 lifts the high-salt wastewater from the high-salt wastewater collection pool 1 into the electrolytic oxidation tank 3, and pumps it into the electrolytic tank 5 through the electrolytic oxidation circulation pump 4 for oxidation treatment, controlling the current 20A, voltage 8V, and hydraulic retenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com