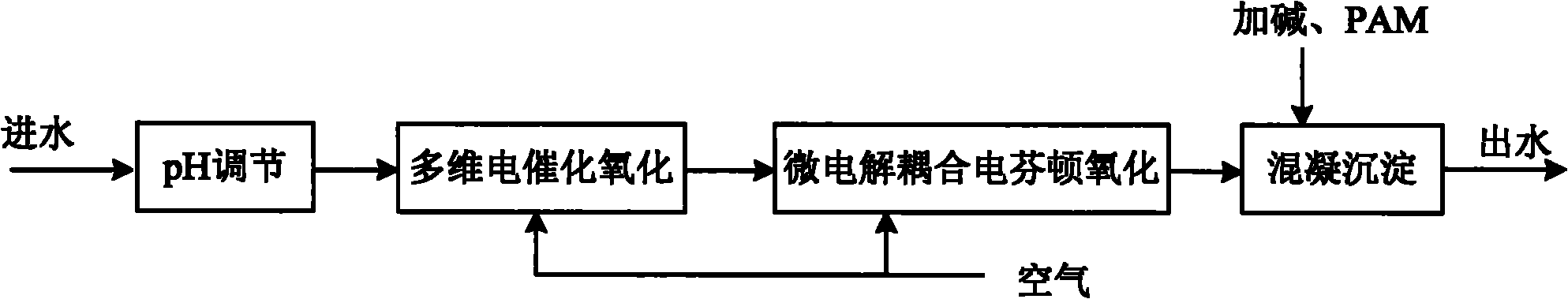

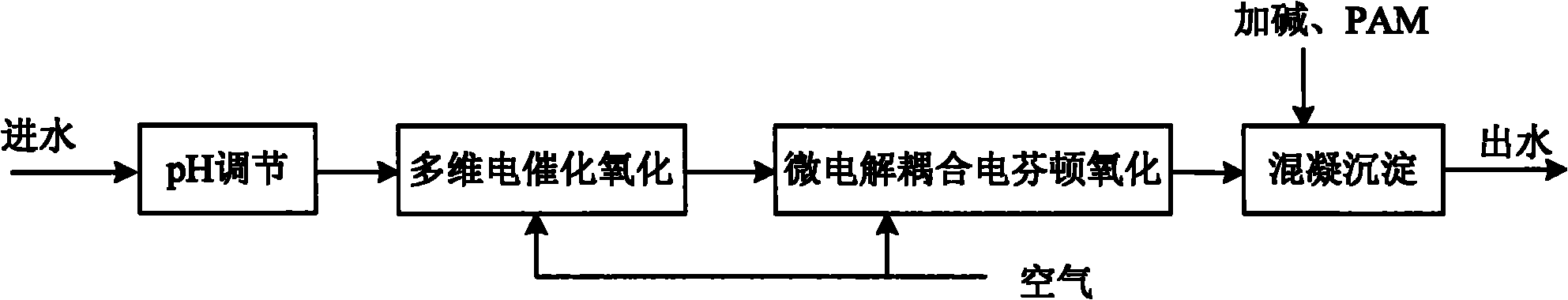

Technology for processing high-concentration organic wastewater in composite electrochemical method

A technology with high concentration of organic wastewater, applied in the field of composite technology, can solve the problems of high treatment cost and no obvious improvement in treatment efficiency, and achieve the effects of low operating cost, low chemical consumption, and improved biochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Pyridine wastewater treatment. A fine chemical company produces 2-chloro-3-amino-4-picoline, raw water quality: COD 13700mg / L, NH 3 -N 1120mg / L, TP 142mg / L, pH 1.5-2.0. By adopting the composite electrochemical process of the present invention, the pH of the raw water meets the requirement of water inflow; it directly enters the oxidation treatment process. The distance between the cathode and anode plates of the multi-dimensional electrode electrolysis reactor is 100mm, and the current density of the reactor is 20mA / cm 2 , multi-dimensional electrocatalytic oxidation section treatment residence time 0.5 hours; micro-electrolysis coupling electro-Fenton oxidation section treatment residence time 1 hour; coagulation precipitation treatment section, add NaOH, adjust the pH value of wastewater to 8.0, and add PAM for coagulation reaction, Effluent after coagulation and sedimentation: COD 162mg / L, removal rate 88%, NH 3 -N 286mg / L, the removal rate is 74%, TP 1.5mg / L, th...

Embodiment 2

[0046] The production wastewater of a pesticide enterprise, the raw water COD is 22400mg / L, and the main pollutants are m-dichloropyridine and o-dichloropyridine. Using this composite electrochemical process to adjust the pH of the raw water to 3.0; enter the multi-dimensional electrocatalytic oxidation section for treatment, the distance between the cathode and anode plates of the multi-dimensional electrode electrolysis reactor is 150mm, and the electrolysis current density is controlled at 15mA / cm 2 , the residence time is 1 hour, and the pH of the effluent in this section is 3.3; then enter the micro-electrolysis coupled electric Fenton oxidation section for treatment, the reaction residence time is 1.5 hours, and the pH rises to 3.7; the coagulation precipitation treatment section, add Ca(OH) 2 Adjust the pH of the wastewater to 9.0, and add PAM for coagulation reaction. After coagulation and sedimentation treatment, the effluent COD is 3578mg / L, and the removal rate is 76...

Embodiment 3

[0048] Fine chemical EDTA (ethylenediaminetetraacetic acid) production wastewater, raw water COD 8800mg / L, pH 2.6. The pH of the raw water has been within the scope required by step A of the present invention, so the raw water can be directly entered into the multidimensional electrocatalytic oxidation section for processing, the distance between the cathode and anode plates of the multidimensional electrode electrolysis reactor is 125mm, and the electrolytic current density is controlled at 20mA / cm The time is 1.5 hours; the residence time of the micro-electrolysis coupling Fenton oxidation section is 2 hours, and the pH is about 4.0 during the treatment process; the coagulation precipitation treatment section, add Ca(OH) 2 Adjust the pH of the wastewater to 9.0, and add PAM for coagulation reaction. After coagulation and precipitation, the effluent: COD 2580mg / L, removal rate 70.6%. The raw water is light yellow and becomes colorless and transparent after treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com