Advanced treatment method for coking distilled ammonia wastewater

A technology for advanced treatment and ammonia distillation of wastewater, which is applied in the directions of oxidized water/sewage treatment, water/sewage treatment, anaerobic digestion treatment, etc. It can solve the problem that the removal efficiency of biochemical systems is not high, it is difficult to meet the discharge or reuse standards, and it is difficult to reach Index requirements and other issues to achieve the effect of improving biodegradability, low processing cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Ammonia distillation wastewater from a coking plant: COD is 2600mg / L, ammonia nitrogen is 1100mg / L, and total nitrogen is 1500mg / L.

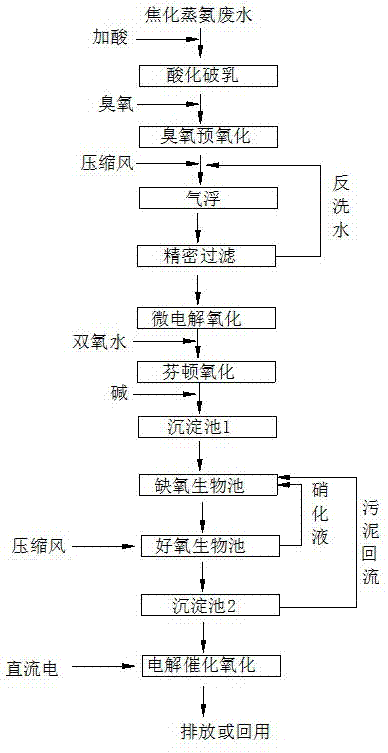

[0031]Adopt the treatment method provided by the present invention to process: the wastewater to be treated first adds acid to adjust the pH to 3.5, then acidifies the demulsification tank to demulsify and remove oil, and the acidification and demulsification time is 1 hour; the acidified demulsification effluent is added with 50mg / L ozone and then enters the ozone Pre-oxidation tank, the pre-oxidation time is 20 minutes; the ozone pre-oxidation water enters the air flotation for oil-water separation, and the air flotation hydraulic retention time is 10 minutes; the air flotation water enters the precision filtration unit with a filtration accuracy of 0.05um for secondary oil removal , precision filtration backwash water back to the air flotation unit; precision filtration effluent enters micro-electrolysis for oxidation, removes some orga...

Embodiment 2

[0034] Ammonia distillation waste water produced in coking workshop of a joint iron and steel plant: COD is 6500mg / L, ammonia nitrogen is 2200mg / L, and total nitrogen is 2500mg / L.

[0035] Adopt the processing method provided by the present invention to process: the wastewater to be treated first adds acid to adjust the pH to 1.5, then acidifies the demulsification pool to demulsify and remove oil, and the acidification and demulsification time is 3 hours; the acidified demulsification effluent is added with 200mg / L ozone and then enters the ozone Pre-oxidation tank, the pre-oxidation time is 60 minutes; the ozone pre-oxidation water enters the air flotation for oil-water separation, and the air flotation hydraulic retention time is 60 minutes; the air flotation water enters the precision filtration unit with a filtration accuracy of 0.05um for secondary oil removal , the backwashing water after precision filtration is returned to the air flotation unit; the effluent from preci...

Embodiment 3

[0038] Coking ammonia distillation wastewater produced by a coal coke joint plant: COD is 4000mg / L, ammonia nitrogen is 1300mg / L, and total nitrogen is 1740mg / L.

[0039] Adopt the processing method provided by the present invention to process: the wastewater to be treated first adds acid to adjust the pH to 2.5, then acidifies the demulsification pool to demulsify and remove oil, and the acidification and demulsification time is 2 hours; the acidified demulsification effluent is added with 100mg / L ozone and then enters the ozone Pre-oxidation tank, the pre-oxidation time is 30 minutes; the ozone pre-oxidation water enters the air flotation for oil-water separation, and the air flotation hydraulic retention time is 30 minutes; the air flotation water enters the precision filtration unit with a filtration accuracy of 0.05um for secondary oil removal , precision filtration backwash water back to the air flotation unit; precision filtration water enters micro-electrolysis for oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com