Method for preparing fracturing fluid by utilizing seawater

A fracturing fluid and seawater technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems that restrict the development of fracturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

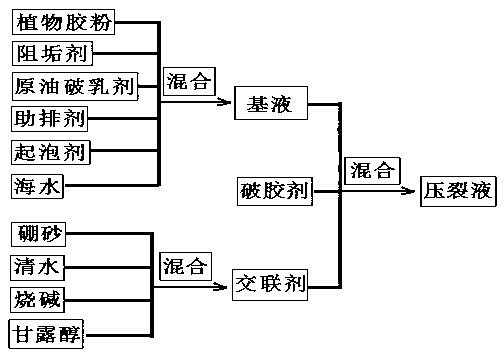

Image

Examples

specific Embodiment example 1

[0056] Preparation of base liquid: Add 99,470 kg of seawater into a container with a vacuum jet pump, start the jet pump, and evenly suck 400 kg of coriander film powder into the water. After adding the rubber powder, add 30 kg of crude oil demulsifier and 100 kg of drainage aid respectively. After the addition, continue to circulate evenly with the pump, and then put it aside for later use.

[0057] Preparation of cross-linking agent: Add 300 kg of clear water into a container with a stirrer, start the stirrer, then add 100 kg of mannitol and 100 kg of borax respectively, stir until the two are completely dissolved and set aside.

[0058] Preparation of fracturing fluid:

[0059] During fracturing construction, use the built-in pump of the sand mixer in the fracturing unit to pump 2.0m 3 The base liquid is pumped into the sand mixing tank at a flow rate of 10.0 liters per minute, and the crosslinking agent is pumped into the sand mixing tank at a flow rate of 10.0 liters per...

specific Embodiment example 2

[0062] Preparation of base liquid: add 98,970 kilograms of seawater into a container with a vacuum jet pump, start the jet pump, and evenly suck 400 kilograms of hydroxypropyl guar gum powder into the water. After adding the rubber powder, add 30 kg of crude oil demulsifier, 100 kg of drainage aid, and 500 kg of foaming agent. After the addition, continue to circulate evenly with the pump, and then put it aside for use.

[0063] Preparation of cross-linking agent: Add 400 kg of clear water into a container with a stirrer, start the stirrer, then add 160 kg of mannitol, 160 kg of borax, and 80 g of caustic soda, stir until the three are completely dissolved and set aside.

[0064] Preparation of fracturing fluid:

[0065] During fracturing construction, use the built-in pump of the sand mixer in the fracturing unit to pump 2.5m 3 The base liquid is pumped into the sand mixing tank at a flow rate of 20.0 liters per minute, and the crosslinking agent is pumped into the sand mixi...

specific Embodiment example 3

[0068] Preparation of base liquid: add 98,800 kilograms of seawater into a container with a vacuum jet pump, start the jet pump, and evenly suck 550 kilograms of hydroxypropyl guar gum powder into the water. After adding the rubber powder, add 50 kg of crude oil demulsifier, 100 kg of drainage aid, and 500 kg of foaming agent respectively. After the addition, continue to circulate evenly with the pump, and then store it for later use.

[0069] Preparation of cross-linking agent: Add 500 kg of water into a container with a stirrer, start the stirrer, then add 100 kg of mannitol, 200 kg of borax, and 200 g of caustic soda, stir until the three are completely dissolved and set aside.

[0070] Preparation of fracturing fluid:

[0071] During fracturing construction, use the built-in pump of the sand mixer in the fracturing unit to pump 2.8m 3 The base liquid is pumped into the sand mixing tank at a flow rate of 28.0 liters per minute, and the crosslinking agent is pumped into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com