Compound potassium hydrogen persulfate powder sanitizer and preparation method thereof

A technology of potassium hydrogen sulfate powder and potassium hydrogen persulfate, which is applied in the field of poultry and livestock disinfectants and its preparation, and can solve problems such as easy to be affected by moisture, decline in active ingredients, and easy moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

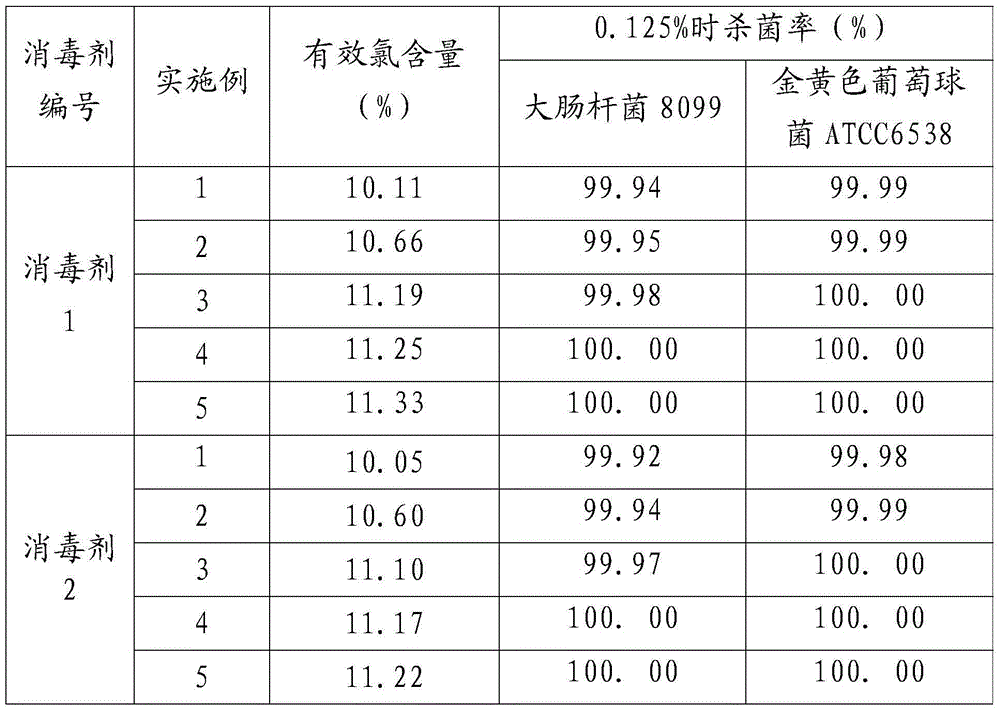

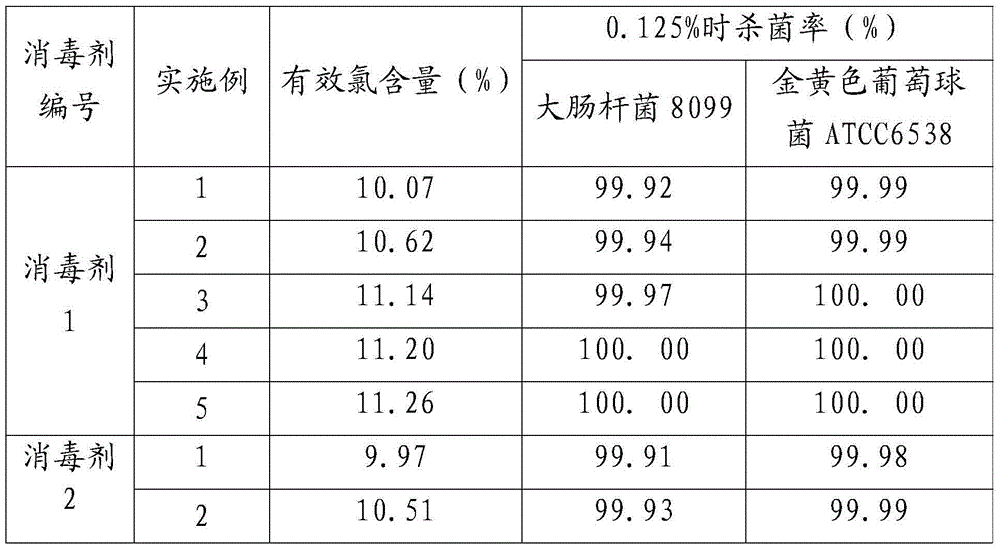

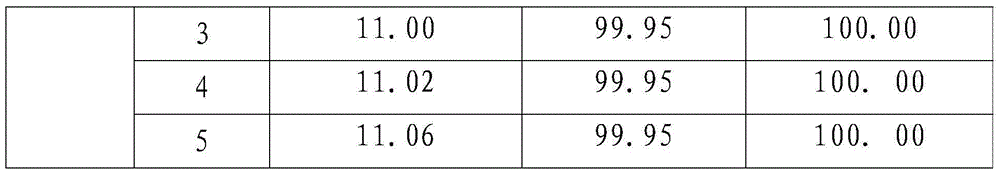

Examples

Embodiment 1

[0029] A compound potassium hydrogen persulfate powder disinfectant, the mass ratio of its components is 20% potassium hydrogen persulfate, 1.5% sodium chloride coating, organic acid, anionic surfactant, builder, thinner 78.5%.

[0030] The sodium chloride coating in this embodiment consists of a coated core material and a wall material for coating. The coated core material is granular sodium chloride with a particle size of 100 μm to 1000 μm; the coated wall material is starch, methyl cellulose, hydroxymethyl cellulose, gum arabic, polyester Any polymer slow-release carrier in acrylic resin.

[0031] Described sodium chloride coating adopts following preparation method to obtain:

[0032] 1. Mix the wall material with water at a ratio of 0.005:1 to 0.20:1 to make a gelatinized wall material with adhesive effect;

[0033] 2. Mix the gelatinized wall material and sodium chloride uniformly according to the ratio of 0.3:1 to 0.8:1 to form a mixture of sodium chloride and gelat...

Embodiment 2

[0037] A compound potassium hydrogen persulfate powder disinfectant, the mass ratio of its components is 40% potassium hydrogen persulfate, 5% sodium chloride coating, organic acid, anionic surfactant, builder, thinner 55%.

[0038] The sodium chloride coating in this embodiment consists of a coated core material and a wall material for coating. The coated core material is granular sodium chloride with a particle size of 100 μm to 1000 μm; the coated wall material is starch, methyl cellulose, hydroxymethyl cellulose, gum arabic, polyester Any polymer slow-release carrier in acrylic resin.

[0039] The preparation process steps and process parameters of the sodium chloride coating in this embodiment are the same as those in Example 1, except that the coated wall material raw materials can be replaced accordingly.

[0040] The above-mentioned sodium chloride coating is mixed with potassium hydrogen persulfate and other components to prepare a compound potassium hydrogen persul...

Embodiment 3

[0042] A compound potassium hydrogen persulfate powder disinfectant, the mass ratio of its components is 50% potassium hydrogen persulfate, 15% sodium chloride coating, organic acid, anionic surfactant, builder, thinner 35%.

[0043] The sodium chloride coating in this embodiment consists of a coated core material and a wall material for coating. The coated core material is granular sodium chloride with a particle size of 100 μm to 1000 μm; the coated wall material is starch, methyl cellulose, hydroxymethyl cellulose, gum arabic, polyester Any polymer slow-release carrier in acrylic resin.

[0044] The preparation process steps and process parameters of the sodium chloride coating in this embodiment are the same as those in Example 1, except that the coated wall material raw materials can be replaced accordingly.

[0045] The above-mentioned sodium chloride coating is mixed with potassium hydrogen persulfate and other components to prepare a compound potassium hydrogen persu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com