Fertilizer water-dispersion granule and preparation thereof

A technology for dispersing granules and fertilizers, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems affecting fertilizer application and promotion, and achieve the effects of broad market application prospects, improved utilization rate, and fast disintegration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

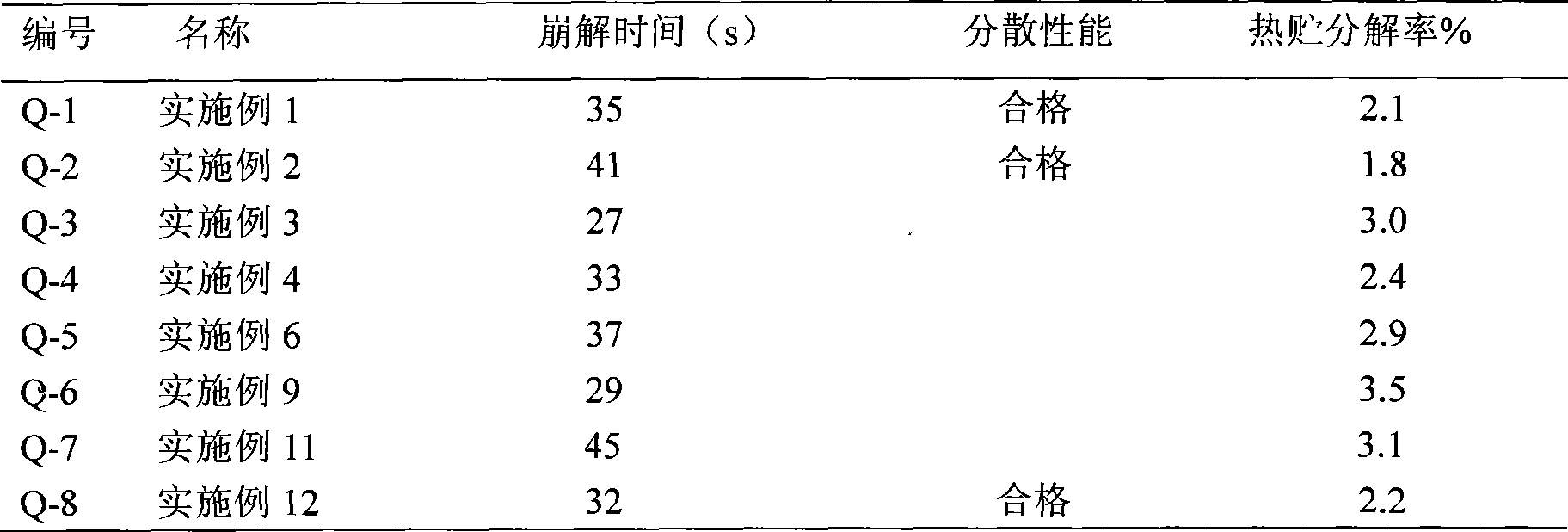

Examples

Embodiment 1

[0047] Weigh the raw materials of each component according to the following ratio

[0048] Potassium dihydrogen phosphate 49 parts

[0049] Boric acid 10 parts

[0050] Gibberellin GA 4 0.5 parts

[0051] Gibberellin GA 7 0.5 parts

[0052] Succinic acid half ester sulfonate fatty acid amide 25 parts

[0053] Sodium dodecylbenzenesulfonate 15 parts

[0054] Gibberellin GA 4 gibberellin GA 7 Superfinely pulverized to more than 250 mesh, mixed with other components, prepared mother powder by crushing, mixed with an appropriate amount of aqueous solution, then extruded and granulated, dried, sieved, analyzed and tested for storage to obtain columnar Potassium dihydrogen phosphate gibberellin water dispersible granules.

Embodiment 2

[0056] Weigh the raw materials of each component according to the following ratio

[0057] Potassium nitrate 70 parts

[0058] Calcium carbonate 6 parts

[0059] Naphthalene acetic acid 1 part

[0060] Succinic acid half ester sulfonate fatty acid amide 5 parts

[0061] Fatty alcohol polyoxyethylene ether 3 parts

[0062] Carboxymethylcellulose 15 parts

[0063] Firstly, naphthyl acetic acid and calcium carbonate are superfinely pulverized to more than 250 meshes, mixed with other components, and pulverized to prepare mother powder, mixed with an appropriate amount of aqueous solution, and then fluidized bed granulation, drying, pressing Tablets, analysis, inspection, and storage to obtain spherical potassium nitrate naphthaleneacetic acid water-dispersible granules.

Embodiment 3

[0065] Weigh the raw materials of each component according to the following ratio

[0066] 65 parts boric acid

[0067] Low-substituted hydroxypropyl cellulose 30 parts

[0068] Alkylphenol polyoxyethylene ether succinate sulfonate 5 parts

[0069] The above components are mixed evenly, the mother powder is prepared by pulverization, the mother powder is uniformly mixed with an appropriate amount of alcohol solution, and then drum granulated, dried, analyzed and checked for storage to obtain boric acid water-dispersible granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com